Welding fixture and welding process for magnetic medium box

A magnetic medium box and welding process technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the requirements of uneven welding seam, large deformation of the outer dimensions of the medium box, and impact on the assembly size requirements of the magnetic medium box structure. and other problems, to achieve the effect of saving stainless steel wire, reducing welding thermal deformation, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

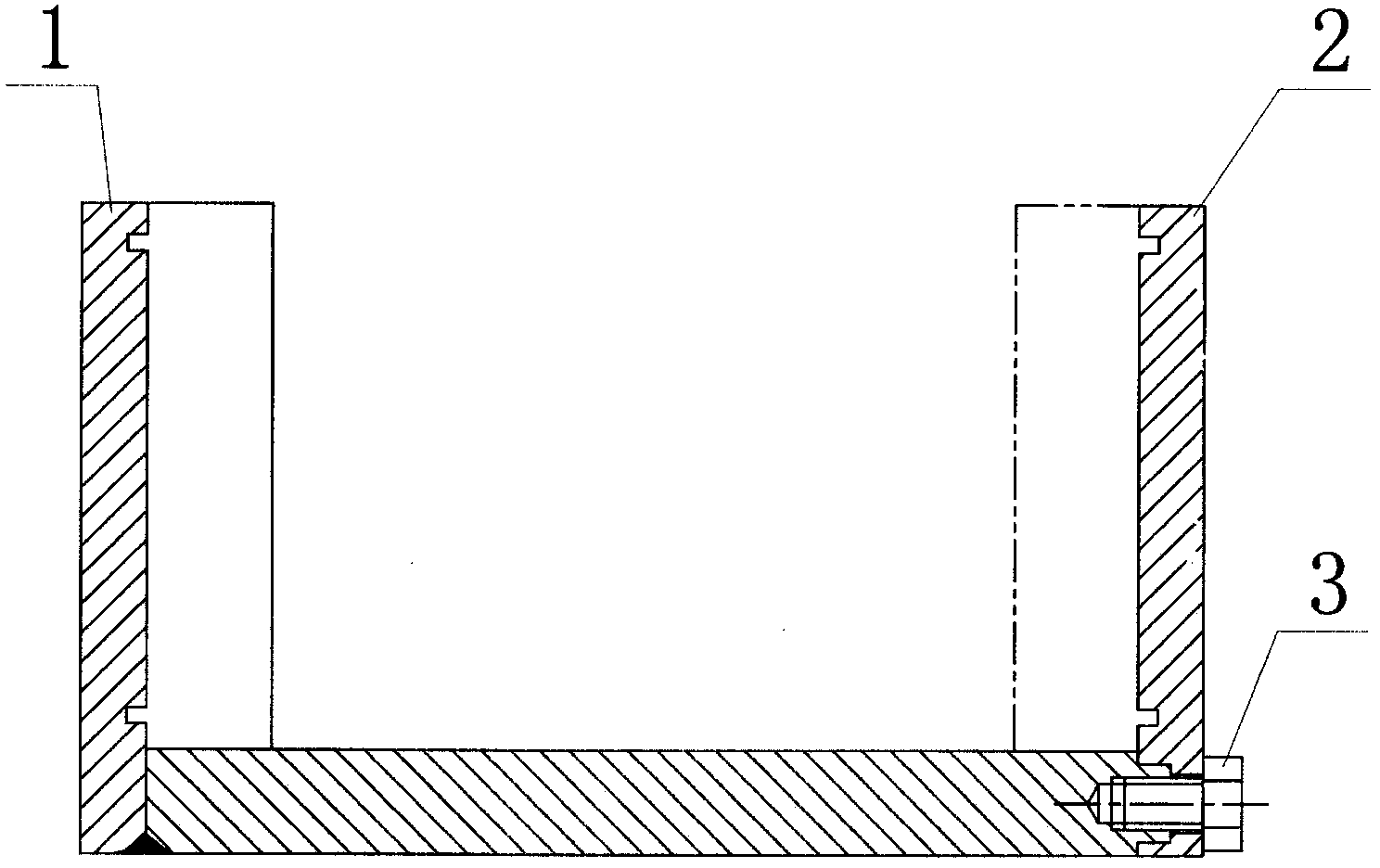

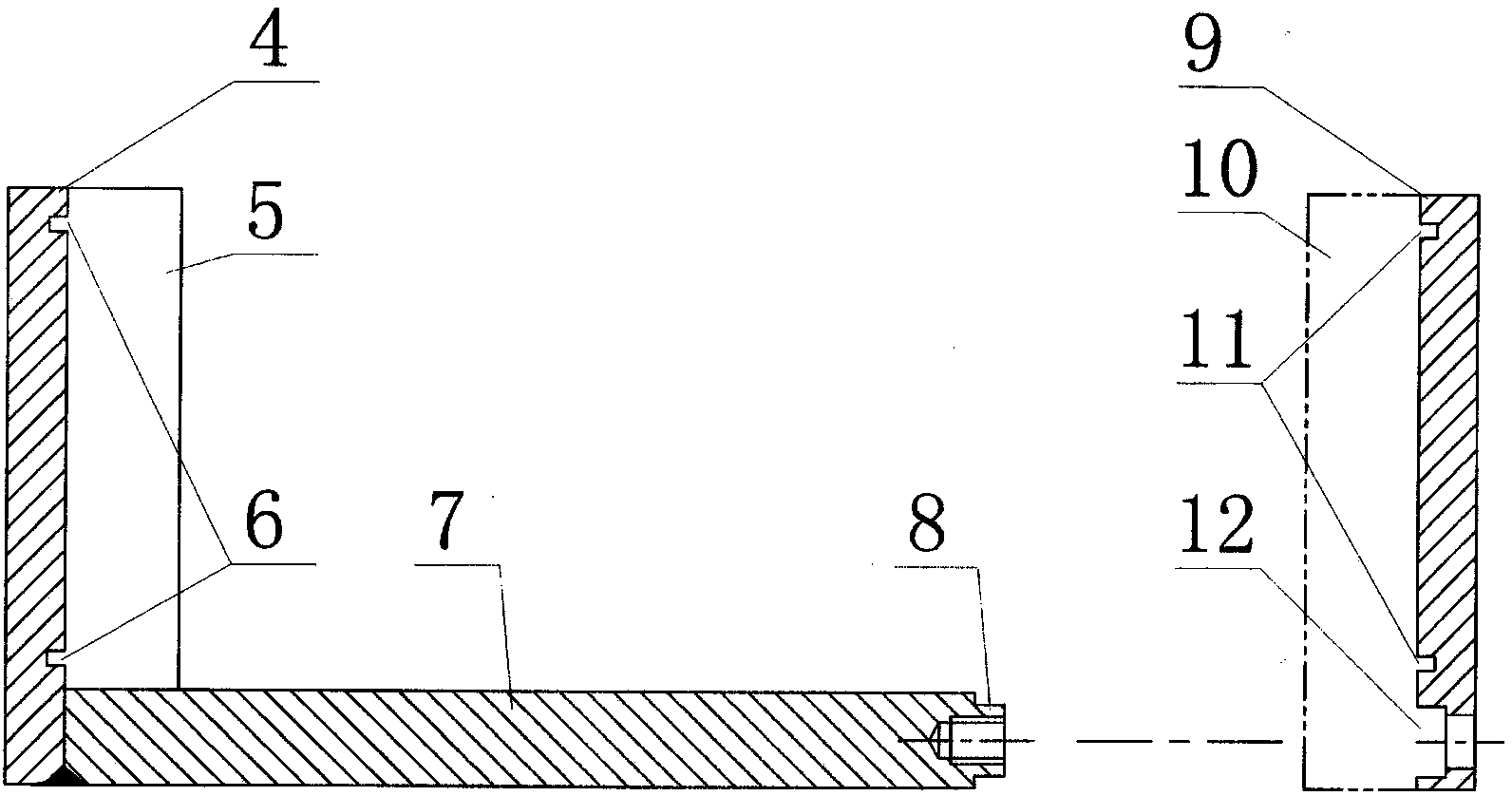

[0040] Unscrew the connecting bolt 3 first, remove the side formwork 2 from the bottom plate 7, put the magnetic medium box orifice plate 14 into the main formwork orifice slot 6, and insert the magnetic medium rod 13 into the two corner holes on the right, Adjust the position and the distance of the orifice plate, spot weld the contact points of the upper and lower magnetic medium box orifice plate 14 and the magnetic medium rod 13 to form a fixed frame, as Image 6 Shown in step ①. Then insert all magnetic media sticks, such as Image 6Shown in step ②. Then the tenon groove 12 of the side formwork 2 is aligned with the tenon 8 of the main formwork 1, and the distance and the position of the magnetic medium orifice 14 are adjusted simultaneously (the frame formed by the magnetic medium orifice 14 and the magnetic medium rod 13 It can be properly adjusted because it is not welded), so that the edge of the magnetic medium orifice plate 14 is embedded in the slot 11 of the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com