Full-feeding type peanut combined harvester

A combine harvester, full-feeding technology, which is used in excavator harvesters, harvesters, agricultural machinery and implements, etc. problems, to achieve the effect of improving harvesting efficiency, convenient drying and storage, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

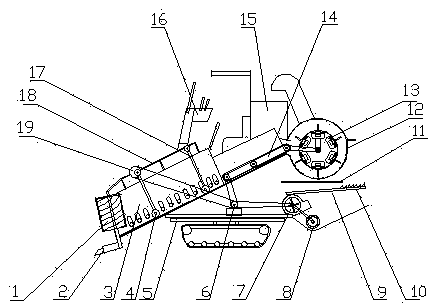

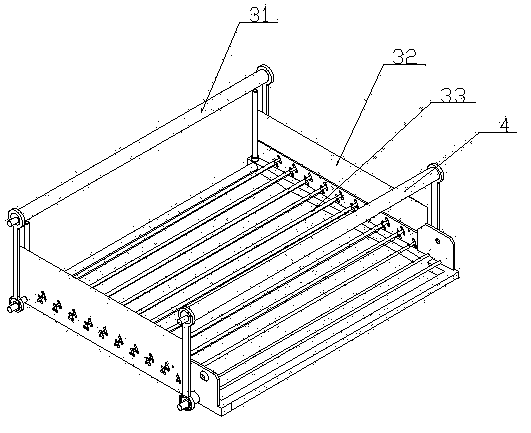

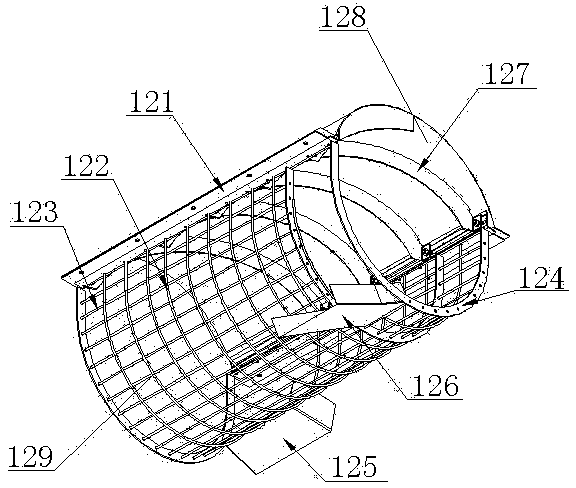

[0028]The full-feed peanut combine harvester of the present invention includes a seedling supporter, a vibrating excavating shovel, a soil separating and conveying screen, a fruit picking device, a cleaning device, a fruit collecting device, a peanut fruit conveying device, a manipulation device, a frame and engine, the vibrating excavating shovel is located at the front end of the frame; the seedling supporter is located above the position of the vibrating excavating shovel; the rear part of the vibrating excavating shovel is provided with a soil-dividing conveyor screen; the rear side of the soil-dividing conveyor screen is provided with a feeding conveyor Belt and fruit picking device, the peanut seedlings are sent to the fruit picking device through the feeding conveyor belt; the cleaning device is located on the lower side of the fruit picking device, and the peanut fruit conveying device is installed on the lower side; the above devices are connected by the frame and insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com