Device and method for monitoring residual capacity of grain tank and residual walking distance of combine harvester

A combine harvester and residual capacity technology, which is applied in the fields of harvesters, agricultural machinery and implements, computer control, etc., can solve the problems of inability to grasp the accumulation of grains in the grain tank, reduction of rice production, and increase of machine rolling, etc., to improve harvesting. Work efficiency, avoid grain leakage, reduce the effect of empty travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

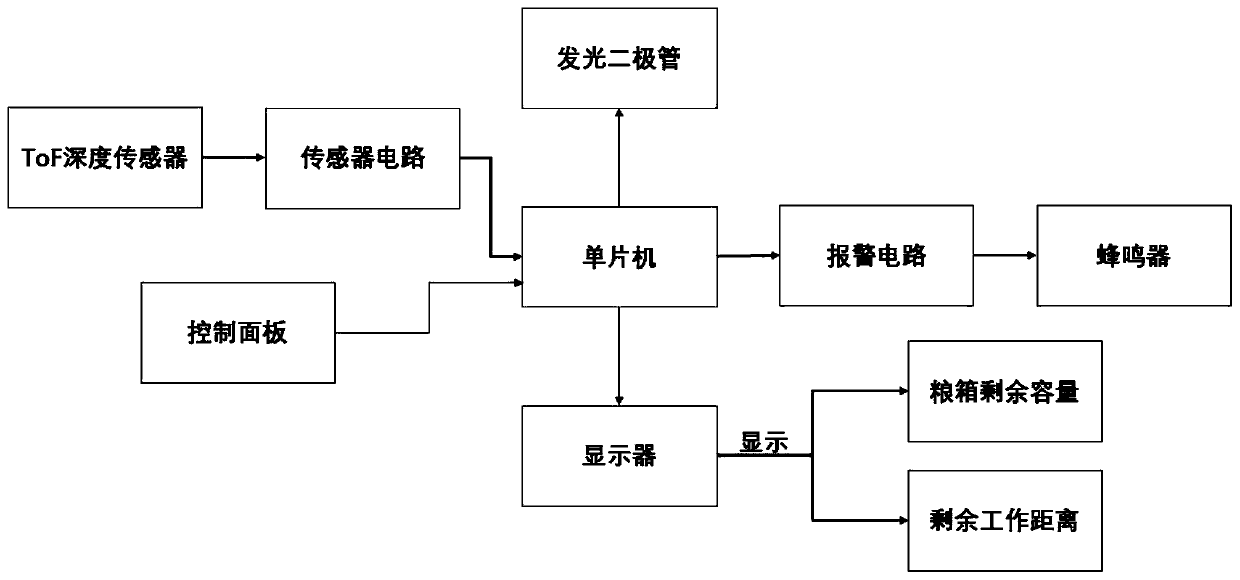

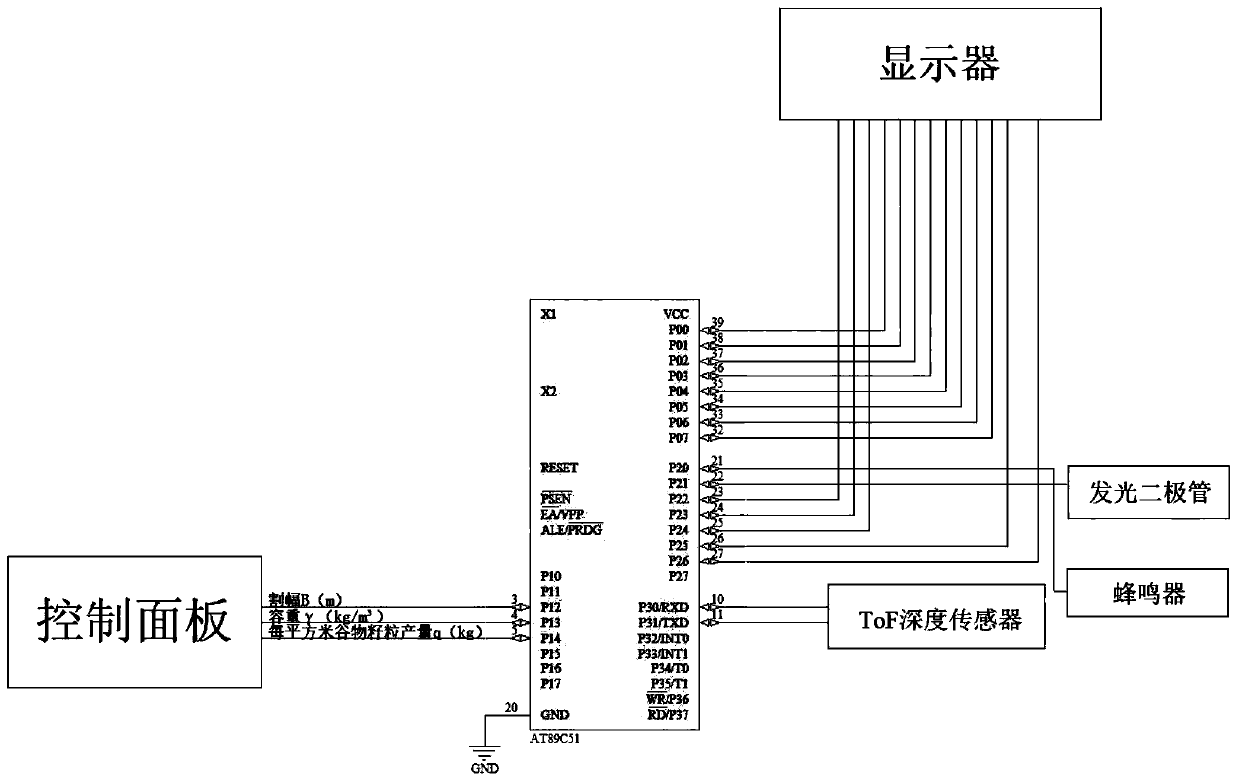

[0039] figure 1 Shown is a preferred implementation of the remaining capacity of the grain tank of the combine harvester and the remaining walking distance monitoring device. The monitoring device for the remaining capacity of the grain tank of the combine harvester and the remaining walking distance includes a grain tank, a detection device, a control Panels, control units, alarm devices and displays. The detection device is used to detect the average distance information from the grain accumulation surface in the grain tank to the top of the grain tank, and transmits it to the control unit; the control panel is used to at least input the cross-sectional area of the grain tank, the height of the grain tank, width, grain yield per square meter and grain bulk density, and transmit them to the control unit; the control unit is respectively connected with the detection device, control panel, alarm device and display, and the control unit calculates the grain size according to t...

