High-efficiency crawler-type pick-up baler and bale automatic stacking system thereof

An automatic stacking, crawler-type technology, applied in the direction of cutting balers, balers, loaders, etc., can solve the problems of easy blockage of the feeding inlet of the straw conveying device and baling device, poor ground adaptability, and manual re-handling, etc. Picking and baling performance and work efficiency, high level of automation, the effect of improving ground clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

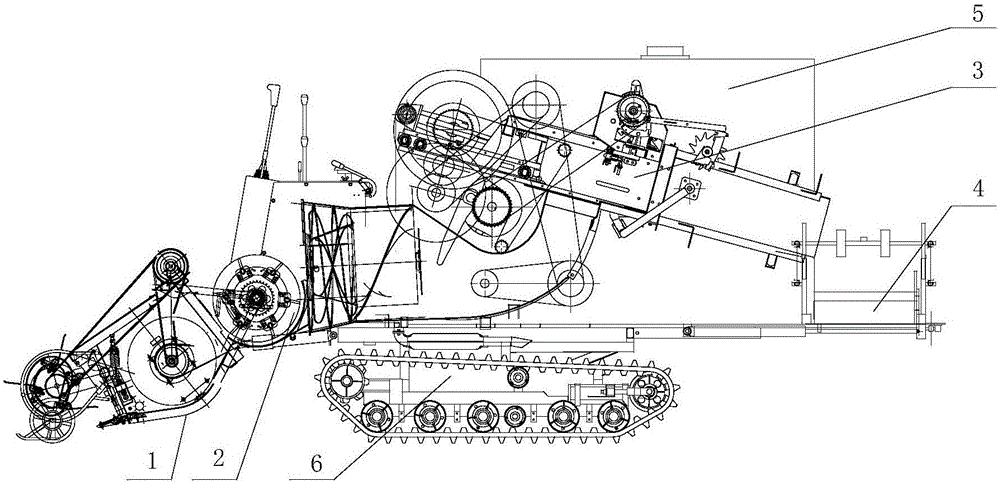

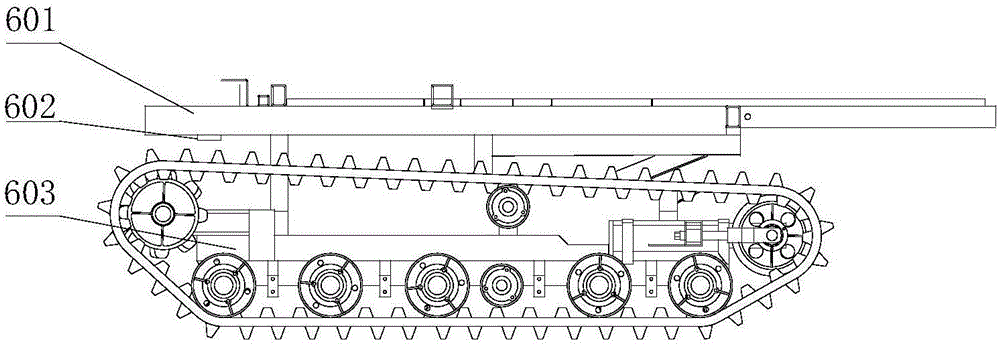

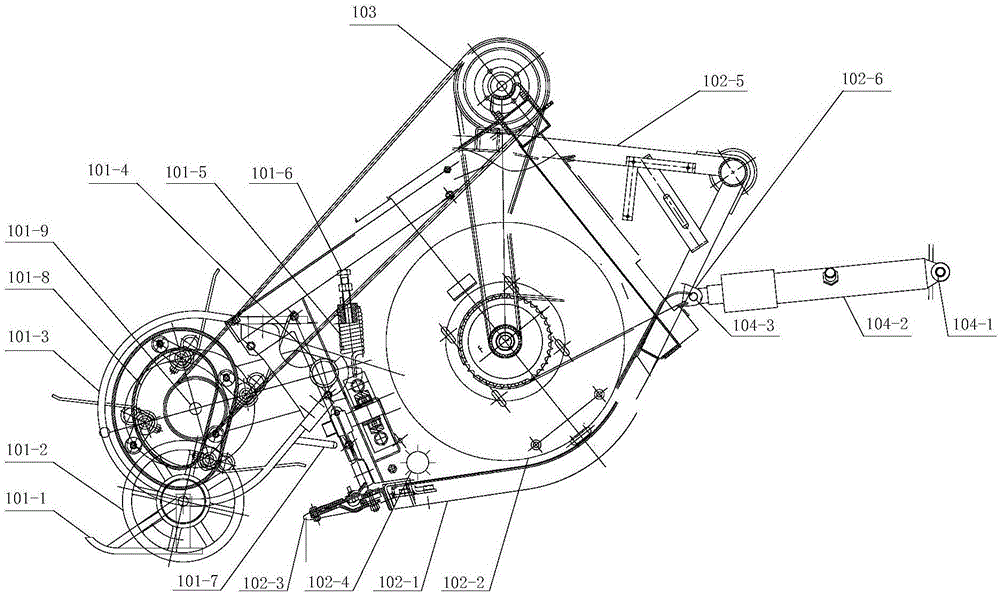

[0056] figure 1 Shown is a specific embodiment of the high-efficiency crawler-type picking and bundling machine and its bale automatic stacking system according to the present invention, including a straw picking and stubble harvesting device 1, a continuous conveying pre-pressing device 2, a bottom feeding type Compression and bundling device 3, bale conveying arrangement device 4, bale stacking device 5, walking device 6 and control system. The traveling device 6 is mainly composed of a frame 601 and a crawler chassis 603. The continuous conveying pre-pressing device 2, the lower feeding compression bundling device 3, the bale conveying and arranging device 4 and the bale stacking device 5 are all installed on the traveling device. 6 on rack 601. The straw picking and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com