Transverse flux switched reluctance motor and its control method

A switched reluctance motor and transverse flux technology, applied in the direction of AC motor control, control systems, electromechanical devices, etc., can solve the problems of excessive length of motor ends, noise and vibration, and large magnetic flux leakage, so as to improve efficiency and reduce Loss, the effect of increasing the power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

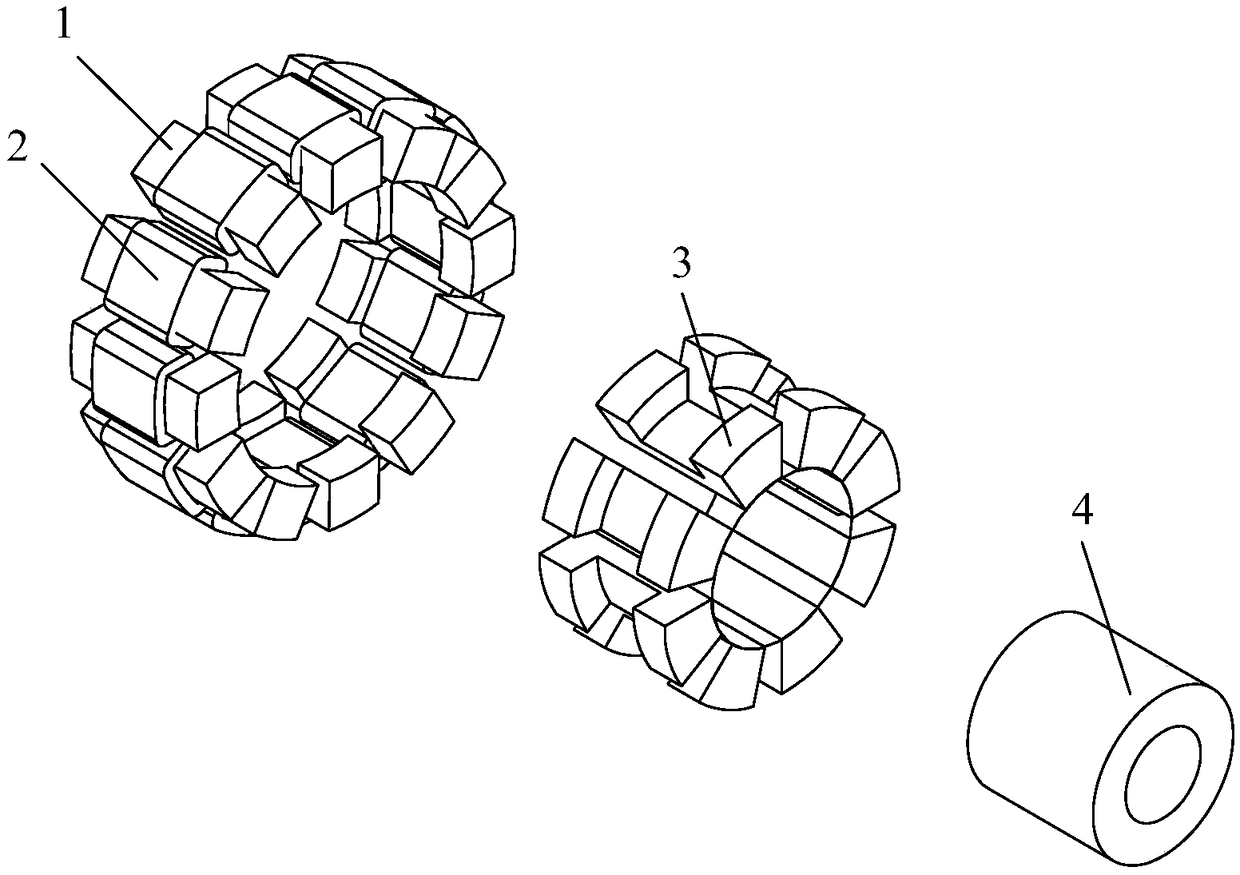

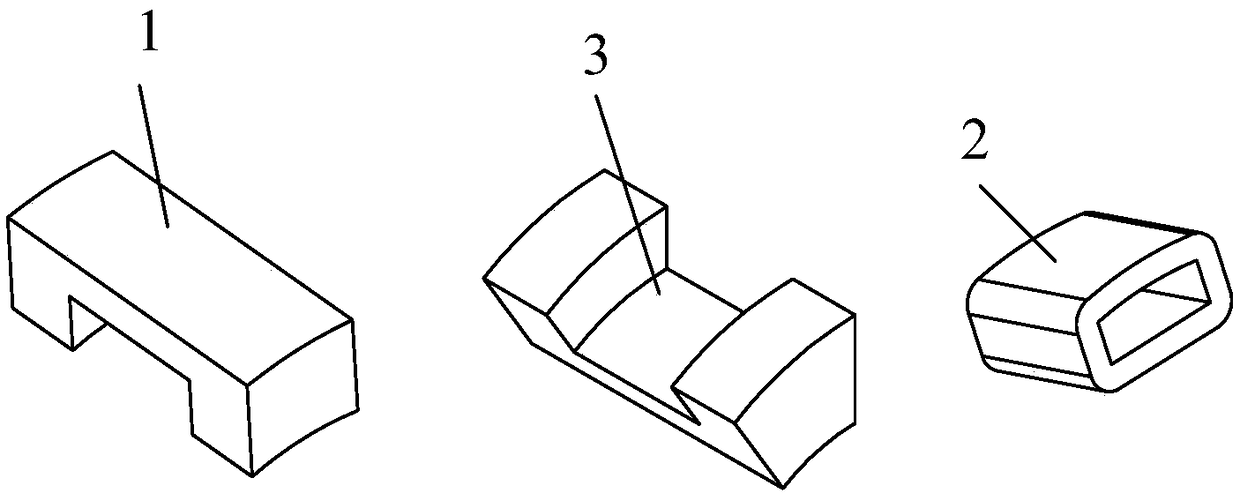

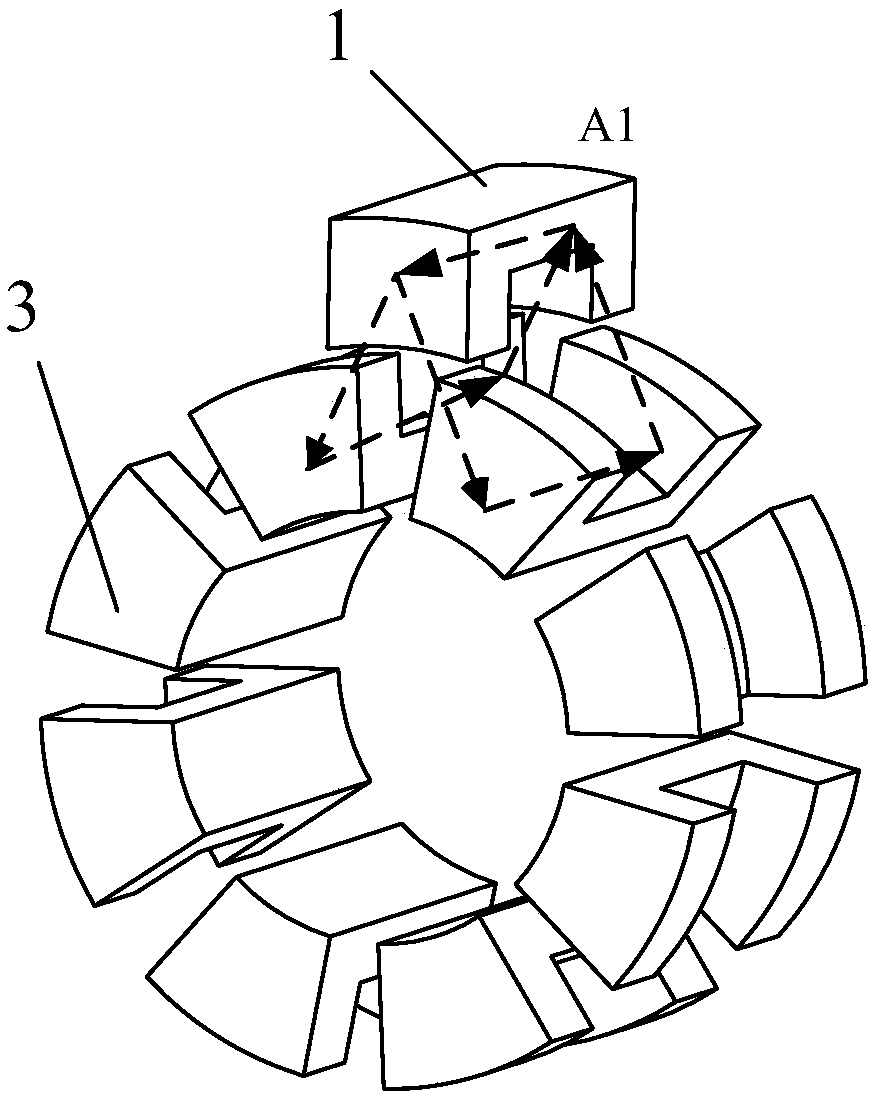

[0032] combine Figure 1-Figure 4 , for a 12 / 8 inner rotor three-phase transverse flux switched reluctance motor, the solid model of the motor is mainly composed of the following parts: stator core 1, stator armature winding 2, rotor core 3 and magnetic material rotor The sleeve consists of 4. Each stator is composed of stator core 1 and stator armature winding 2, and is evenly arranged along the circumferential direction. Each stator core 1 has the same size, and is made of silicon steel sheets, and is pasted and installed in a non-magnetic material sleeve with glue to form a The stator as a whole; the stator armature winding 2 adopts a centralized annular armature winding, and is wound in the U-shaped slot of the stator core 1, and is separated by three armature windings to form a phase; the rotor part includes rotor cores uniformly arranged along the circumferential direction 3 and non-magnetically conductive rotor cylinder 4, each rotor core 4 has the same size, and is ma...

Embodiment 2

[0034] combine Figure 1-Figure 4 , for the 12 / 8 inner rotor six-phase transverse flux switched reluctance motor, the solid model of the motor is mainly composed of the following parts: stator core 1, stator armature winding 2, rotor core 3 and magnetic material rotor The sleeve consists of 4. Each stator is composed of stator core 1 and stator armature winding 2, and is evenly arranged along the circumferential direction. Each stator core 1 has the same size, and is made of silicon steel sheets, and is pasted and installed in a non-magnetic material sleeve with glue to form a The stator as a whole; the stator armature winding 2 adopts a centralized annular armature winding, and is wound in the U-shaped slot of the stator core 1, and is separated by 6 armature windings to form a phase; the rotor part includes rotor cores uniformly arranged along the circumferential direction 3 and non-magnetically conductive rotor cylinder 4, each rotor core 4 has the same size, and is made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com