Embodiment 2

[0046] A method for monitoring the remaining capacity of the combine harvester grain tank and the remaining walking distance monitoring device according to Embodiment 1, combining figure 1 with figure 2 , including the following steps:

[0047] Before the harvesting work starts, according to the machine structure and actual working conditions, the control panel inputs the grain tank cross-sectional area S (m 2 ), grain tank height H(m), combine harvester cutting width B(m), grain yield per square meter q(kg) and grain bulk density γ(kg / m 3 ) information and pass it to the control unit;

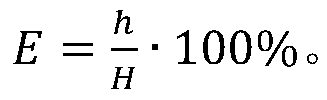

[0048] The detection device detects the information of the average distance h (m) between the grain accumulation surface in the grain tank and the top of the grain tank, and transmits it to the control unit; specifically, the detection device is a ToF depth sensor, and the ToF depth sensor is installed in the grain tank On the top surface, the grain accumulation surface in the grain tank i...

Embodiment 3

[0070] A combine harvester, comprising the remaining capacity of the grain tank of the combine harvester and the remaining walking distance monitoring device described in Embodiment 1, and adopting the monitoring method described in Embodiment 2 to monitor the remaining capacity of the grain tank of the combine harvester and the remaining walking distance Monitoring has the beneficial effects of embodiments 1 and 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com