Corn straw harvester

A technology of corn stalks and harvesters, which is applied in the direction of harvesters, balers, cutters, etc., can solve the problems of safety accidents of hands and arms crushed by pressure plates, and high labor intensity, so as to reduce labor intensity and avoid potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

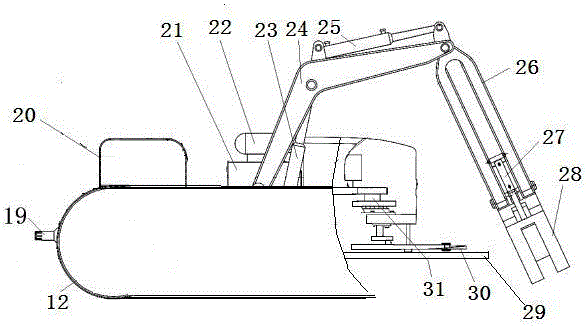

[0029] Example 1: figure 1 As shown, the present embodiment comprises frame, engine 20, crawler type traveling device 12, mechanical arm, mechanical arm rotary device, cutting device 31, hydraulic system, crawler type traveling device 12, mechanical arm, mechanical arm rotary device, cutting device 31. The hydraulic system is connected with the frame; the mechanical arm is installed on the rotary device of the mechanical arm, the hydraulic pump is placed on the top cover of the hydraulic oil tank, and the cutting device is located in the front of the frame;

[0030] Figure 4 As shown, the crawler-type traveling device 12 includes a crawler frame, a crawler chain, a power unit, a steering gear, a drive gear, a tensioning device, and a braking device. The crawler chain is installed on the crawler frame, and the drive shaft of the drive motor 3 is installed There is a driving gear 4, the driving gear 4 meshes with the driven gear 5, and the driving wheel 6 is installed on the i...

Embodiment 2

[0051] Embodiment 2: The steering device of this embodiment includes a steering pump, a steering gear, and a steering oil cylinder. The steering pump provides hydraulic oil to the steering oil cylinder. The steering gear is connected to a controller, and the controller provides the hydraulic oil output by the steering pump to the steering oil cylinder. The oil cylinder drives the steering rod to expand and contract, so that the steering wheel deviates from the driving center line to realize the steering action. Other structures are the same as in Embodiment 1.

Embodiment 3

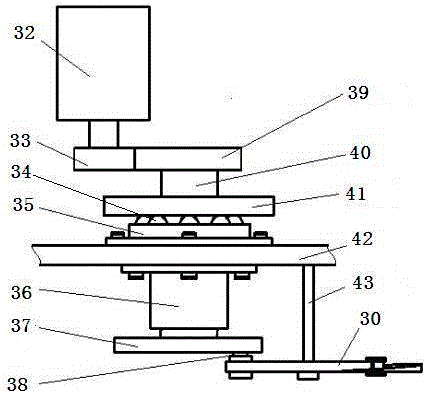

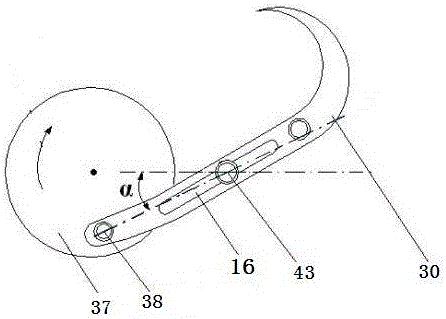

[0052] Embodiment 3: The mechanical arm rotation device of this embodiment includes a hydraulic motor 32, a support ring 35 and a shaft sleeve 36. The output shaft of the hydraulic motor 32 is equipped with a driving gear 33, and the driving gear 33 meshes with the driven gear 39. The gear 39 is connected to the drive shaft 40, the support ring 35 and the shaft sleeve 36 are coaxial with the installation hole of the drive shaft 40 on the frame 42, the support ring 35 is fixed on the frame, and the support ring 35 is provided with some steel balls 34 , the shaft sleeve 36 is fixed below the frame 42, the drive shaft 40 rotates in the inner ring of the support ring 35, the mounting hole of the drive shaft 40 of the frame 42 and the inner ring of the shaft sleeve 36, and the upper turntable 41 Coaxially fixed on the upper end of the drive shaft 40, the upper turntable 41 is in rolling contact with the support ring 35, the gear is coaxially fixed on the lower end of the drive shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com