Patents

Literature

33results about How to "Shorten the length of the magnetic circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

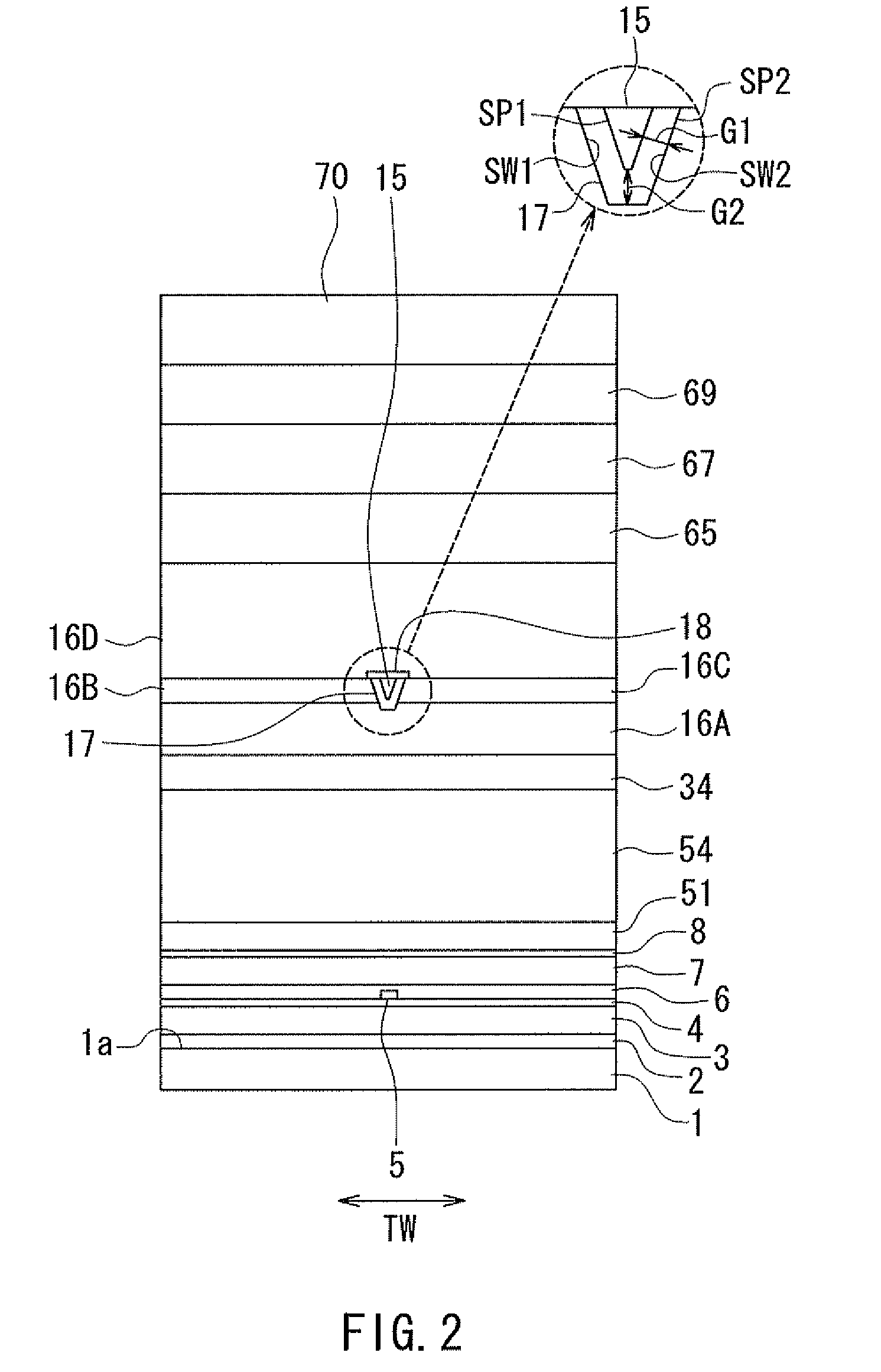

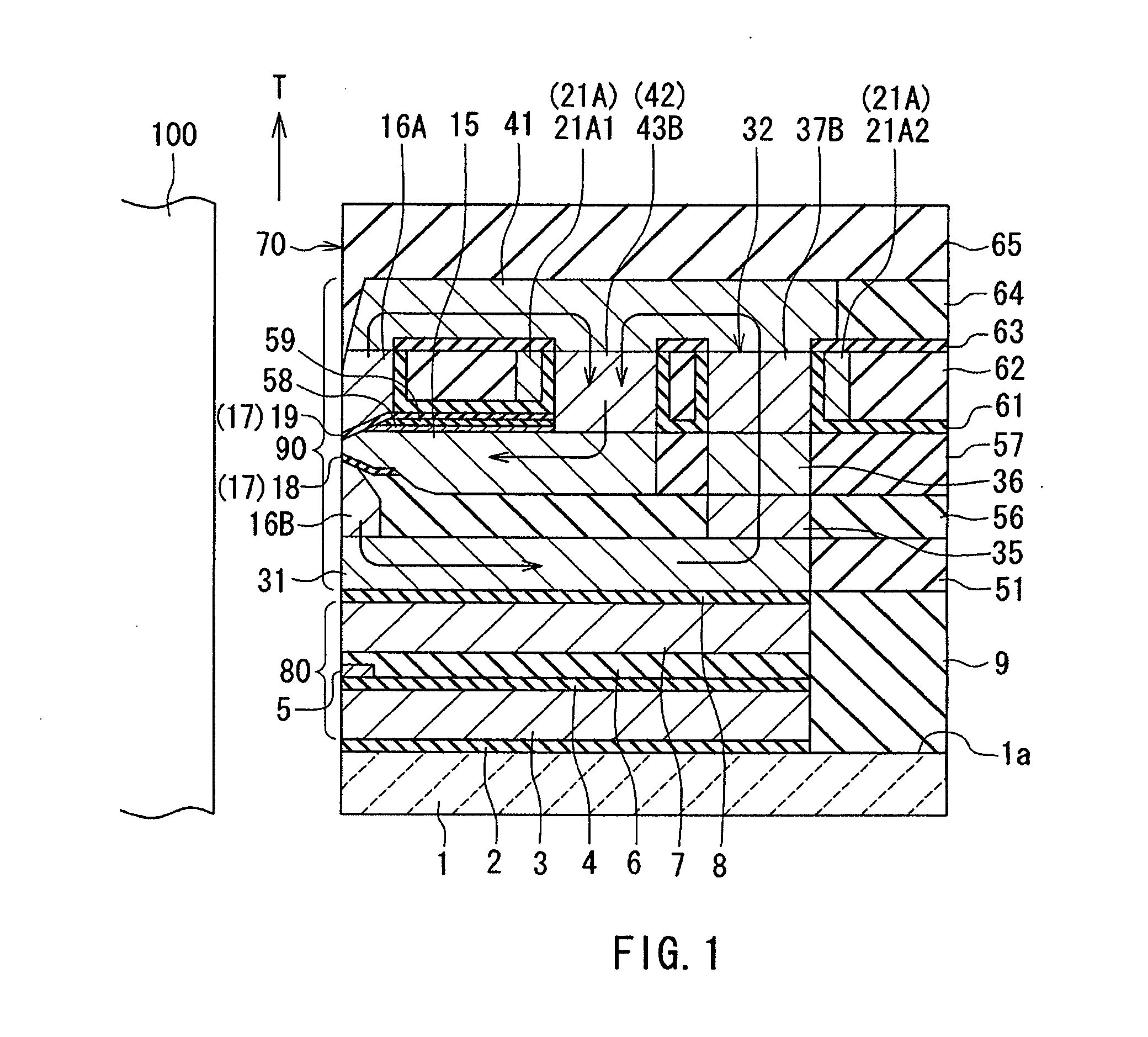

Thin-film magnetic head with thin-film coil of low resistance

InactiveUS6950279B2Small in magnetic path lengthExcellent in recording characteristicConstruction of head windingsNanomagnetismShortest distanceCoupling

