A Segmented Cylindrical Transverse Flux Linear Motor

A linear motor and transverse magnetic flux technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of low effective length ratio of motor armature winding, low utilization rate of primary space, difficulty in realizing multi-phase structure, etc. , to achieve the effect of simple manufacturing process, simple structure and high utilization rate of magnetic poles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

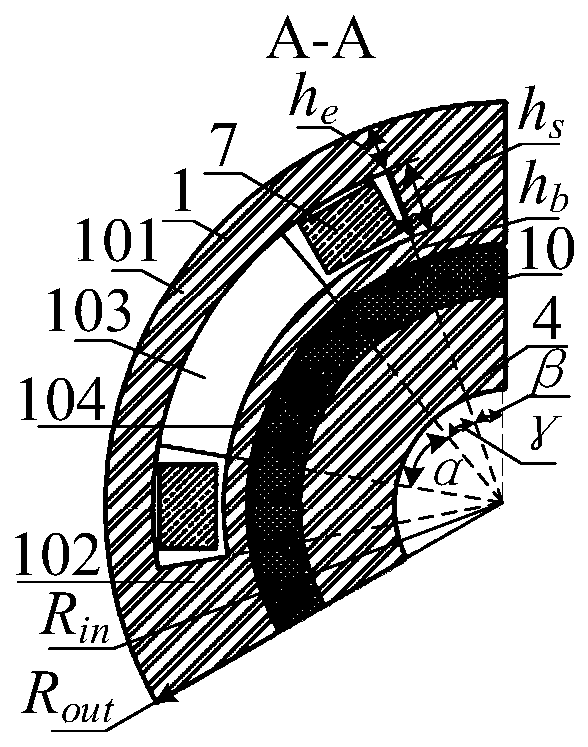

[0029] There are analytic and numerical methods for solving general electromagnetic field problems. The analytical method includes the equivalent magnetic circuit method and the layered model method; the equivalent magnetic circuit method is a traditional method for solving the motor magnetic field, and the motor magnetic field is expressed by drawing a magnetic circuit diagram, which has the characteristics of clear concept and simple calculation ; The layered model method uses partial differential or integral equations to describe the electromagnetic field, and then solves it directly with methods such as the separation of variables method. Its application is generally limited to occasions where the boundary conditions are simple and the medium is linear. Numerical solutions have a wider range of applications and can solve a large number of practical problems in the electromagnetic field of motors. With the rapid development of computer technology in modern times, numerical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com