Hot melting connector capable of being quickly positioned, and water dissolving core injection molding process thereof

A hot-melt joint and water-dissolving technology, which is applied to other household appliances, household components, household appliances, etc., can solve the problems of insufficient sealing, large welding positions, waste of time and cost, etc., to achieve low manufacturing costs and ensure flow channels The effect of area and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

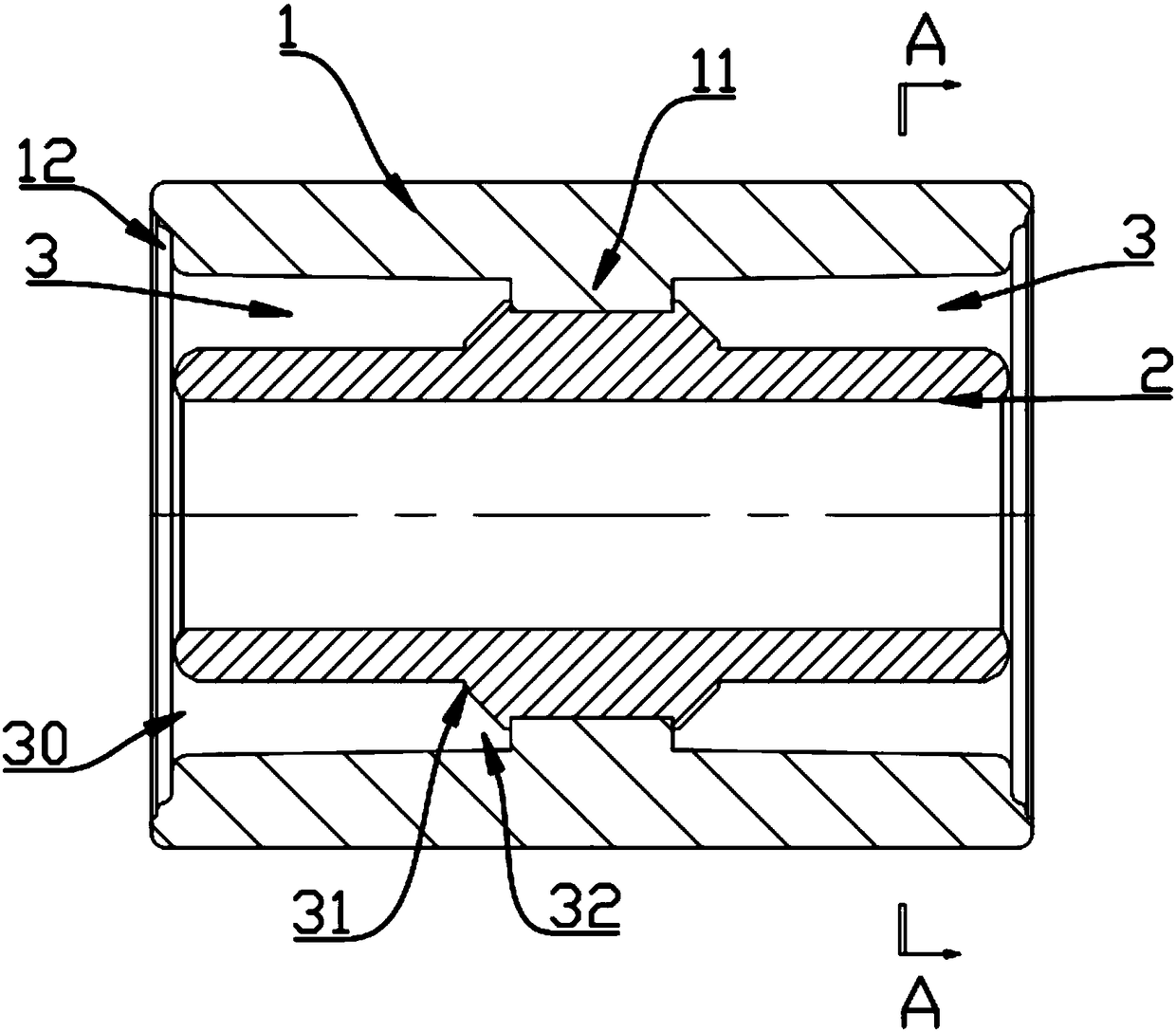

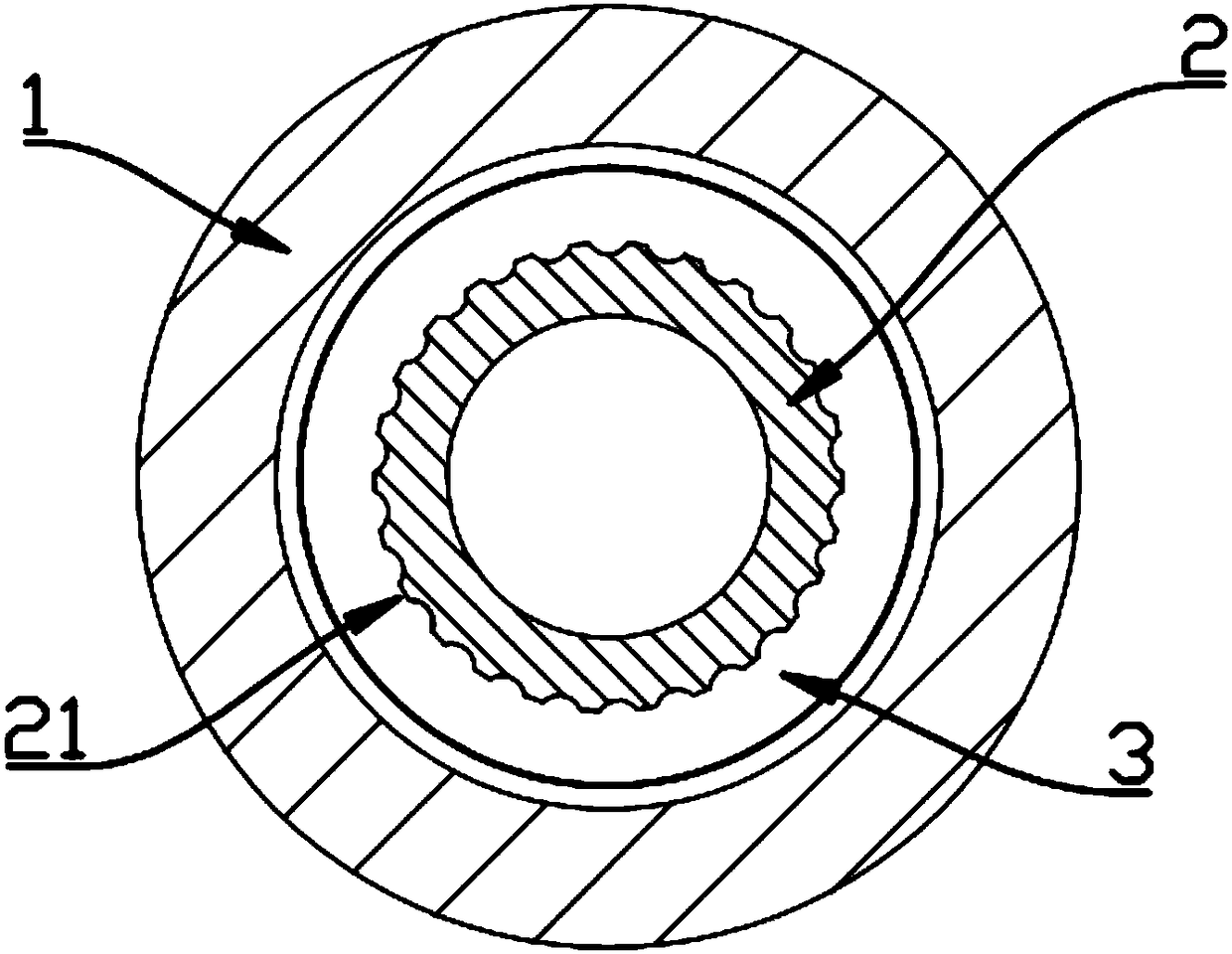

[0073] Such as Figure 1-2 As shown, in addition to the basic embodiment, this embodiment is further provided with: the guide core 2 is a water-soluble guide core, and its components are: 58-70 parts of sugar, 5-15 parts of fiber and 25-40 parts of starch. The inner diameter of the water-dissolving guide core of the present invention is as large as that of common joints, and can be slowly dissolved under the washing of water flow during use after welding and forming, so as to ensure the flow channel area and make it a full-diameter pipeline.

[0074] Preferably, the inner end of the hot-melt guide part 3 is formed with a hot-melt tube limiting part 31 for restricting the position of the pipe fitting and a hot-melt filling groove 32 for filling excess eluate. In the embodiment of the water-dissolving guide core, the The heat-melt tube limiting part 31 is a stepped structure, and the hot-melt filling groove 32 is an inclined slope. When the water-dissolving guide core is dissolv...