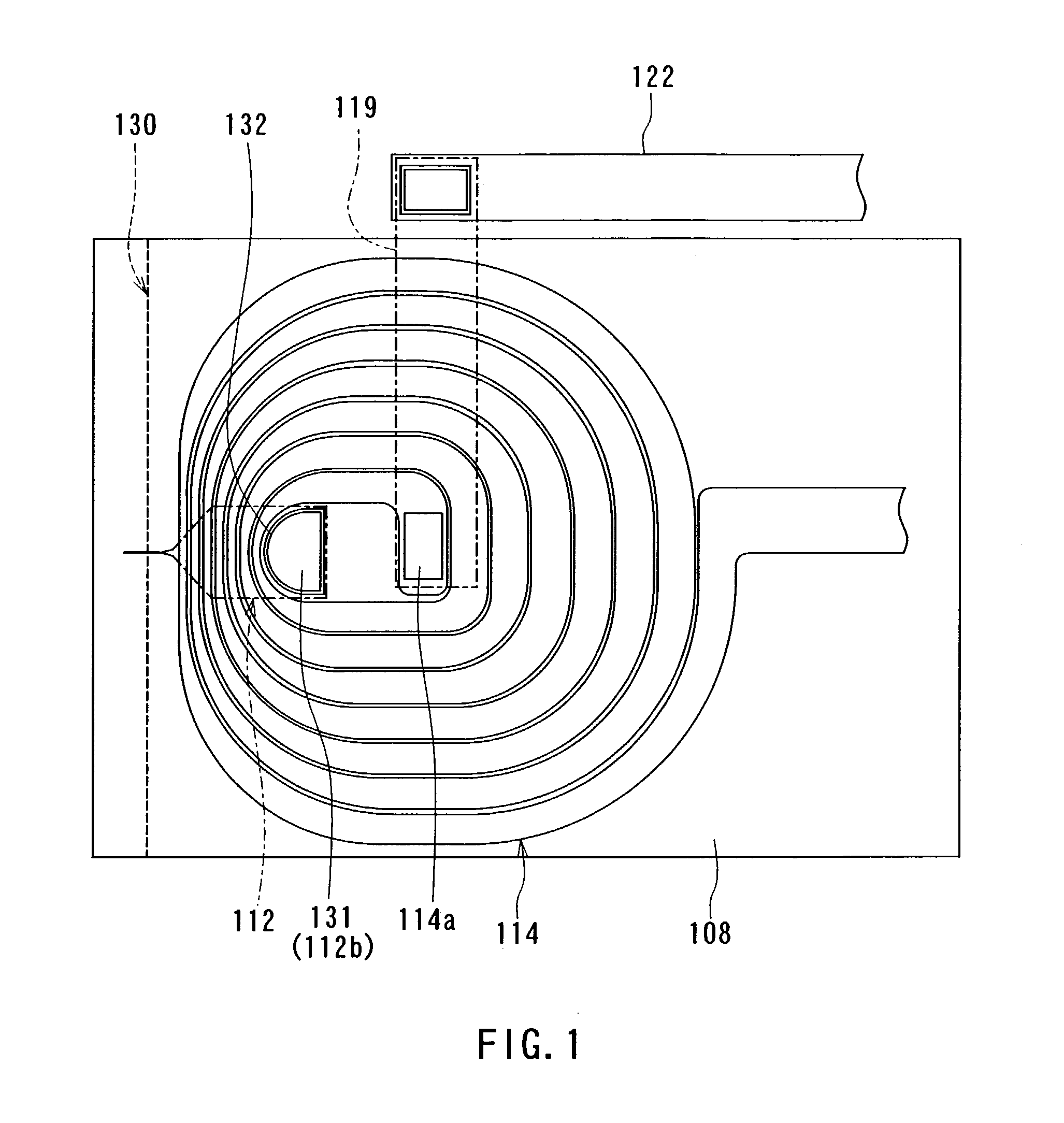

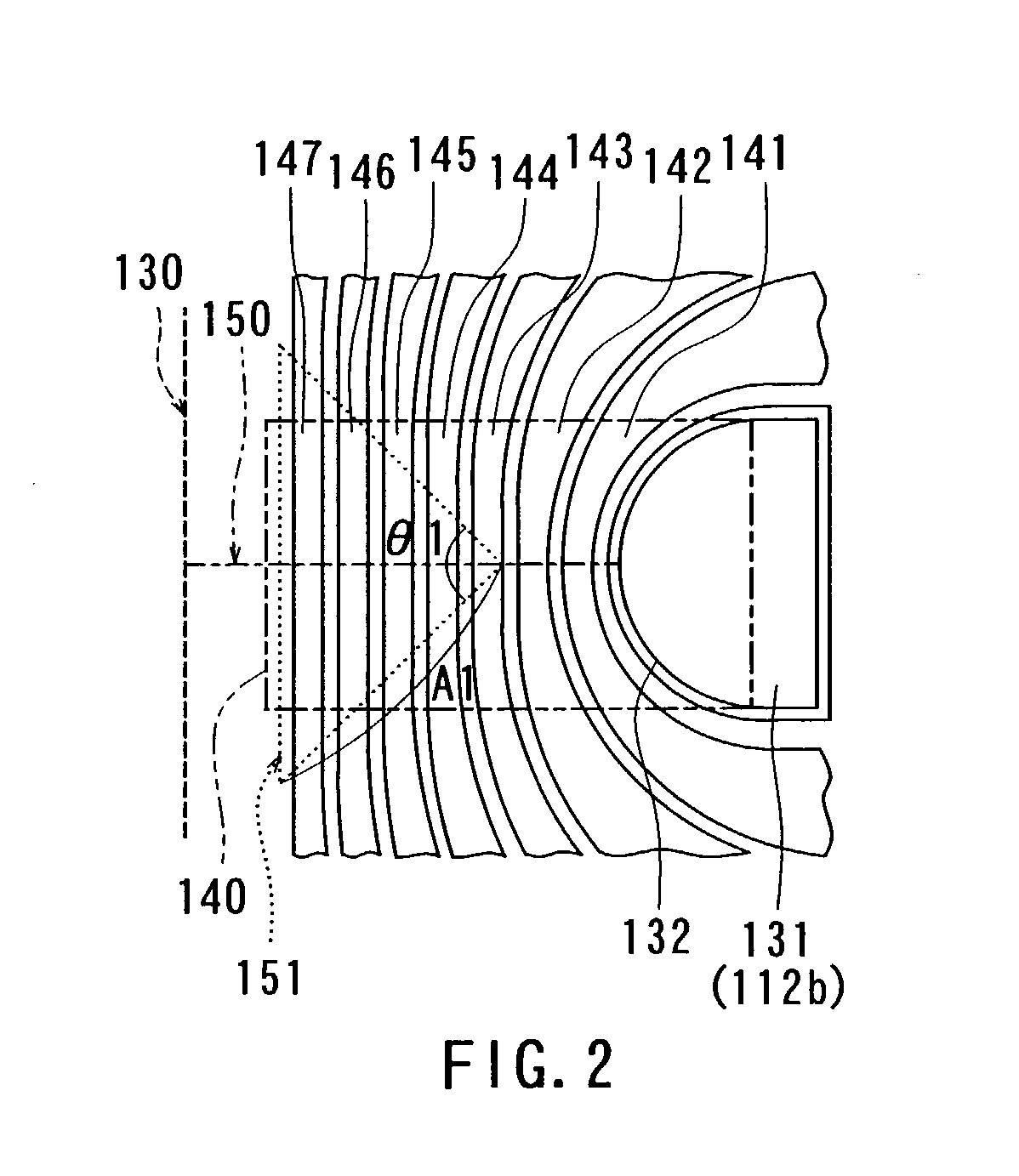

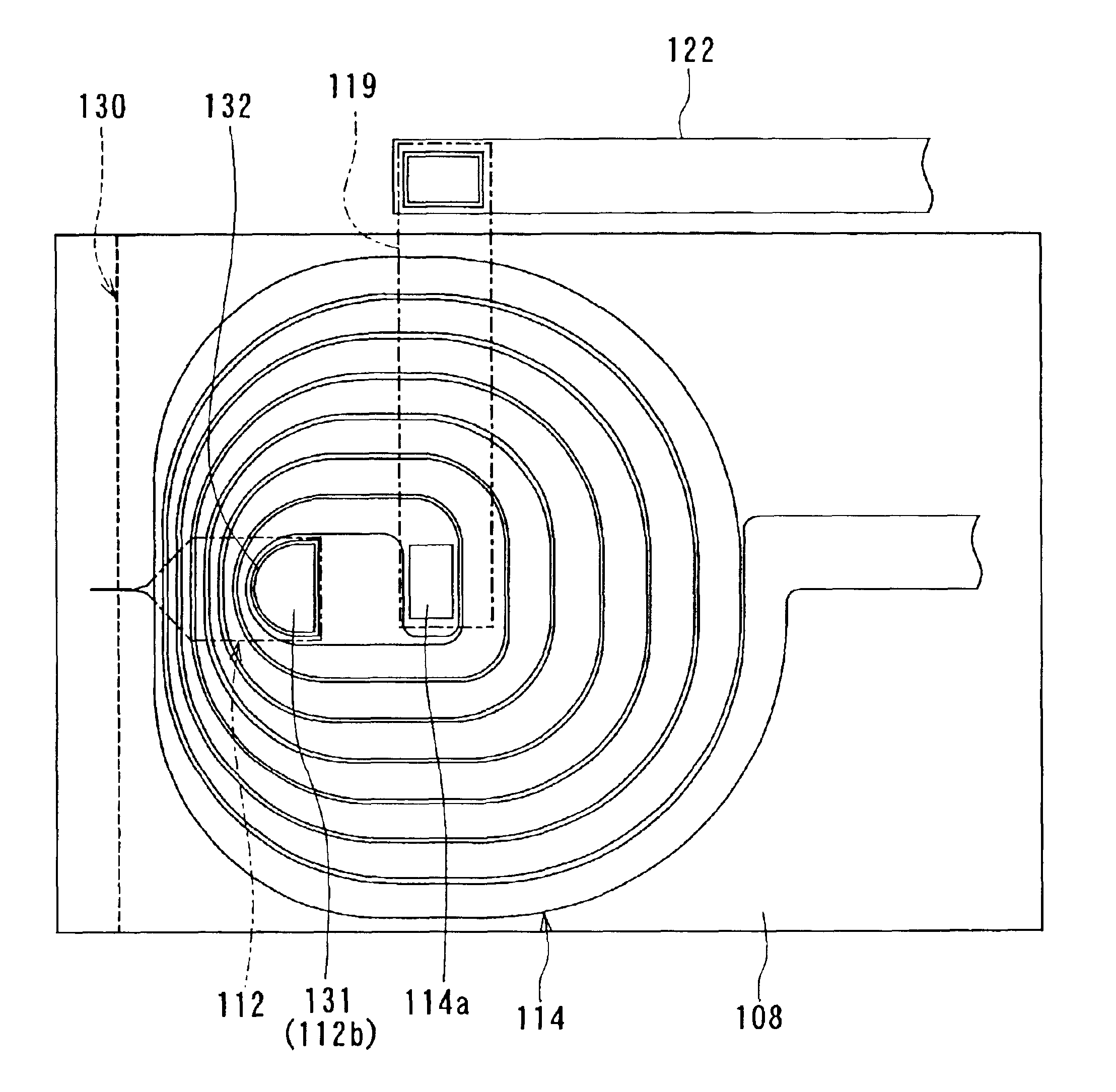

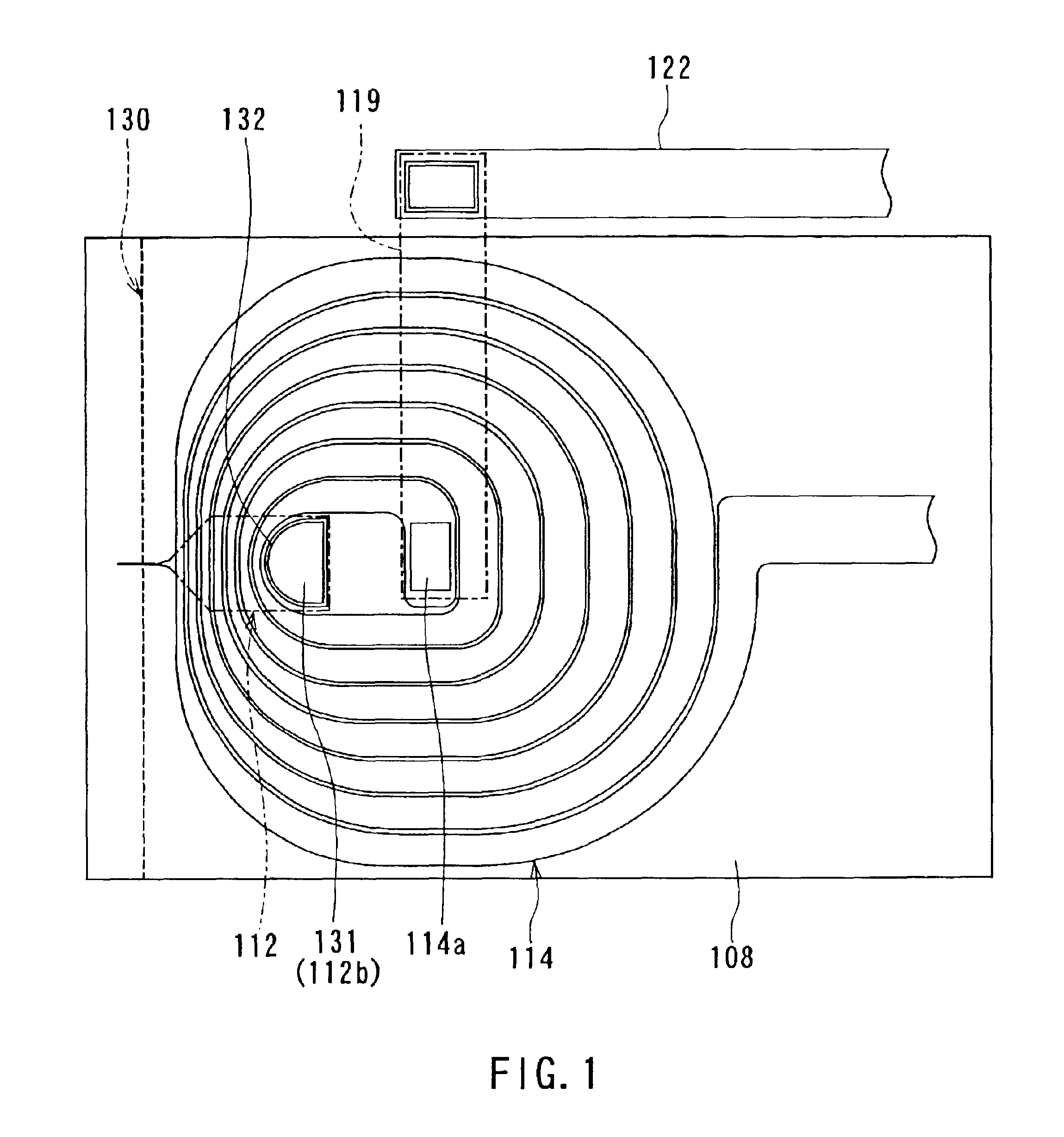

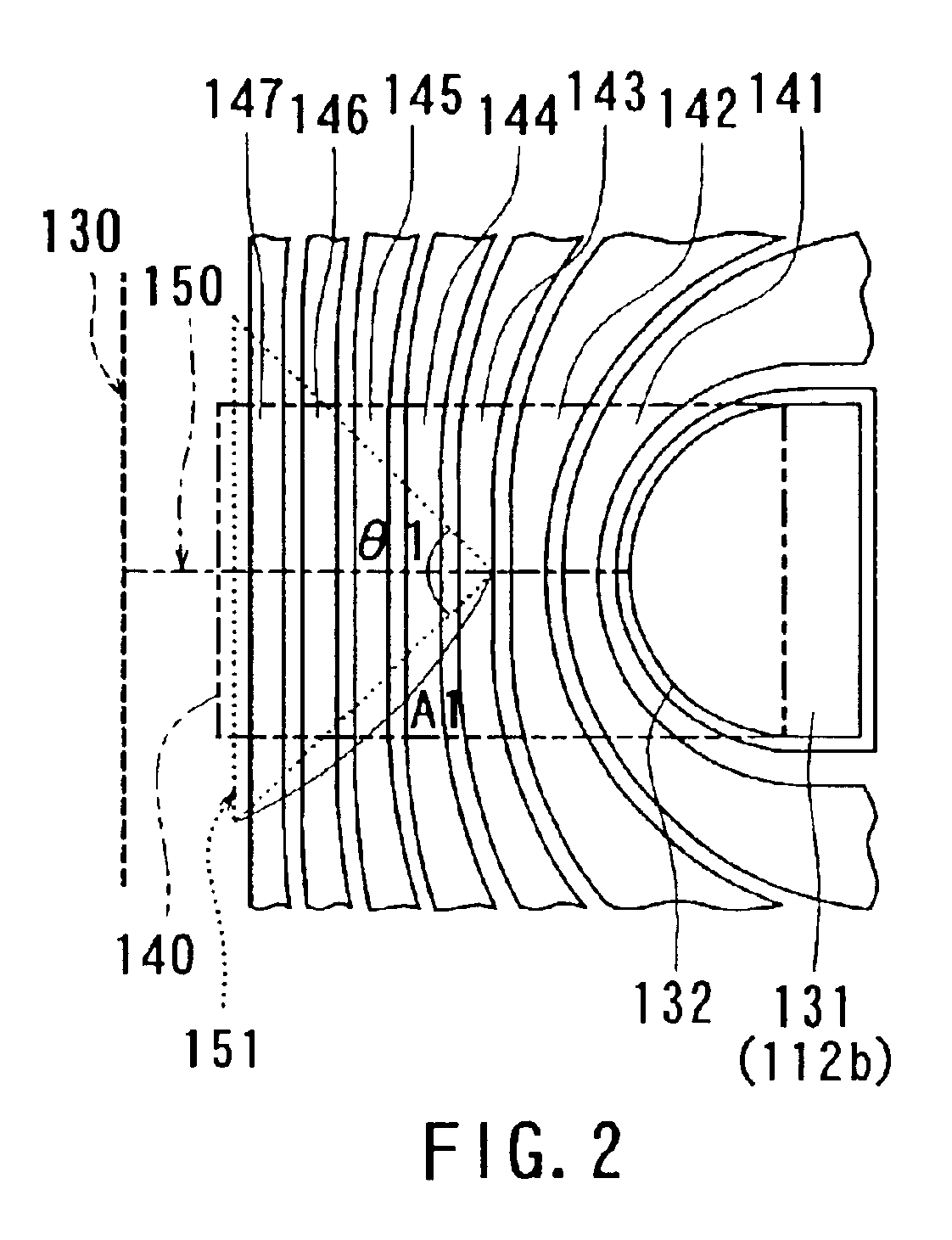

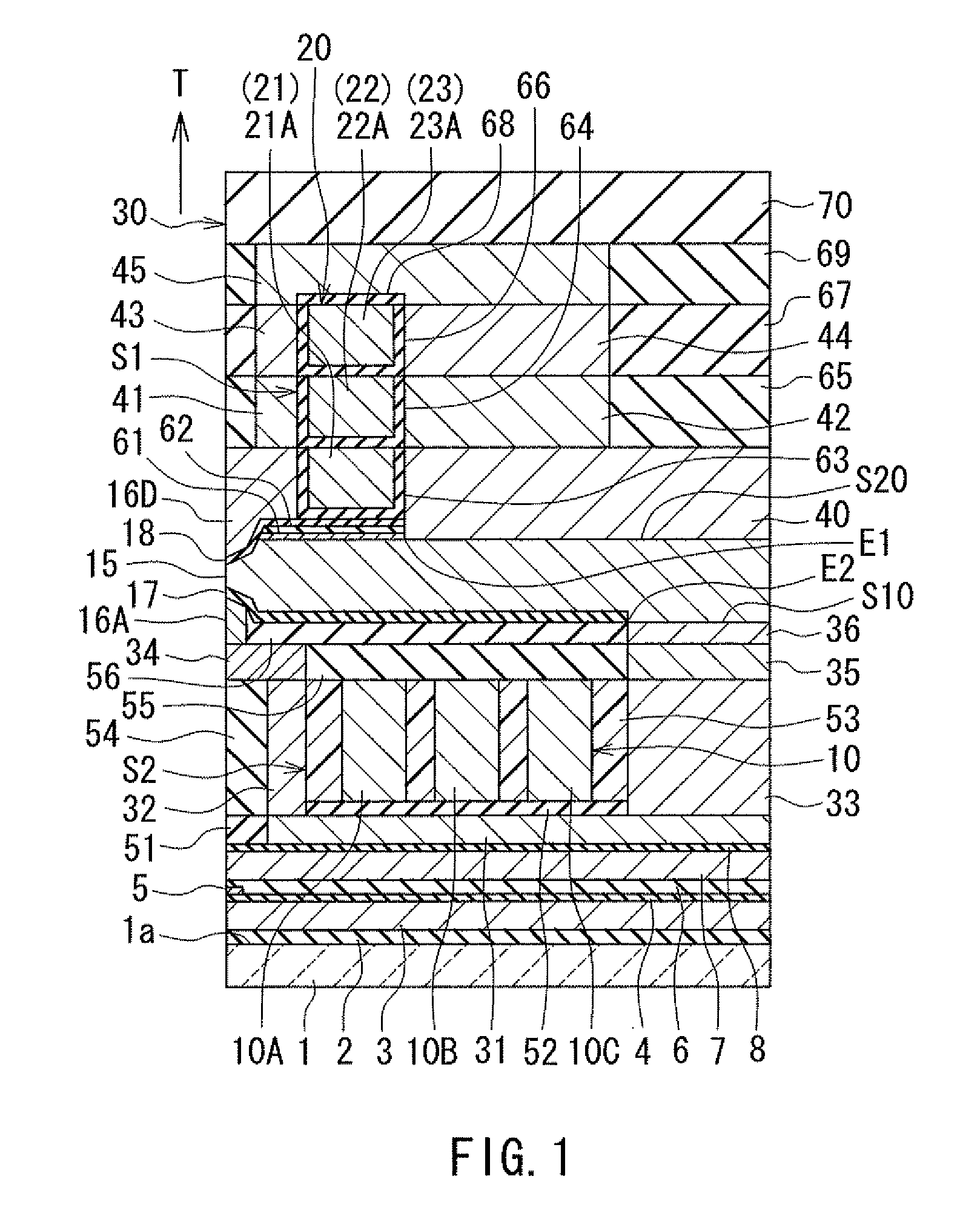

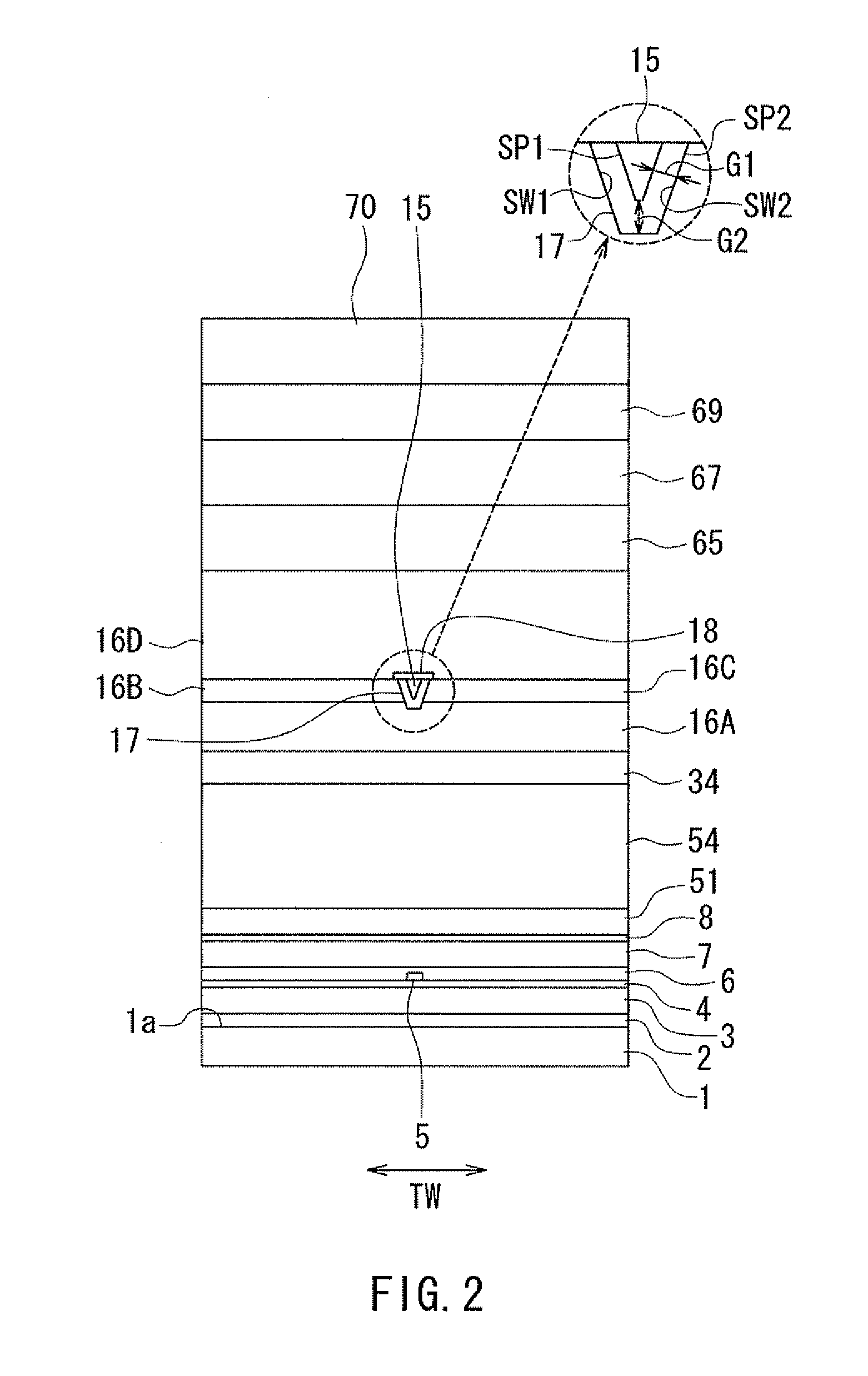

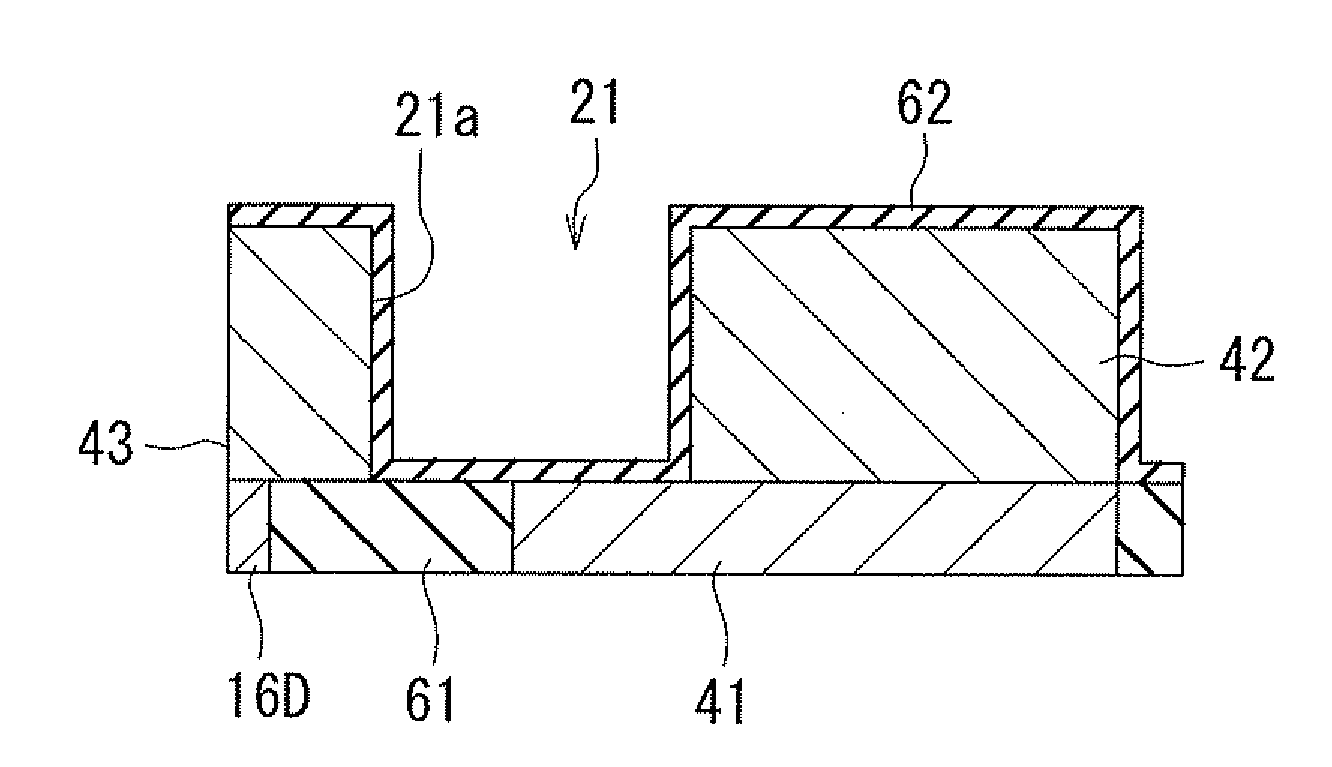

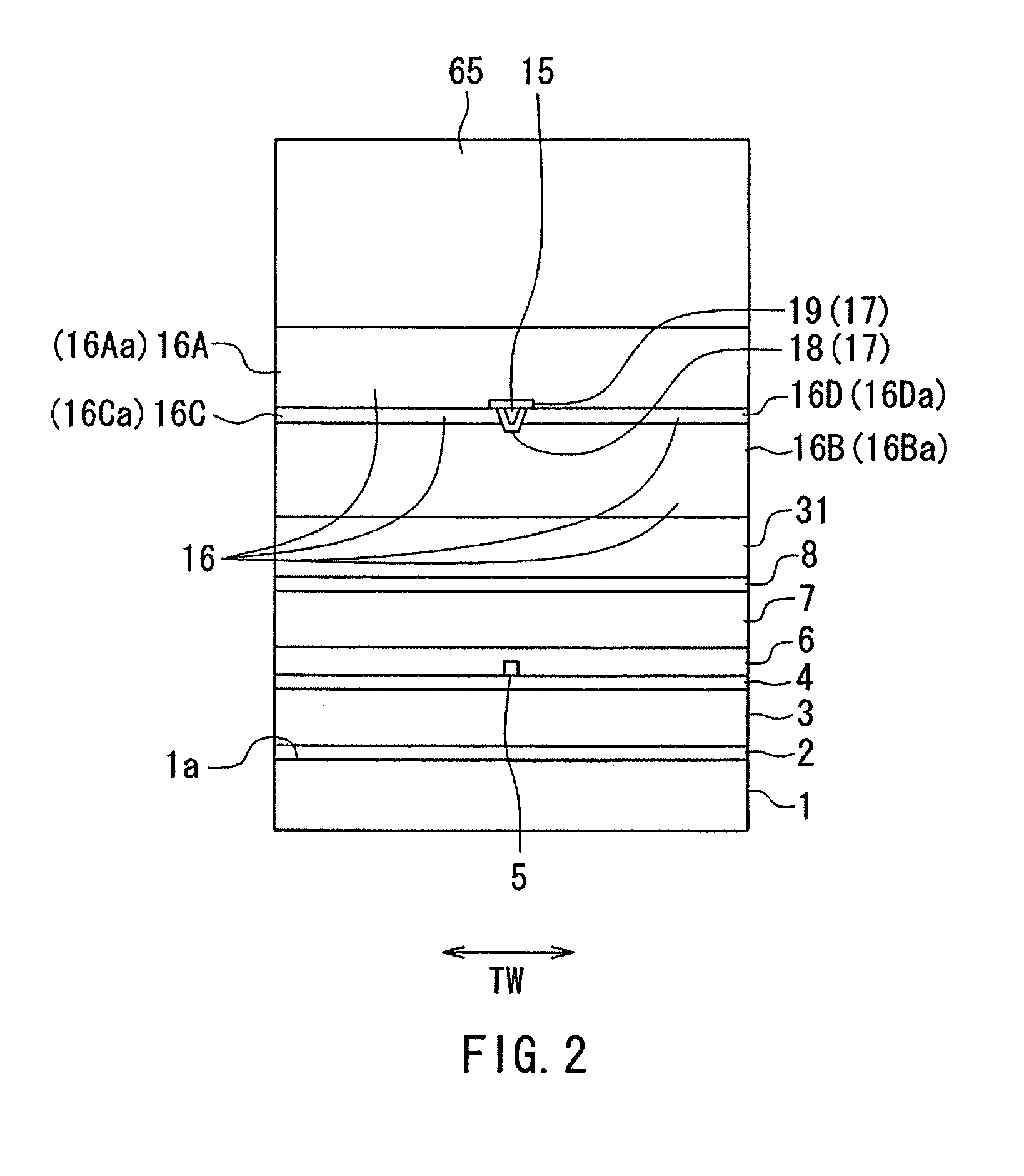

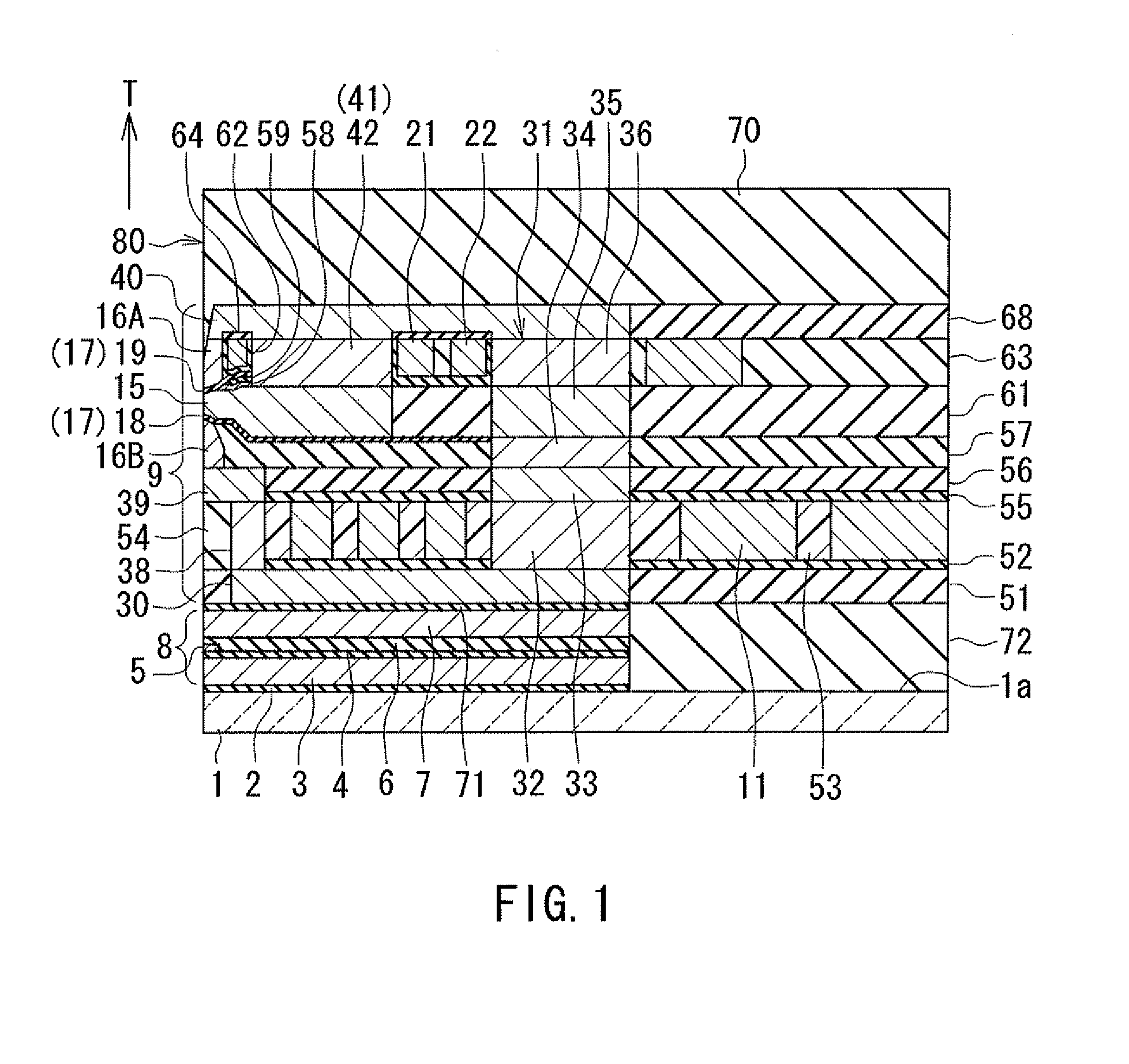

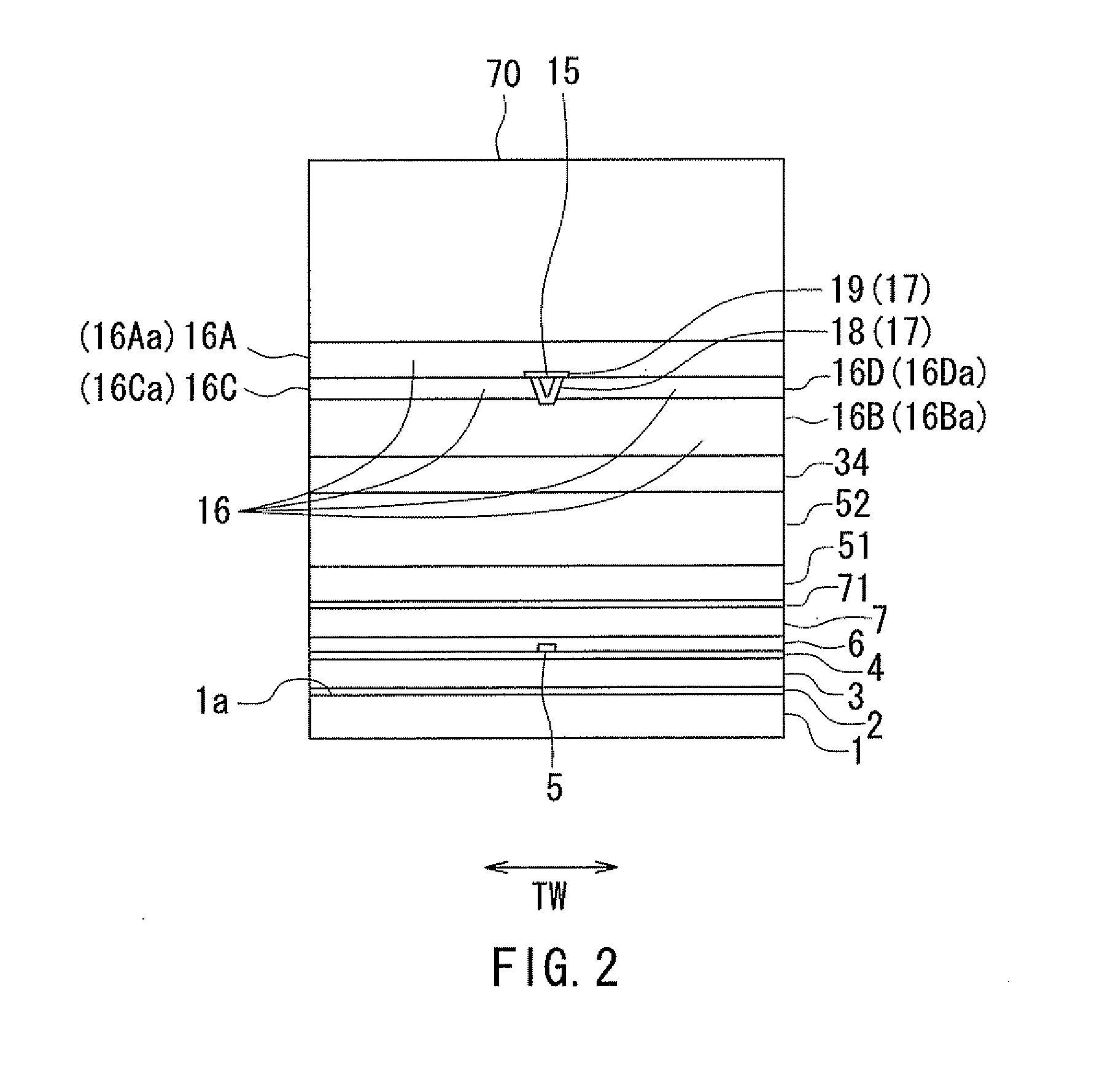

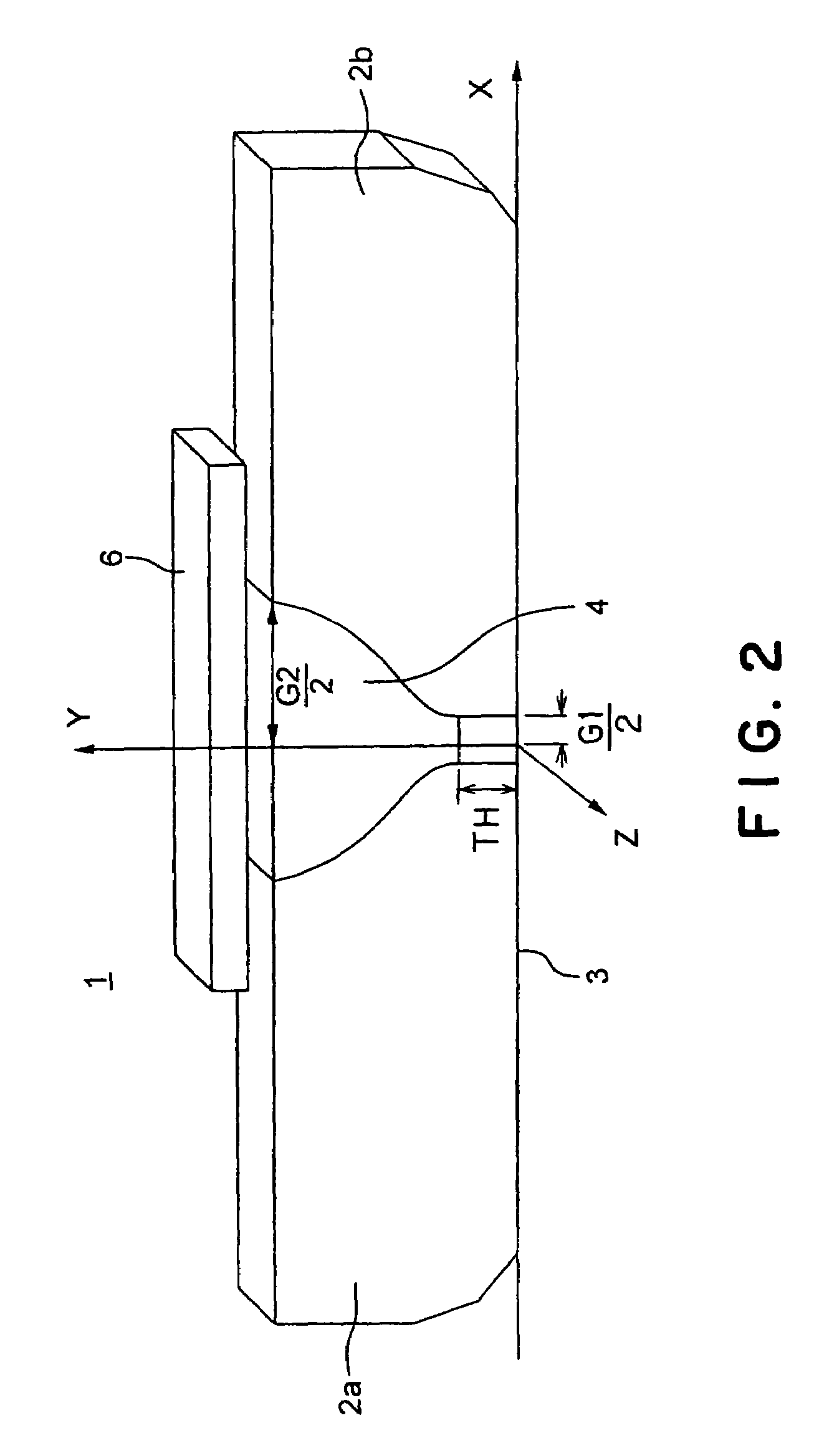

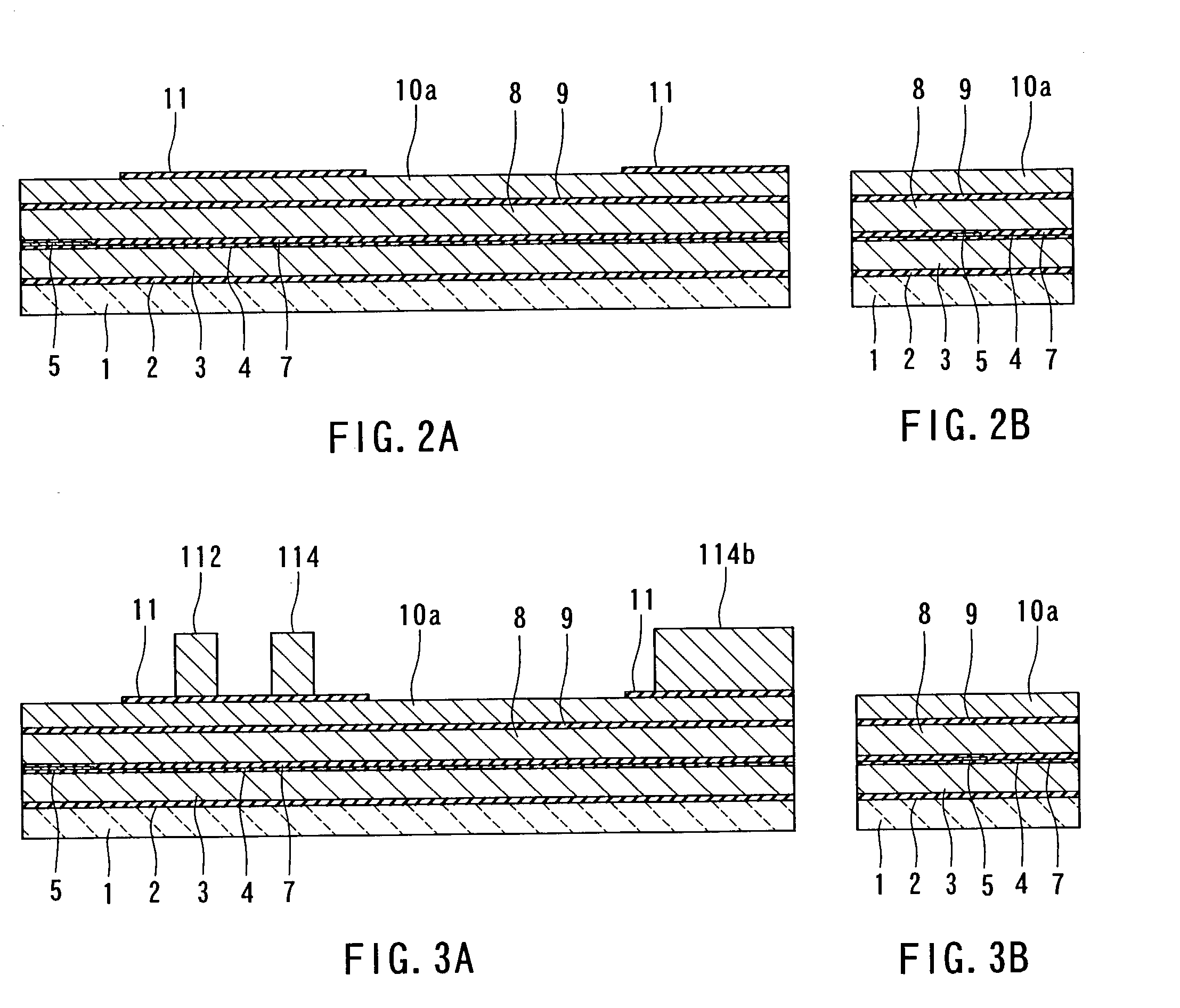

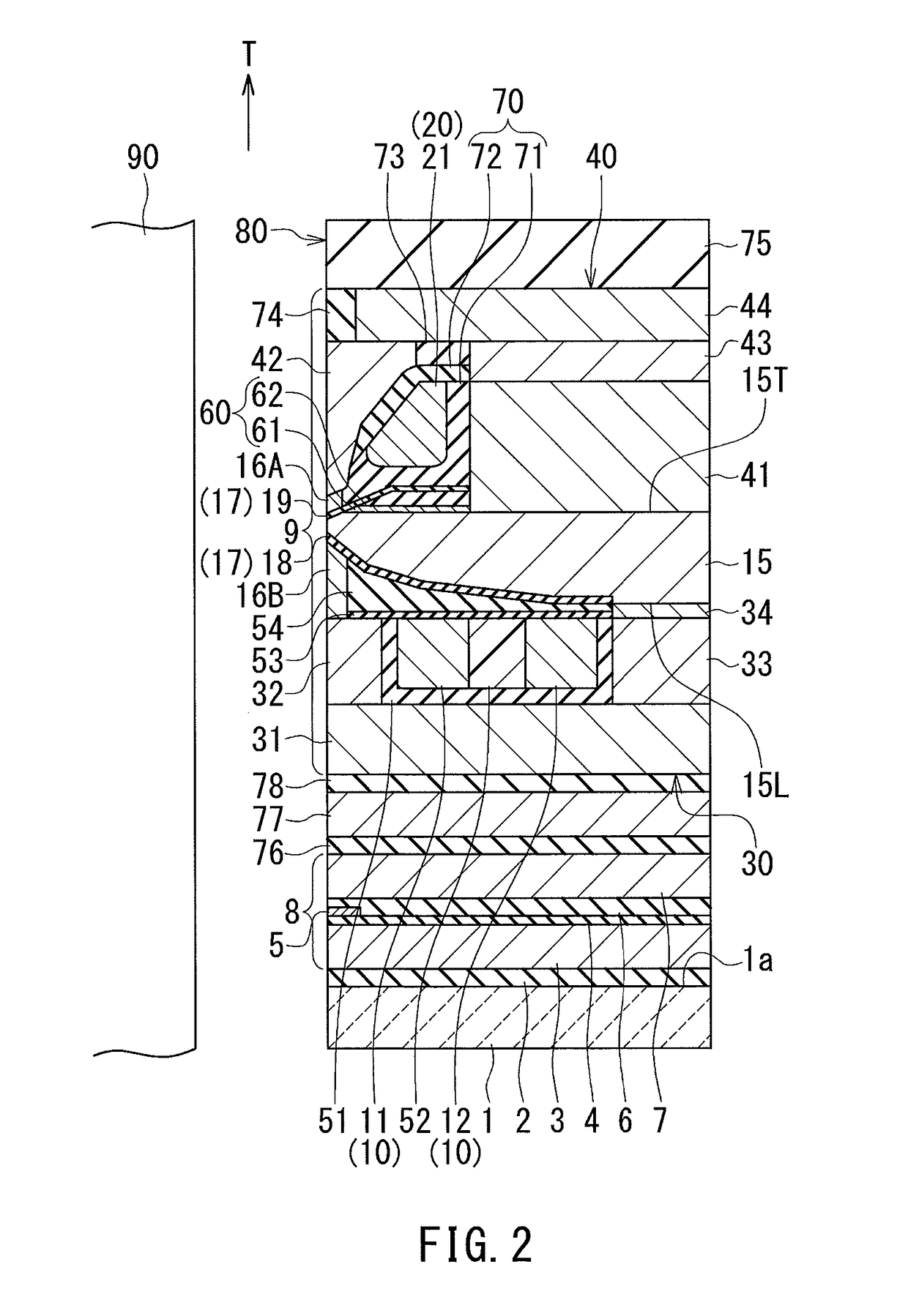

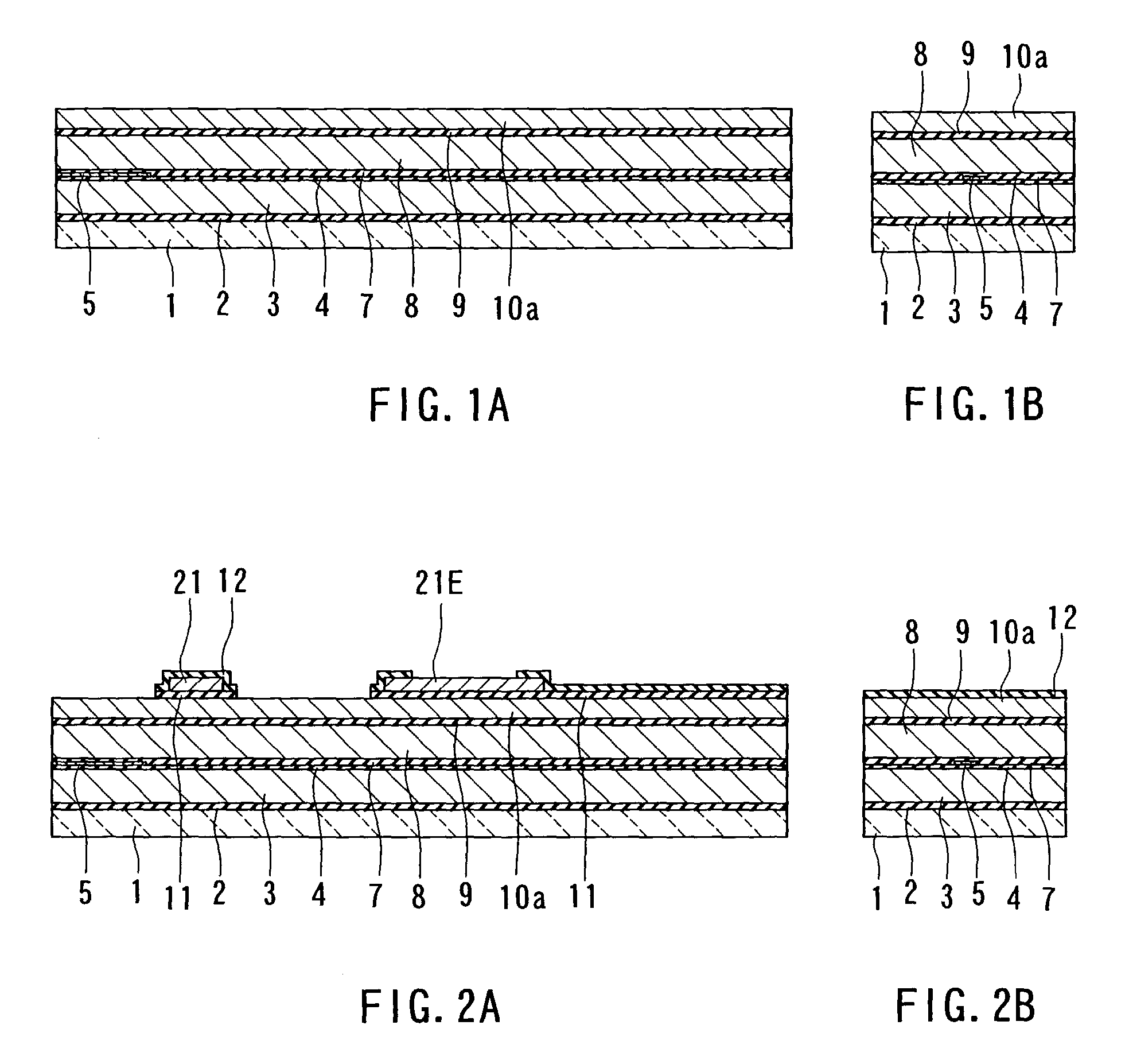

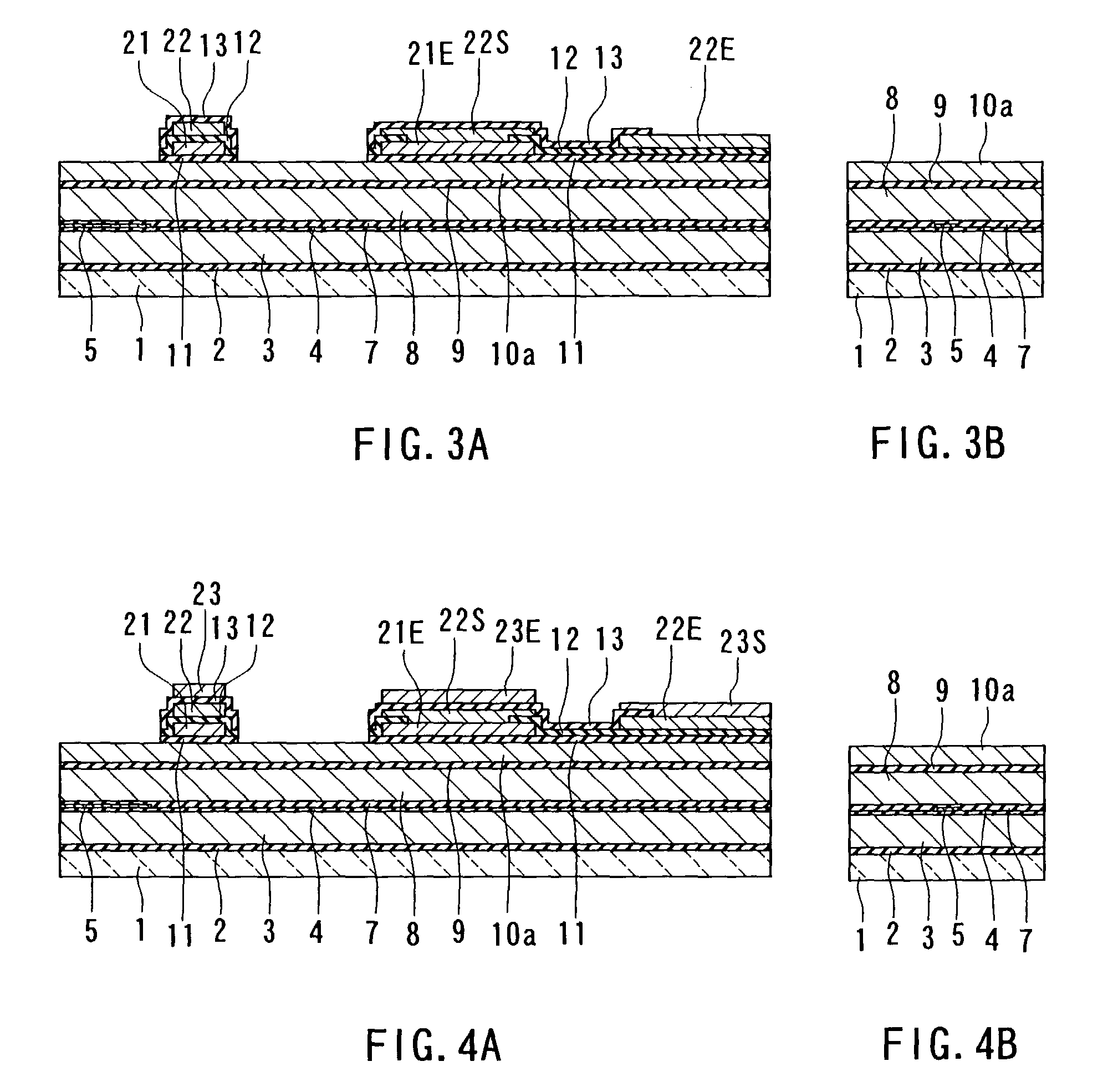

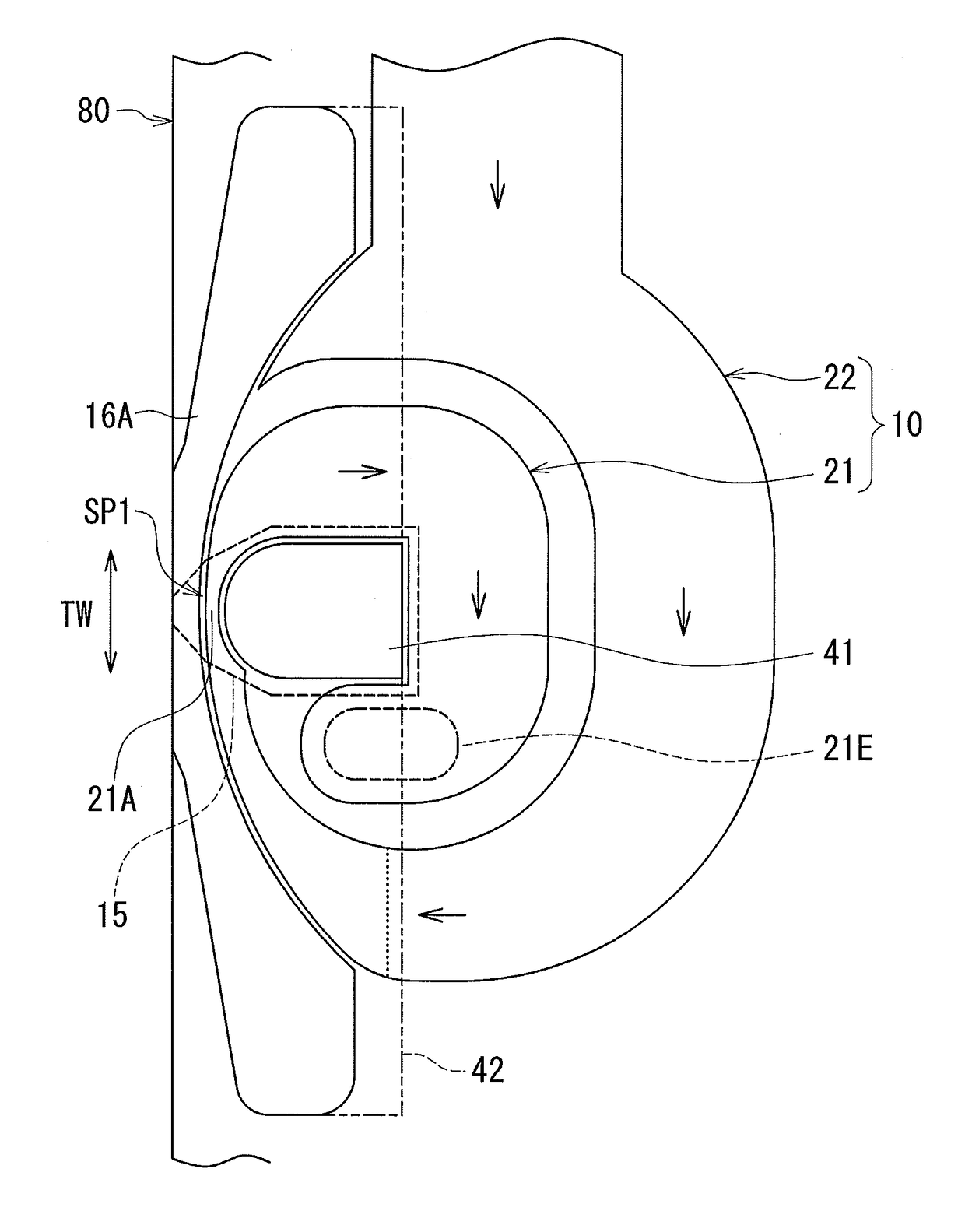

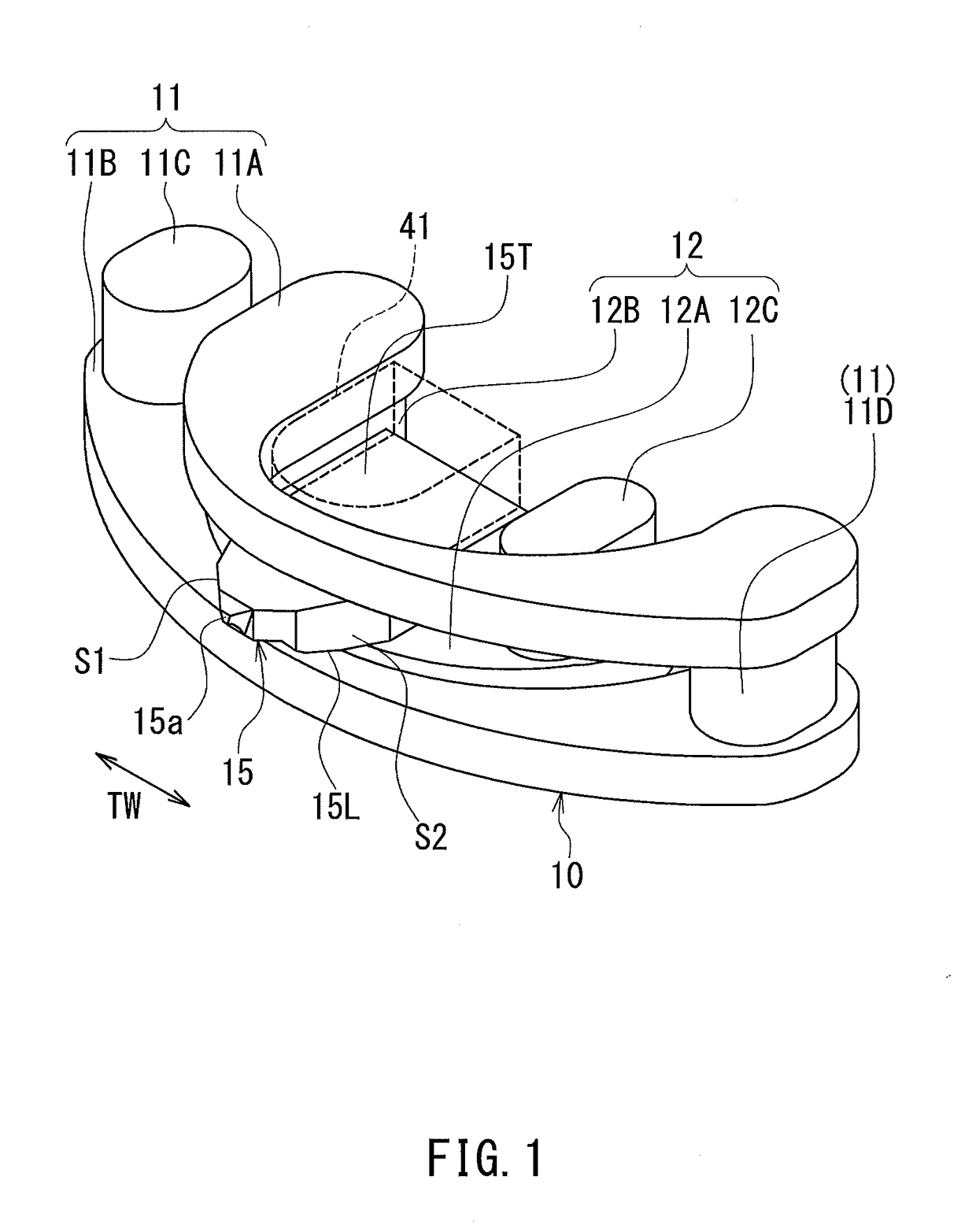

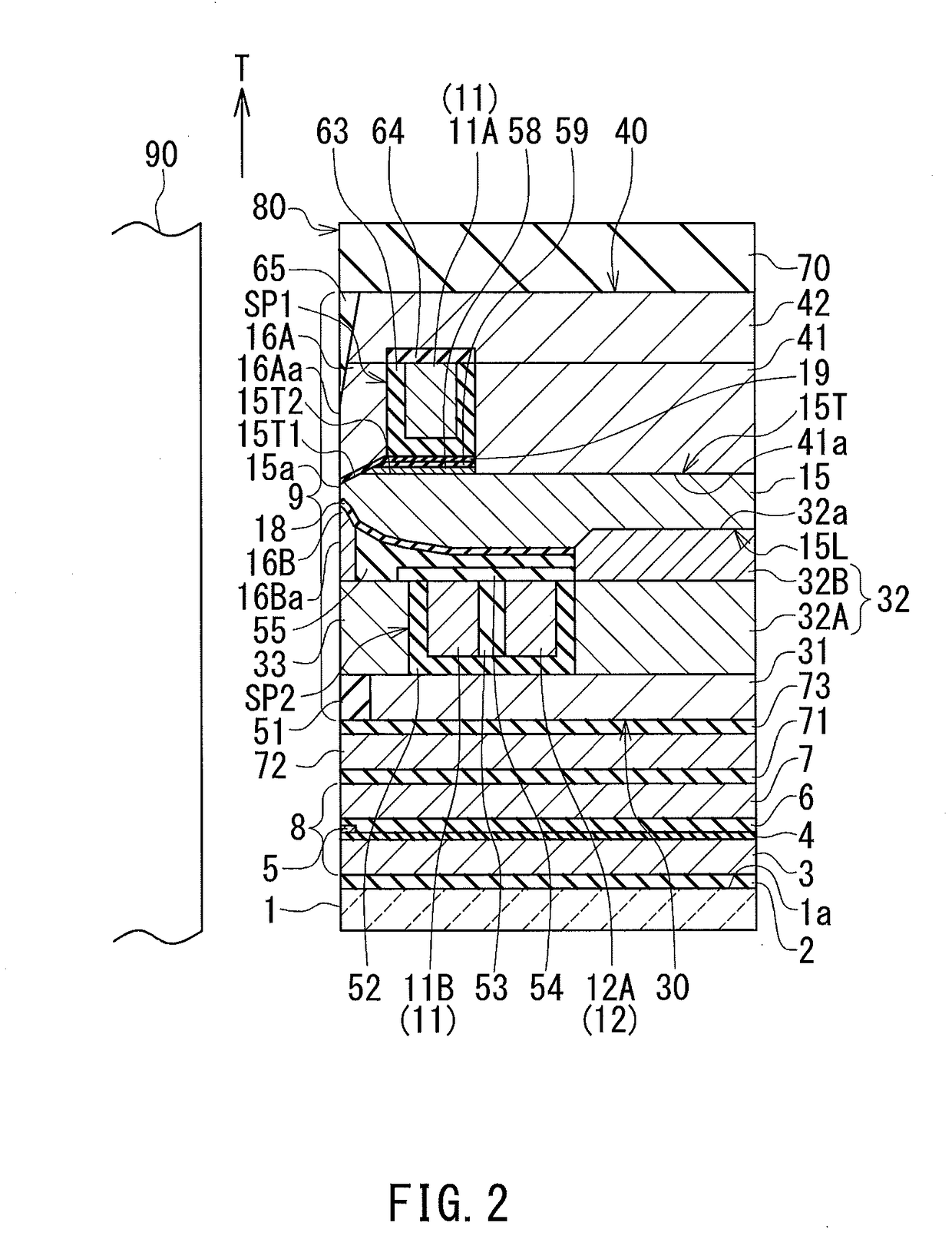

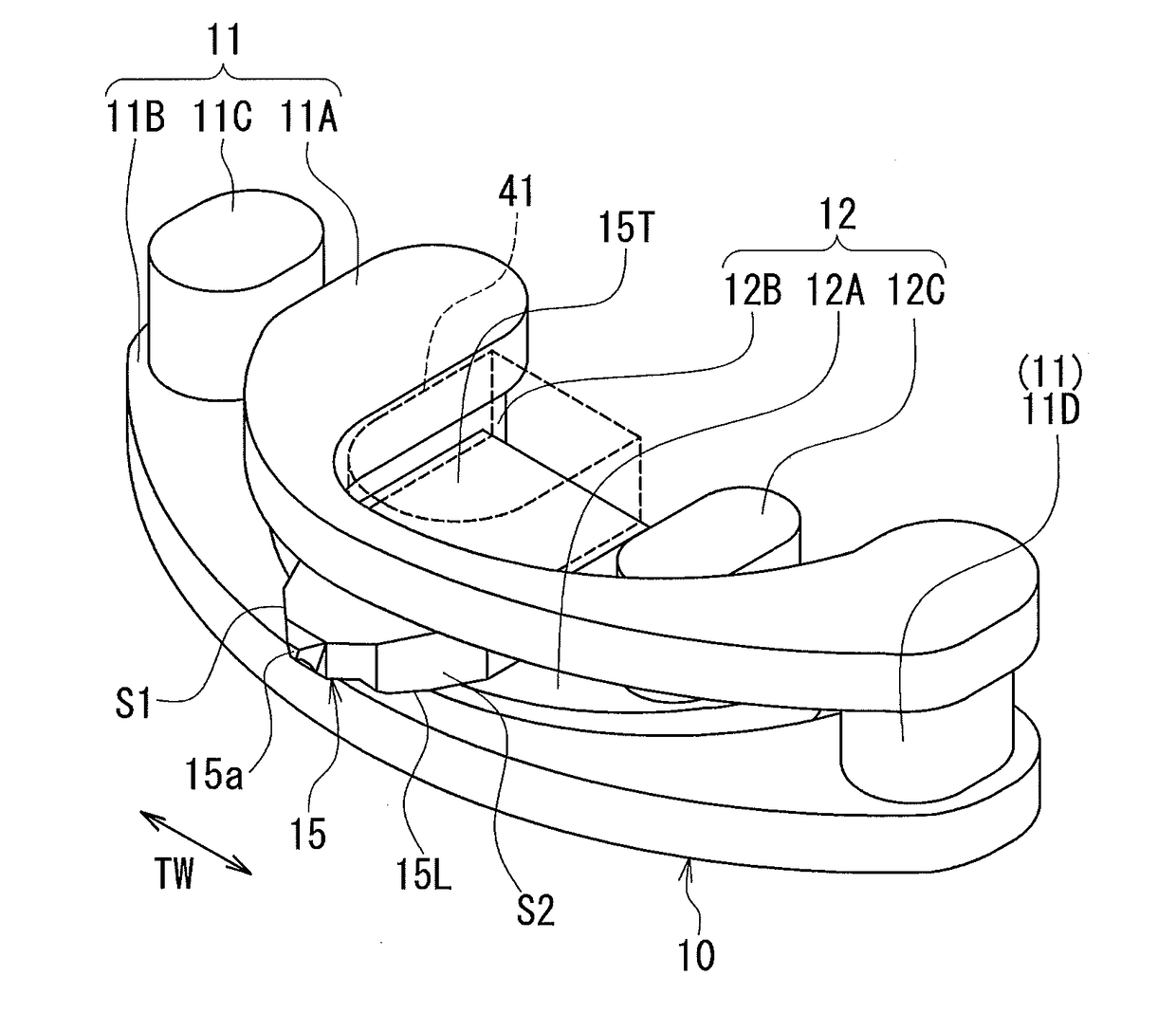

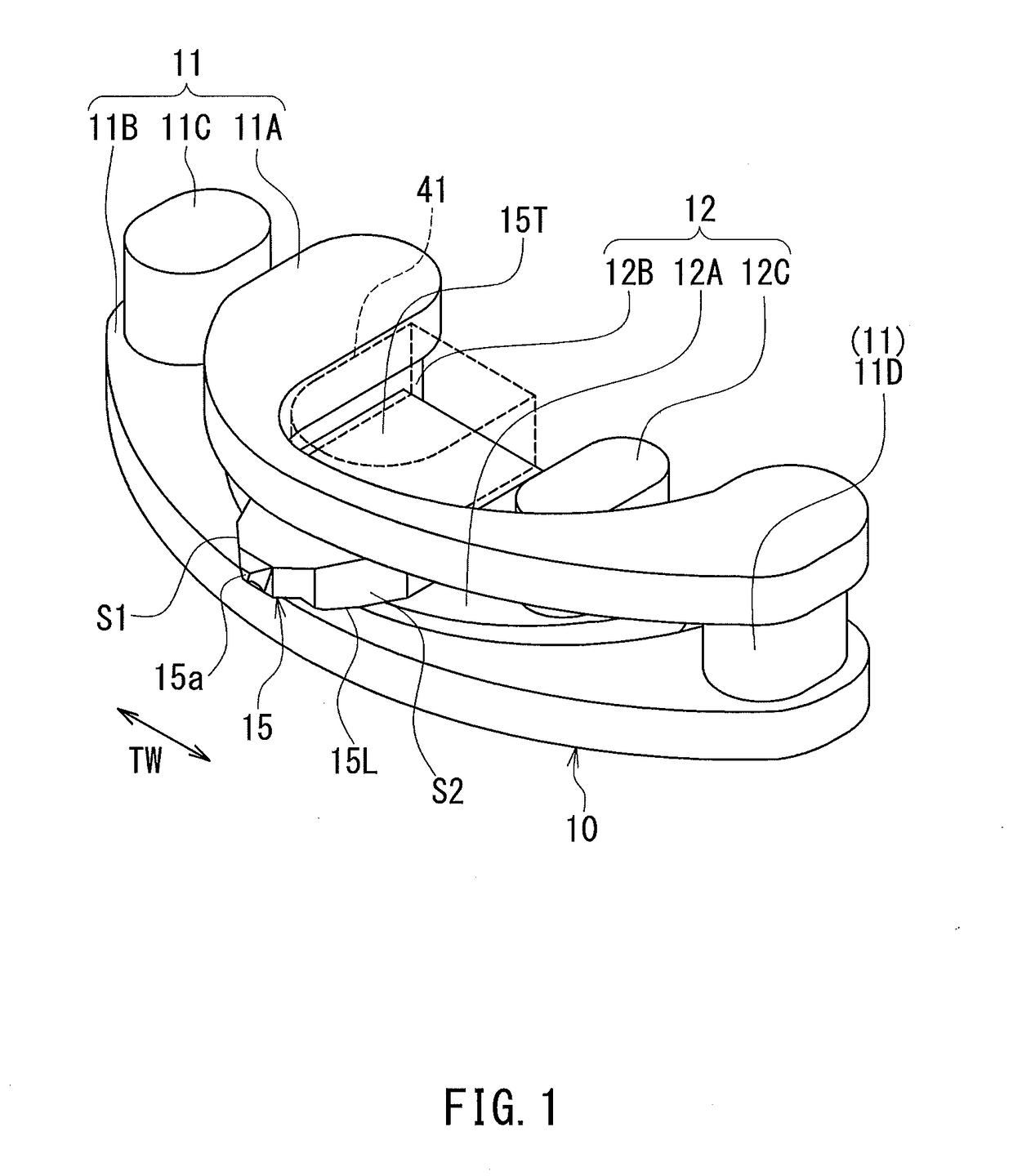

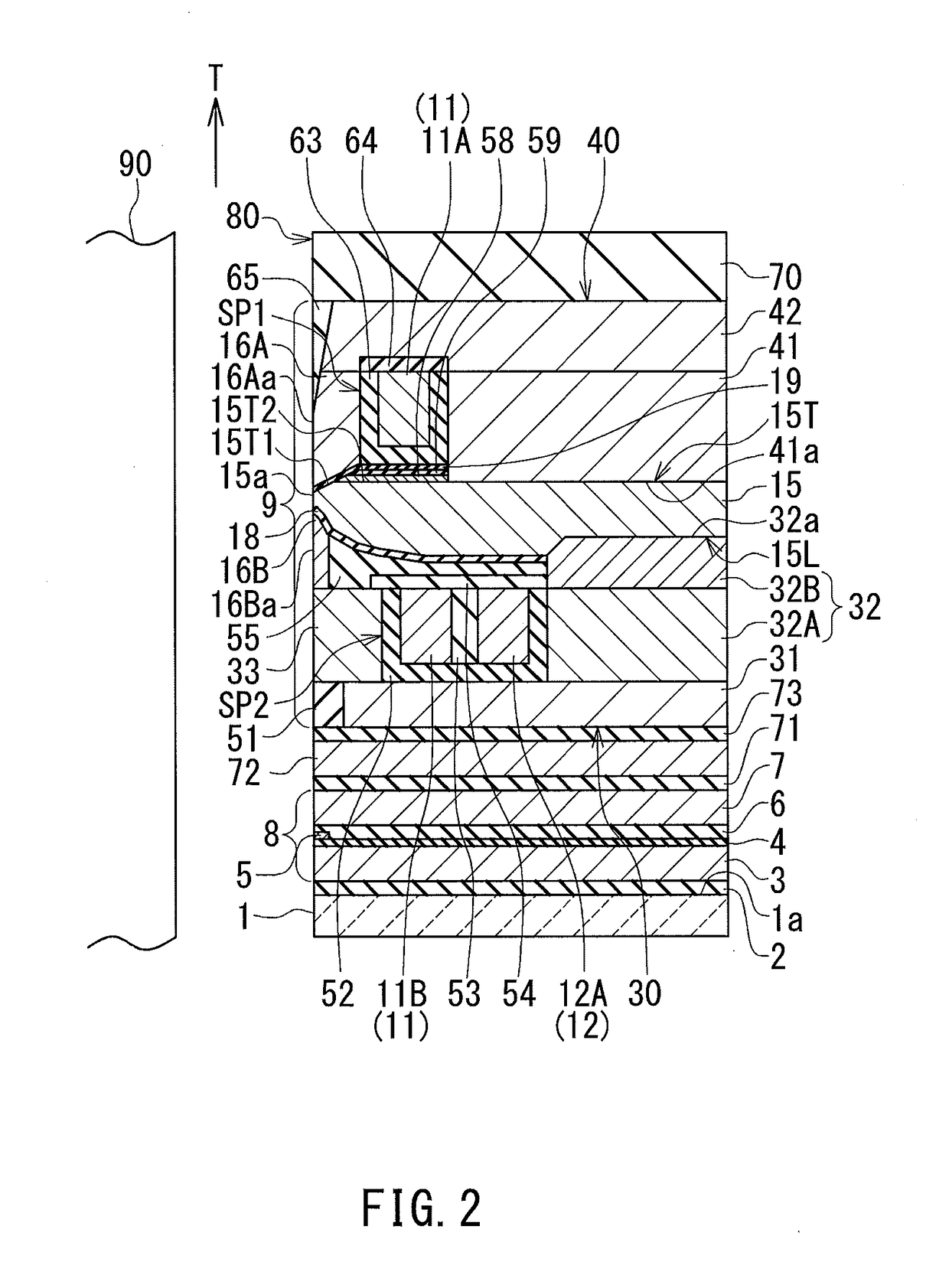

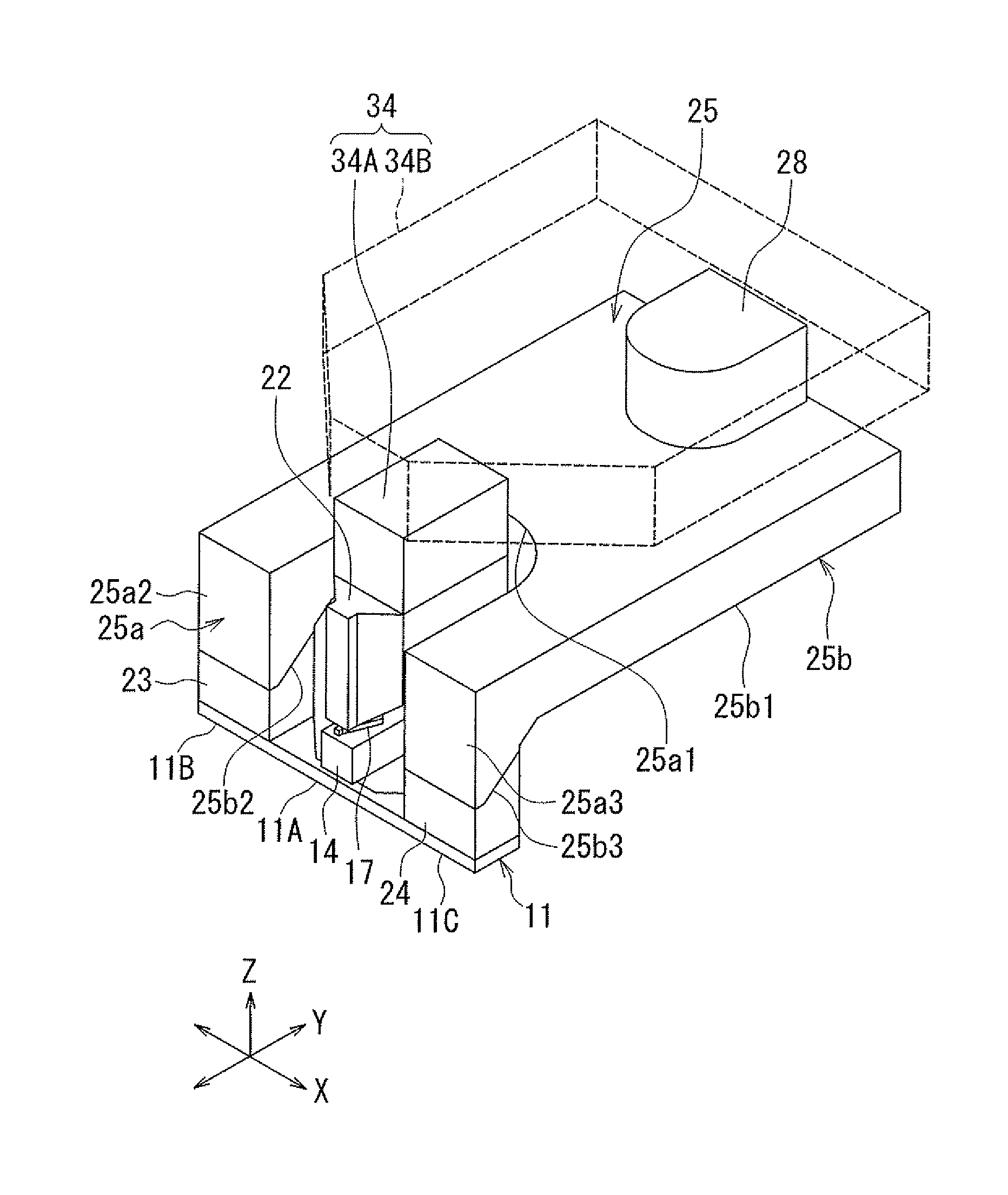

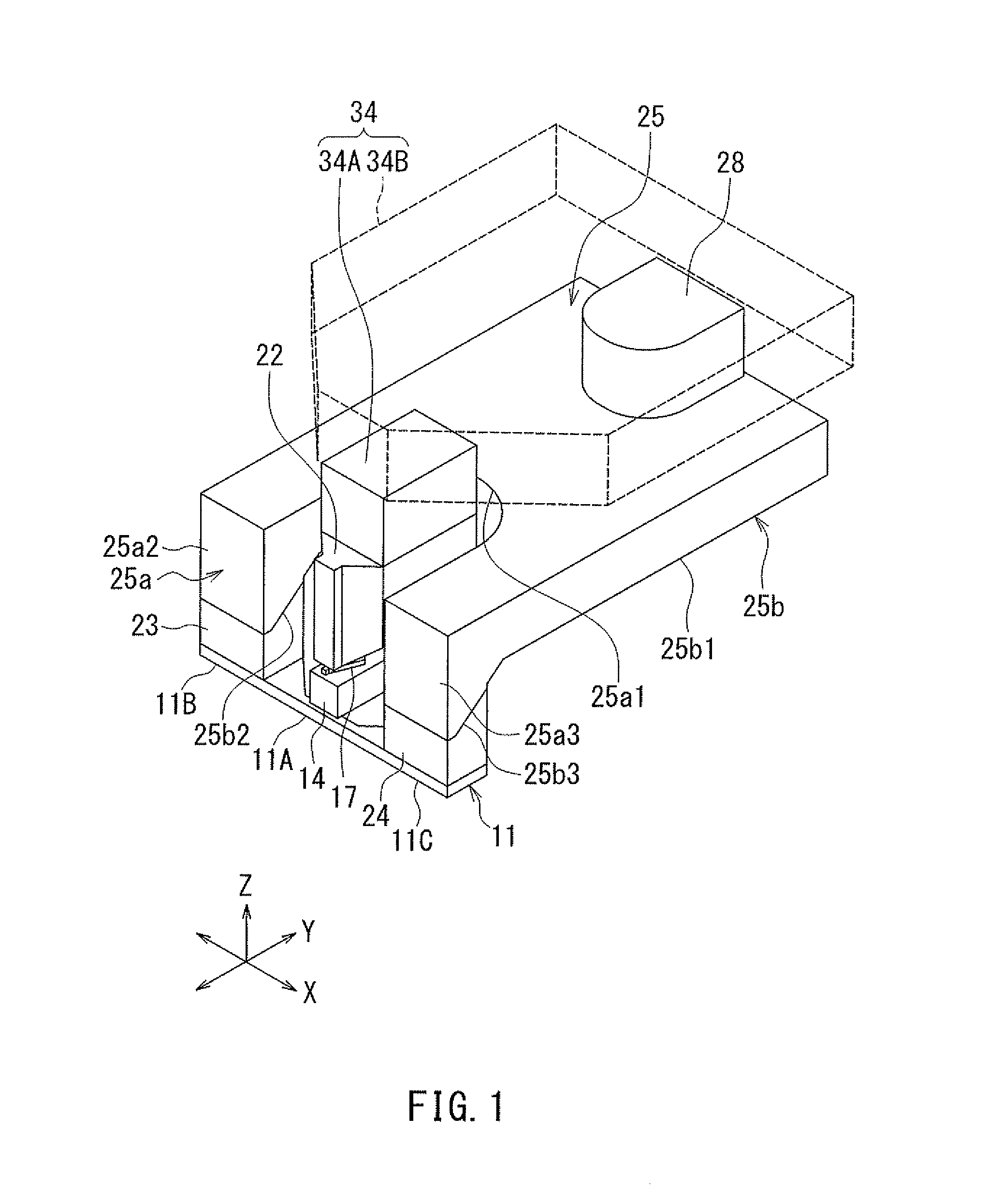

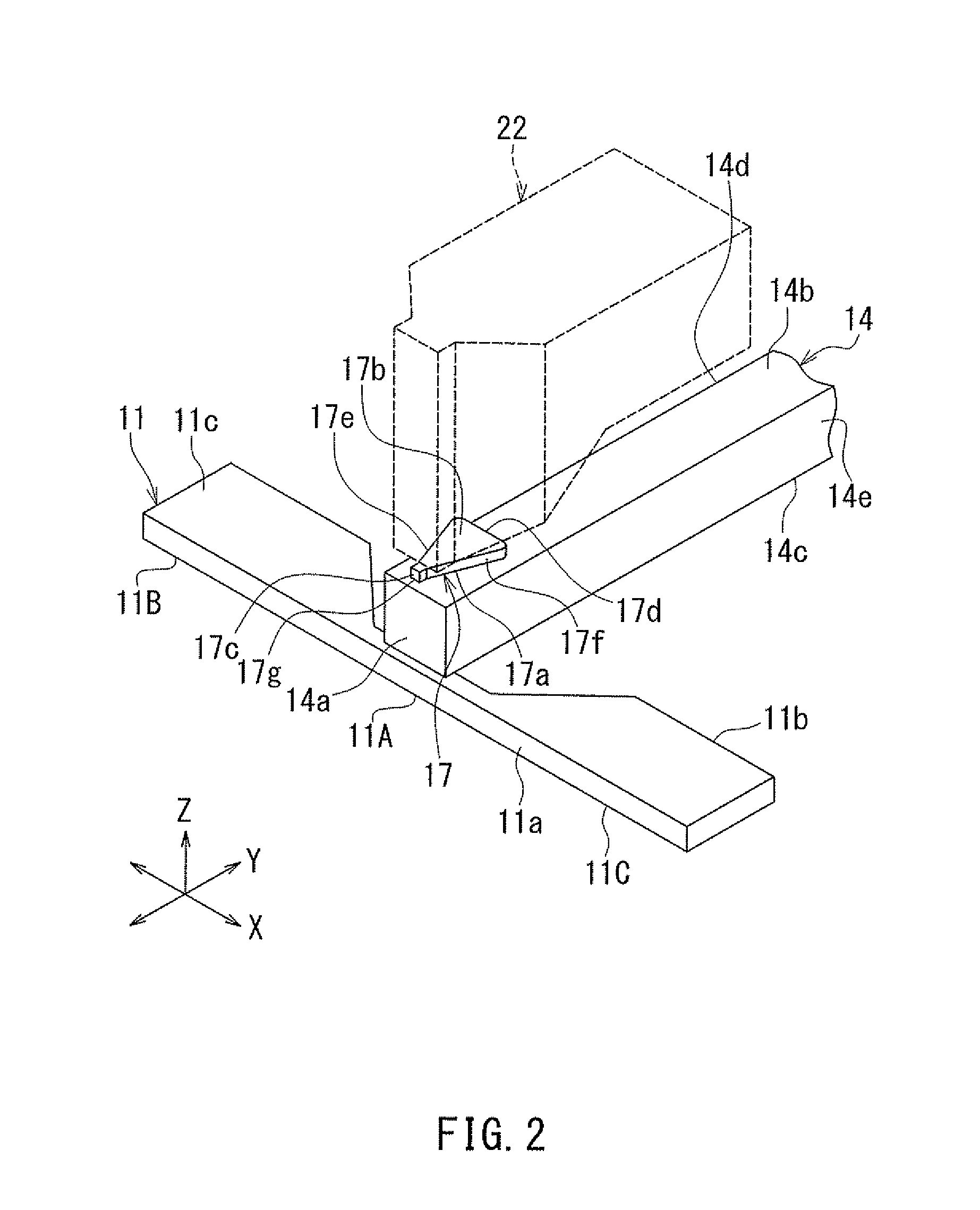

A thin-film magnetic head comprises a medium facing surface, a bottom pole layer, a top pole layer, a recording gap layer, and a thin-film coil. The bottom pole layer and the top pole layer are coupled to each other via a coupling portion located away from the medium facing surface. The coupling portion has an end face facing toward the medium facing surface. The end face includes a curved surface convex toward the medium facing surface. The thin-film coil has a conductive layer of three turns disposed around the coupling portion. The first turn of the conductive layer from an inner side thereof includes a portion disposed between the end face of the coupling portion and the medium facing surface. This portion has a minimum width of the conductive layer at a position on a virtual line connecting the end face of the coupling portion and the medium facing surface in the shortest distance, and increases in width with distance from the virtual line.

Owner:HEADWAY TECH INC +1

Magnetic head for perpendicular magnetic recording having a main pole and two shields

ActiveUS8218264B1Shorten the length of the magnetic circuitShorten the lengthRecord information storageHeads for perpendicular magnetisationsMagnetic polesRecording media

