Collecting and bundling device of cane harvesting machine

A technology of a baling device and a harvester, which is applied in the direction of a harvester, a baler, a cutter, etc., can solve the problems that the sugarcane harvesting efficiency cannot be further improved, and the sugarcane cannot be baled, and achieves the effect of reducing labor costs and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the drawings:

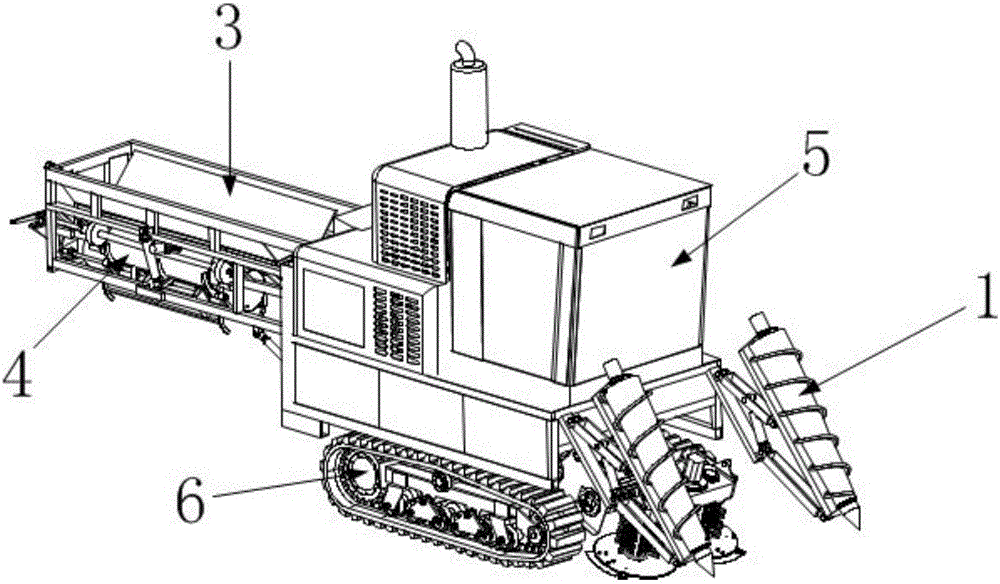

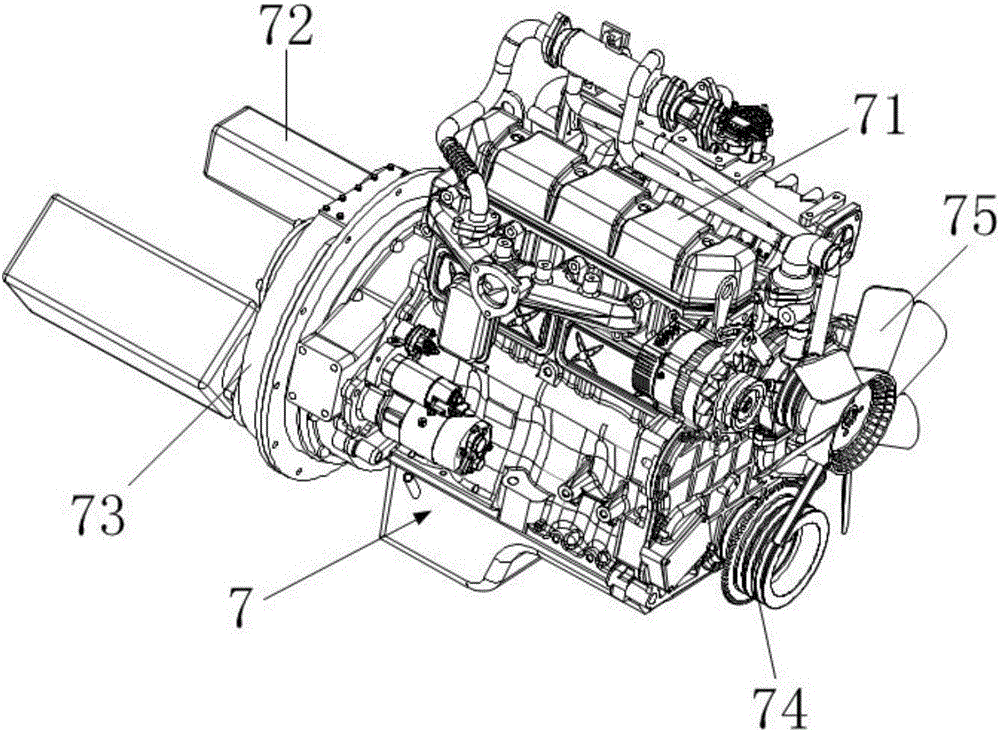

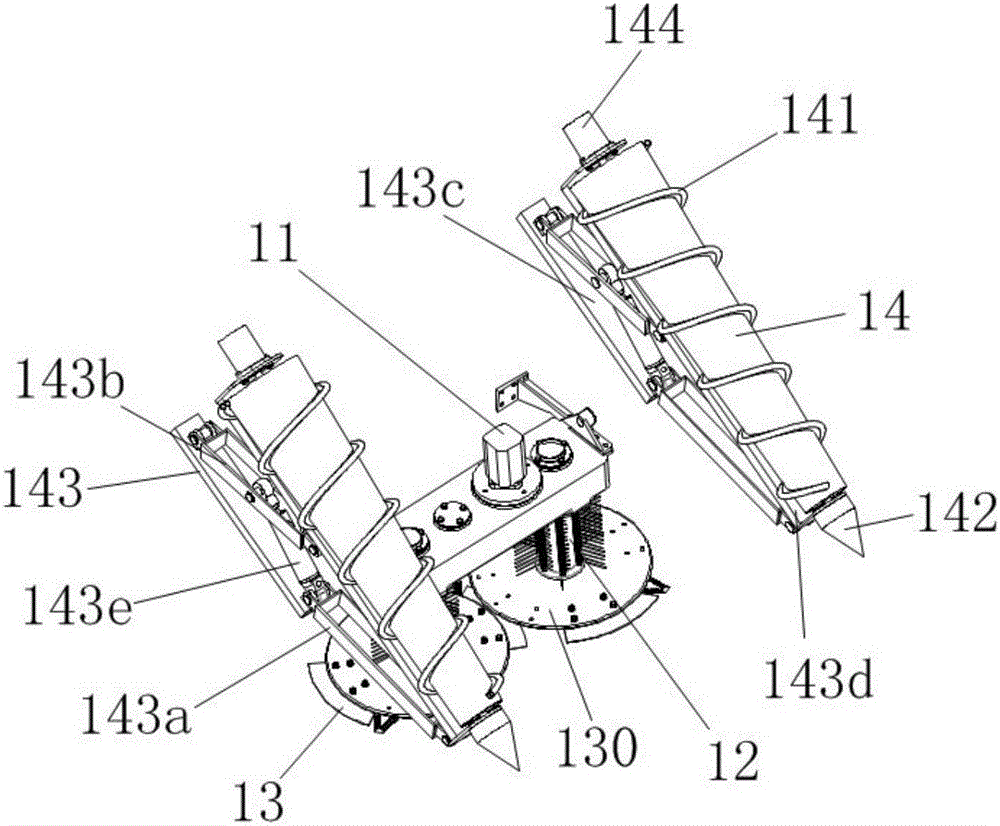

[0027] Such as figure 1 As shown, the sugarcane harvester includes: a cutting mechanism 1, a collection and bundling device, a housing 5 and a chassis 6, wherein the collection and bundling device includes: a collection mechanism 3 and a bundling mechanism 4. In addition, the sugarcane harvester also includes: leaf peeling mechanism 2 ( Figure 4 Shown) and diesel engine 7 ( figure 2 Shown). The cutting mechanism 1, the leaf peeling mechanism 2 and the collecting mechanism 3 are arranged in sequence, the bundling mechanism 4 is located below the collecting mechanism 3, the chassis 6 is located below the housing 5, the leaf peeling mechanism 2 and the diesel engine 7 are located inside the housing 5, and the housing 5 The bottom is hollowed out.

[0028] Among them, the chassis 6 is a crawler type chassis with driving wheels, tensioning wheels and crawlers. The chassis 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com