Embodiment 2

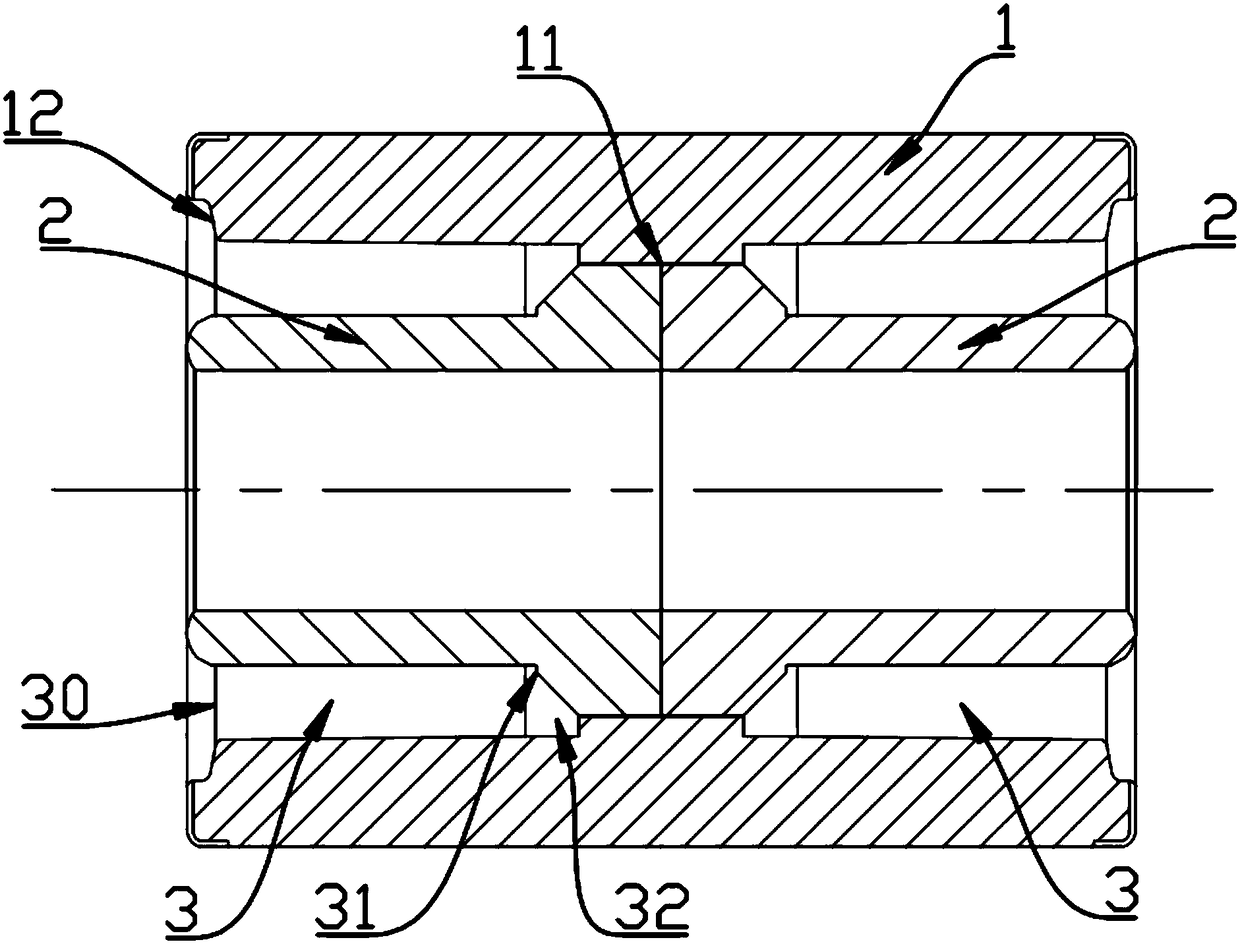

[0077] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1, the difference is that: the joint main body 1 is coaxially provided with two installation ends, and the installation position 11 is oppositely provided with two guide cores 2 with the same structure , The outer wall of the inner end of the guide core 2 is provided with embossing to increase the strength of the fixed position. The method of this embodiment is convenient to process and has low manufacturing cost.

Embodiment 3

[0079] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the difference is that: the joint main body 1 is provided with two installation ends, and the apertures of the installation ends are different, commonly known as "small and small joints".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com