Owner:HEADWAY TECH INC +1

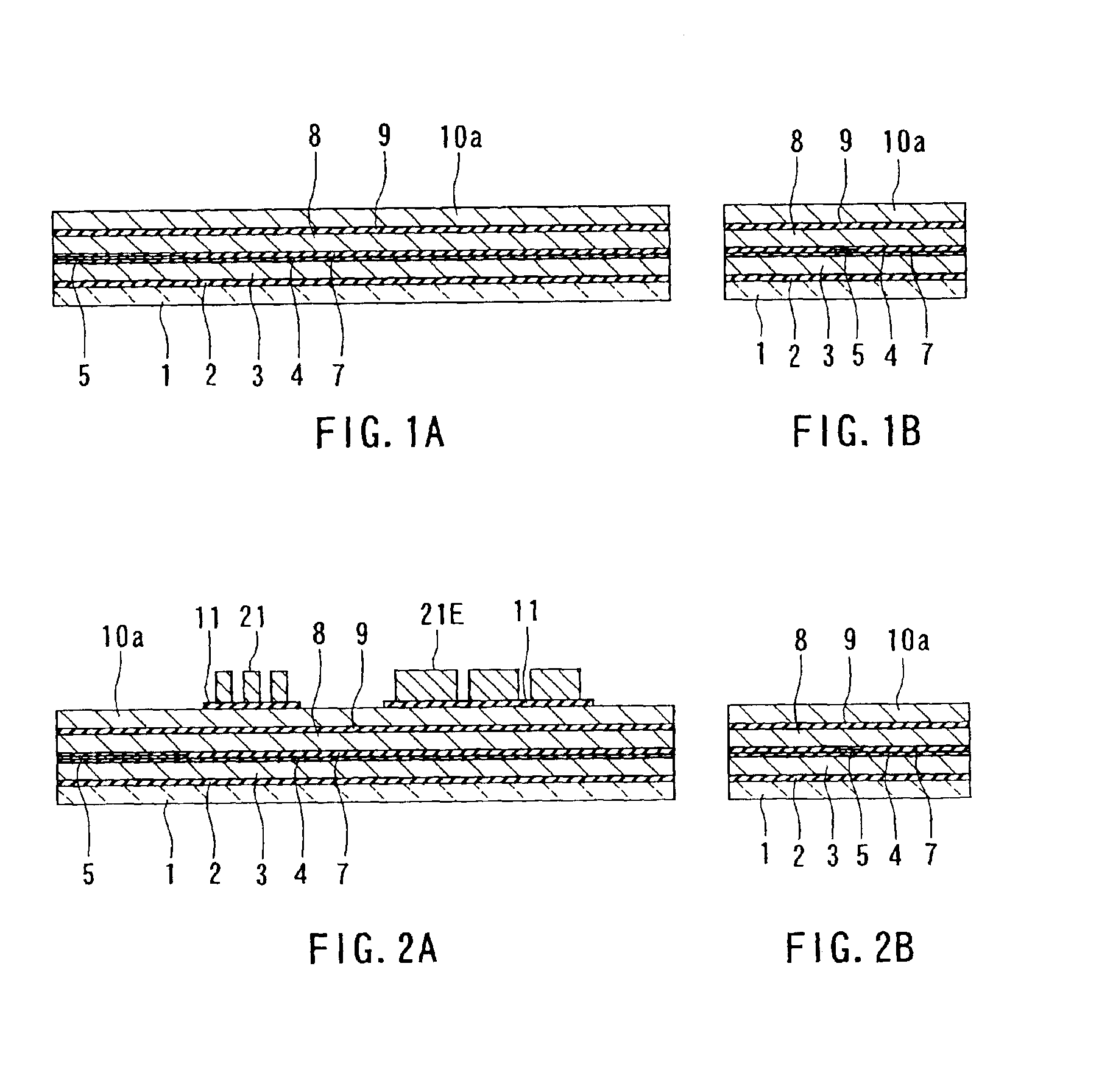

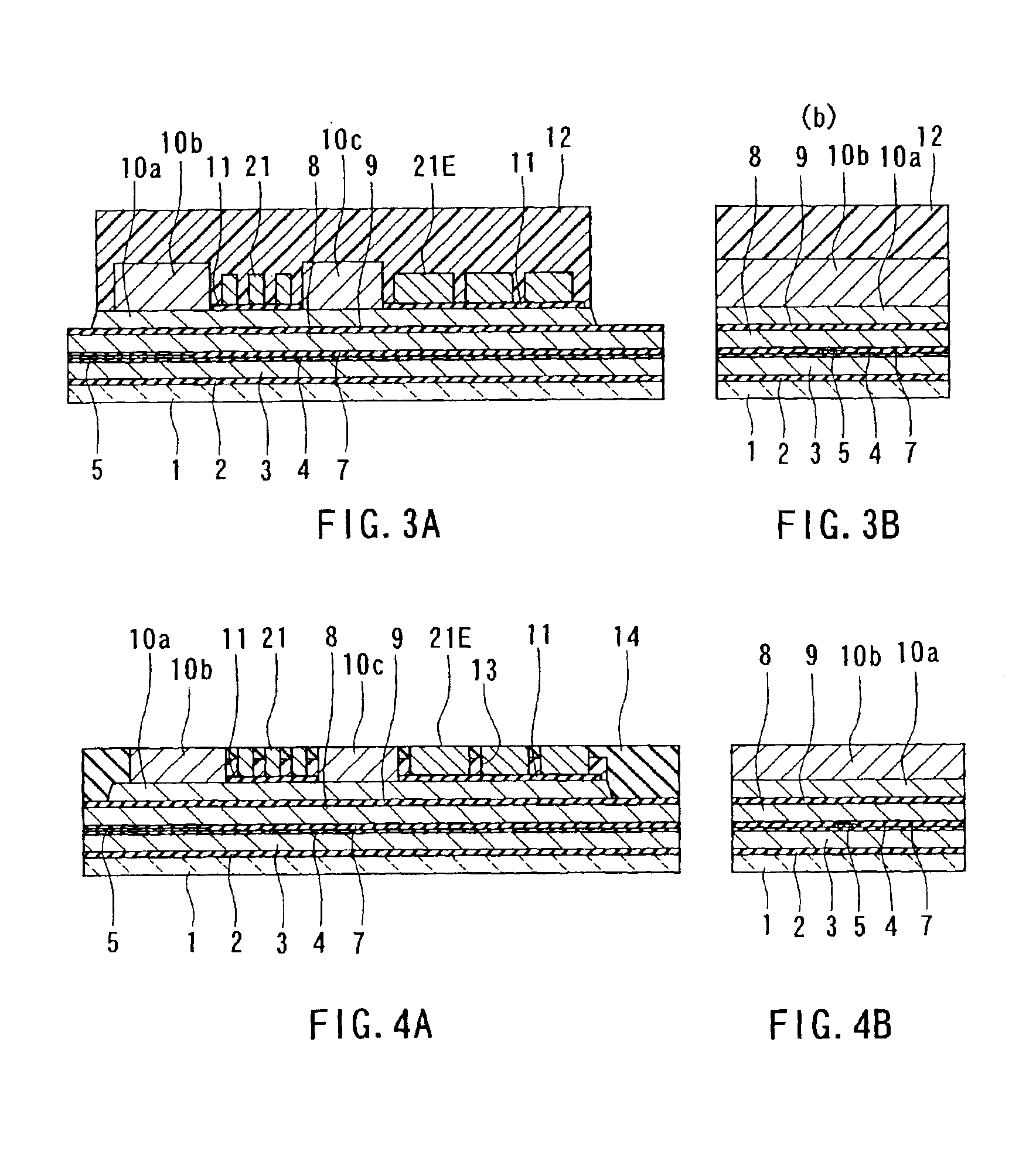

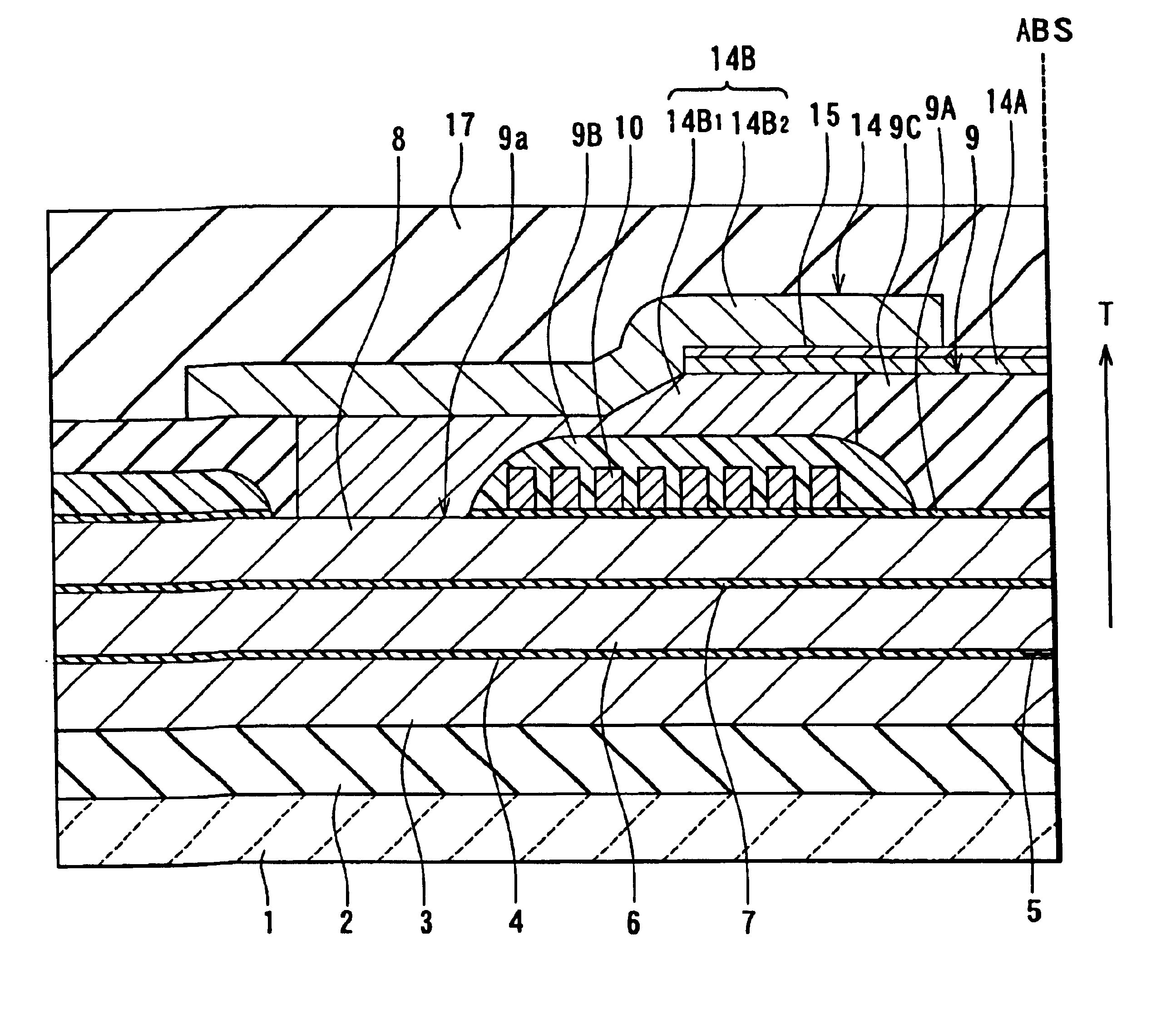

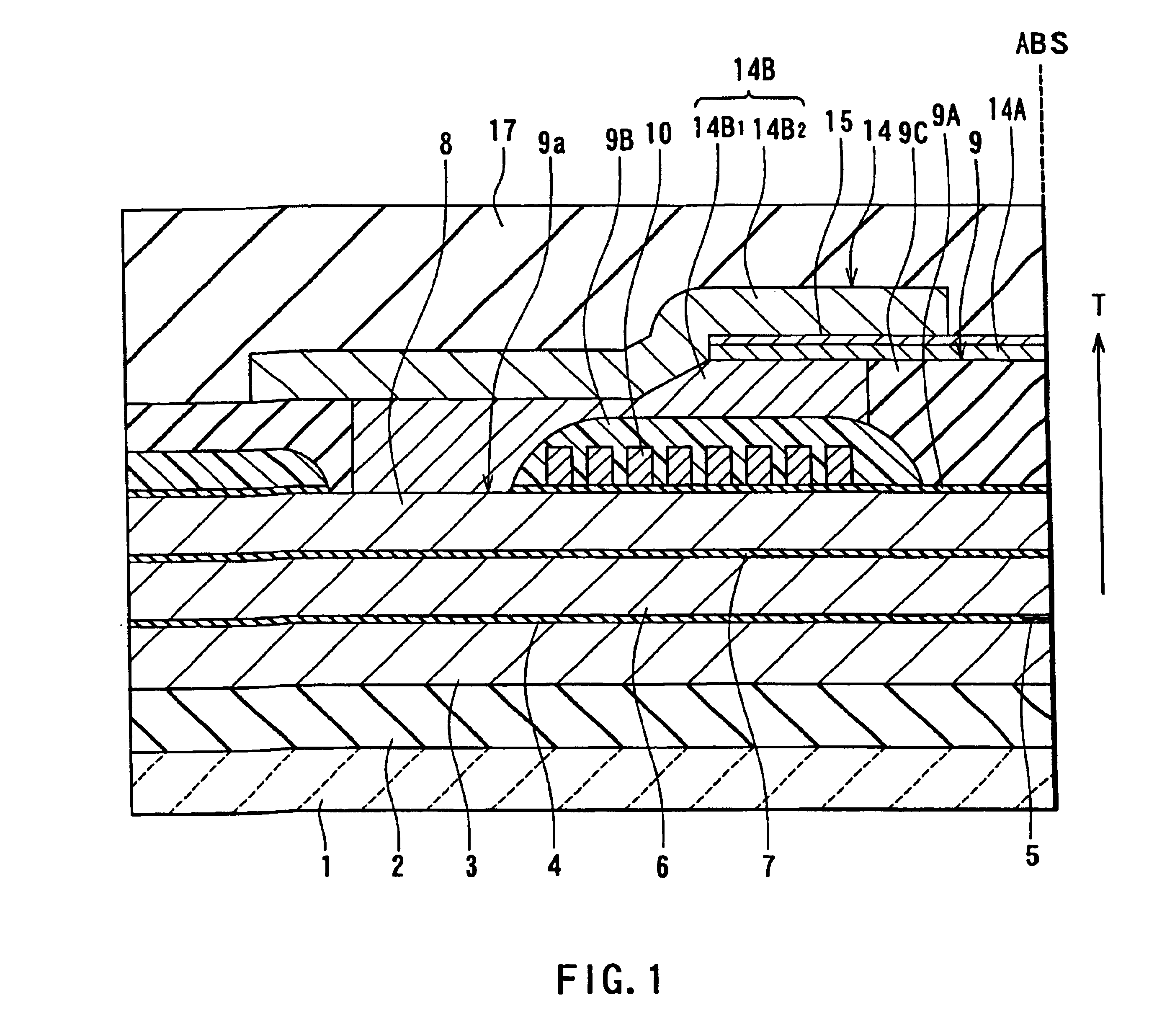

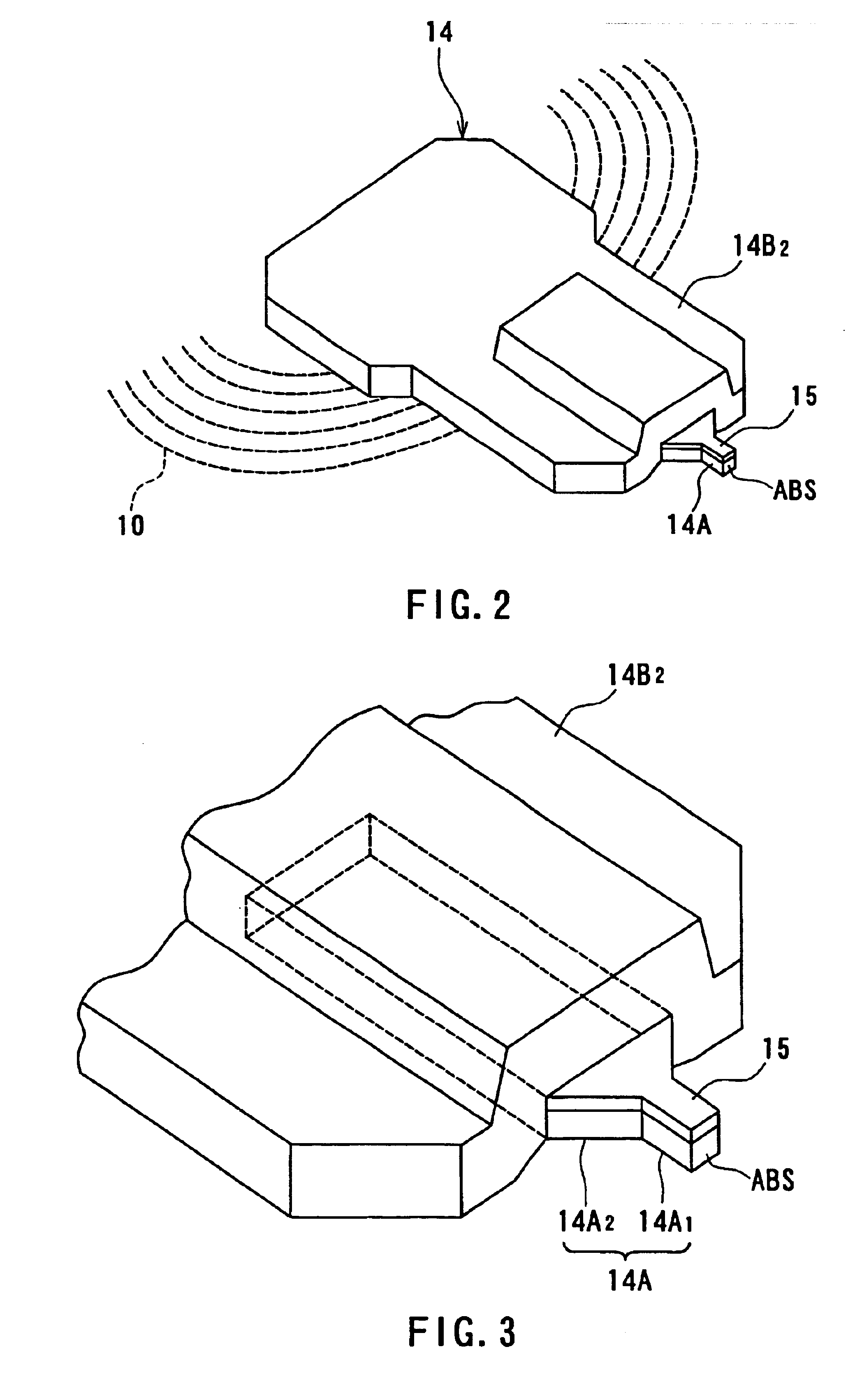

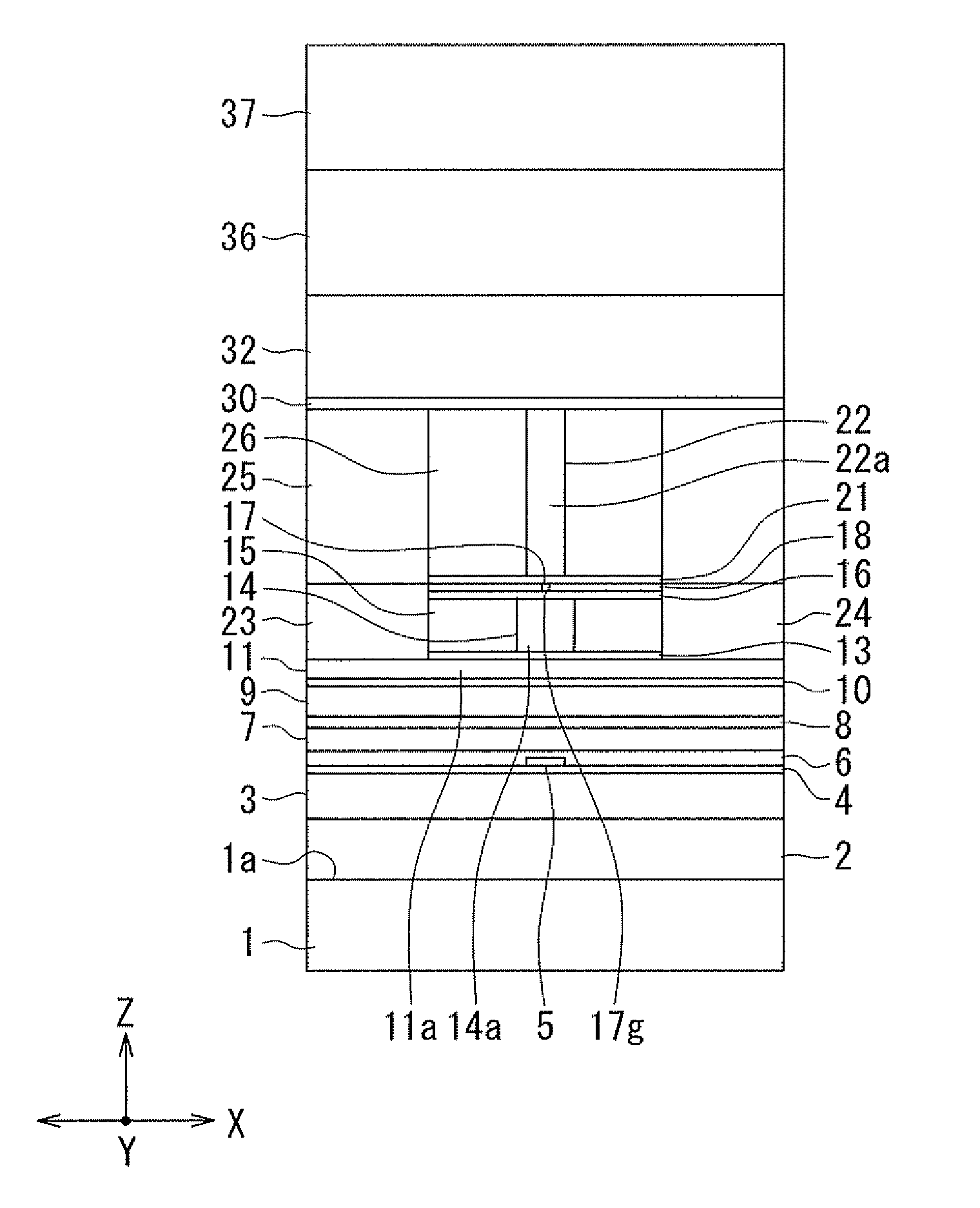

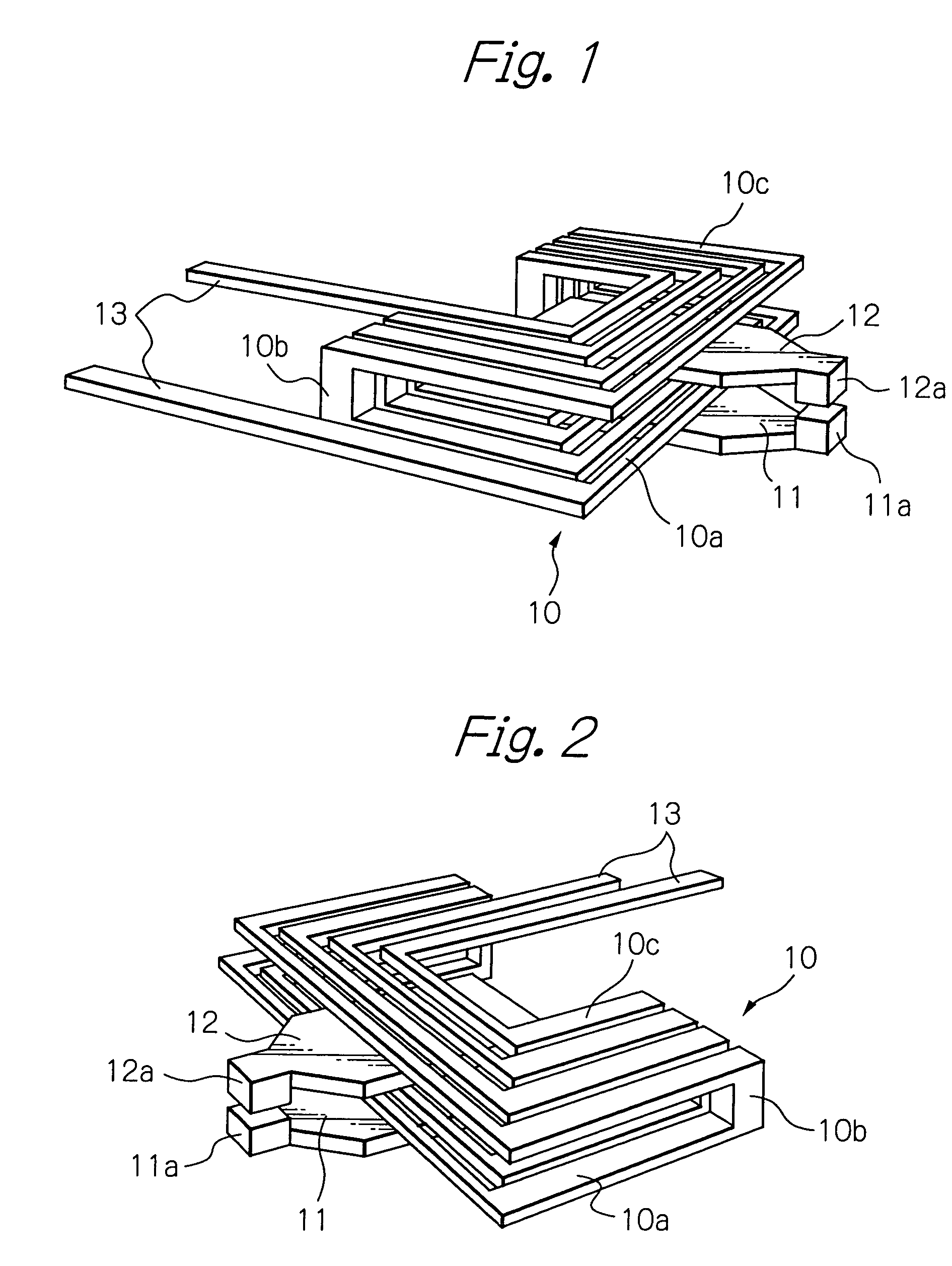

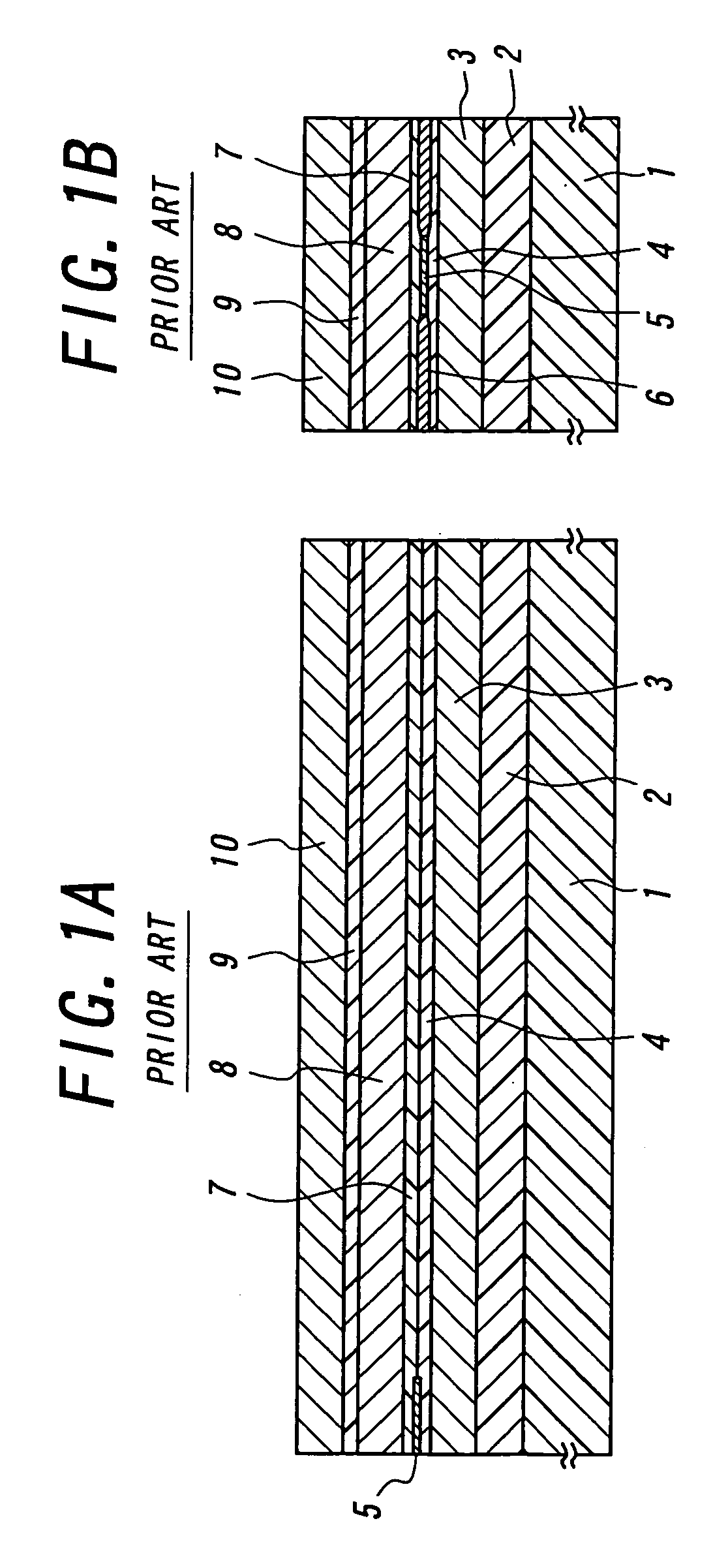

Thin-film magnetic head and method of manufacturing same

InactiveUS6922316B2High strengthShorten the length of the magnetic circuitNanomagnetismElectrical transducersMagnetic polesMagnetic flux

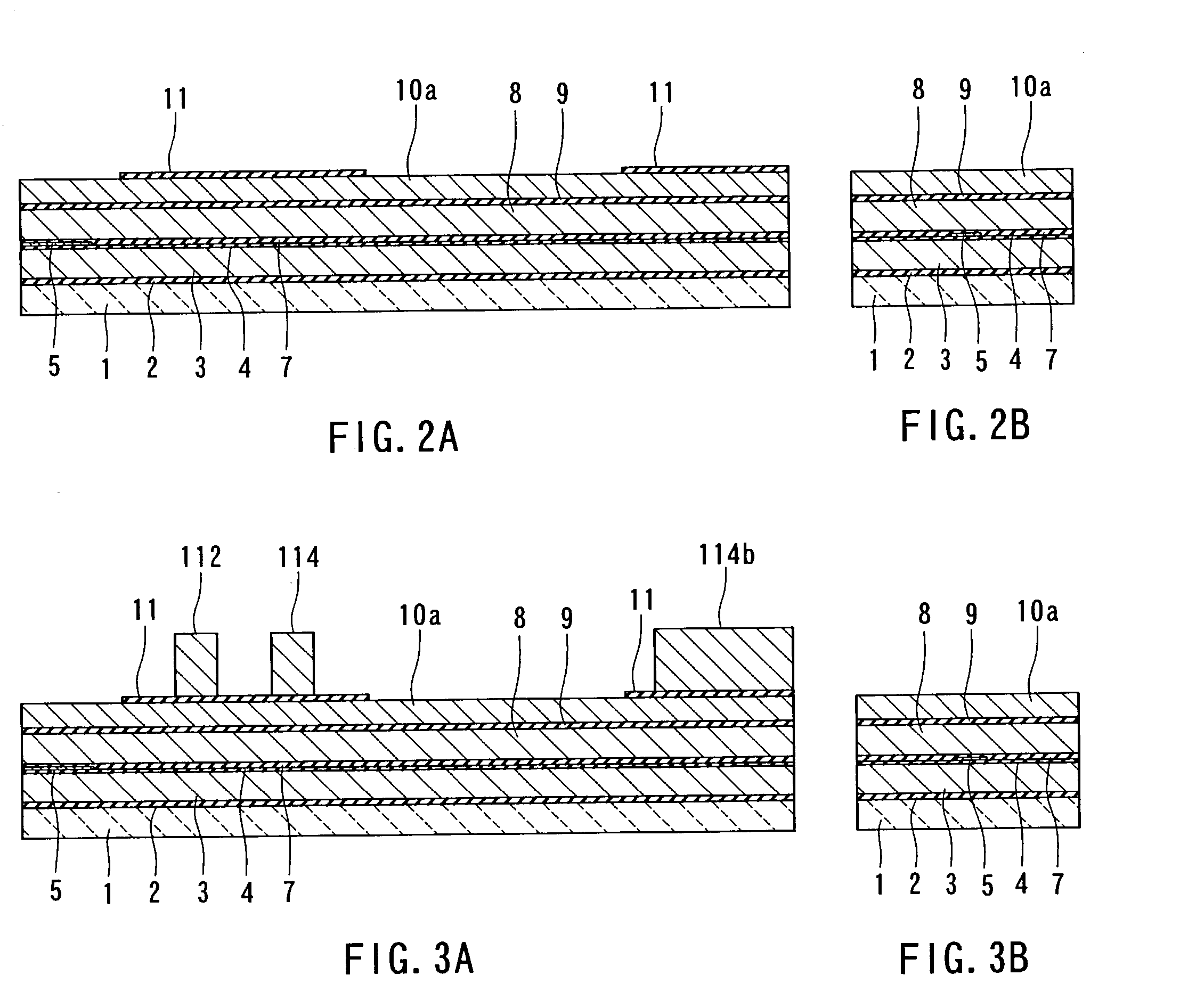

A thin-film magnetic head comprises: a first magnetic layer and a second magnetic layer each of which includes a magnetic pole portion, the first and second magnetic layers being magnetically coupled to each other at a distance from the medium facing surface ABS; a gap layer provided between the first and second magnetic layers; and a thin-film coil at least a part of which is disposed between the first and second magnetic layers. The second magnetic layer has a pole portion layer and a yoke portion layer. The pole portion layer has a saturated magnetic flux density equal to or greater than that of the yoke portion layer. The yoke portion layer includes: a first layer and a second layer, of which the first layer is in contact with the first magnetic layer and a surface of the pole portion layer that is closer to the gap layer; and the second layer is in contact with the first layer, the rear end surface of the pole portion layer and both side surfaces of the pole portion layer in the width direction.

Owner:TDK CORPARATION

Magnetic head for perpendicular magnetic recording having a main pole and a shield

ActiveUS8300357B1Shorten the length of the magnetic circuitSufficient magnitudeConstruction of head windingsRecord information storageRecording mediaElectrical and Electronics engineering

Owner:HEADWAY TECH INC +1

Magnetic head for perpendicular magnetic recording having a main pole and a shield and specifically structured and located coil elements and magnetic coupling layers

ActiveUS8345382B1Preventing undesirable protrusionShorten the length of the magnetic circuitConstruction of head windingsRecord information storageCouplingMagnetic poles

Owner:HEADWAY TECH INC +1

Thin-film magnetic head and method of manufacturing same

ActiveUS20050073773A1Small in magnetic path lengthExcellent characteristicConstruction of head windingsHeads using thin filmsEngineeringAir bearing surface

A thin-film magnetic head comprises a bottom pole layer, a top pole layer, a recording gap layer, and a thin-film coil. The thin-film magnetic head further comprises a coupling portion which is located away from an air bearing surface and establishes coupling between the bottom pole layer and the top pole layer. The coupling portion has an end face facing toward the air bearing surface. The end face includes a curved surface convex toward the medium facing surface. A part of the thin-film coil, which is disposed between the end face and the air bearing surface, has a minimum width of the thin-film coil in a position on a virtual line connecting the end face and the air bearing surface in the shortest distance, and increases in width with distance from the virtual line.

Owner:HEADWAY TECH INC

Magnetic head for perpendicular magnetic recording having a main pole, a shield and a coil core part setback away from the medium facing surface a specified distance

ActiveUS8441755B2Shorten the length of the magnetic circuitShorten the lengthConstruction of head windingsElectrical transducersEngineeringRecording media

Owner:HEADWAY TECH INC +1

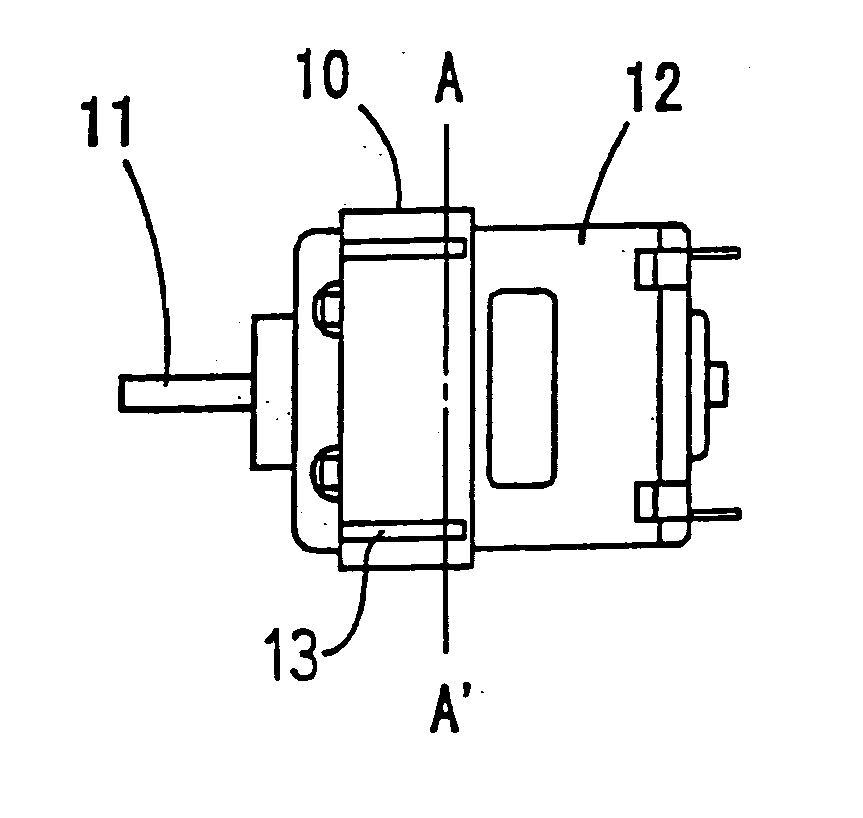

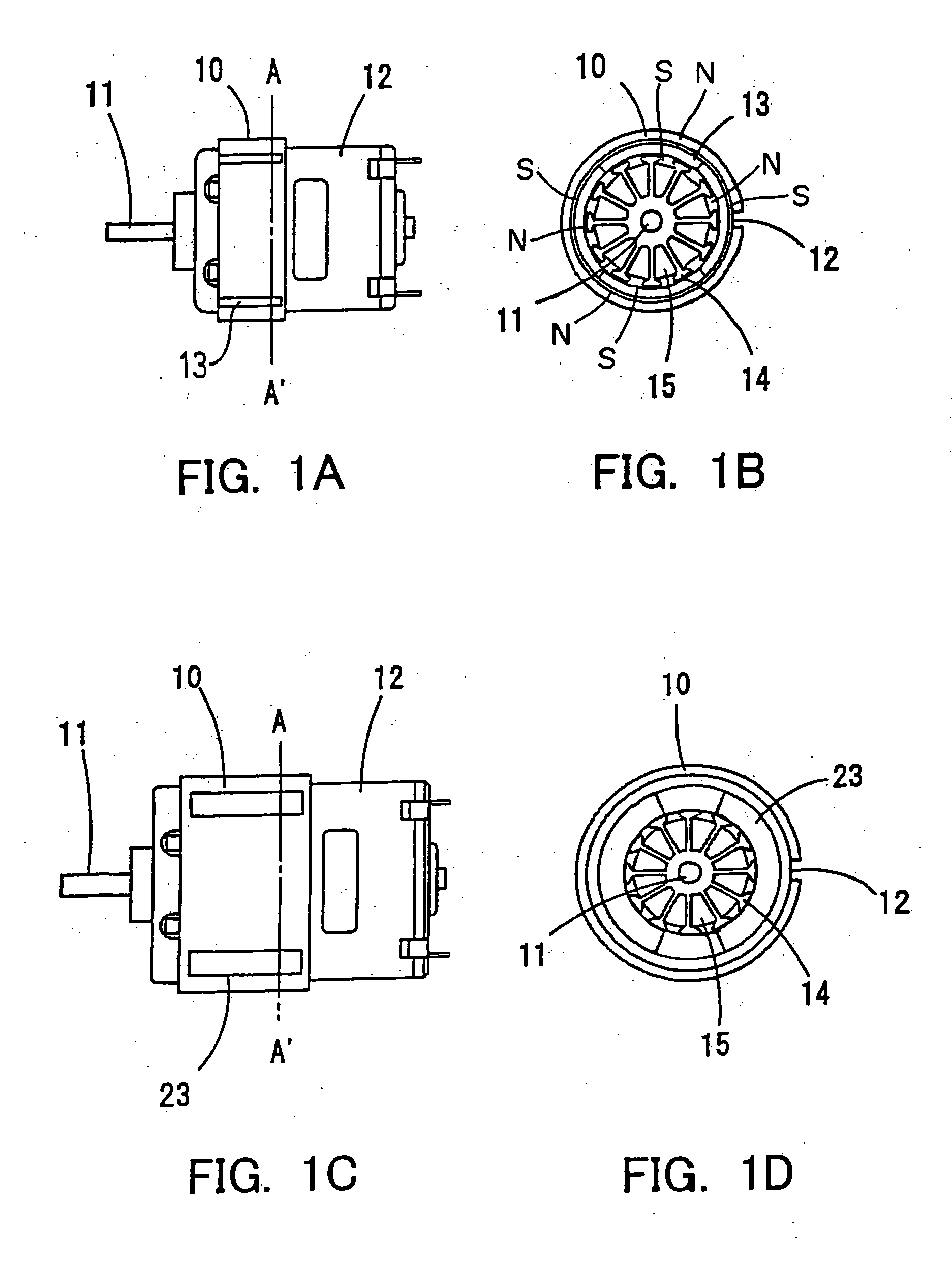

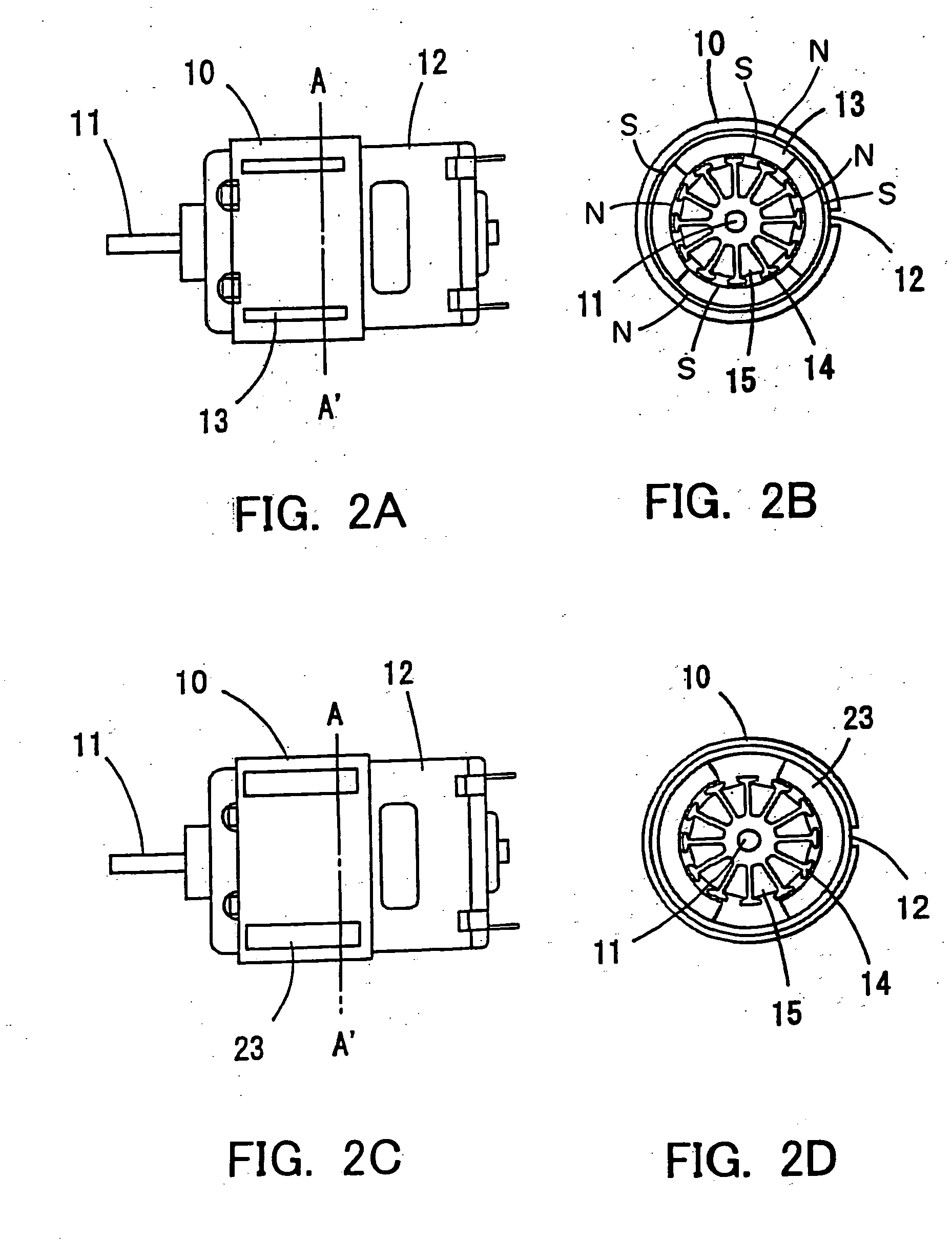

Motor and its permanent magnet

InactiveUS20040201300A1High propertyReduce thicknessPermanent magnetsMagnetic circuit stationary partsElectric machineMiniaturization

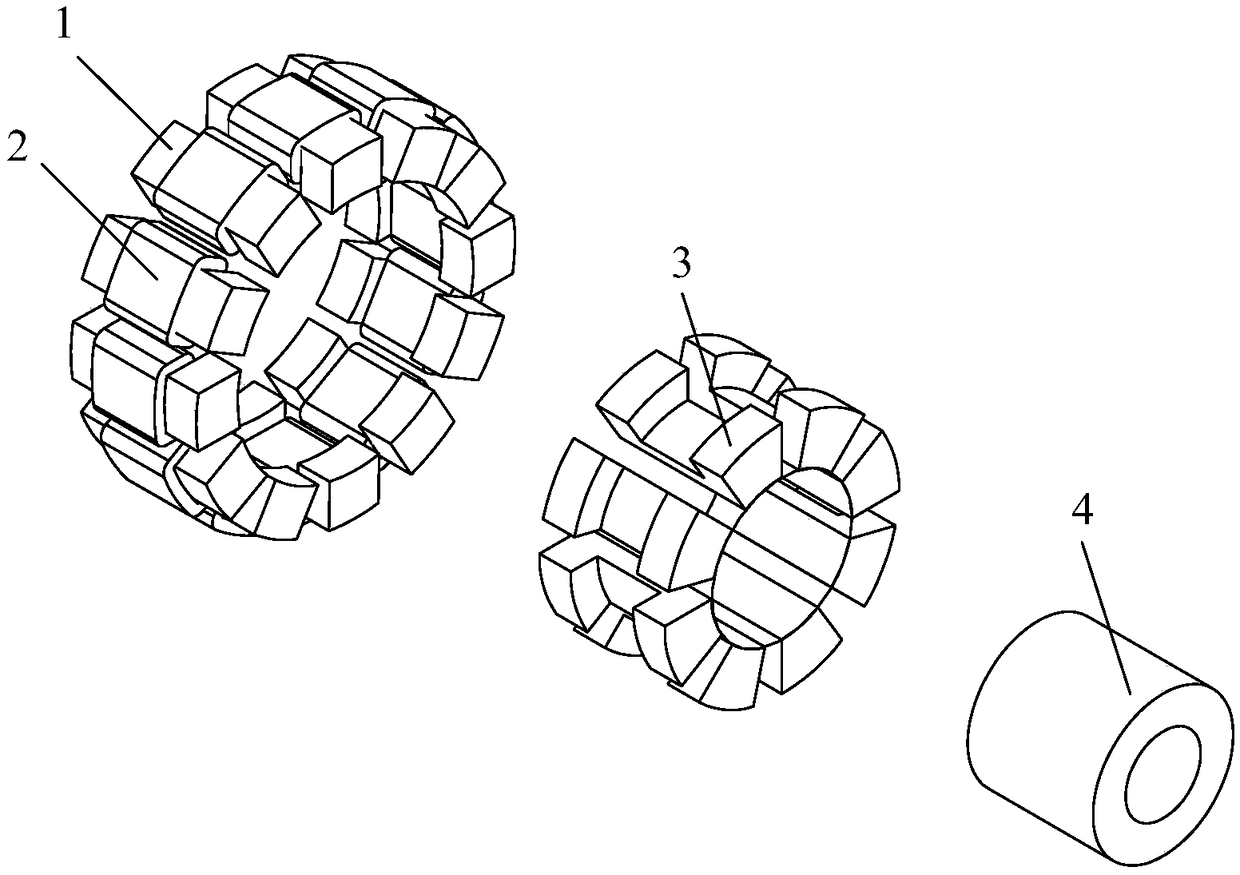

The challenge to be solved by the present invention is the miniaturization of a 1-300 W class of motor. This can be achieved by using a hollow-cylinder shaped anisotropic bonded magnet magnetized in a 4-pole configuration. The anisotropic bonded magnet has a maximum energy product approximately 4 times greater than the conventional sintered ferrite magnets. The use of a 4-pole configuration shortens the magnetic path length of the individual magnetic circuits and the magnetic force contributing to the torque is increased. When the torque is kept the same as in the conventional motor, the length of the electromagnetic rotor core and the axial magnet length can be reduced. In this fashion, 1-300 W class motors can be reduced in size.

Owner:AICHI STEEL

Thin-film magnetic head and method of manufacturing same

InactiveUS6927939B2Small in magnetic path lengthExcellent in recording characteristicConstruction of head windingsHeads using thin filmsShortest distanceCoupling

Owner:HEADWAY TECH INC

Magnetic head for perpendicular magnetic recording having a main pole and a shield

InactiveUS20120188666A1Shorten the length of the magnetic circuitIncrease rate of changeConstruction of head windingsRecord information storageEngineeringRecording media

Owner:HEADWAY TECH INC +1

Magnetic head for perpendicular magnetic recording having a main pole, a shield and a coil core part setback away from the medium facing surface a specified distance

ActiveUS20130038966A1Shorten the length of the magnetic circuitShorten the lengthConstruction of head windingsElectrical transducersRecording mediaElectrical and Electronics engineering

Owner:HEADWAY TECH INC +1

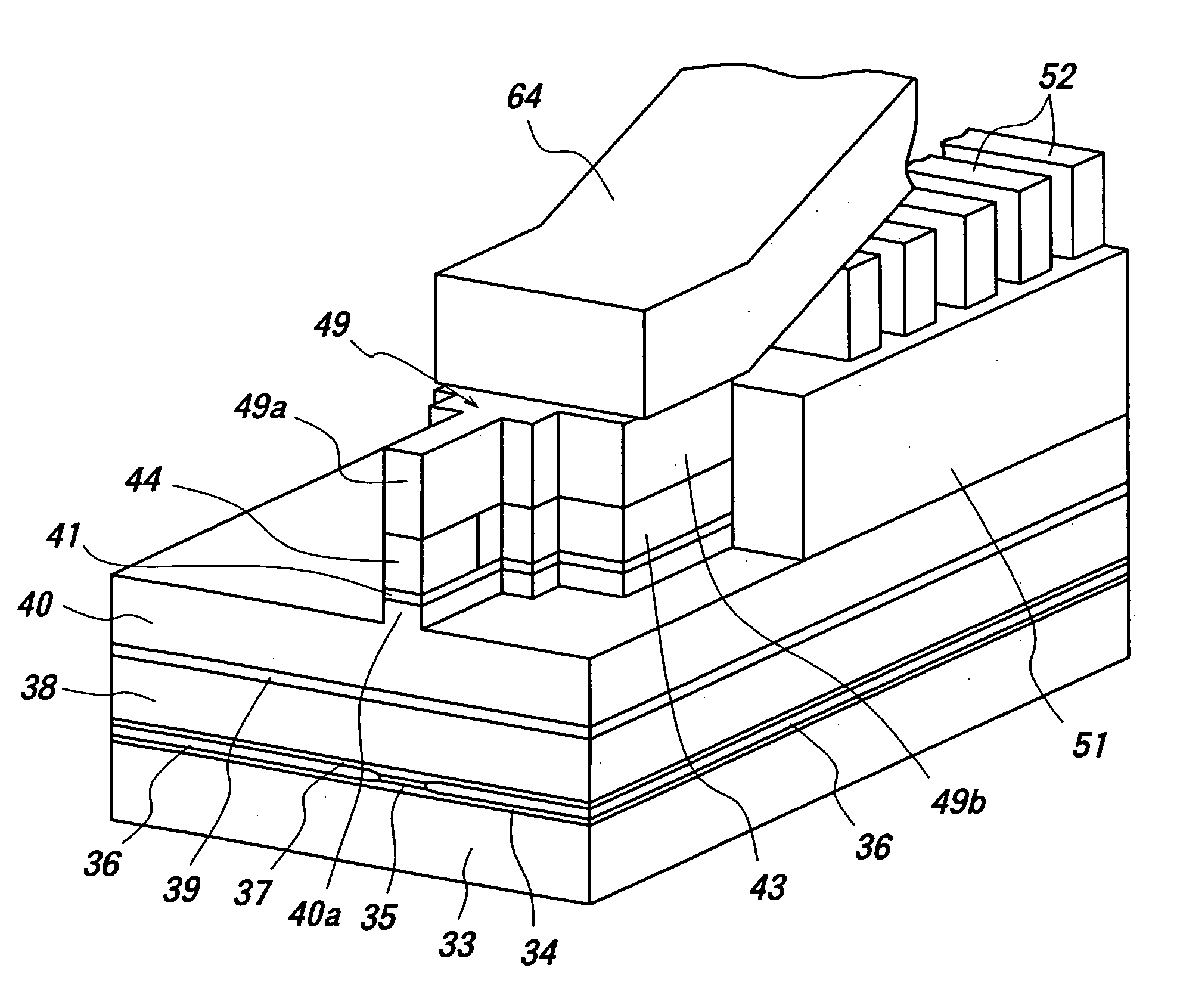

Thermally-assisted magnetic recording head having a plasmon generator

ActiveUS20150071044A1Excellent write characteristicLower resistanceCombination recordingRecord information storageHeat-assisted magnetic recordingRecording media

