Colineation structure of valve with electromagnetic drive

A technology of collinearity and structural size, applied in the direction of non-mechanically actuated valves, electromagnets with armatures, electromagnets, etc., can solve the problems of structural volume reduction, power reduction, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

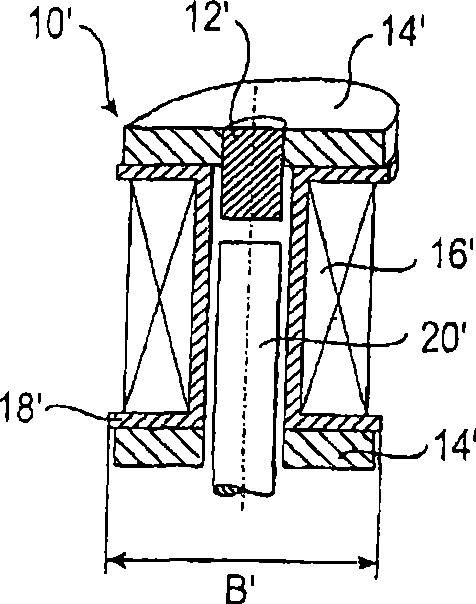

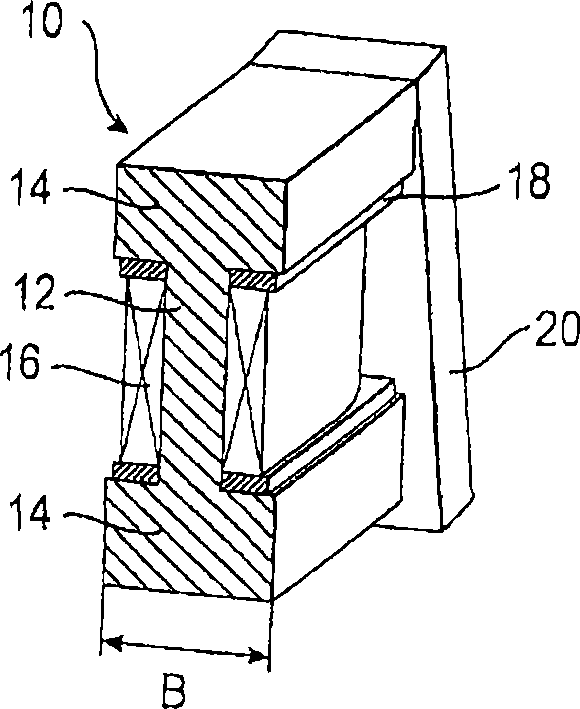

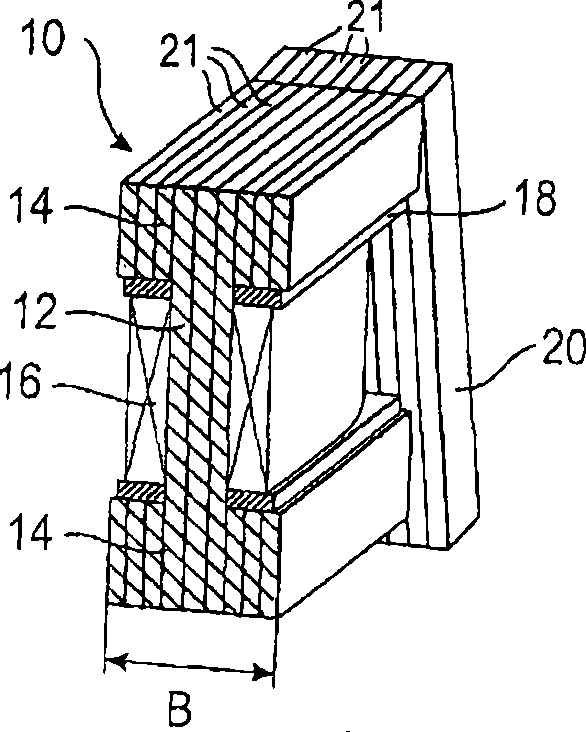

[0028] figure 2 A solenoid drive 10 is schematically shown for a valve according to the invention, more specifically a narrow valve with structural dimensions smaller than or equal to 5 mm, preferably approximately 4.5 mm. The driver 10 has a core 12 disposed between two poles 14 and formed in one piece therewith. The core 12 has disposed thereon a winding 16 formed of a plurality of copper turns (coils). There is also a coil former 18 arranged between the winding 16 and the pole 14, but this coil former differs from that of the prior art, at least in the direction of the dimension B which determines the structural dimensions of the valve, between the core 12 and the winding 16. There are no walls. The pole 14 protrudes over the winding 16 and cooperates with an armature 20 which is arranged relative to the pole 14 in such a way that it does not increase the structural size of the valve along the dimension B. and figure 2 Unlike the example shown, the coil carrier 18 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com