Linear vortex brake device

An eddy current braking and linear technology, applied in the field of rail vehicle braking systems, can solve the problems of adding winding tooling, burning out coils, and magnetic pole shaking, etc., to reduce processing and production requirements, facilitate installation and maintenance, and facilitate installation and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

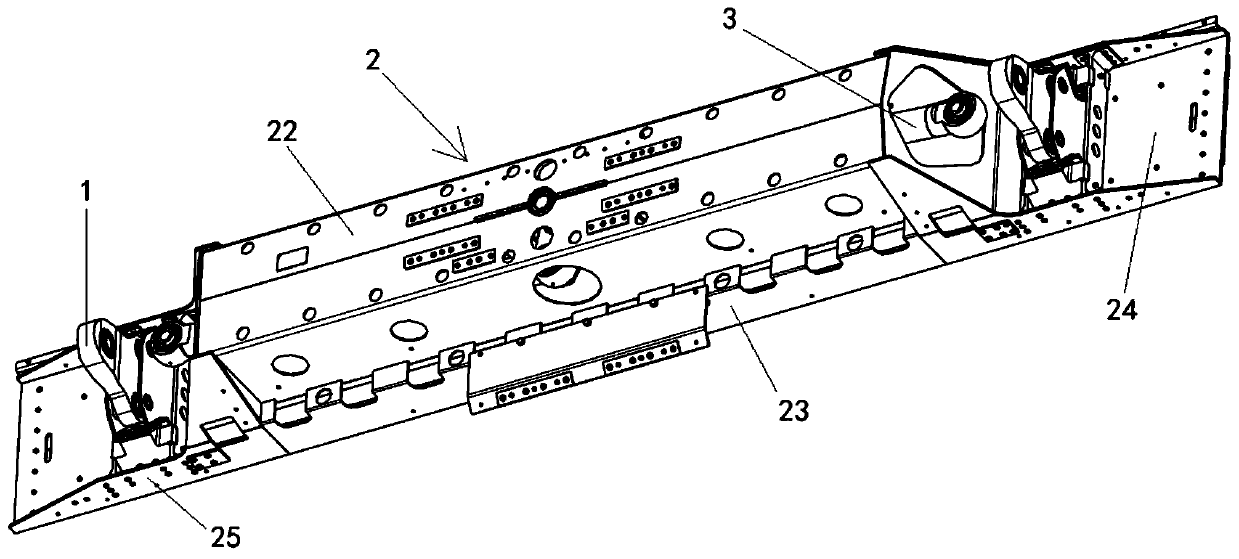

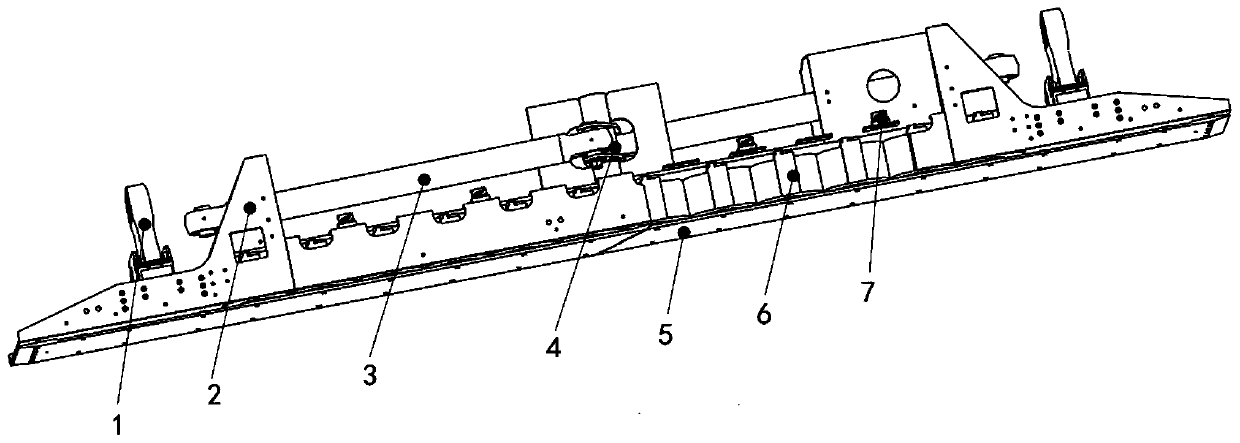

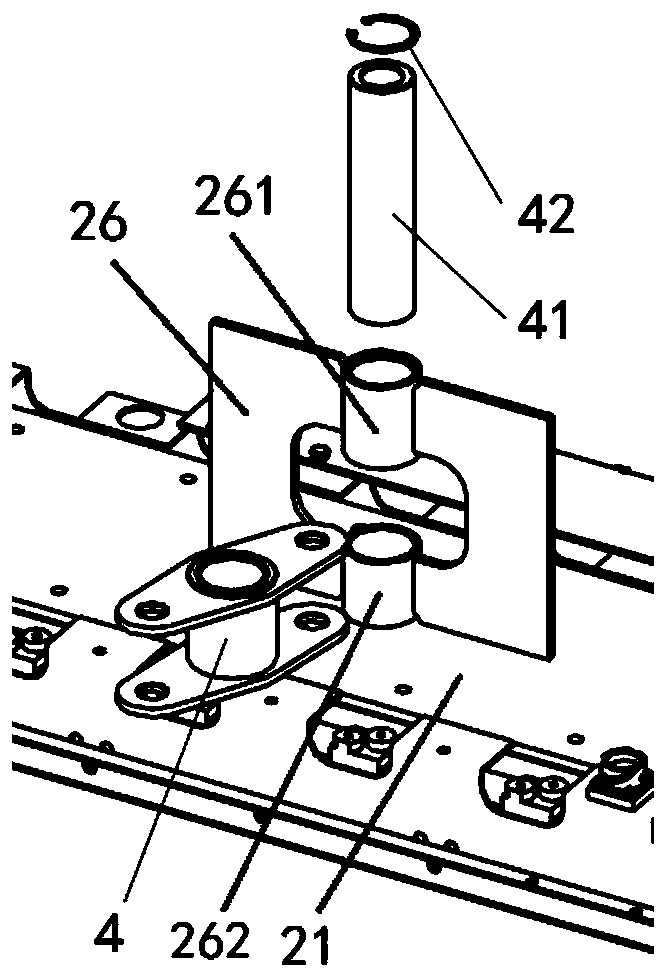

[0027] Such as Figure 1 to Figure 7 As shown, this embodiment is a linear eddy current braking device, including: a support beam assembly 2, two support arm assemblies 1, two pull rod assemblies 3, a lever assembly 4, several magnetic poles 6 and wear plates 5. The supporting arm assembly is connected with the support arm of the magnetic levitation vehicle to ensure the lateral displacement of the vehicle. The support beam component is the integrated main body of the device, which integrates other parts and is also an important part of transmitting torque; the lever component and the tie rod component cooperate to transmit the braking force to the vehicle; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com