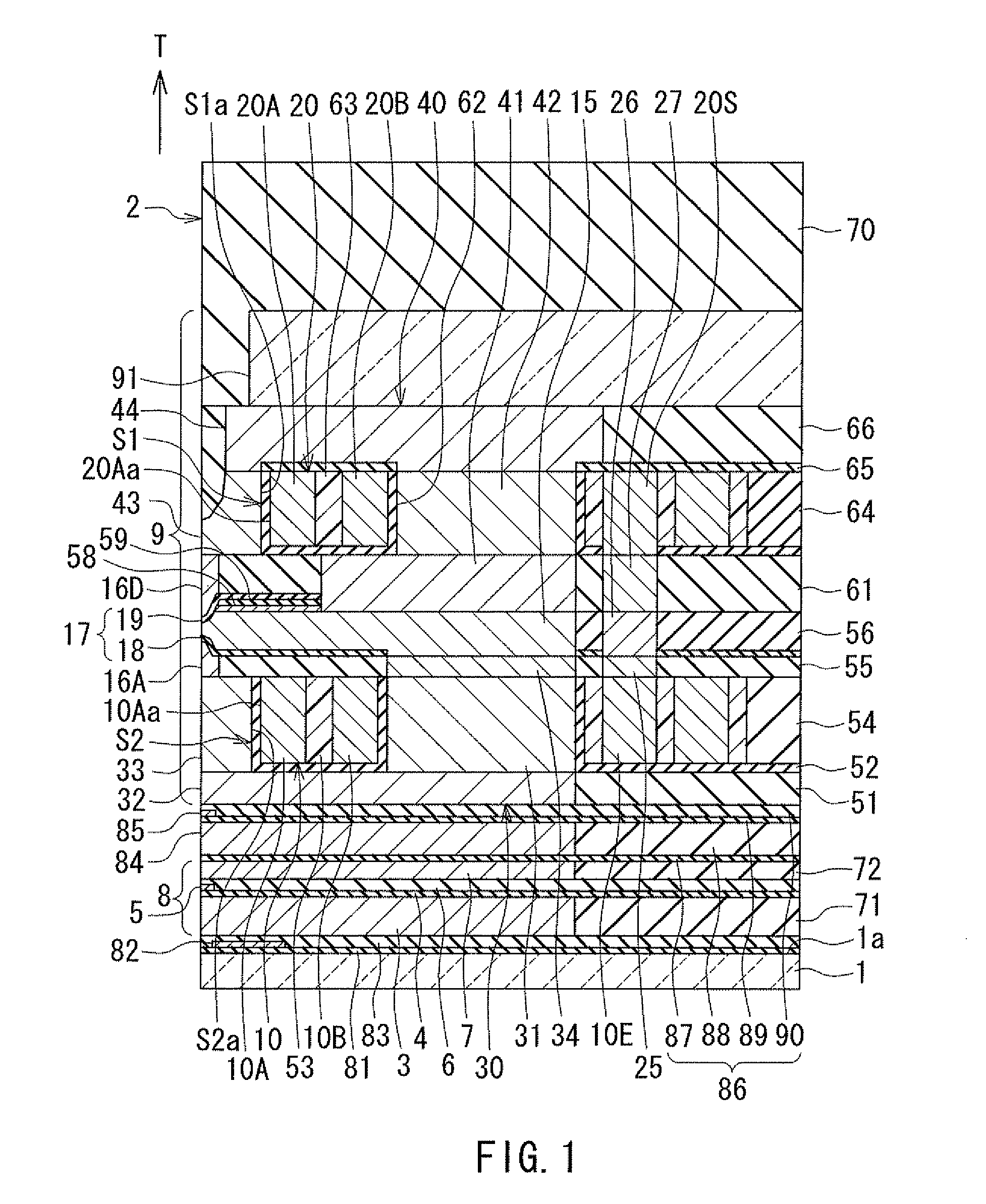

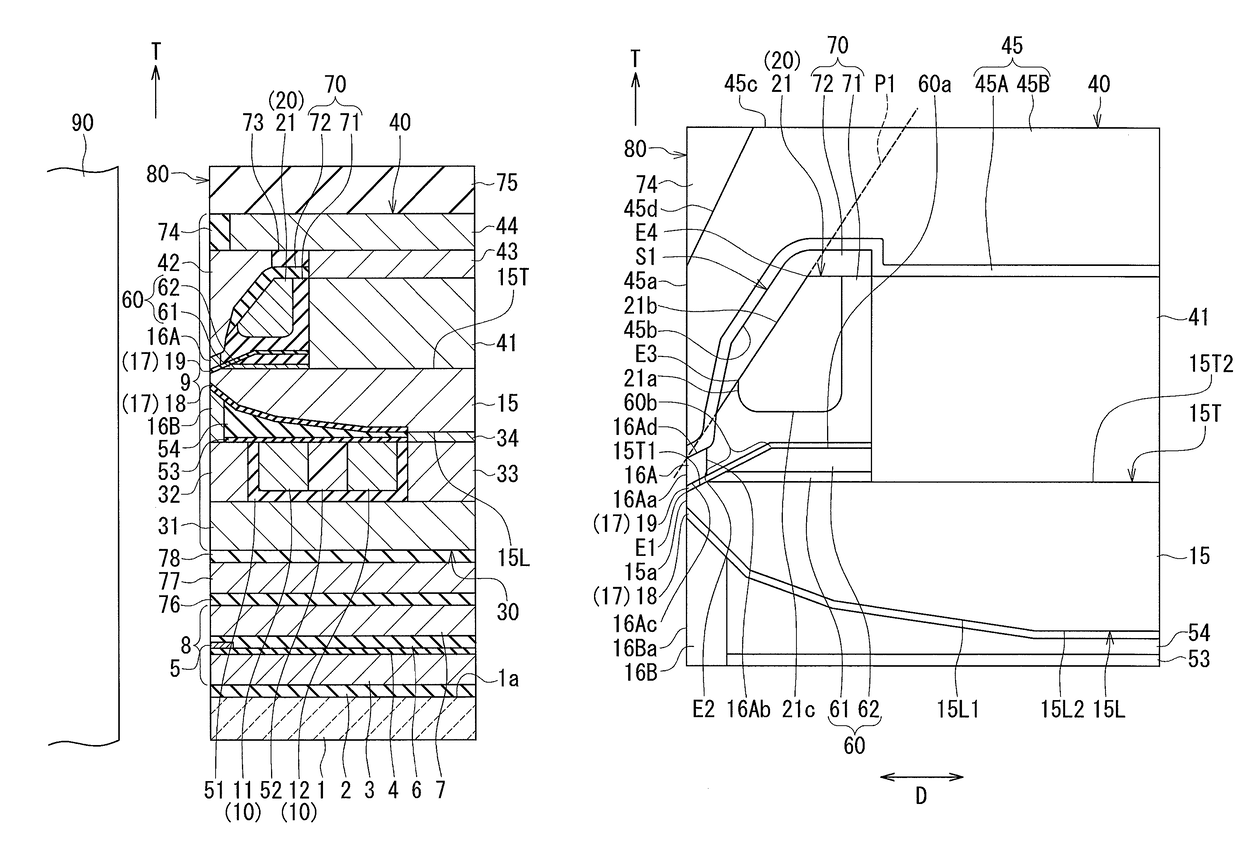

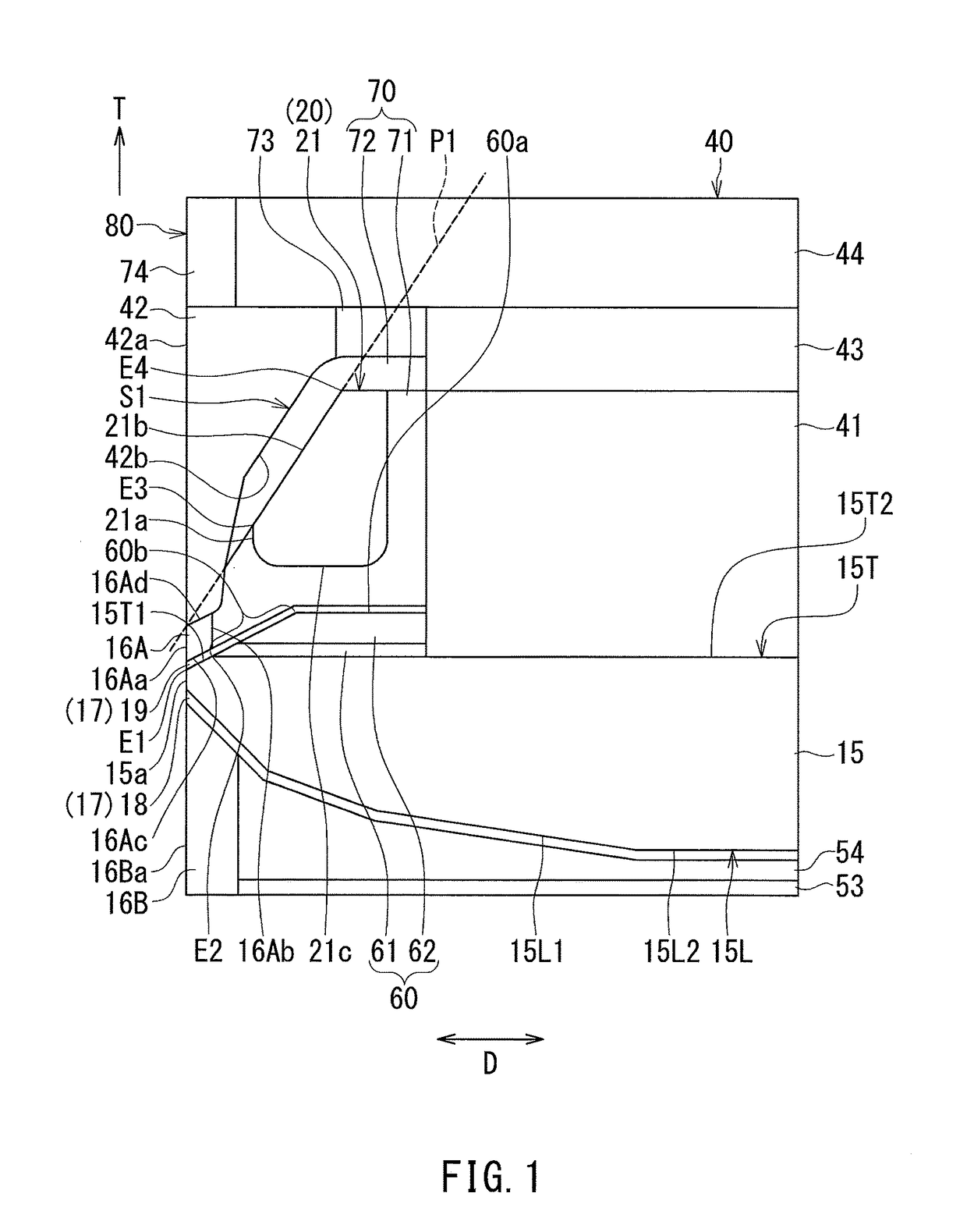

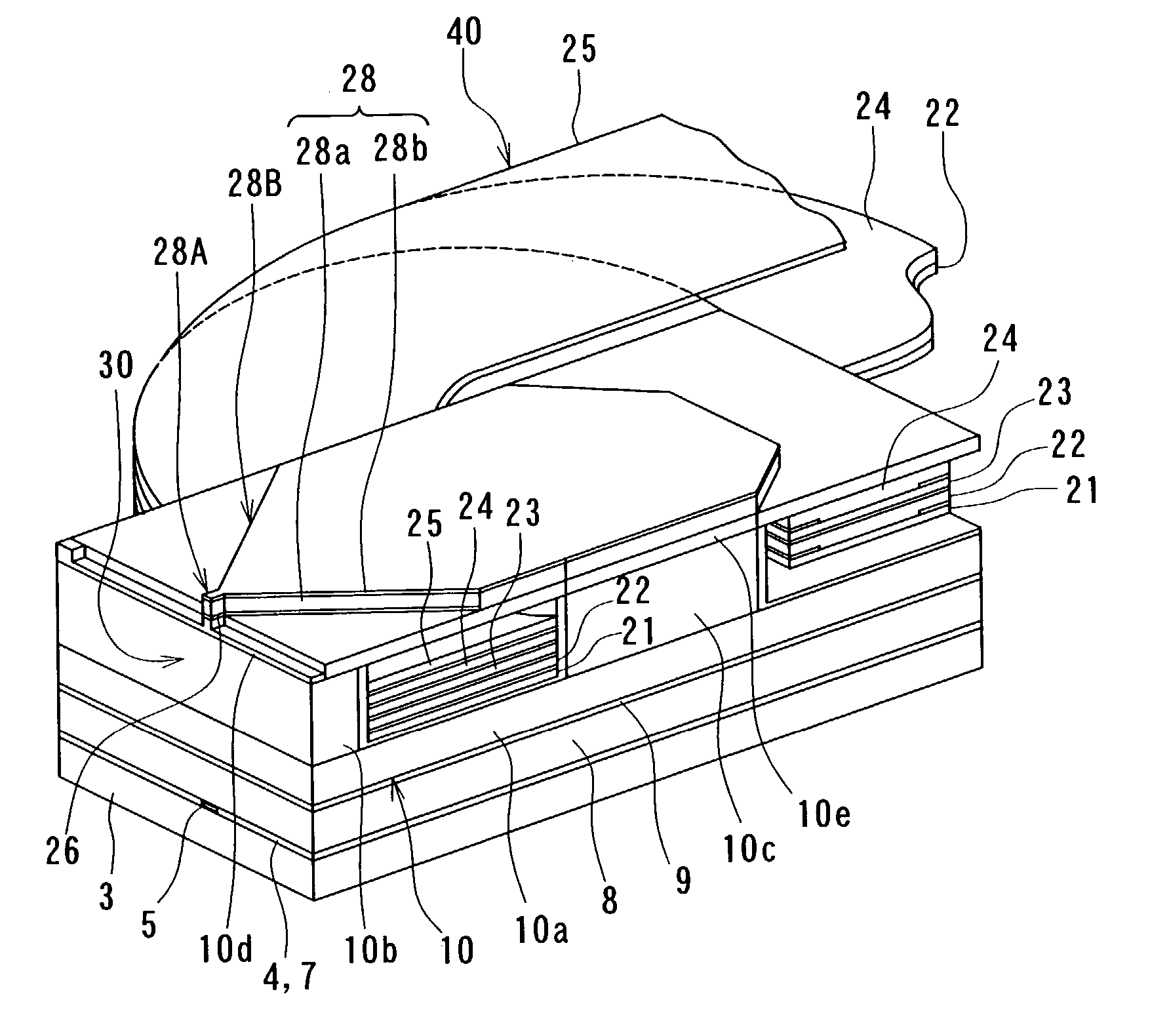

A return path section includes first and second yoke portions and first, second and third columnar portions. The first and second yoke portions and the first columnar portion are located on the same side in the direction of travel of the recording medium relative to a wave guide core. The second and third columnar portions are located on opposite sides of a plasmon generator and connected to a shield. The first yoke portion connects a main pole to the first columnar portion. The second yoke portion connects the first columnar portion to the second and third columnar portions. A coil is wound around the first columnar portion.

Owner:HEADWAY TECH INC +1

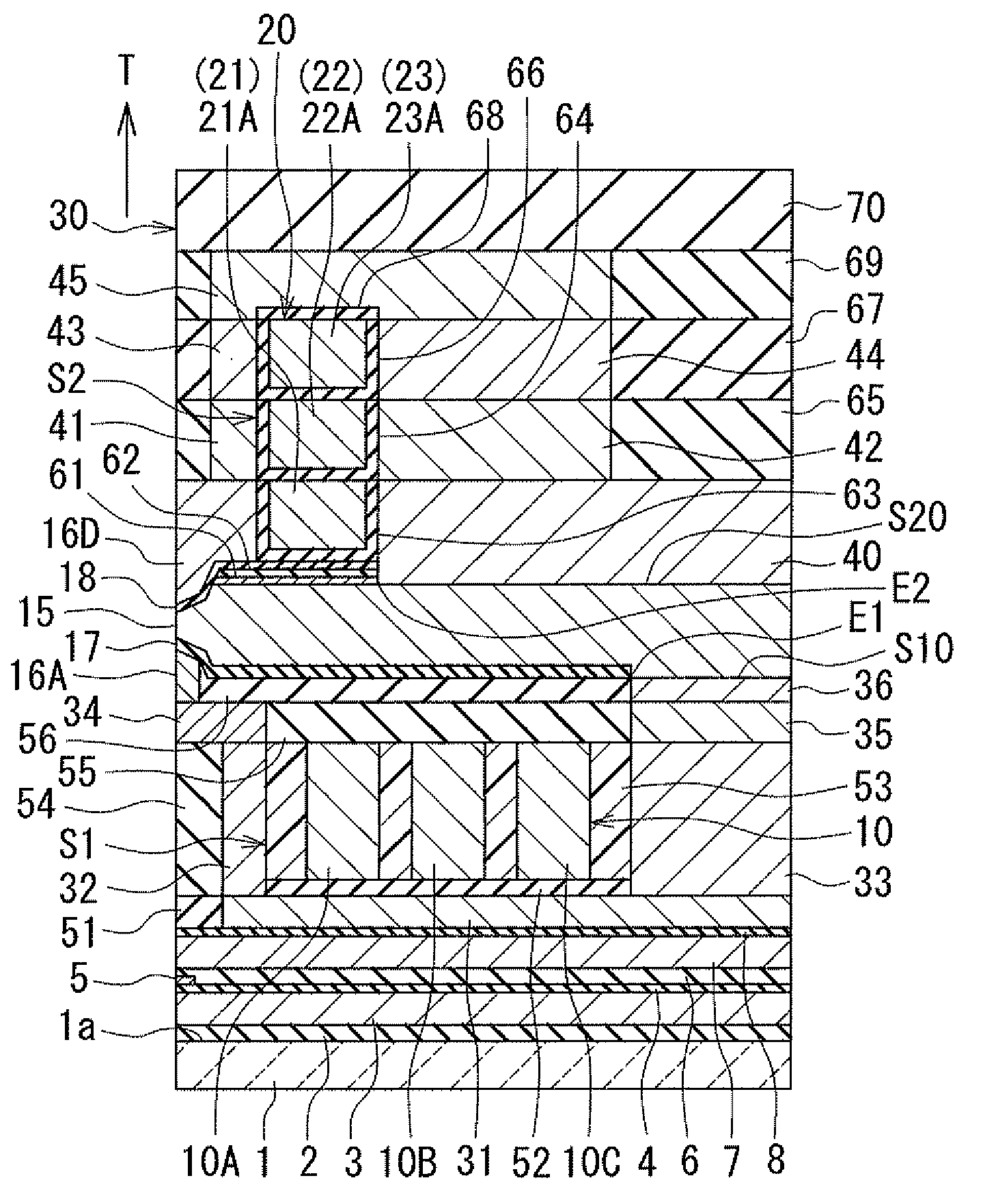

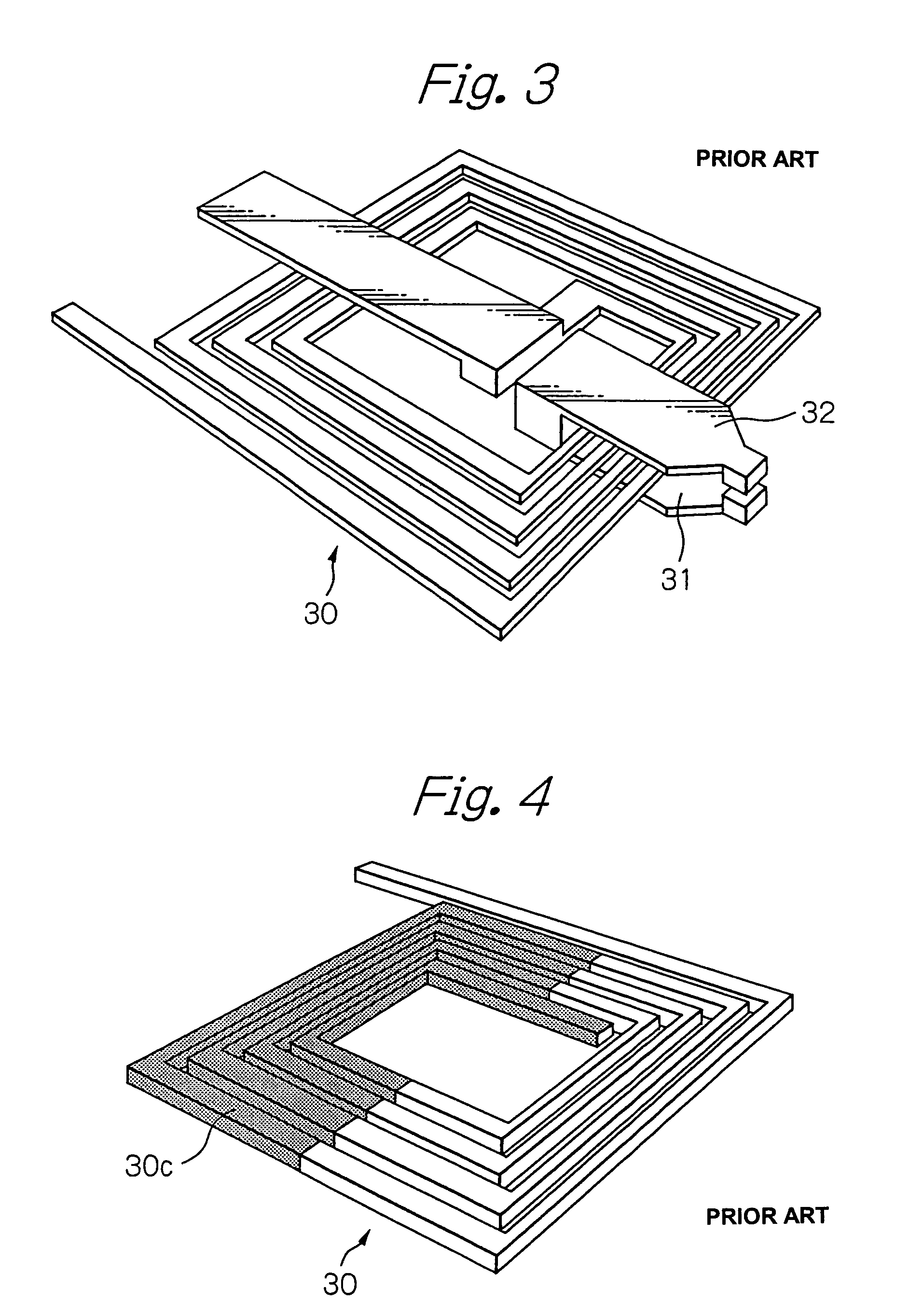

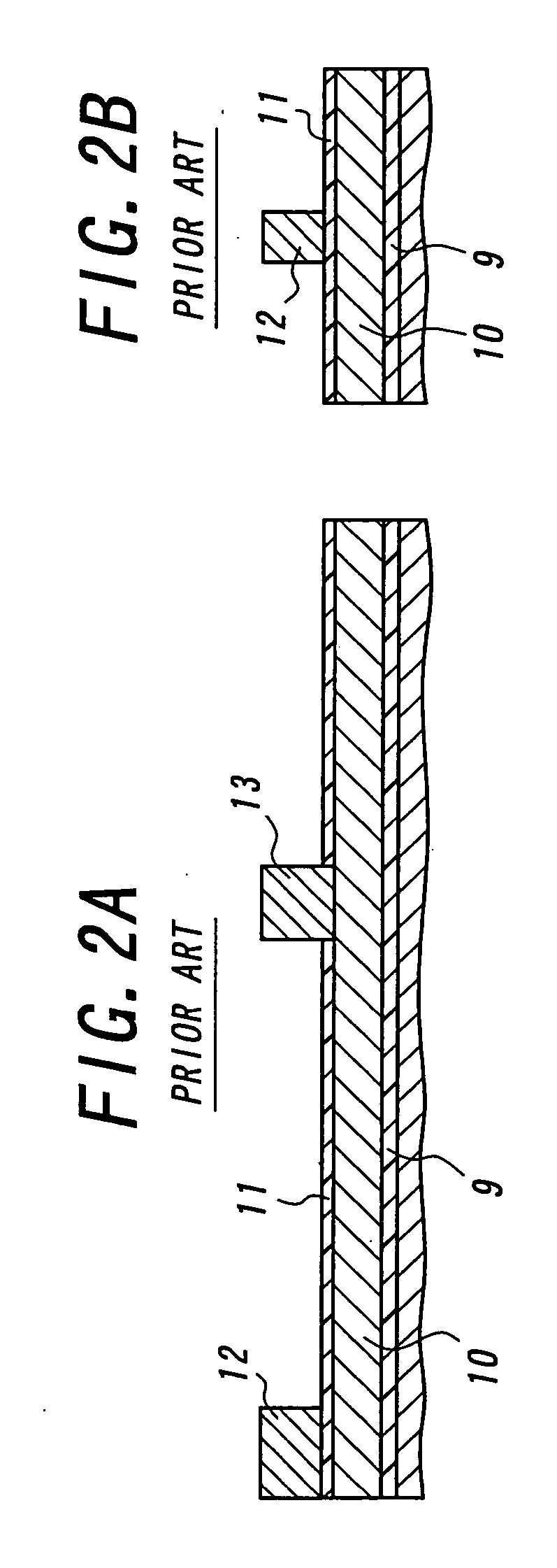

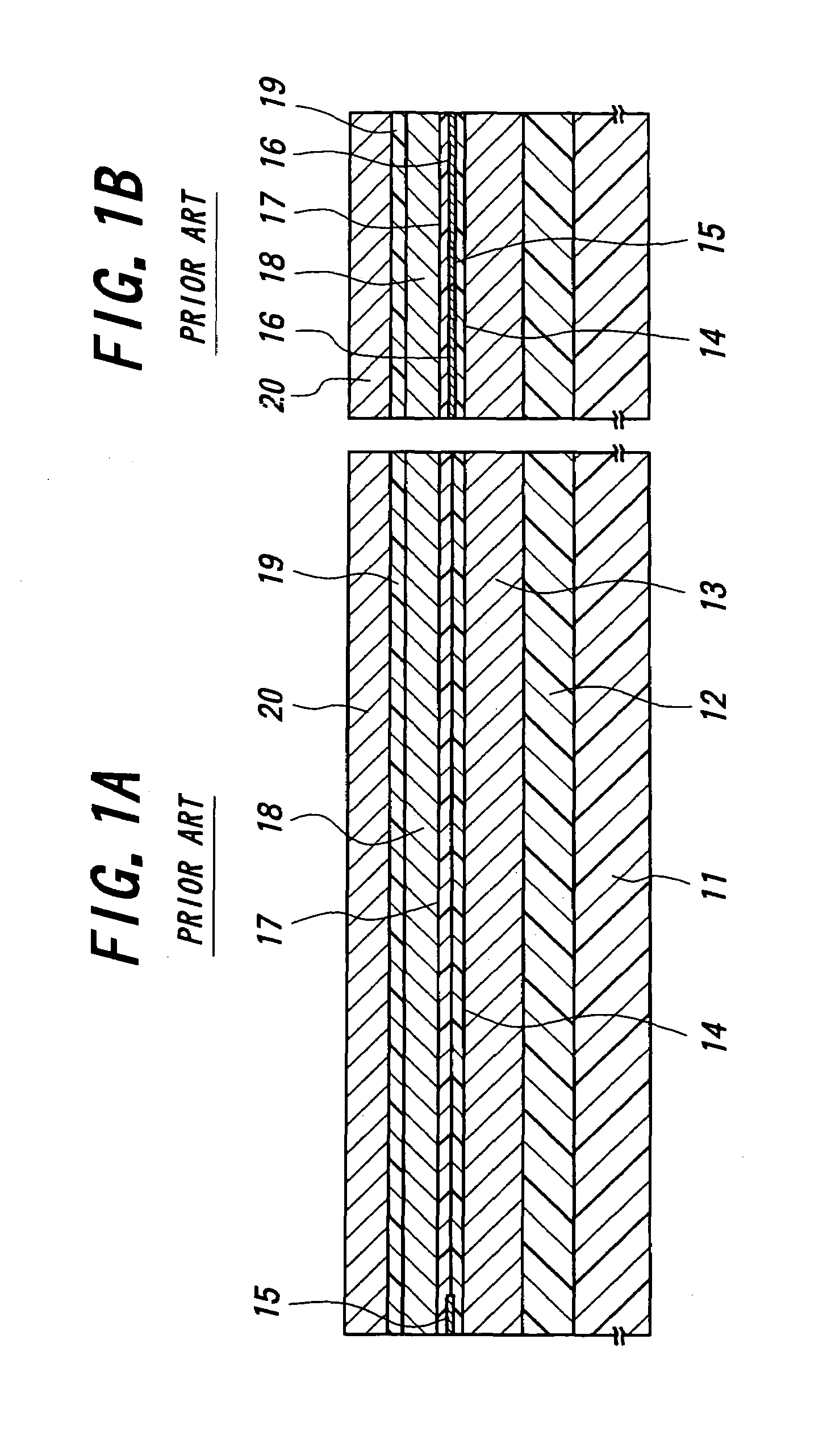

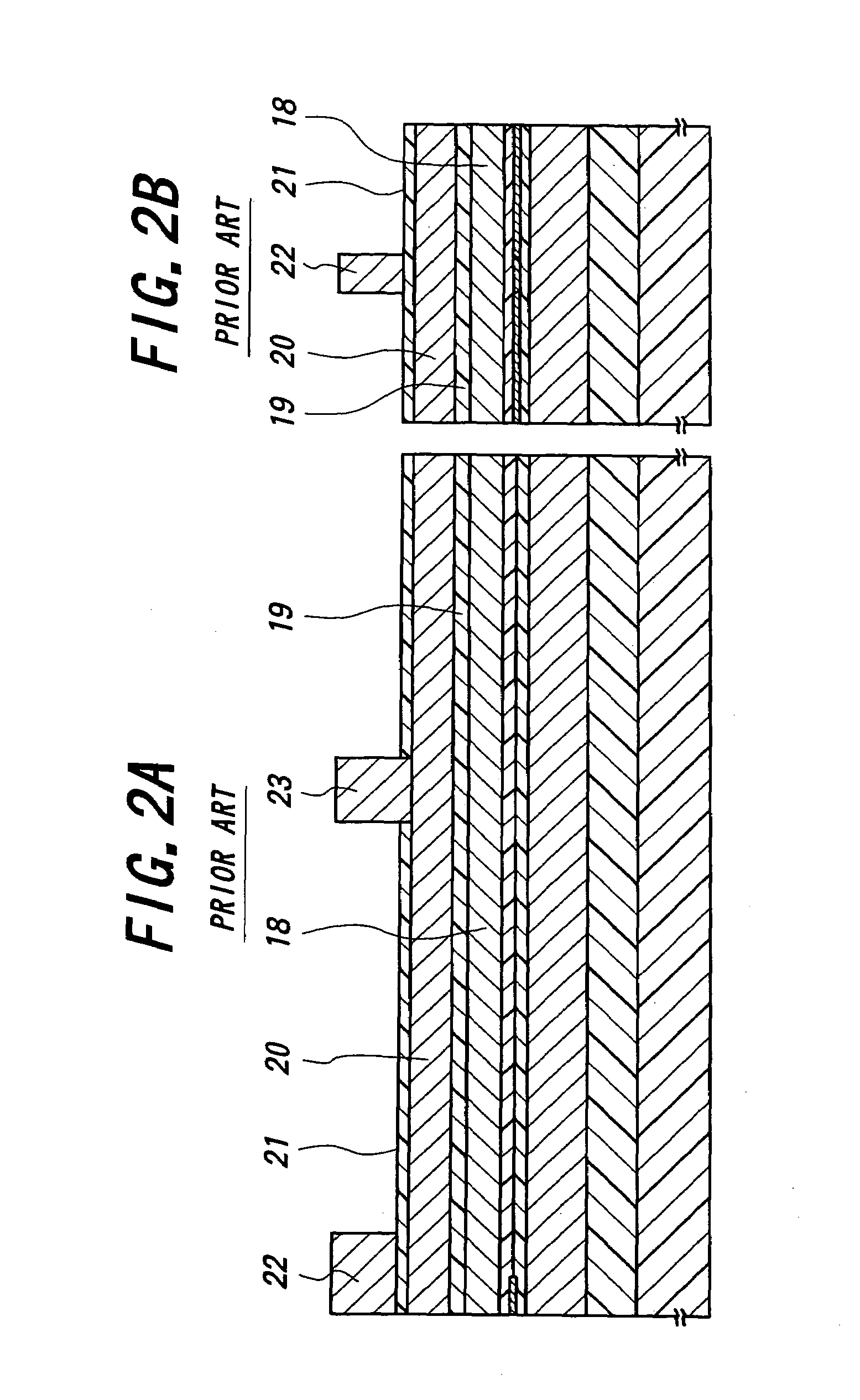

Coil for thin-film magnetic head with inductive write head element

InactiveUS6980396B2Length of coil is shortenedSmall sizeConstruction of head windingsHeads using thin filmsElectrical conductorMagnetic poles

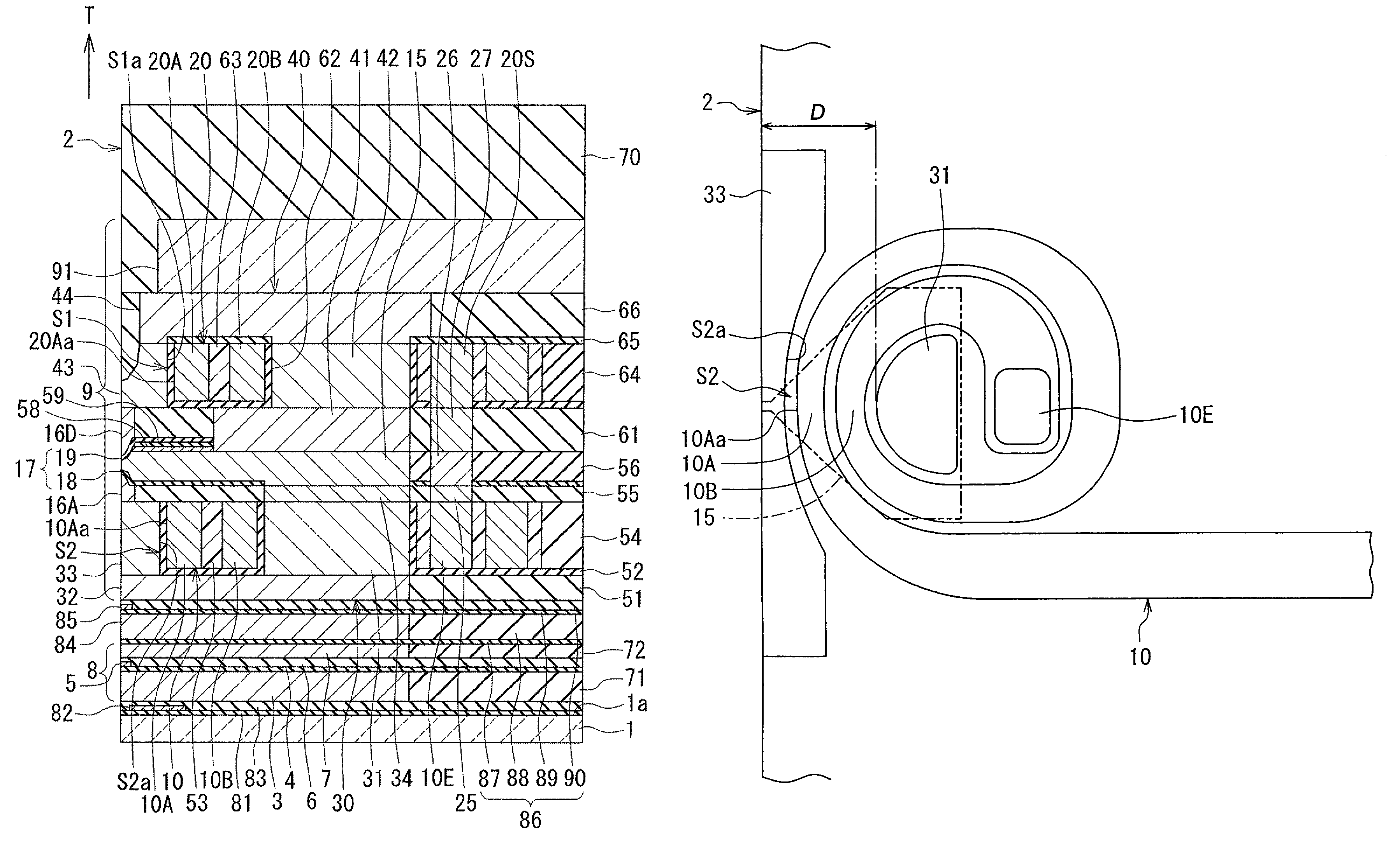

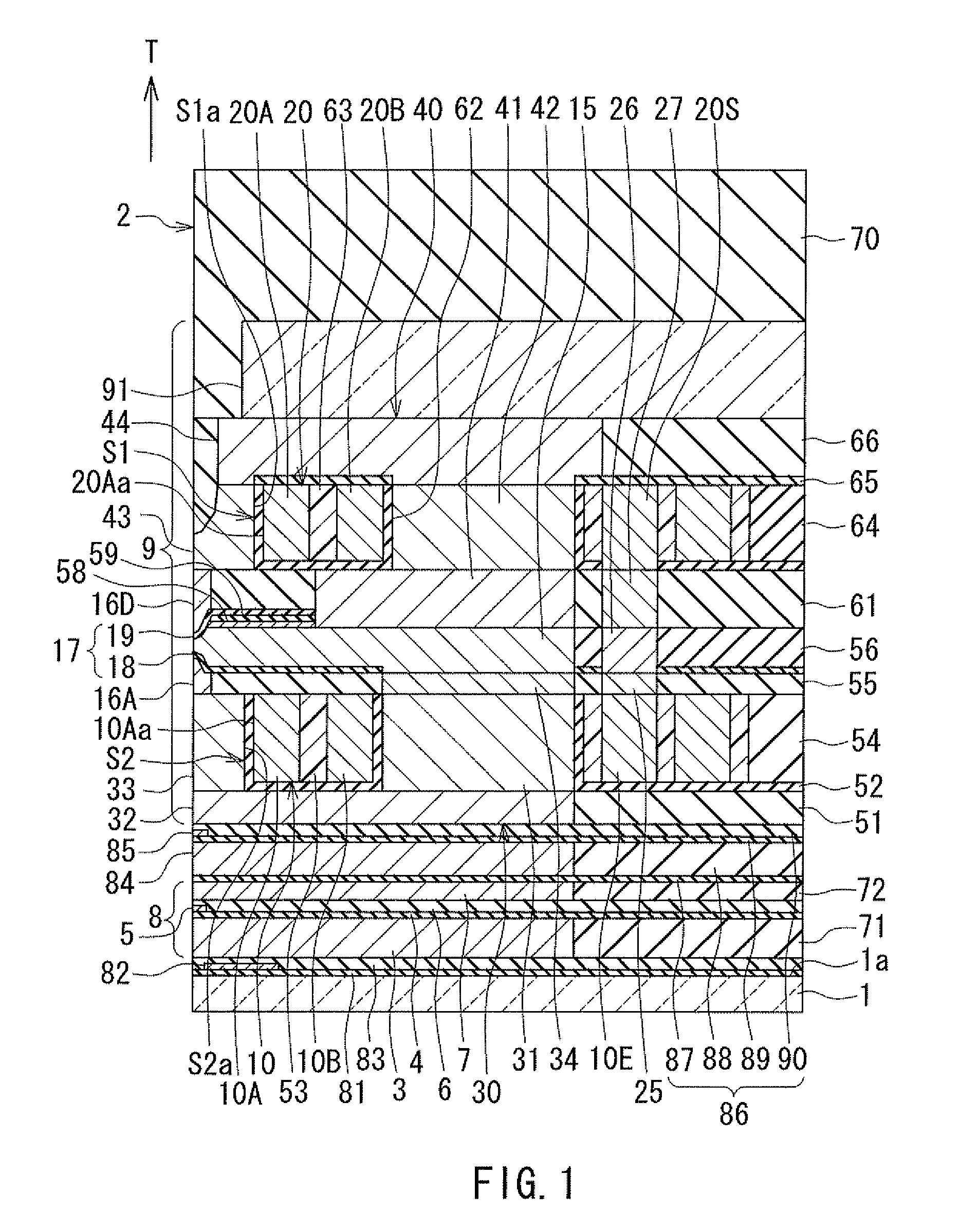

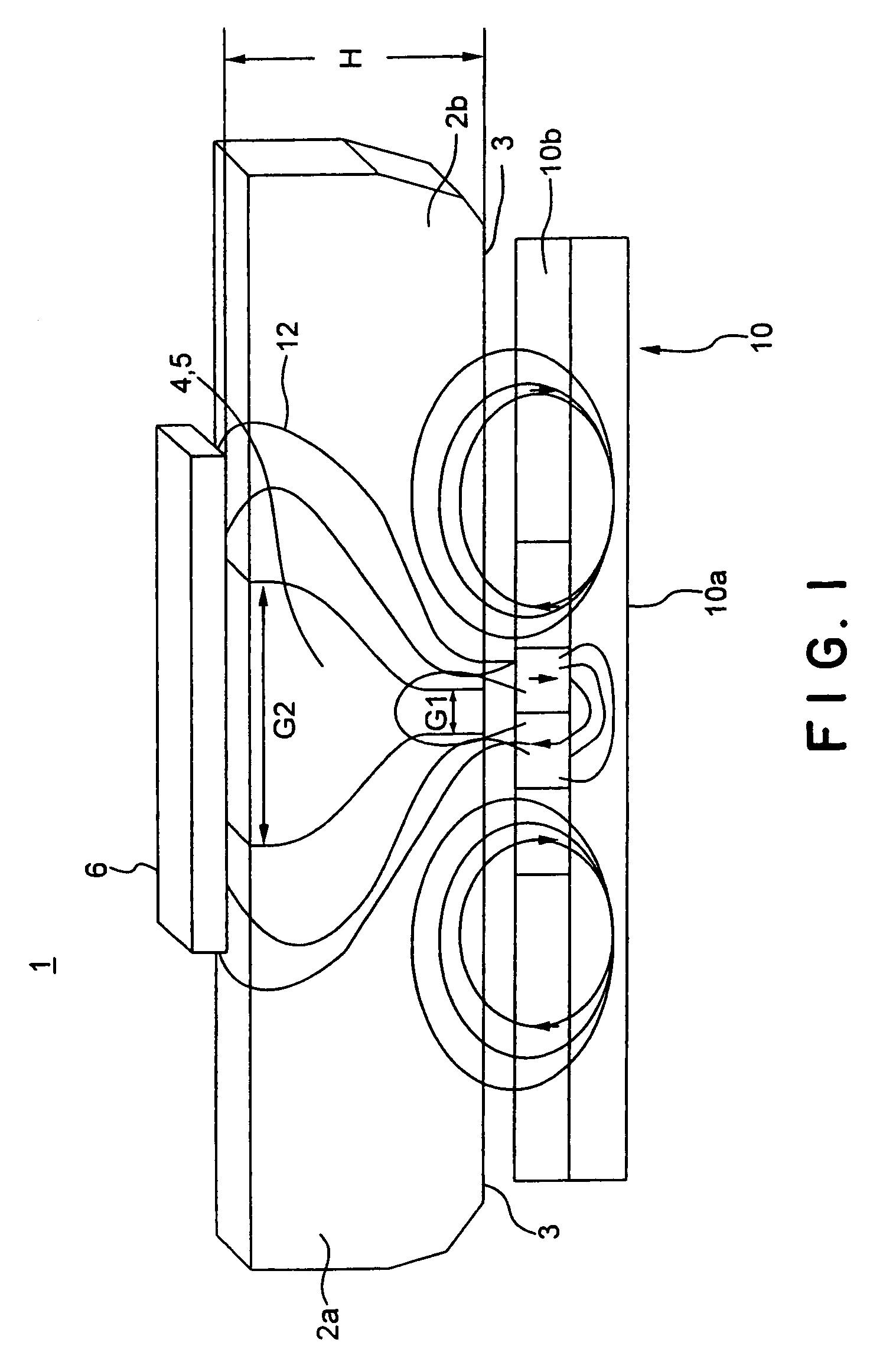

A thin-film magnetic head includes an insulation gap, first and second yoke layers with first and second ends, respectively, the first ends constituting magnetic poles separated from each other by the insulation gap, the second ends being magnetically coupled with each other, and a coil conductor constituted by a plurality of single layer turns, for generating magnetic field and applying the generated magnetic field into the first and second yoke layers. Each turn of the coil conductor includes a first section, a second section with one end coupled with one end of the first section, and a third section with one end coupled with the other end of the second section. The third section travels to pass outside of the first yoke layer in parallel with the surface of the first yoke layer, and to extend over the first yoke layer.

