Lifting type tin soldering device for wiring harnesses

A lift-type, coil device technology, used in auxiliary devices, welding equipment, metal processing equipment, etc., can solve the problems of differences in solder depth, affecting product quality, and single function, to ensure product quality and reduce human labor. Output, easy to operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

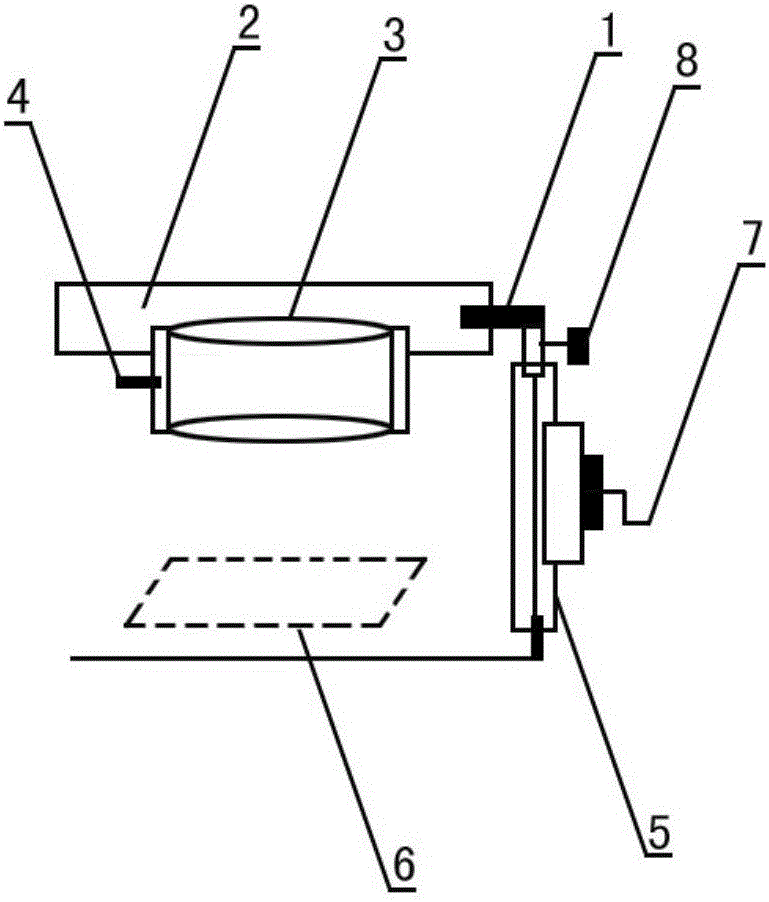

[0012] Embodiment: as shown in the accompanying drawing. The lifting type wire harness soldering device includes a frame (1). The frame (1) is designed in a half-open mode as a whole. The upper part is equipped with a support frame device (2), a fixed coil device (3), and a toggle structure (4). The lifting component (5) is connected to the positioning platform (6), and the manual device (7) is installed on the outer end of the lifting component (5). When in use, the solder furnace is located on the positioning platform (6), and the required soldering wire harness is quantitatively positioned and processed. Manually adjust the height of the support frame device (2) to implement lifting soldering operations.

[0013] As for the lifting type wire harness soldering device, a prompting device (8) is provided on one side of the frame (1) to provide different prompts for fastening state or running state.

[0014] Lifting wire harness soldering device, the way of prompting informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com