Owner:SAE MAGNETICS (HK) LTD

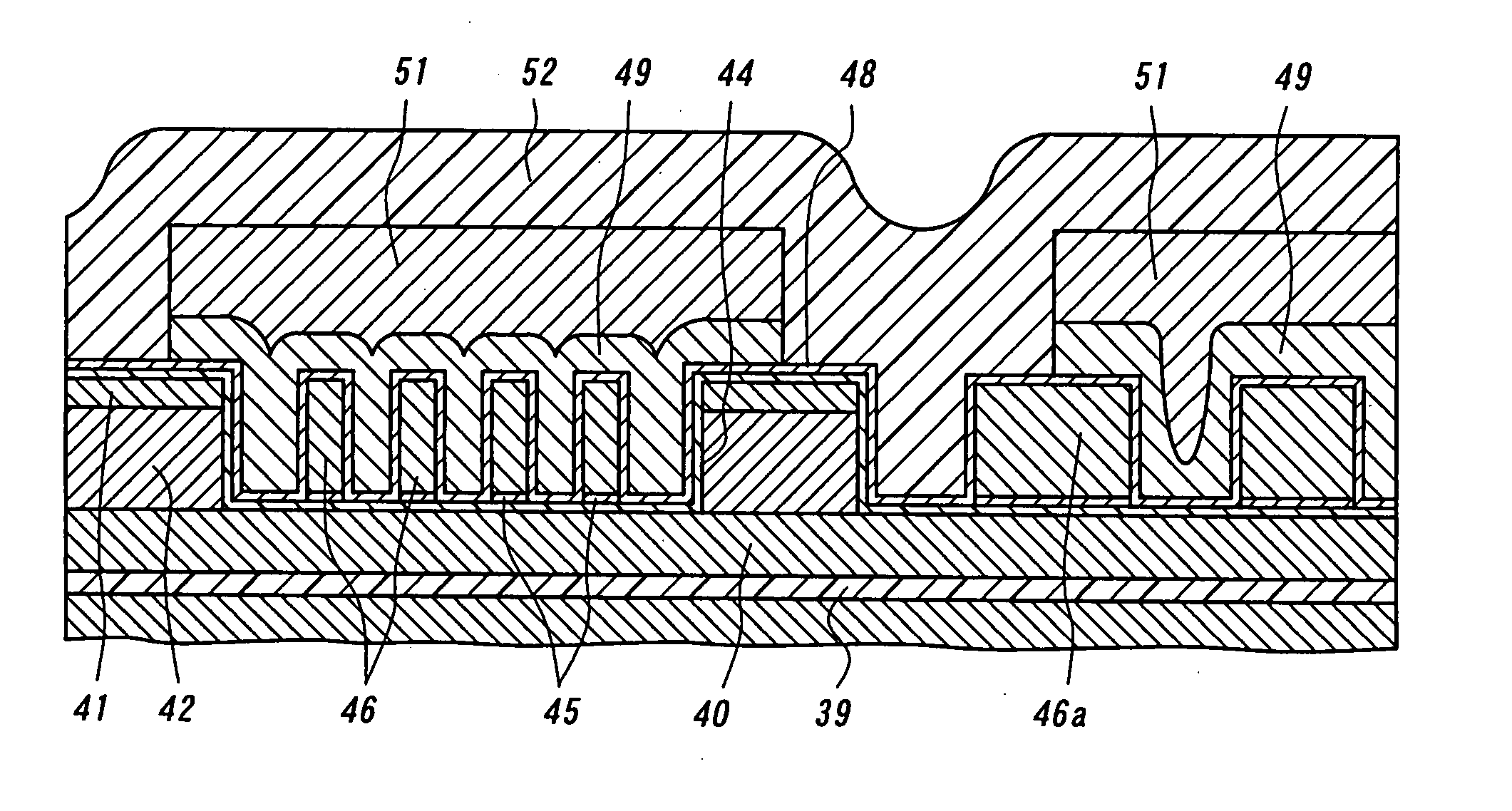

Wiring pattern and method of manufacturing the same and thin film magnetic head and method of manufacturing the same

InactiveUS20060012916A1Improve performanceDistanceRecord information storageAutomatic grinding controlEngineeringConductor Coil

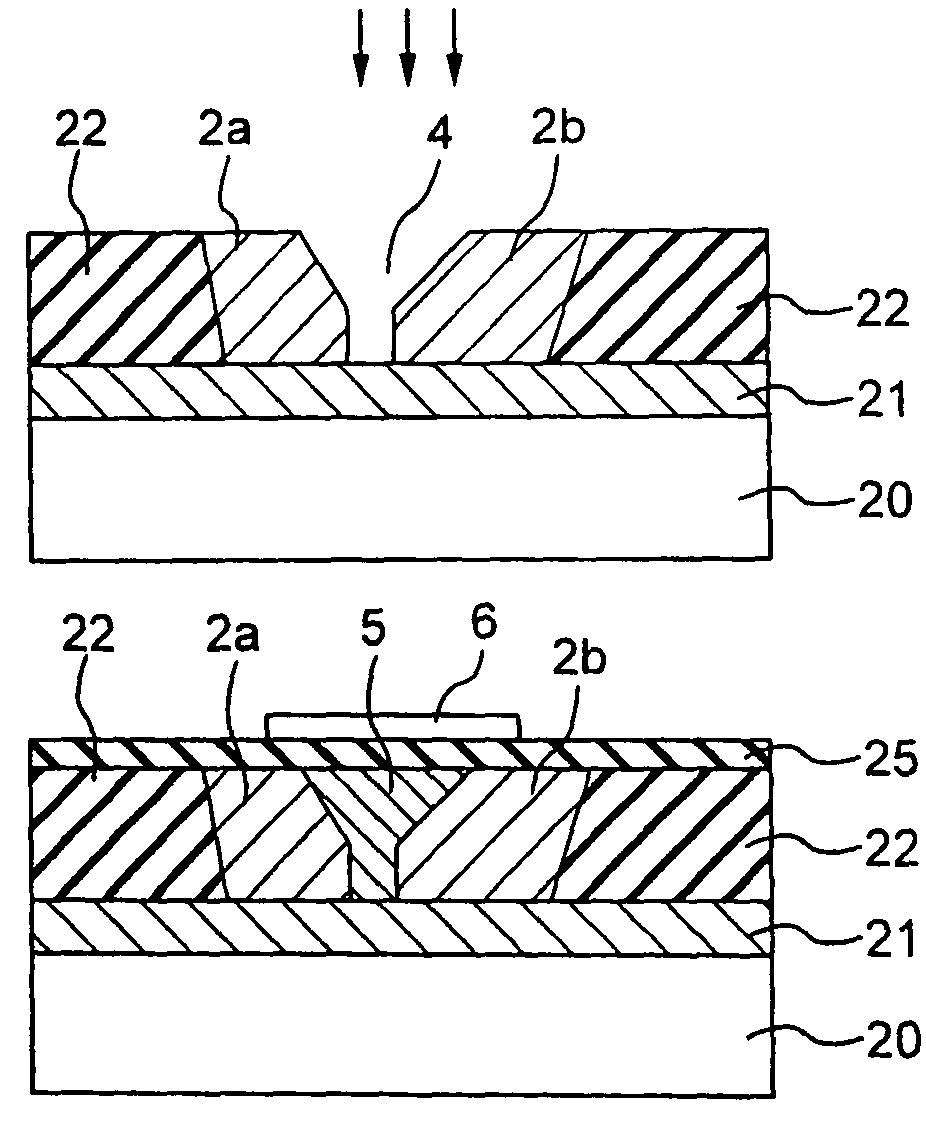

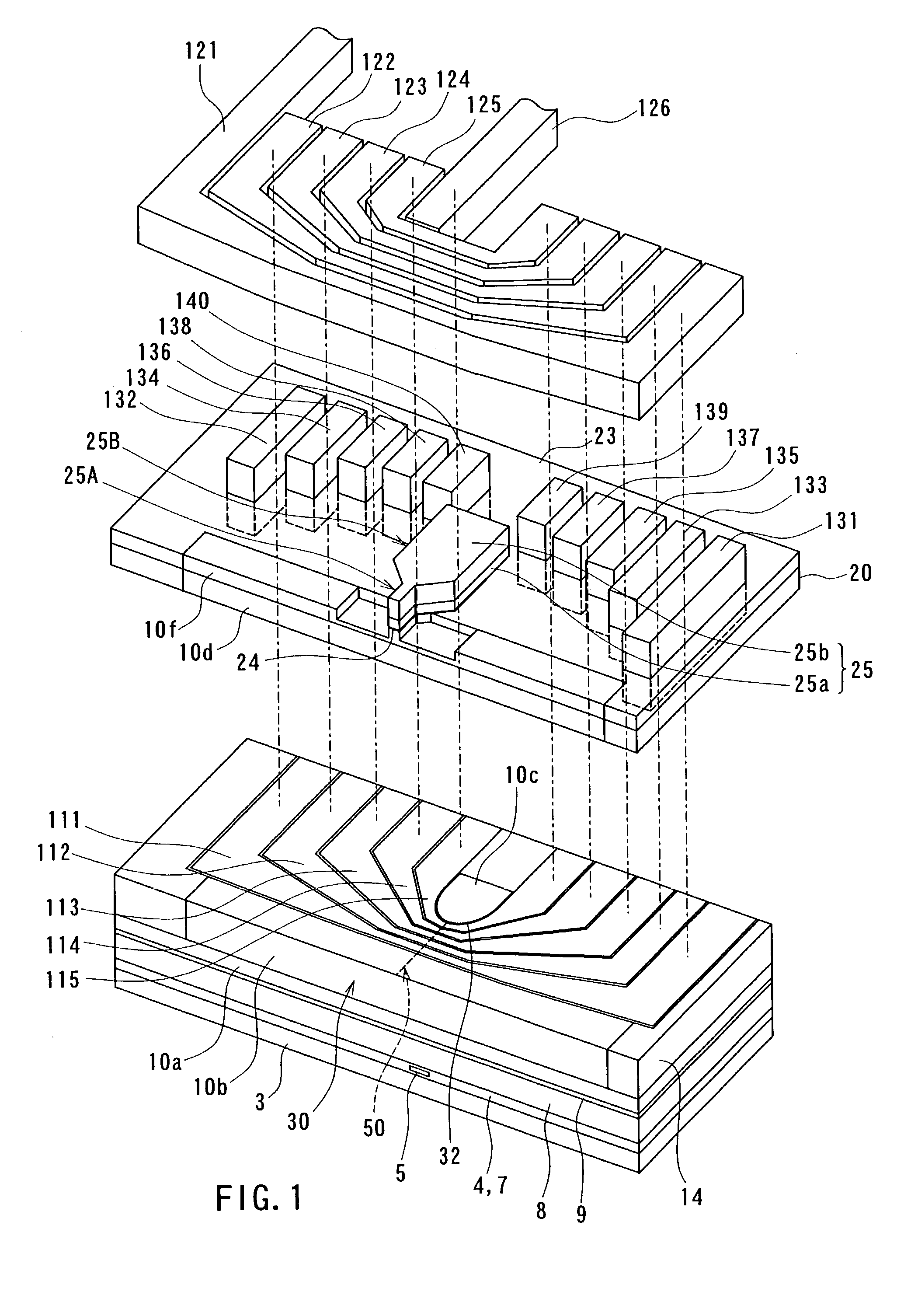

A bottom track pole is formed on a surface of a bottom pole, a thin film coil is formed on the bottom pole to form a flat coplanar surface with the bottom track pole, a write gap film is formed on the flat coplanar surface, first and second magnetic material films constituting a top pole are formed on a flat surface of the thin film coil, and the second magnetic material film, first magnetic material film, write gap film and bottom track pole are partially removed by RIE to form a top track pole and trim structure in a self-aligned manner. The thin film coil is formed by a first thin film coil half and a second thin film coil half having coil windings which are formed in a self-aligned manner between successive coil windings of the first thin film coil half and have a two-layer structure of a first conductive film at least a part of which is formed by CVD and a second conductive film formed by electrolytic plating. A thin insulating film is interposed between successive coil windings of the first and second thin film coil halves. Jumper wirings for connecting an innermost coil winding of the first thin film coil half to an outermost coil winding of the second thin film coil half are formed together with the top pole.

Owner:HEADWAY TECH INC +1

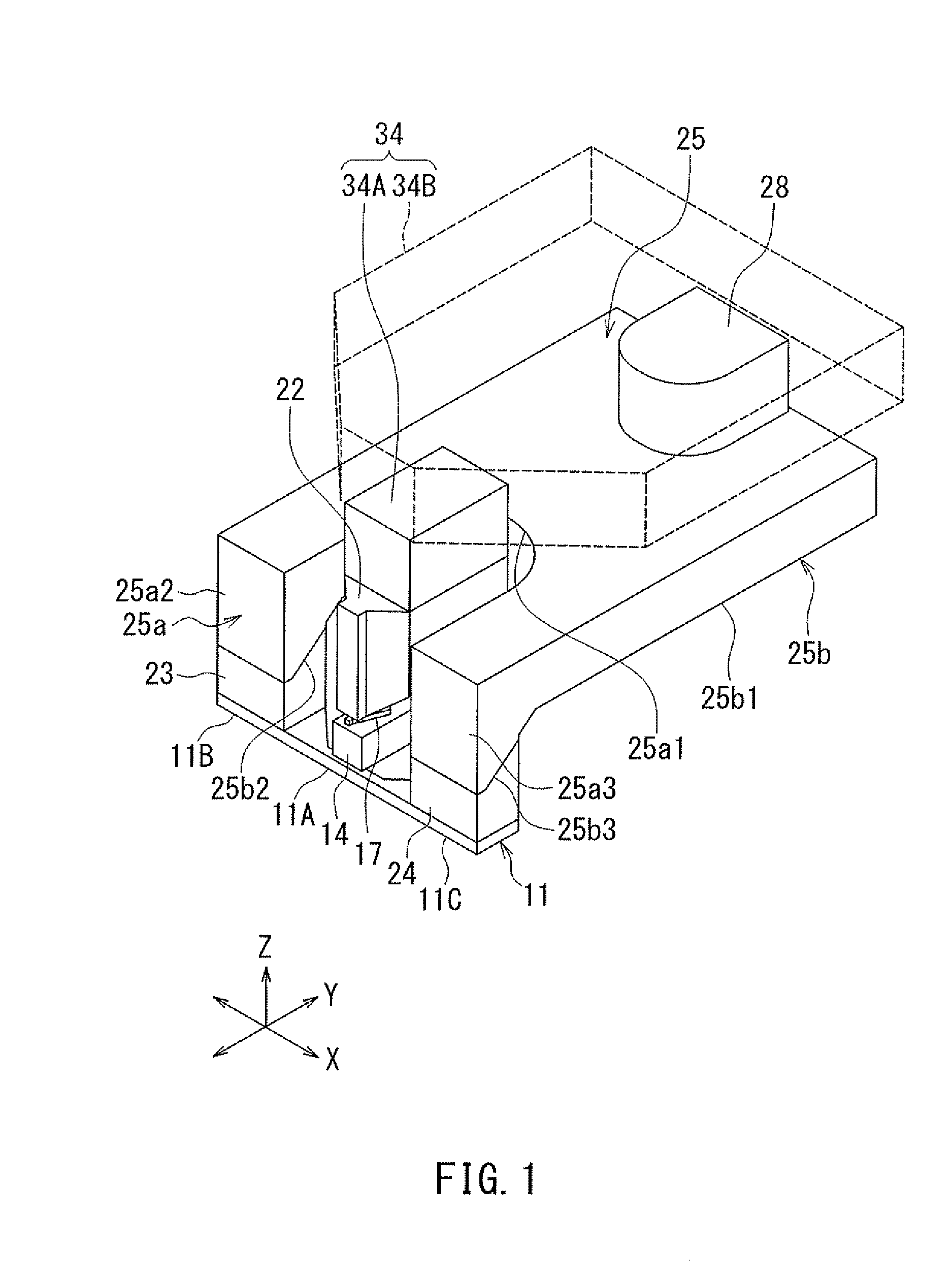

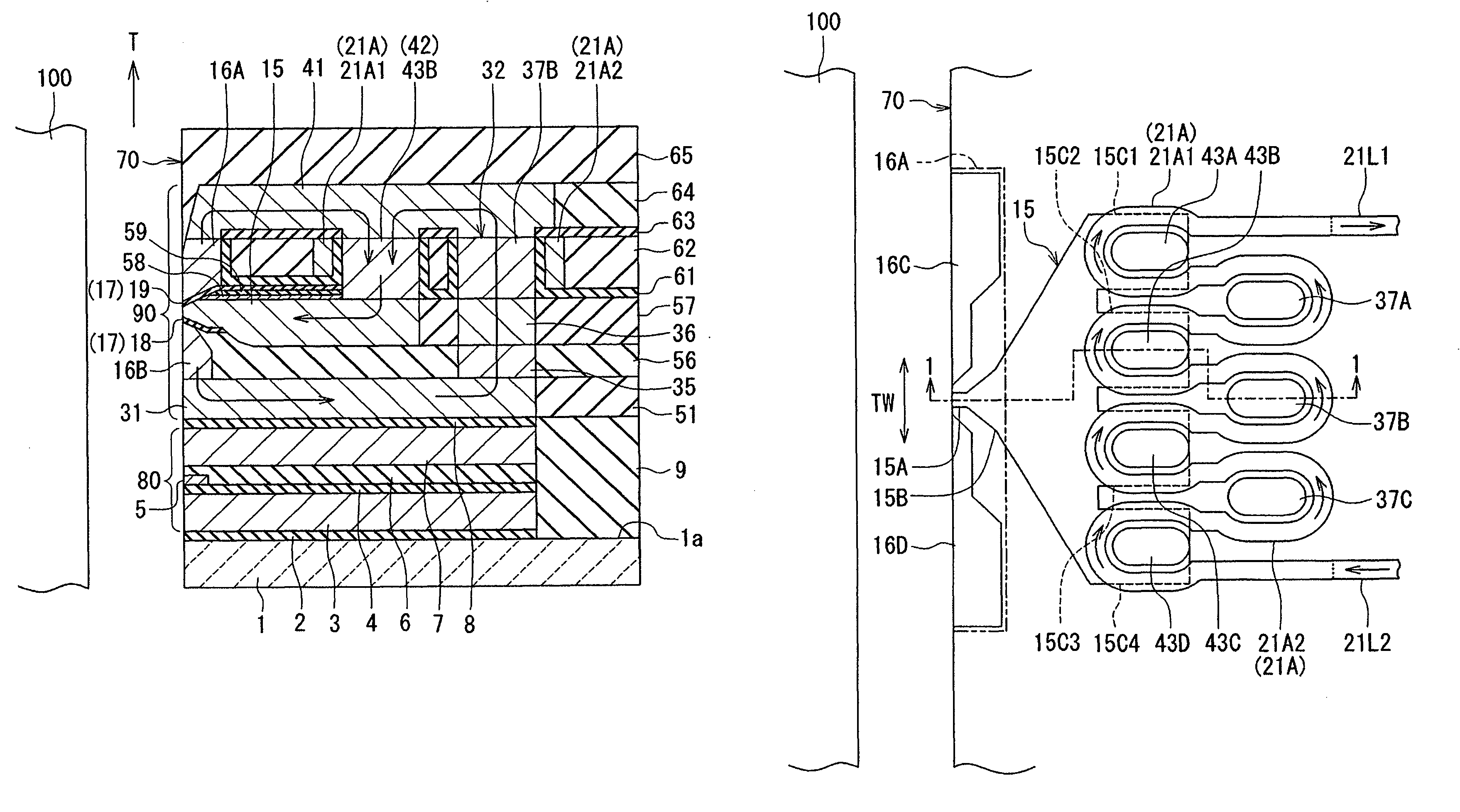

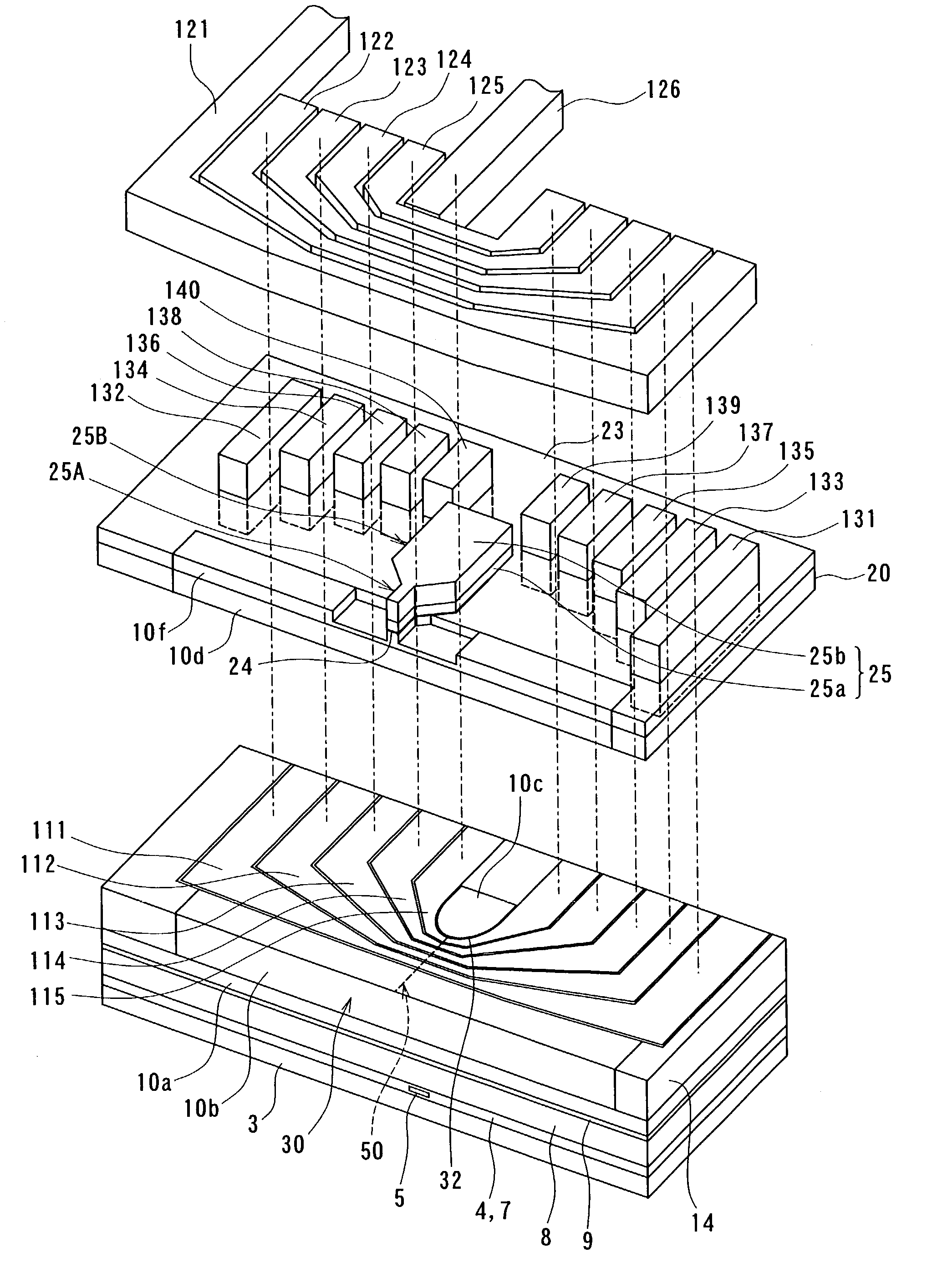

Magnetic head for perpendicular magnetic recording capable of producing a write magnetic field of sufficient magnitude from the main pole while reducing the length of a magnetic path that connects the write shield and the main pole

ActiveUS8593762B1Shorten the length of the magnetic circuitSufficient magnitudeConstruction of head windingsRecord information storageCouplingMagnetic poles

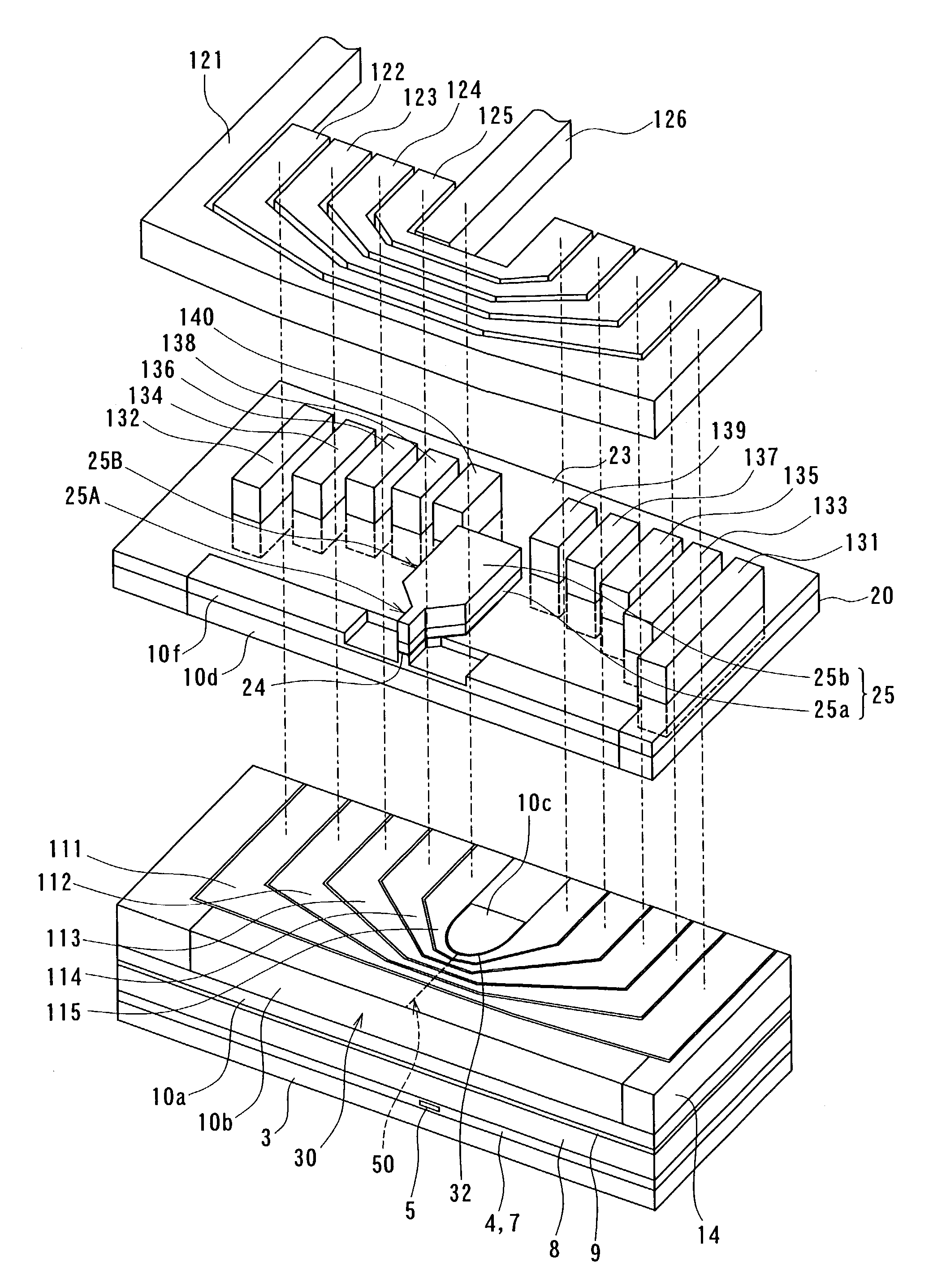

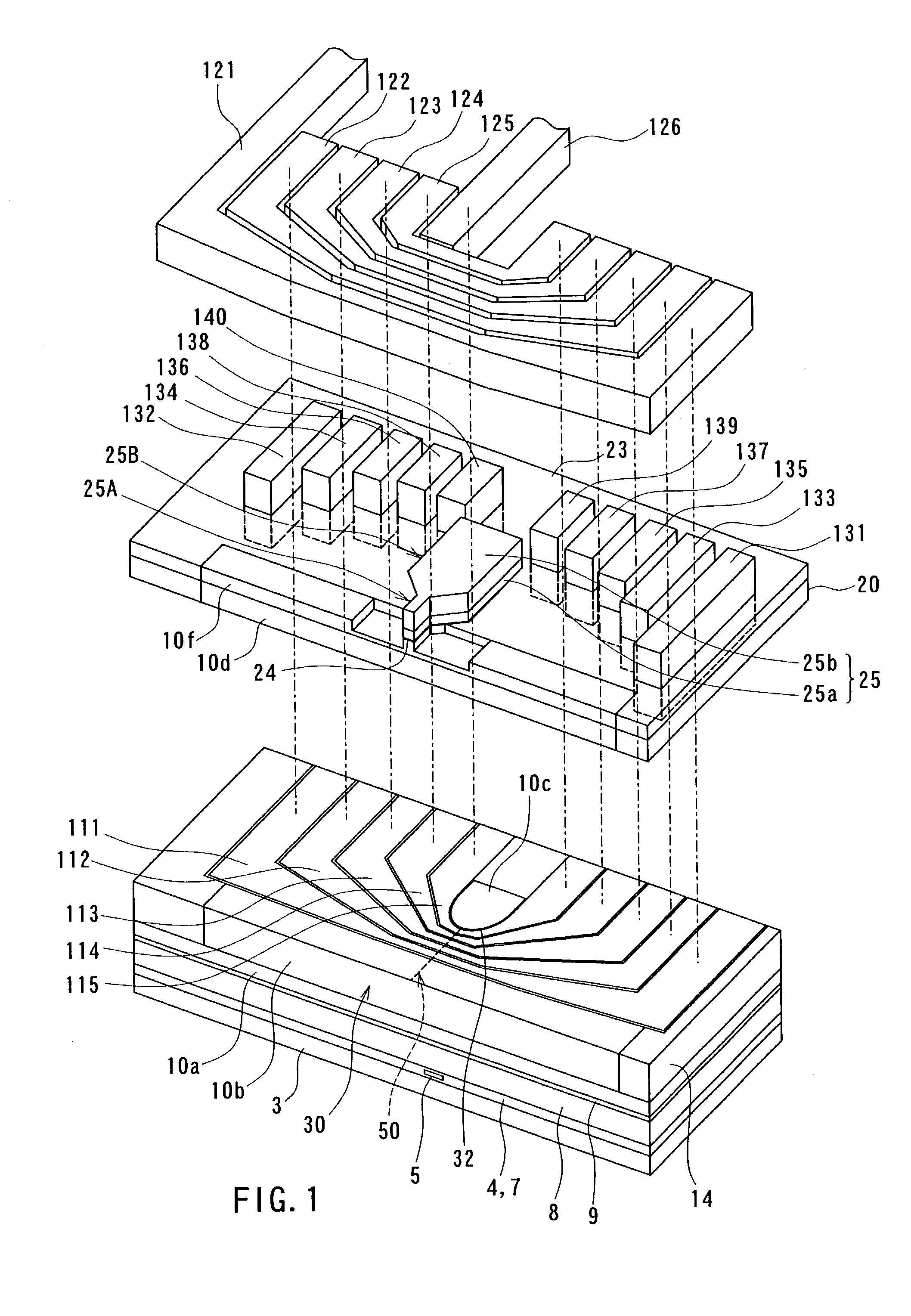

A magnetic head includes a coil, a main pole, a write shield, first and second yoke layers, and first and second coupling parts. The first yoke layer is located on the trailing side relative to the main pole whereas the second yoke layer is located on the leading side relative to the main pole. The first coupling part couples the main pole and the first yoke layer to each other. The second coupling part couples the first yoke layer and the second yoke layer to each other. The first coupling part includes a plurality of first magnetic path portions, and the second coupling part includes a plurality of second magnetic path portions. The coil includes one winding portion extending to pass around the first and second magnetic path portions alternately in a zigzag manner.

Owner:HEADWAY TECH INC +1

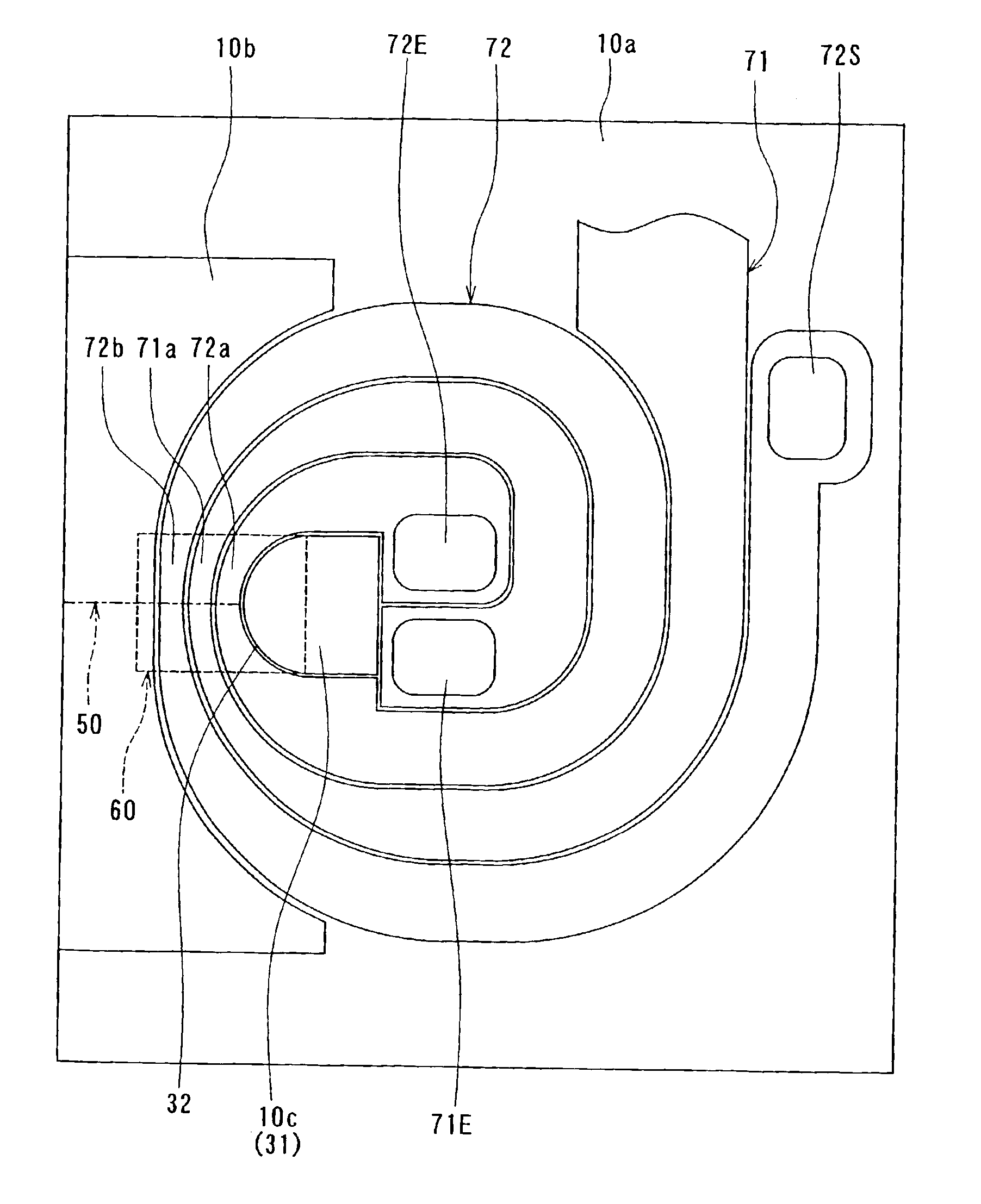

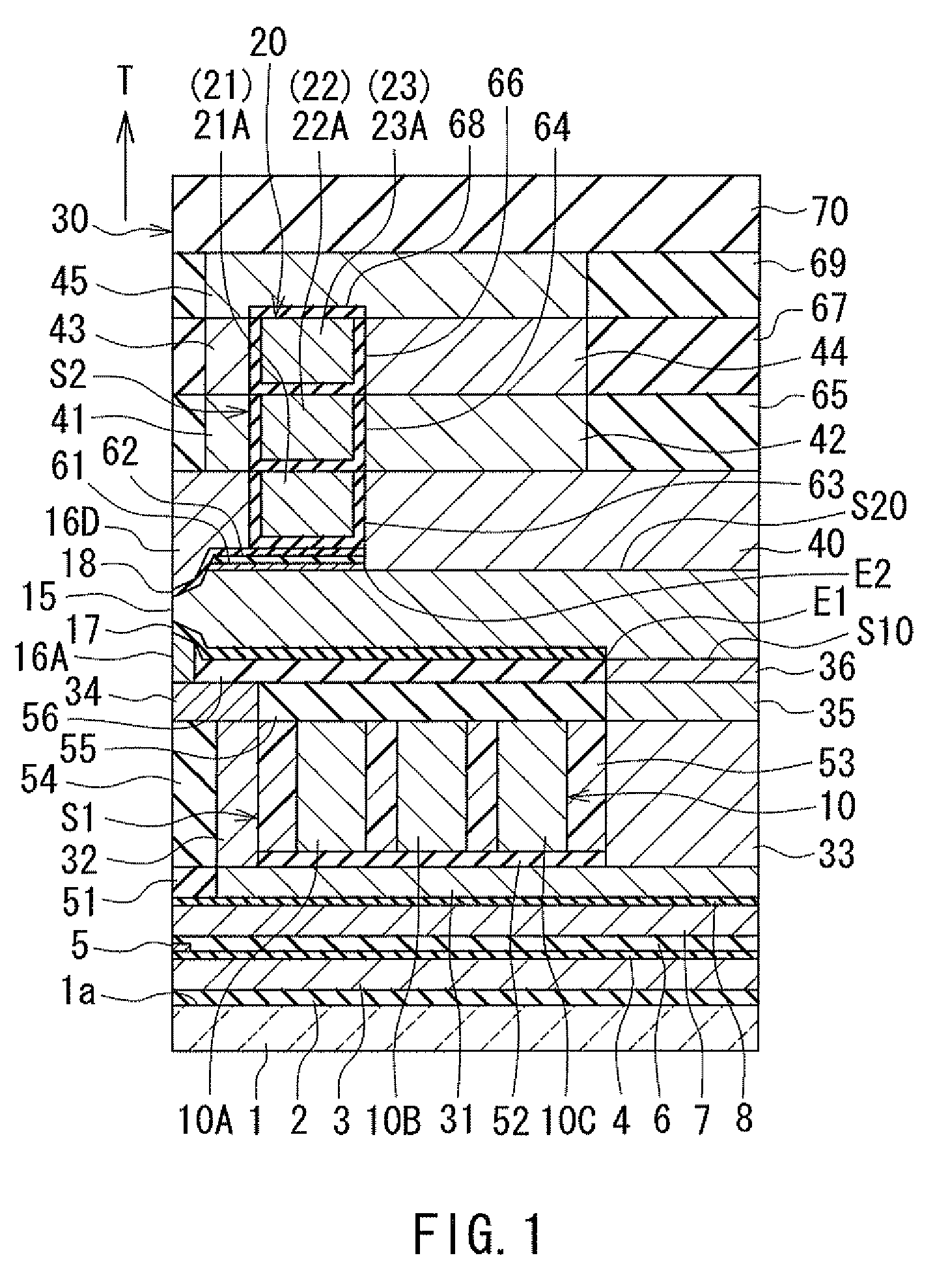

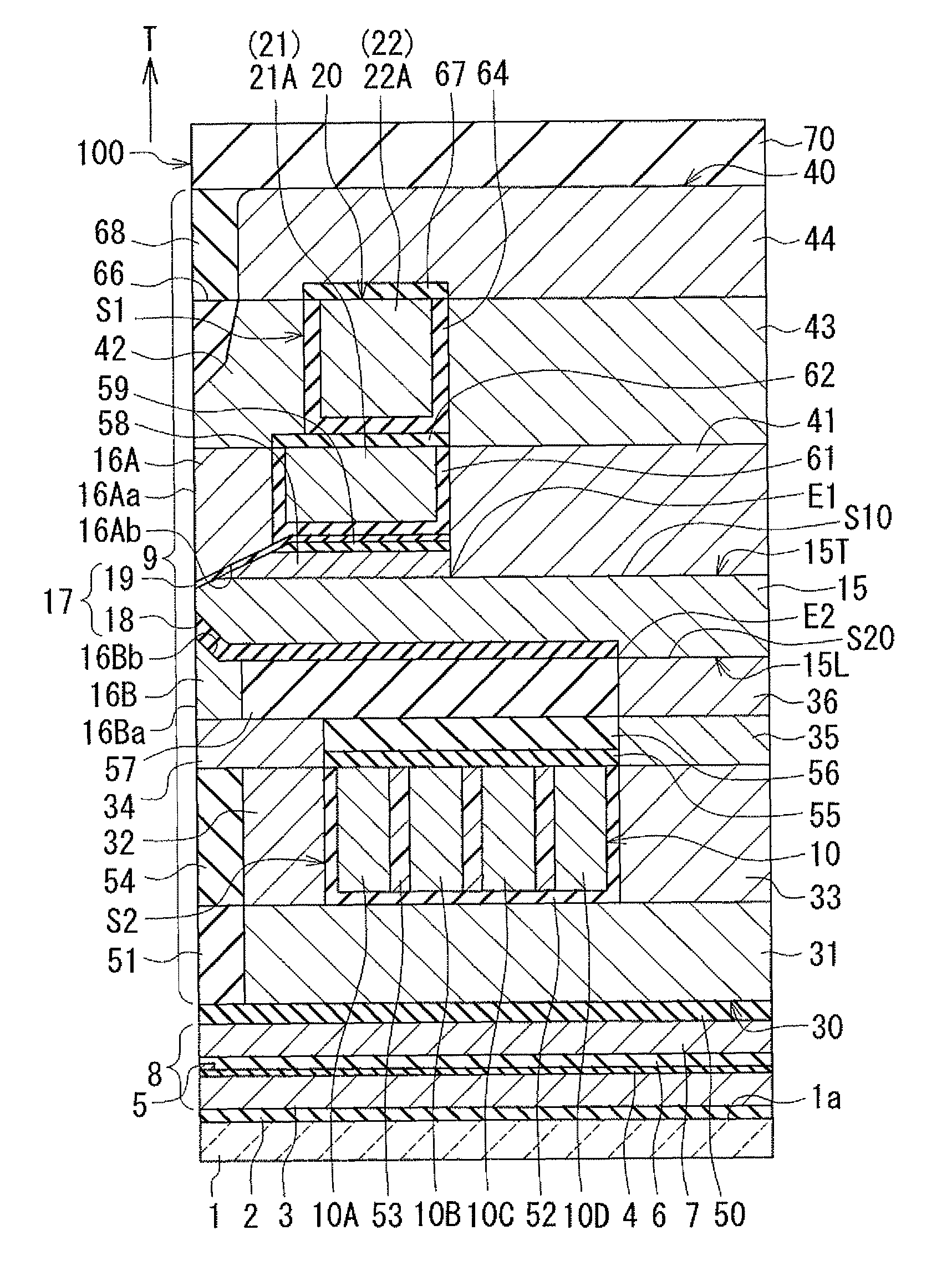

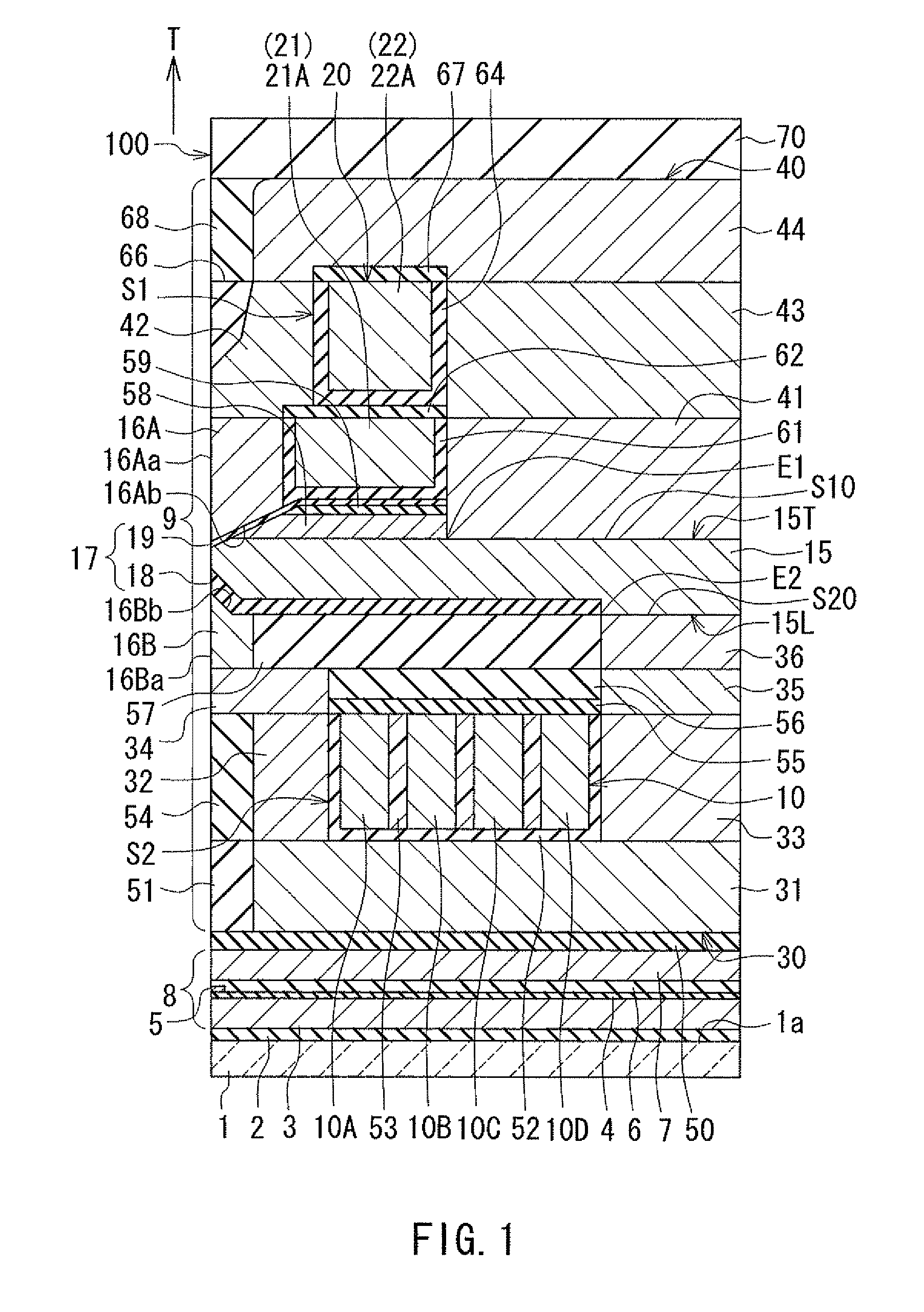

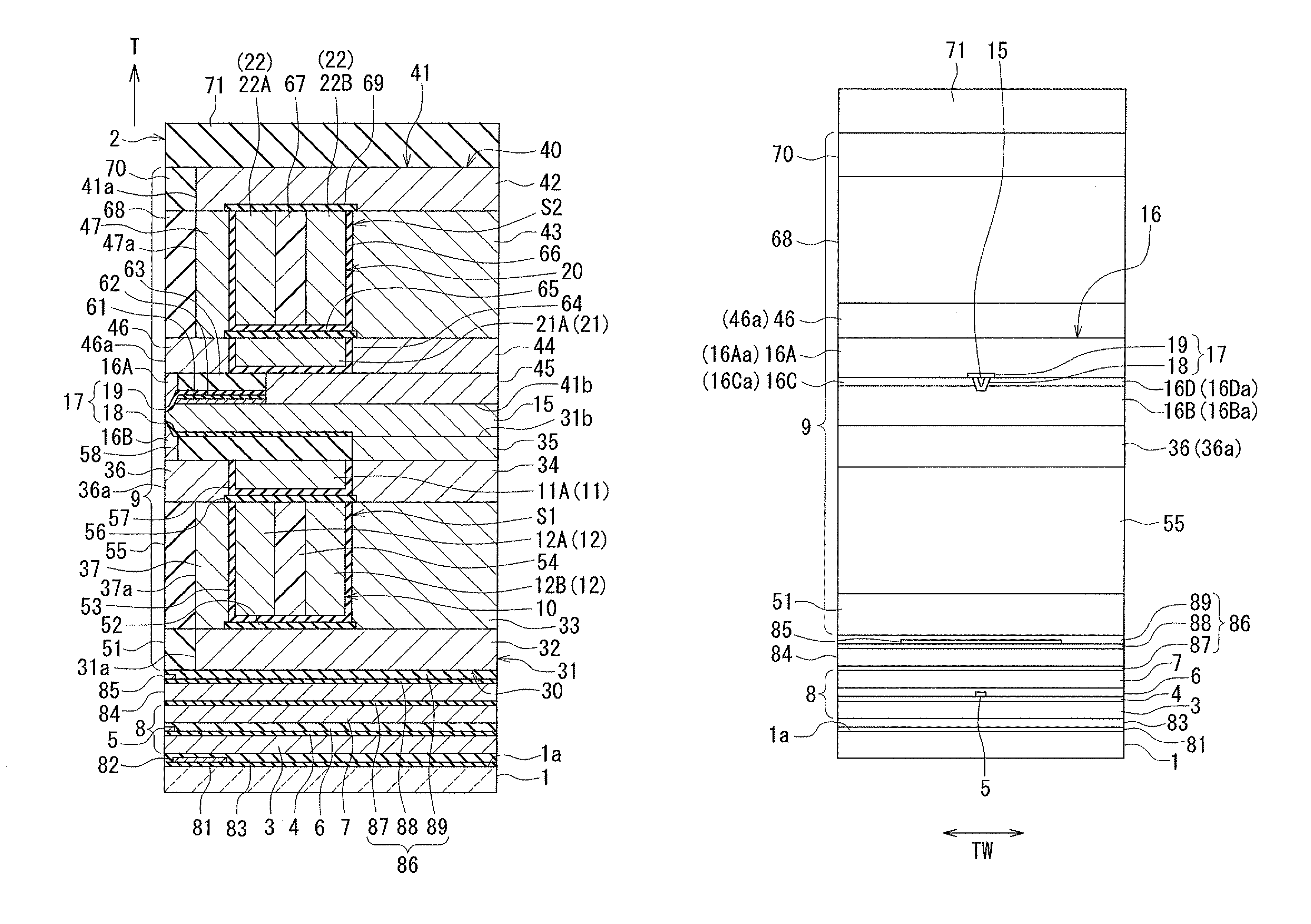

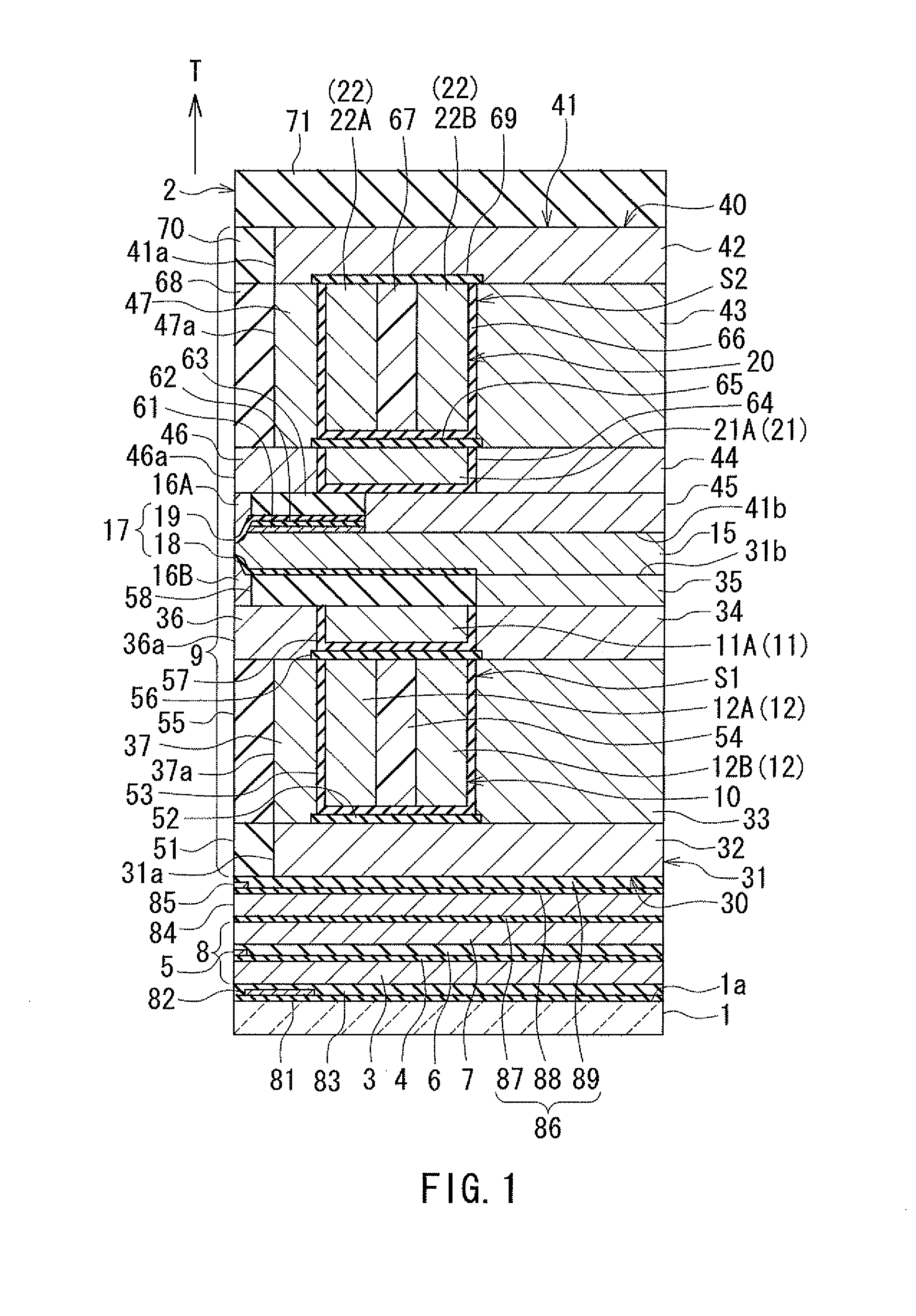

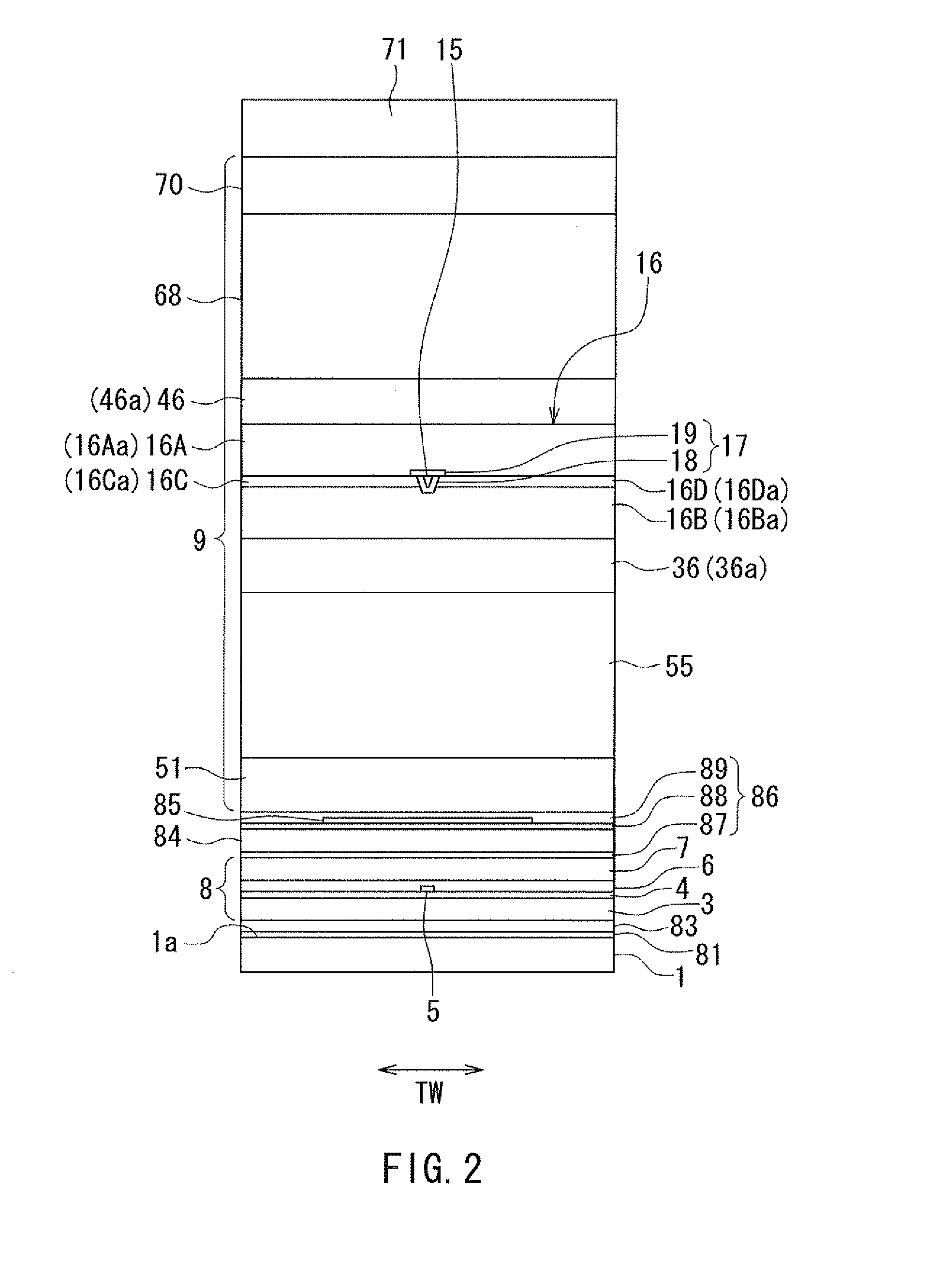

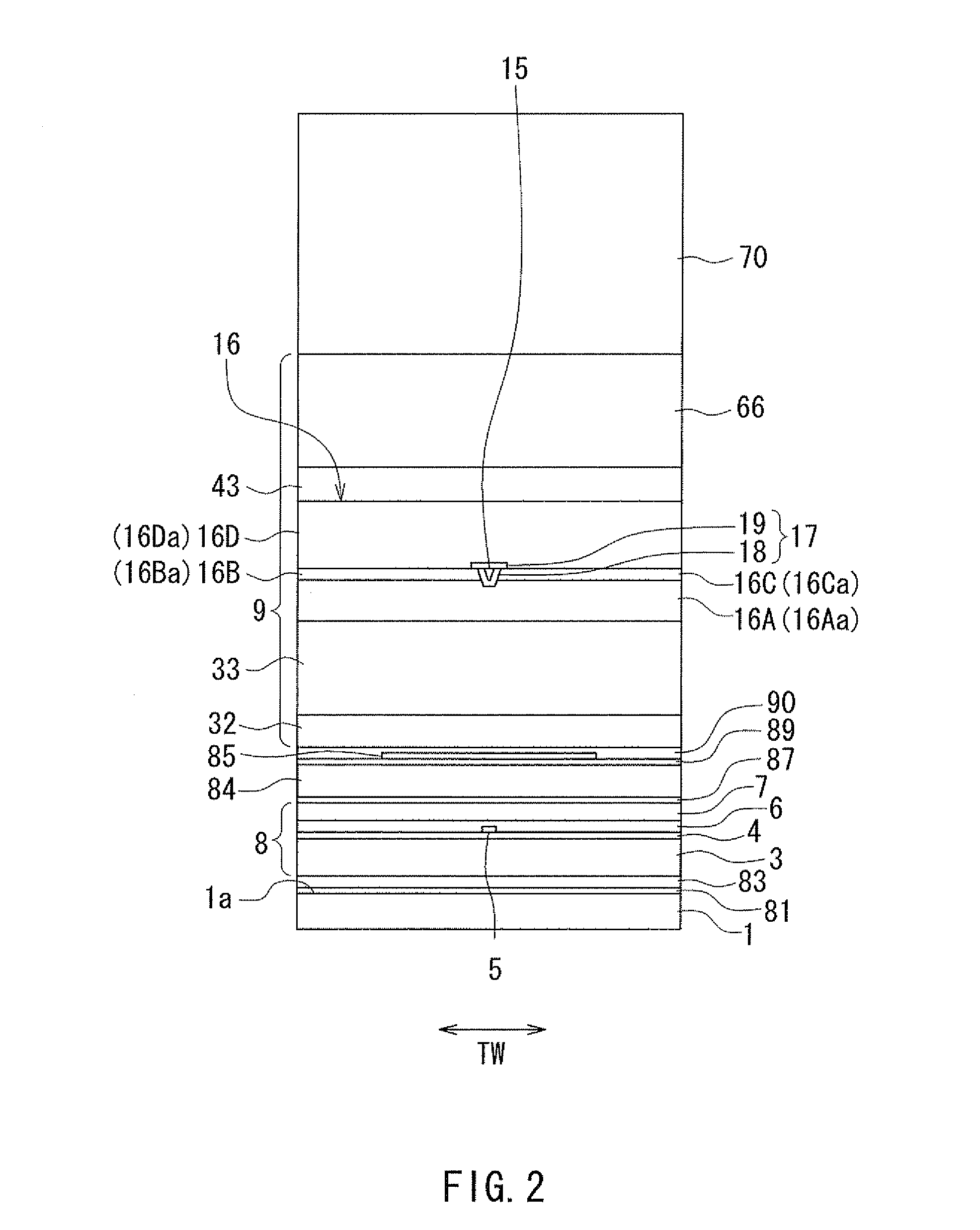

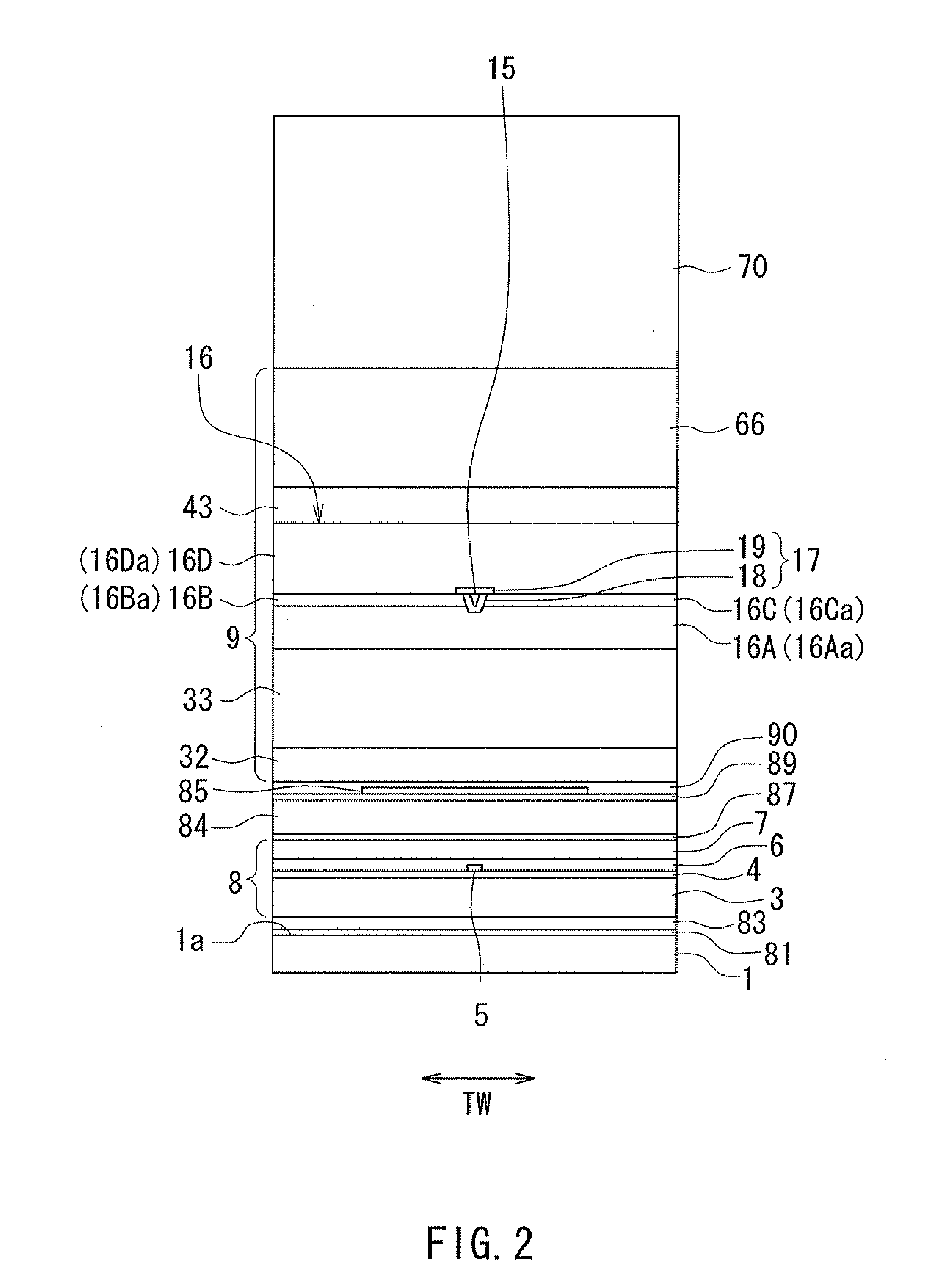

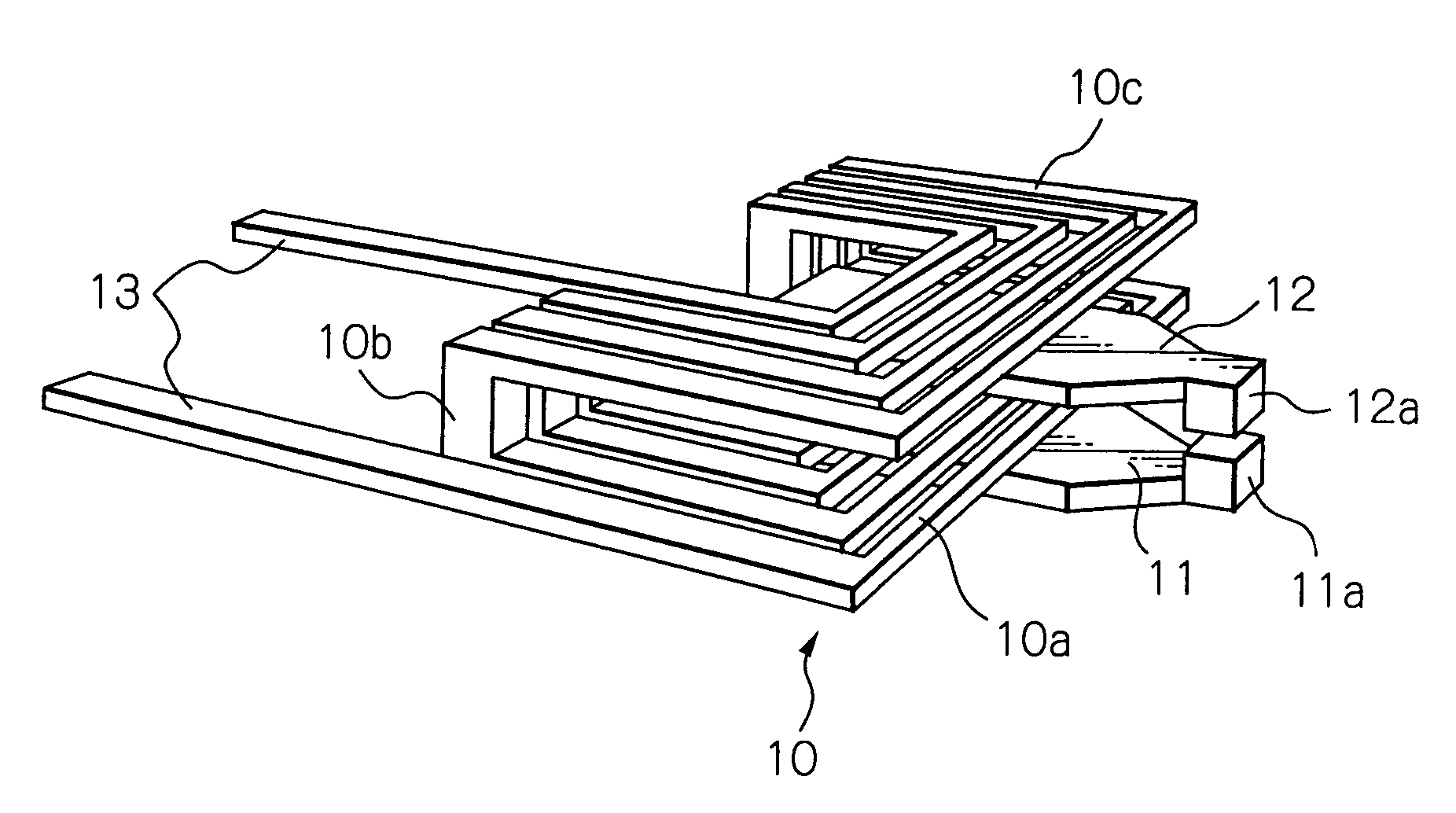

Thin-film magnetic head and method of manufacturing same, and thin-film magnetic head substructure

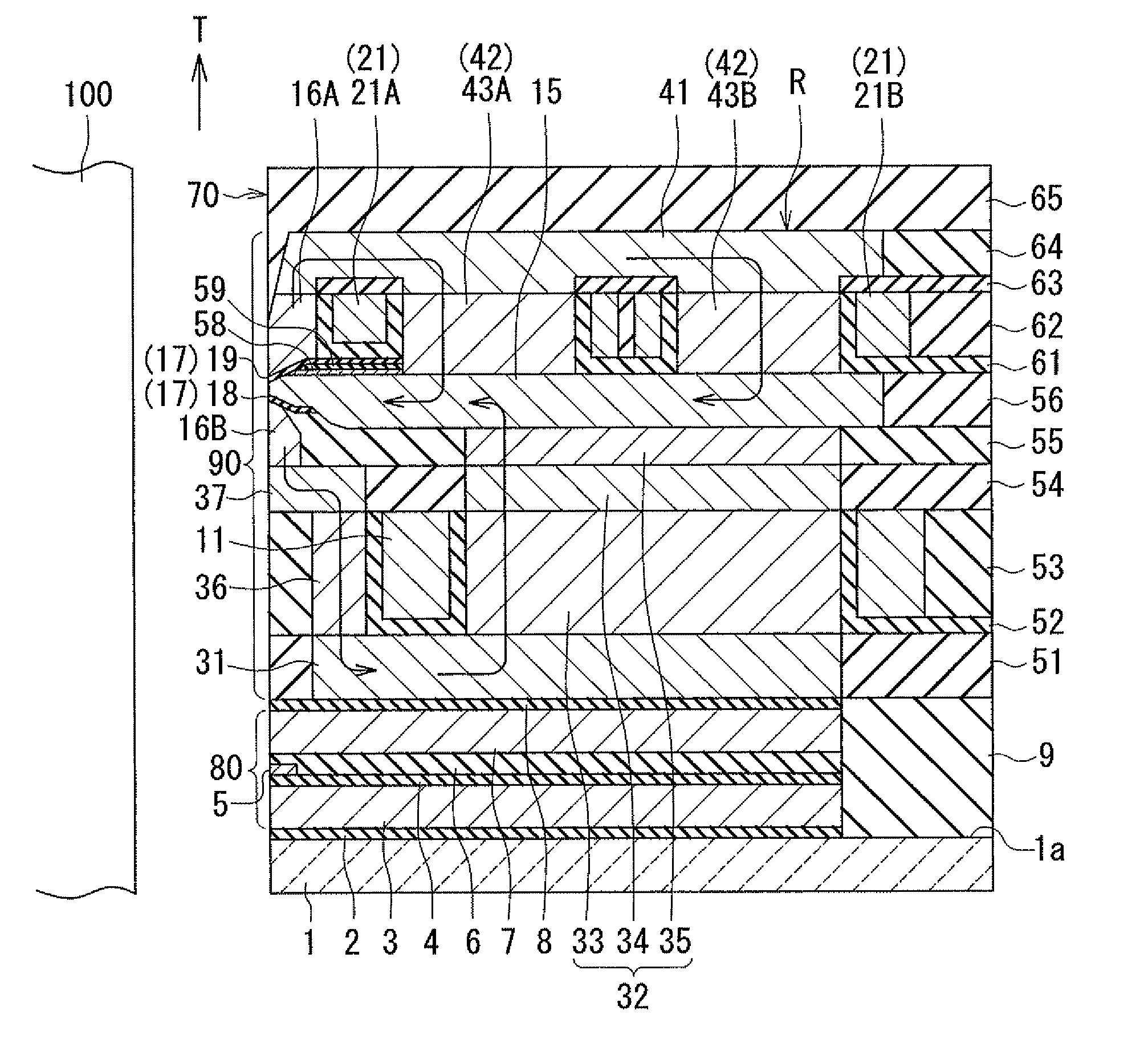

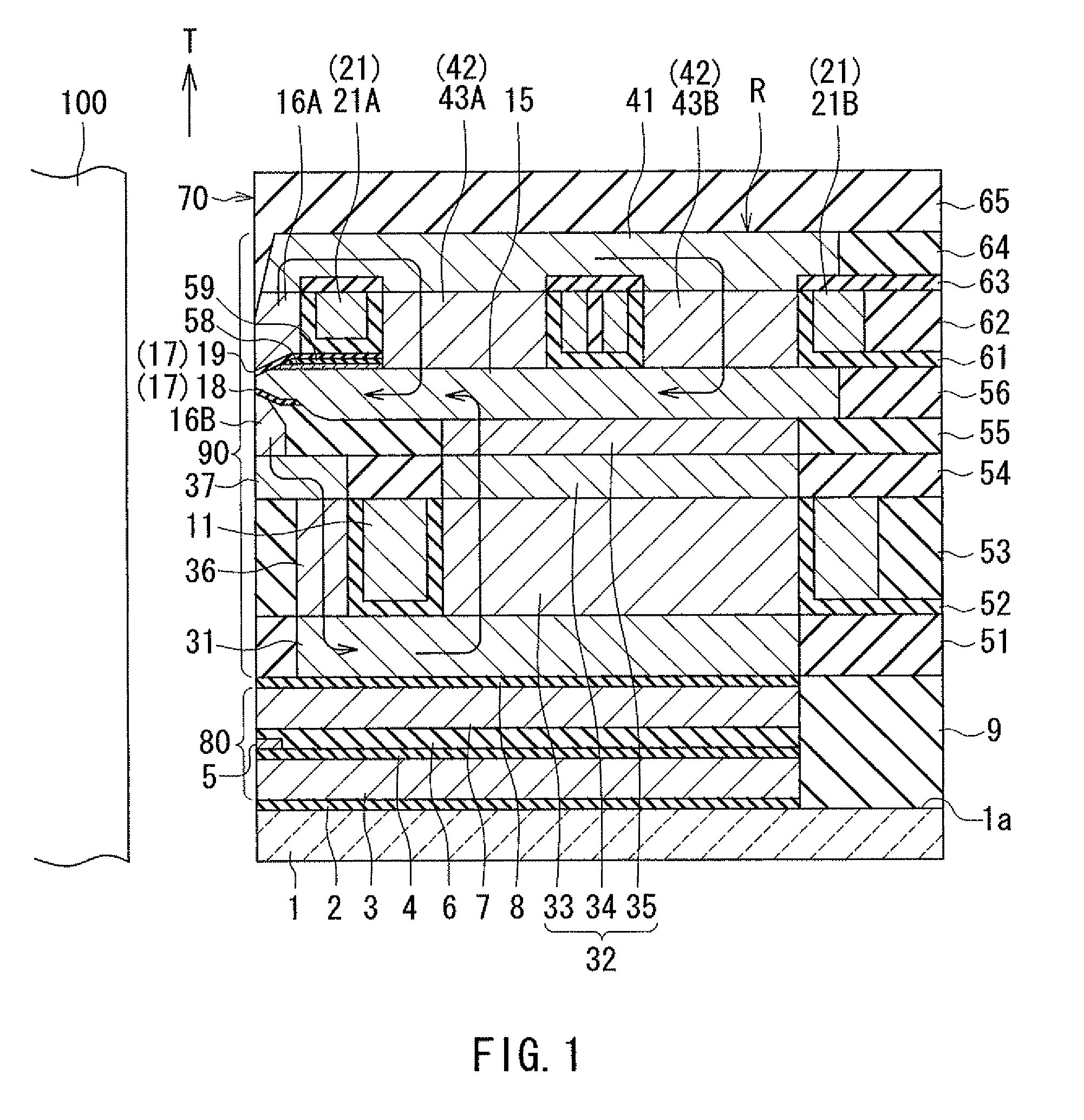

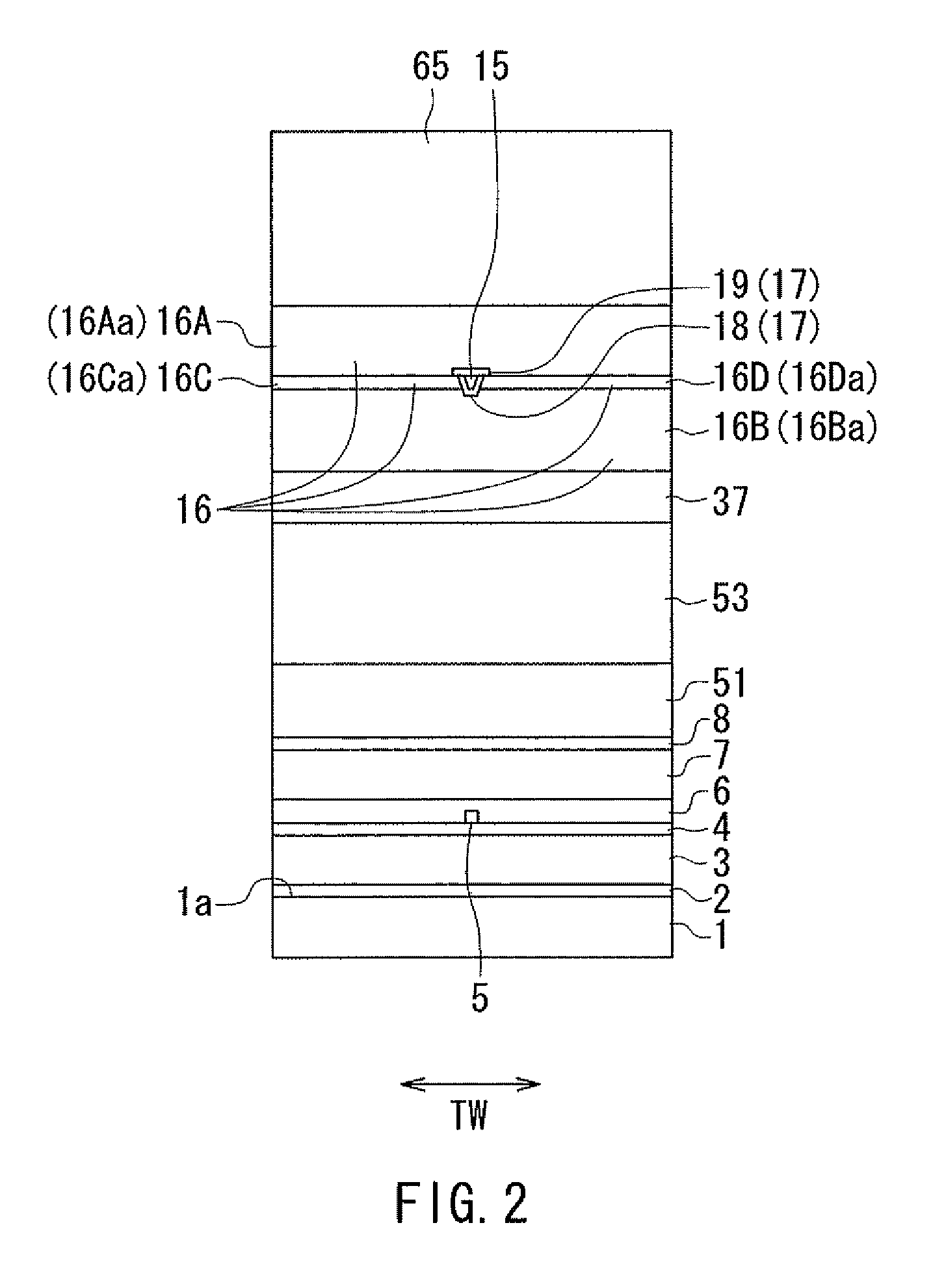

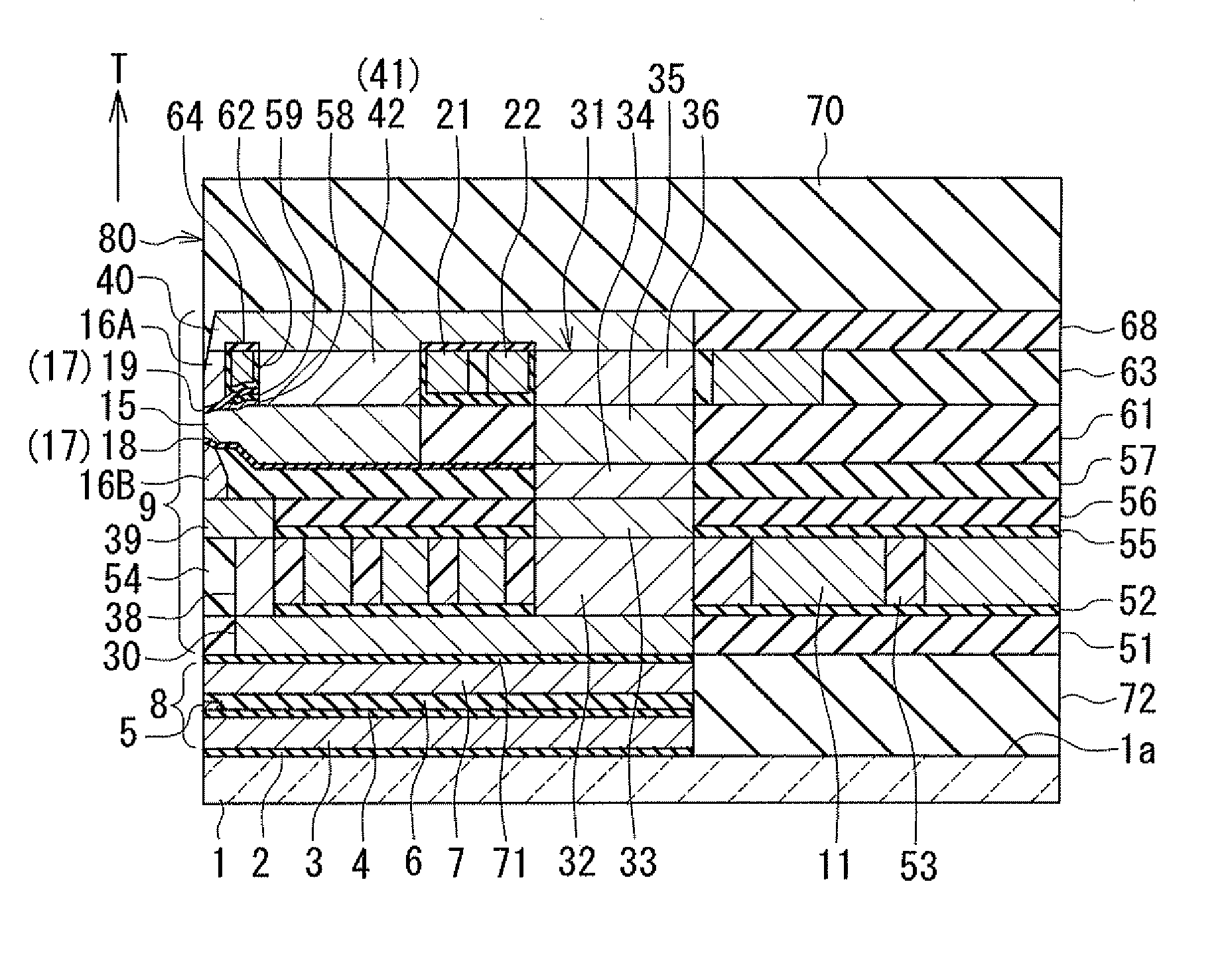

ActiveUS20040196590A1Shorten the length of the magnetic circuitExcellent writing characteristicConstruction of head windingsNanomagnetismElectrical conductorEngineering

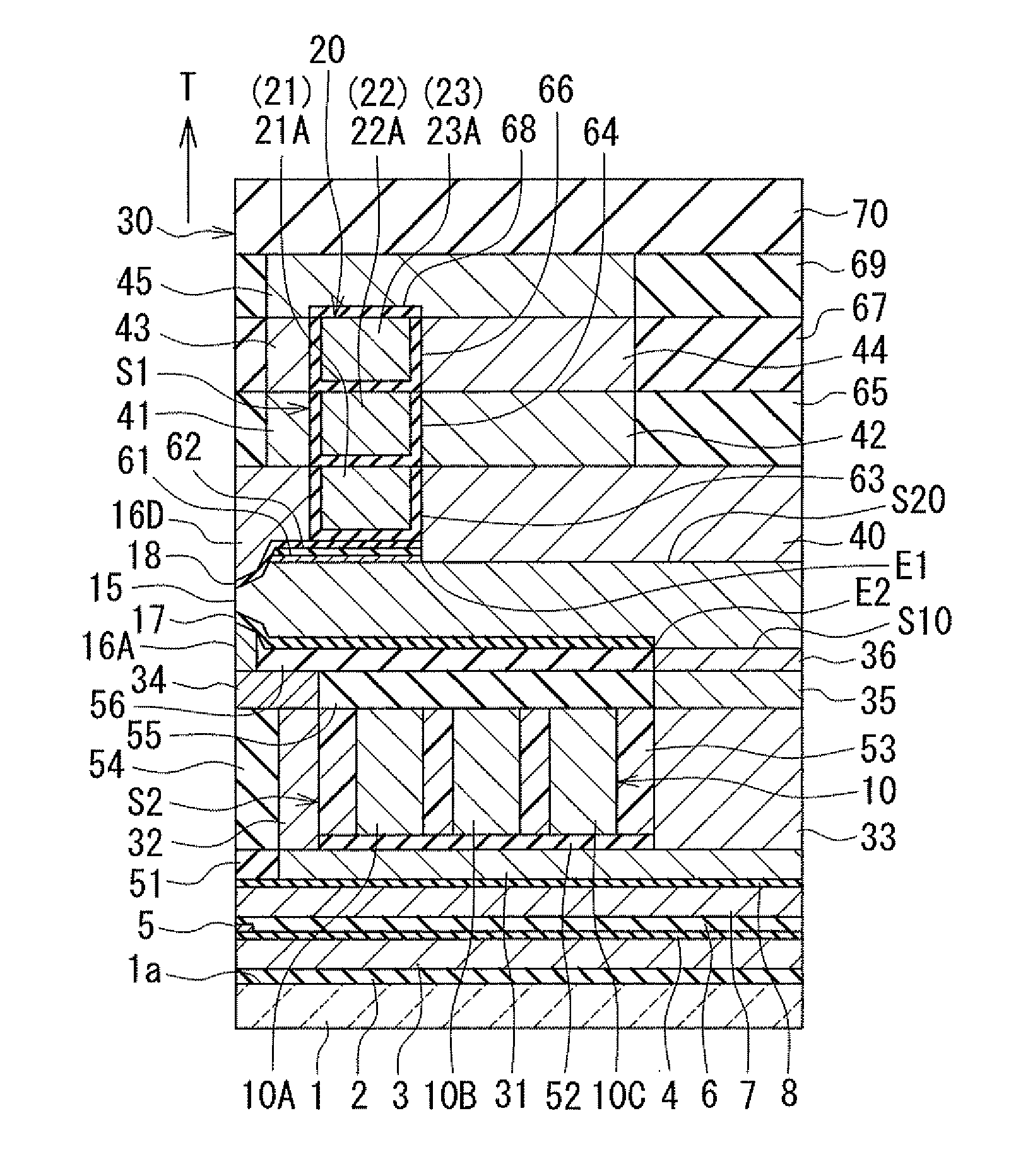

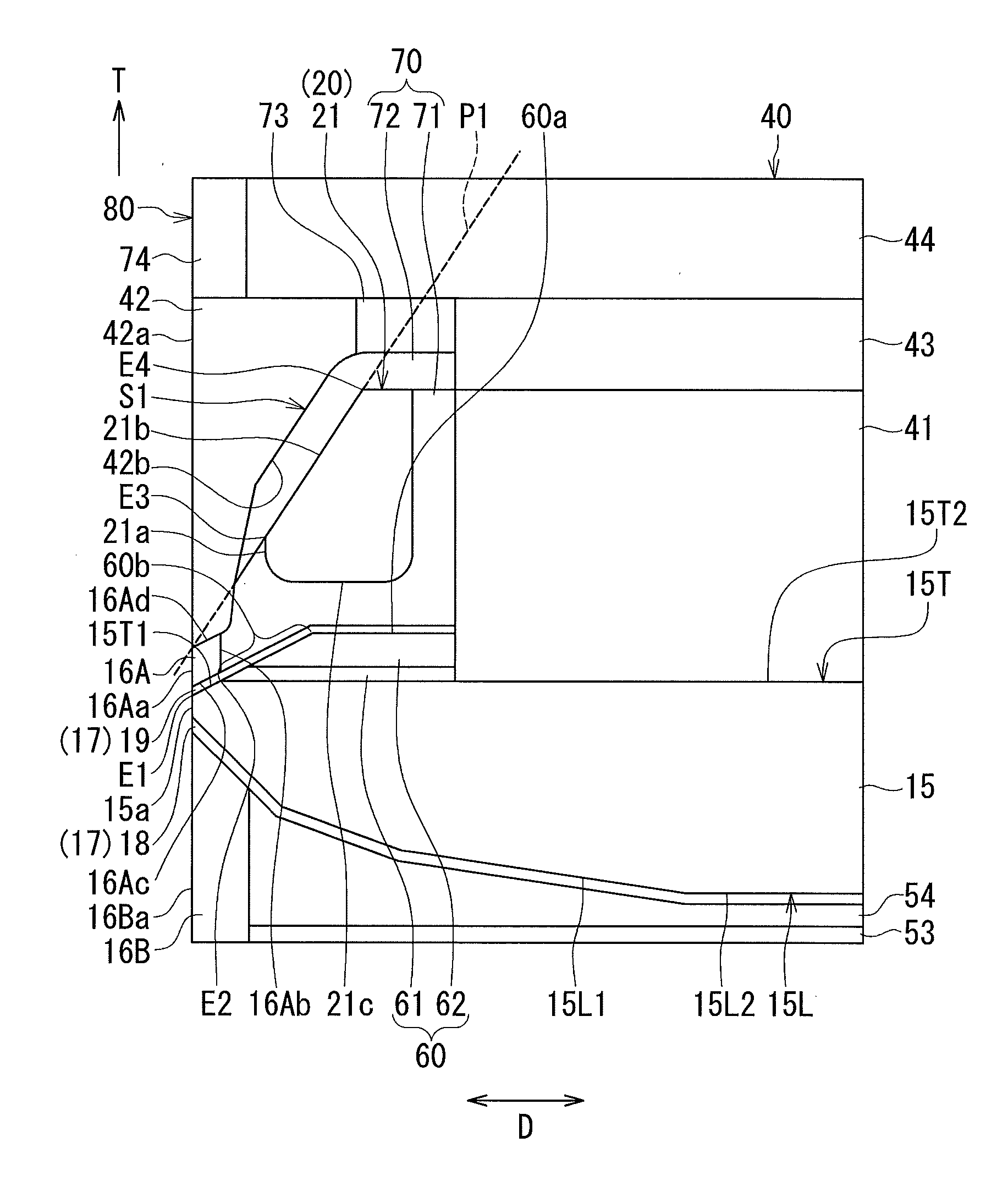

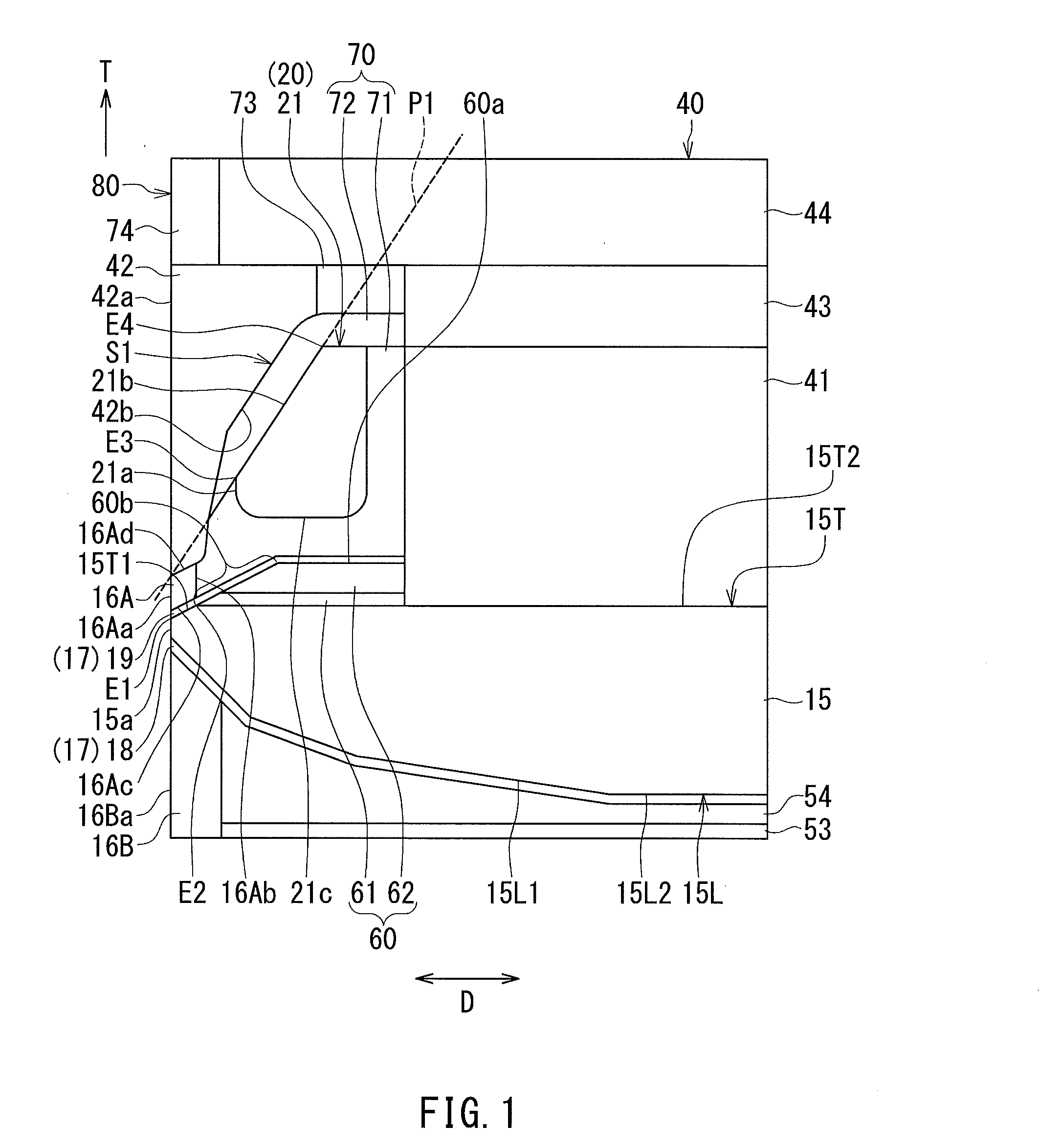

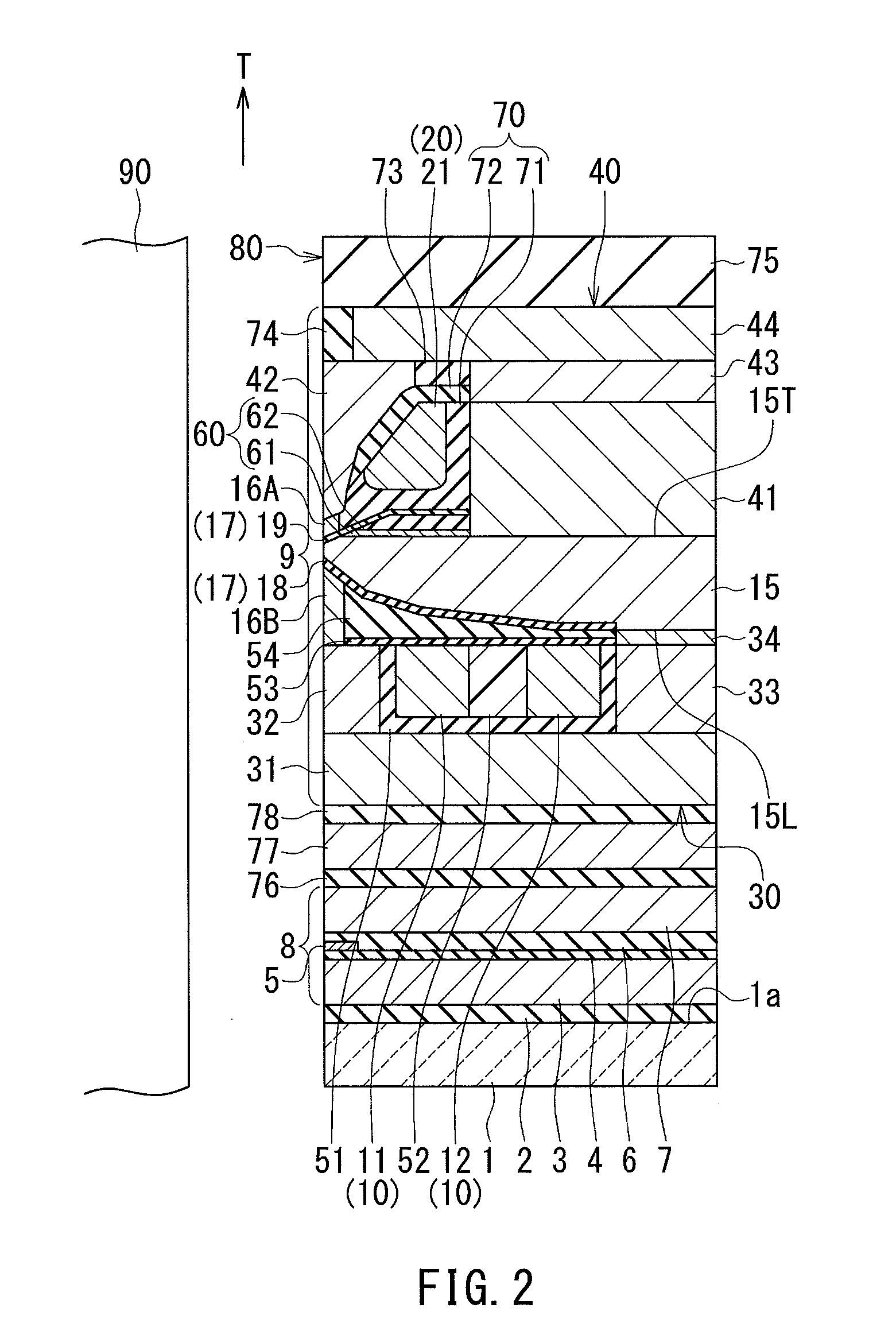

A thin-film magnetic head comprises a bottom pole layer, a top pole layer, a recording gap layer, and a thin-film coil. The thin-film coil is wound in a helical manner around the top pole layer while the coil is insulated from the bottom pole layer and the top pole layer. The thin-film coil includes a plurality of inner conductor portions, a plurality of outer conductor portions, and a plurality of connecting portions that connect the inner conductor portions to the outer conductor portions. The inner conductor portions are disposed between the bottom pole layer and the top pole layer. The outer conductor portions are disposed on a side opposite to the inner conductor portions, the top pole layer being disposed in between. A thin insulating film is only provided between adjacent ones of the inner conductor portions.

Owner:HEADWAY TECH INC +1

Magnetic head for perpendicular recording having a plurality of magnetic path portions

ActiveUS8792209B2Shorten the length of the magnetic circuitSufficient magnitudeConstruction of head windingsHeads using thin filmsEngineeringMagnetic flux

Owner:HEADWAY TECH INC +1

Magnetic head for perpendicular magnetic recording having a main pole and a shield

ActiveUS8498077B1Shorten the length of the magnetic circuitSufficient magnitudeConstruction of head windingsRecord information storageCouplingMagnetic poles

A magnetic head includes first to third coils, a main pole, a write shield, first and second yoke layers, and first and second coupling parts. The first and second yoke layers are magnetically connected to the write shield. The first yoke layer is located on the leading side relative to the main pole, whereas the second yoke layer is located on the trailing side relative to the main pole. The first coupling part magnetically couples the main pole and the second yoke layer to each other. The second coupling part magnetically couples the first yoke layer and the second yoke layer to each other. The first coil is wound around the first coupling part, whereas the second and third coils are wound around the second coupling part.

Owner:HEADWAY TECH INC +1

Energy and material saving magnetic ballast or transformer

InactiveCN102360770ASimple processing technologySuitable for mass productionTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresElectrical resistance and conductanceElectrical ballast

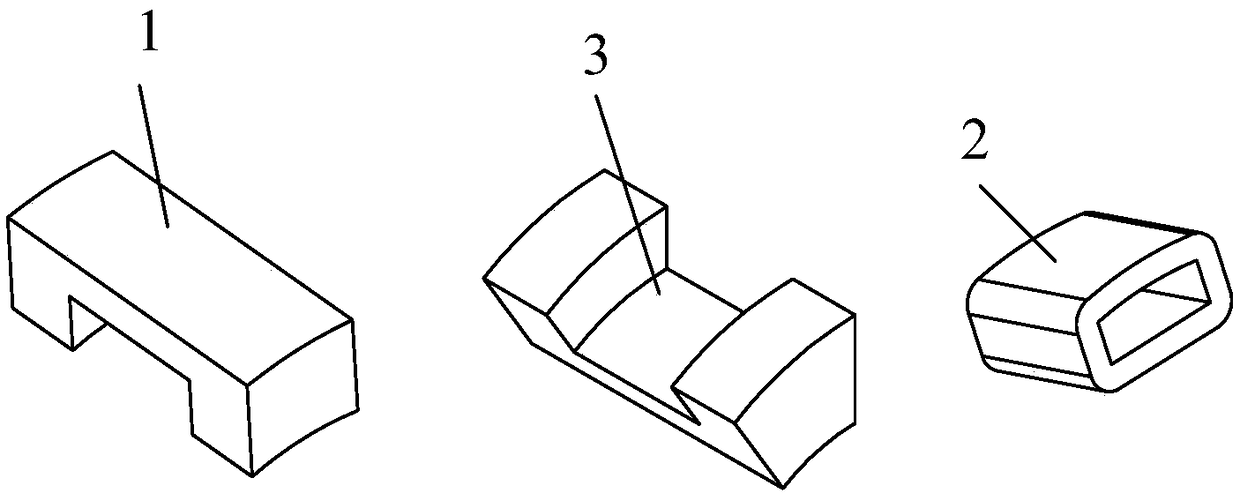

The invention relates to an energy and material saving magnetic ballast or transformer. The magnetic ballast or transformer comprises a magnetic core body and a coil; the magnetic core body is formed by buckling upper and lower E crossed magnetic core bodies which have systematical structures and a magnetic circuit of each magnetic core body is closed; in the upper E crossed magnetic core body or the lower E crossed magnetic core body, the central part is provided with a magnetic core body boss; the periphery corresponding to the magnetic core body boss is provided with vertical magnetic core body side walls; wire insertion grooves are formed between the magnetic core body side walls and the periphery corresponding to the magnetic core body boss; the grooves have groove bottoms; the upper ends of the grooves are provided with openings; and the coil is inserted into whole wire insertion grooves which are formed by bucking the upper and lower E crossed magnetic core bodies which have systematical structures. Compared with the conventional magnetic ballast or transformer, the energy and material saving magnetic ballast or transformer has the advantages that enamelled wires and silicon sheets are saved, electric resistance and magnetic loss are reduced, and energy consumption is reduced.

Owner:温博

Magnetic head, method for producing same, and magnetic recording and/or reproducing system

InactiveUS7100267B2Improve efficiencyShorten the lengthVacuum evaporation coatingSputtering coatingLight beamEngineering

A method for producing a magnetic head, including the steps of forming a magnetic body on a substrate, the magnetic body including a principal plane facing the substrate and a rear plane opposite to the principal plane; applying a beam to the rear plane of the magnetic body and forming a portion defining a hole extending from the rear plane to the principal plane; forming a magnetic gap in the hole; and separating the magnetic body and the magnetic gap from the substrate and forming medium facing surface substantially coplanar with the principal plane.

Owner:KK TOSHIBA

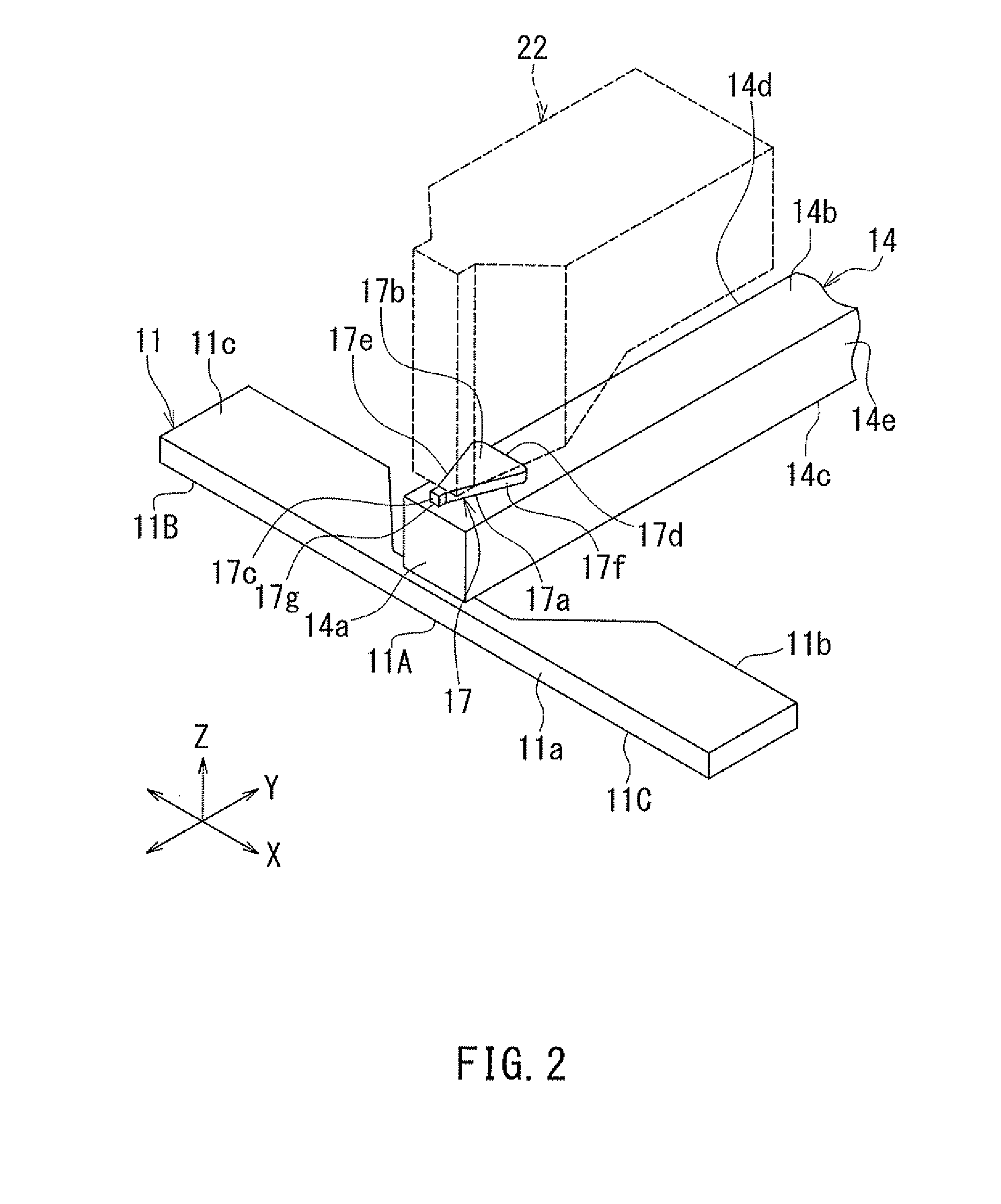

Magnetic head for perpendicular magnetic recording including a coil having an inclined surface

ActiveUS20160275970A1Avoid it happening againShorten the length of the magnetic circuitConstruction of head windingsHeads using thin filmsEngineeringRecording media

Owner:HEADWAY TECH INC

Method of manufacturing combination type thin film magnetic head

InactiveUS7131186B2Preventing undesired side writingImproved surface recording densityElectrical transducersDecorative surface effectsAir bearing surfaceEngineering

On a surface of a bottom pole, a write gap film and first magnetic material film having a high saturation magnetic flux density are formed, and the first magnetic material film is etched to remain a portion extending from an air bearing surface to a throat height zero reference position and a first non-magnetic film is formed in a removed portion. The first non-magnetic material film is polished to obtain a flat surface which is coplanar with a surface of the first magnetic material film. A second magnetic material film having a high saturation magnetic flux density is formed on the flat surface. The second magnetic material film, first magnetic material film, write gap film and bottom pole are partially removed by RIE using a mask formed on the flat surface.

Owner:HEADWAY TECH INC +1

Thin-film magnetic head and method of manufacturing same, and thin-film magnetic head substructure

InactiveUS6987645B2Shorten the length of the magnetic circuitExcellent writing characteristicConstruction of head windingsNanomagnetismElectrical conductorEngineering

A thin-film magnetic head comprises a bottom pole layer, a top pole layer, a recording gap layer, and a thin-film coil. The thin-film coil is wound in a helical manner around the top pole layer while the coil is insulated from the bottom pole layer and the top pole layer. The thin-film coil includes a plurality of inner conductor portions, a plurality of outer conductor portions, and a plurality of connecting portions that connect the inner conductor portions to the outer conductor portions. The inner conductor portions are disposed between the bottom pole layer and the top pole layer. The outer conductor portions are disposed on a side opposite to the inner conductor portions, the top pole layer being disposed in between. A thin insulating film is only provided between adjacent ones of the inner conductor portions.

Owner:HEADWAY TECH INC +1

Magnetic head for perpendicular magnetic recording including a coil having an inclined surface

ActiveUS9741370B2Avoid it happening againShorten the length of the magnetic circuitConstruction of head windingsHeads using thin filmsEngineeringRecording media

Owner:HEADWAY TECH INC

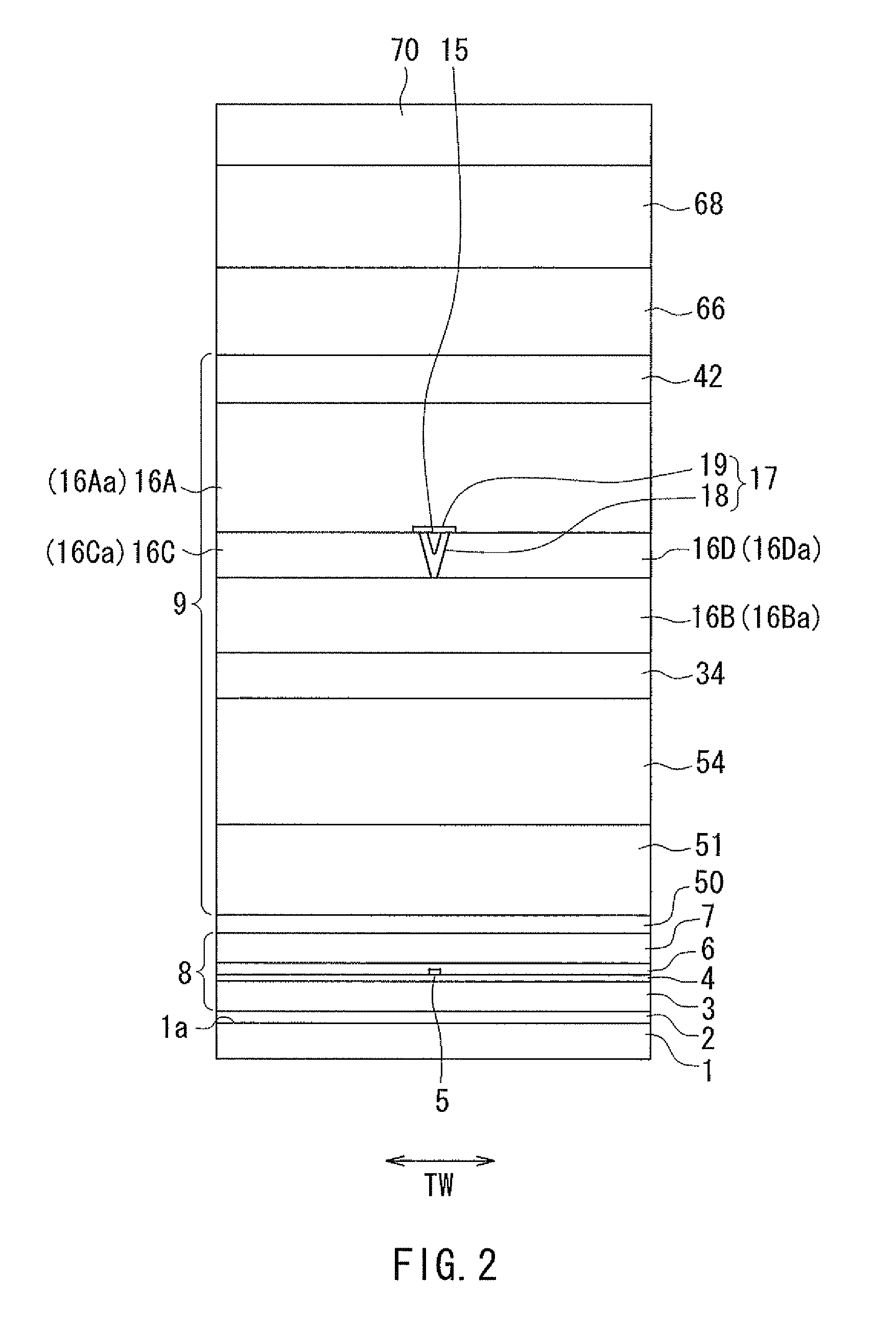

Thin-film magnetic head and method of manufacturing same

ActiveUS7061716B2Small in magnetic path lengthExcellent in recording characteristicConstruction of head windingsNanomagnetismCouplingAir bearing surface

A thin-film magnetic head includes a bottom pole layer, a top pole layer, a recording gap layer, and a thin-film coil. The bottom pole layer has first to fifth layers. The third layer and the fifth layer constitute a coupling portion for establishing magnetic coupling between the bottom pole layer and the top pole layer. The thin-film coil has first to fifth layer portions each of which is made of a flat conductive layer of a single turn. The first to fifth layer portions are laminated, and connected in series to each other. The coupling portion has an end face facing toward the air bearing surface. The end face includes a curved surface convex toward the medium facing surface.

Owner:HEADWAY TECH INC +1

Magnetic head for perpendicular magnetic recording with a coil including a first winding portion of one turn and a second winding portion of less than one turn

ActiveUS9704513B2Shorten the length of the magnetic circuitLarge magnetomotive forceConstruction of head windingsHeads using thin filmsMagnetic polesEngineering

Owner:HEADWAY TECH INC

Magnetic head for perpendicular magnetic recording with a coil including a first winding portion of one turn and a second winding portion of less than one turn

ActiveUS20170125042A1Shorten the length of the magnetic circuitLarge magnetomotive forceConstruction of head windingsRecord information storageEngineeringConductor Coil

Owner:HEADWAY TECH INC

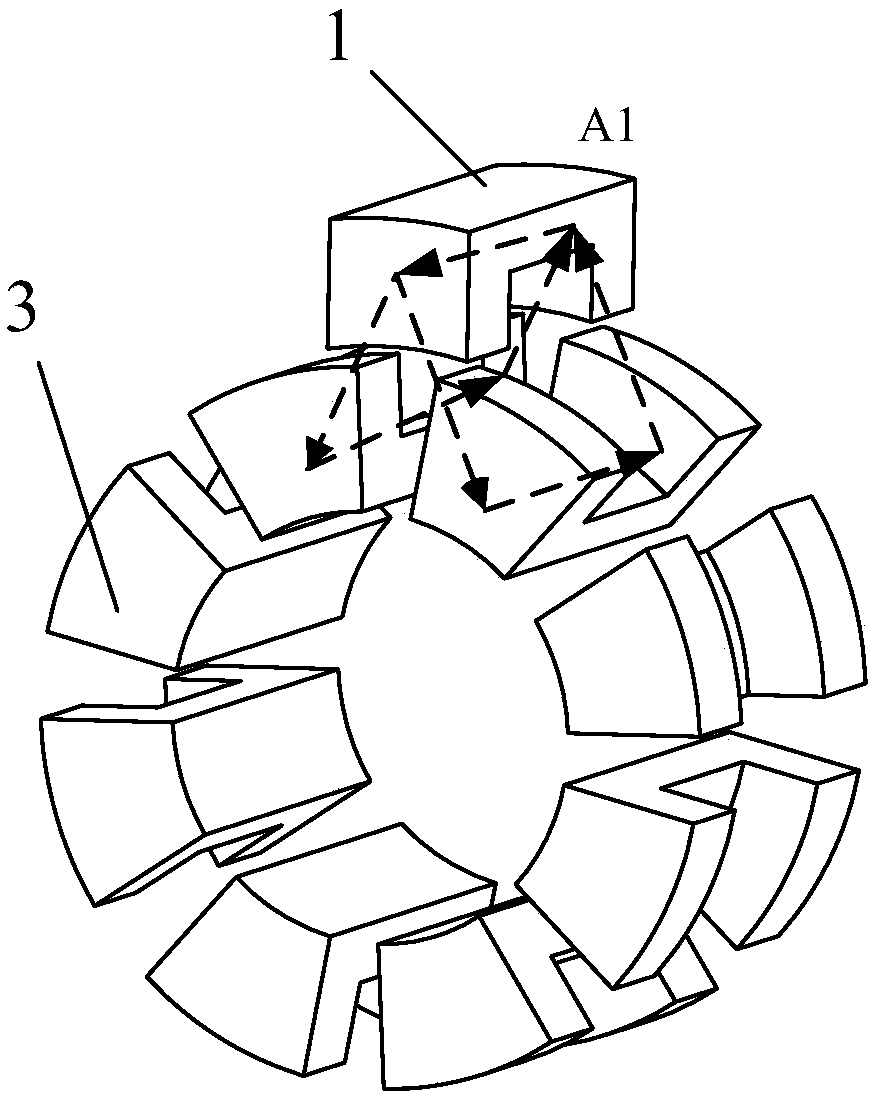

Transverse flux switched reluctance motor and its control method

ActiveCN106849585BReduce complexityReduce the amount of calculationAC motor controlDynamo-electric machinesMagnetic reluctanceNon magnetic

The invention discloses a transverse flux switching reluctance motor and a control method thereof. The motor section comprises stator cores, rotor cores, stator windings, non-magnetic rotor sleeves and bearings. A stator comprises Ns stator cores and Ns circular armature windings embedded in the stator core structures, Ns stator windings can be in symmetrically grouping at the circumference, composing an m-phase winding, wherein Ns=2mk, k is an arbitrary integer greater than 1. A rotor comprises Nr rotor cores, and each rotor core is uniformly disposed on the non-magnetic rotor sleeve at the circumference, wherein Nr=Ns+ / -2k. Each phase of winding is independently energized with direct current in sequence according to the calculated conduction and the extinction angle, forming a reluctance torque of the motor to drive the rotation of the motor. The transverse flux motor is composed of the arrangement of the stator and the rotor and the main flux path, making the inexistence of mutual inductance in the motor. Furthermore, combined with electrification sequence and method of each phase of the winding of the motor, the change of the reluctance of motor for driving of the rotation of motor is achieved, and the power density of motor is raised.

Owner:NANJING UNIV OF SCI & TECH

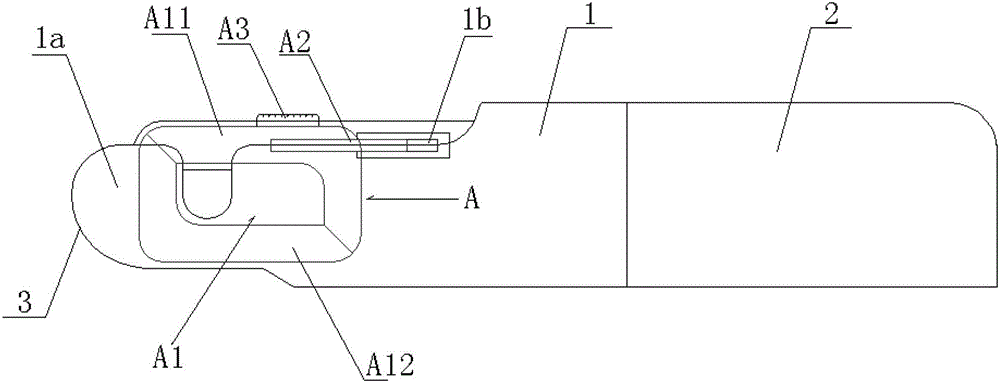

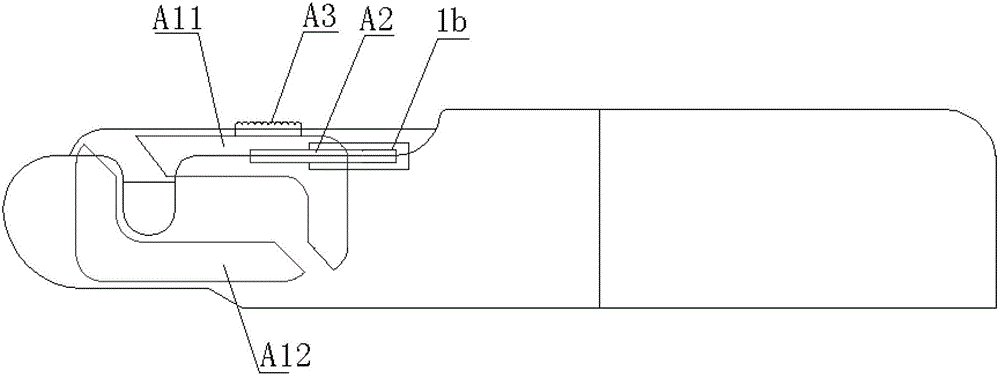

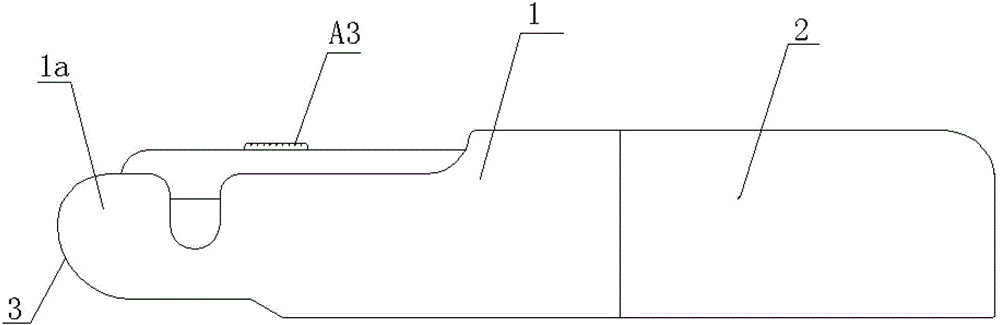

A small current clamp for on-site calibration of live measurement

ActiveCN103048518BChange the problem that the volume is too largeSolve the inconvenienceCurrent/voltage measurementEmbedmentMeasurement precision

The invention provides a small type current clamp for the checking of a live line measurement scene, wherein one end of a current clamp body is arranged in a clamp body jacket; the other end of the current clamp body stretches out of the clamp body jacket; a clamp body embedment is arranged at an out-stretching current clamp head; a clamp body sliding chute in the same direction with a clamp body is formed in the middle part of an out-stretching end of the current clamp body; the interior of the current clamp head is provided with a measurement magnetic core component which can move left and right along the clamp body sliding chute; and a dynamic magnetic arm and a static magnetic arm of the component are closed to form a closed magnetic circuit and are opened to cause the whole closed magnetic circuit to be disconnected. With the adoption of the small type current clamp for the checking of the live line measurement scene, the problem that due to large volume, the current clamp of the prior art is inapplicable for small operation space is solved; moreover, the working position of the measurement magnetic core component extends to the current clamp head from the interior of the current clamp body; in such a way, the length of a magnetic path in the current clamp body is decreased; under the premise of guaranteeing a proportion between the cross section of the magnetic path and the magnetic path length, the measurement precision of the current clamp is guaranteed; and therefore, the small type current clamp for the checking of the live line measurement scene is applicable for the field of various live line measurements.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

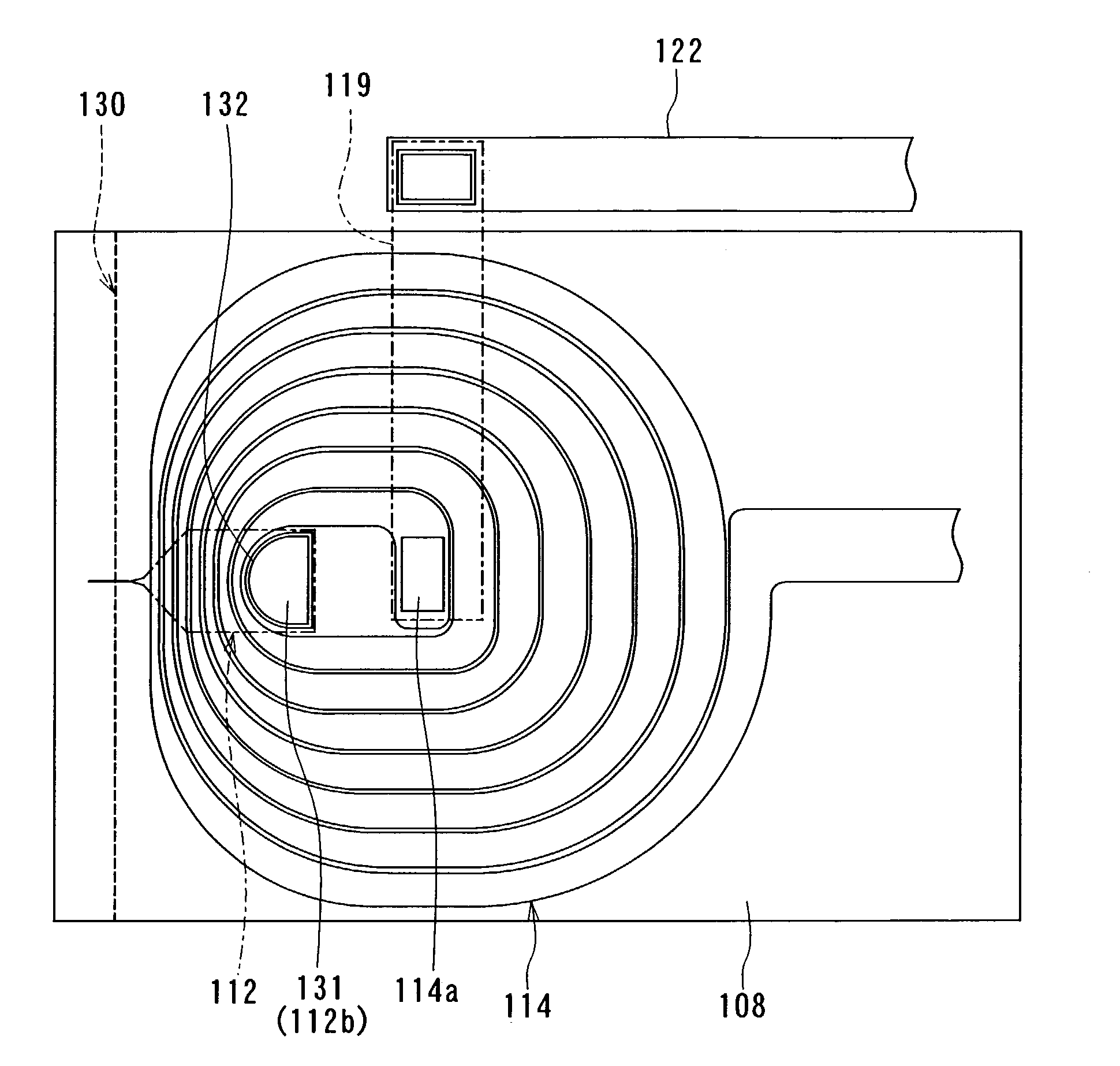

Thermally-assisted magnetic recording head having a plasmon generator

ActiveUS9013964B2Excellent write characteristicLower resistanceCombination recordingRecord information storageHeat-assisted magnetic recordingPlasma generator

A return path section includes first and second yoke portions and first, second and third columnar portions. The first and second yoke portions and the first columnar portion are located on the same side in the direction of travel of the recording medium relative to a wave guide core. The second and third columnar portions are located on opposite sides of a plasmon generator and connected to a shield. The first yoke portion connects a main pole to the first columnar portion. The second yoke portion connects the first columnar portion to the second and third columnar portions. A coil is wound around the first columnar portion.

Owner:HEADWAY TECH INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com