Follow-up intermediate-frequency inductor

An inductor and intermediate frequency technology, applied in the field of follow-up intermediate frequency inductors, can solve the problems affecting the quality of intermediate frequency quenching of spherical flat steel, the working state is not very stable, and the cost of equipment is high, so as to achieve hardness and performance, low production cost, The Effect of Improving the Quality of Power Frequency Quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

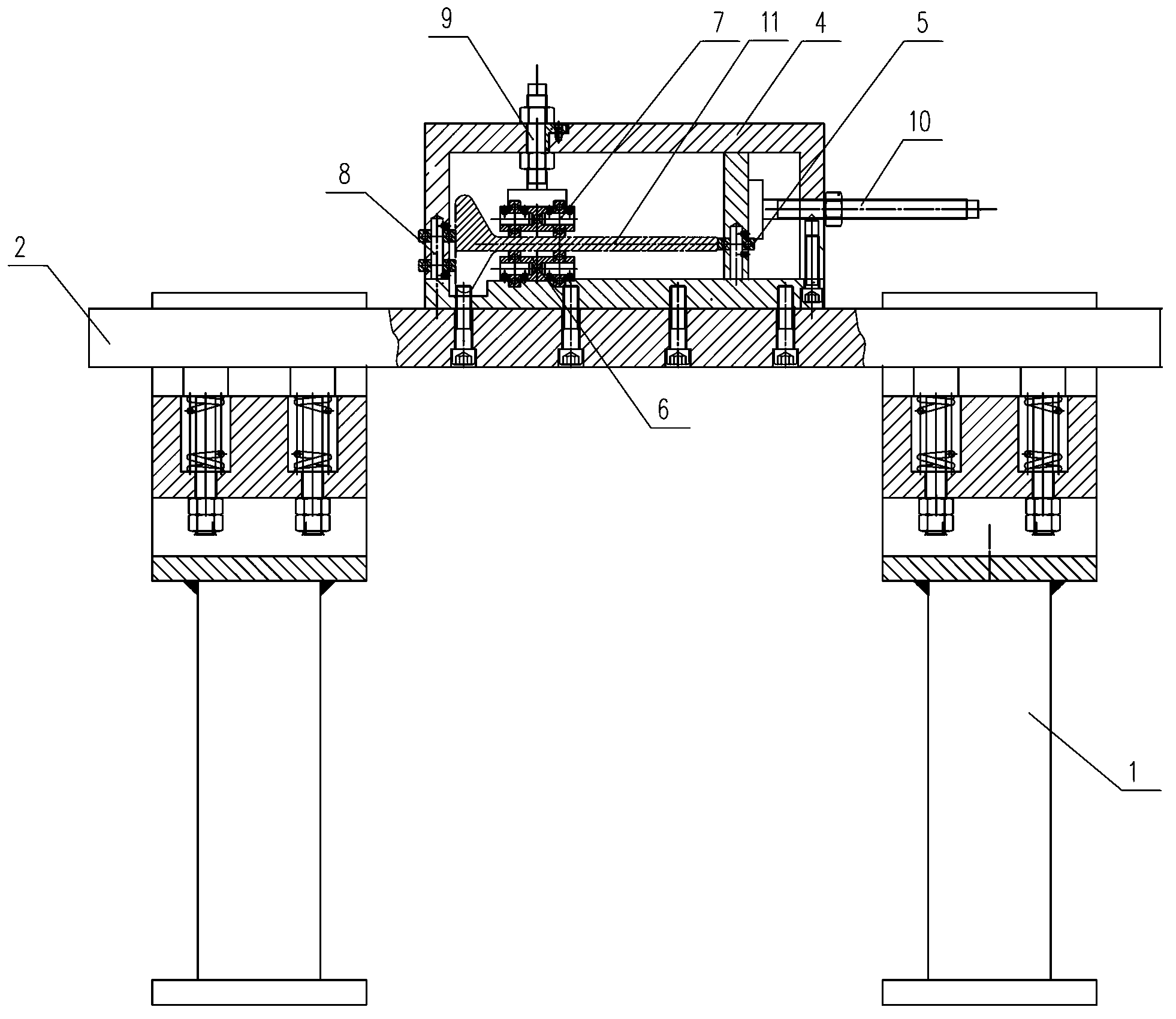

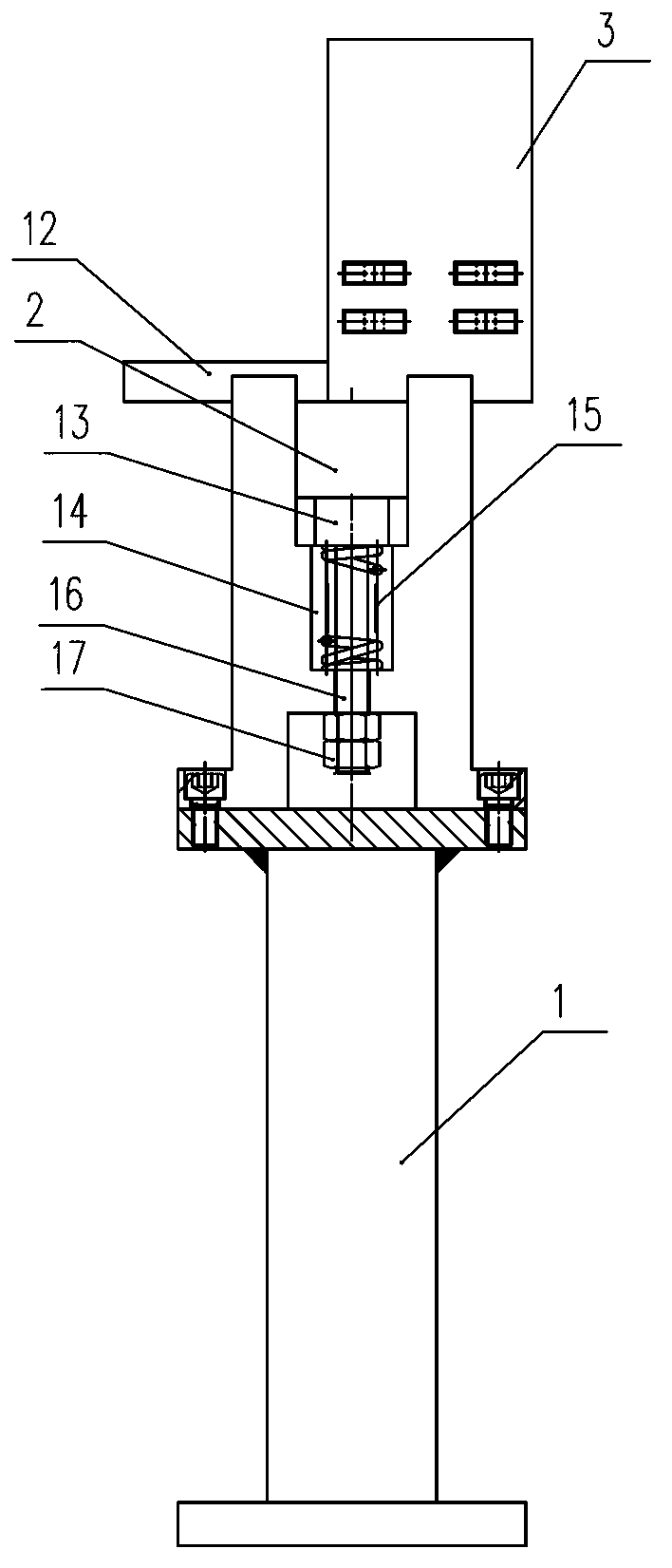

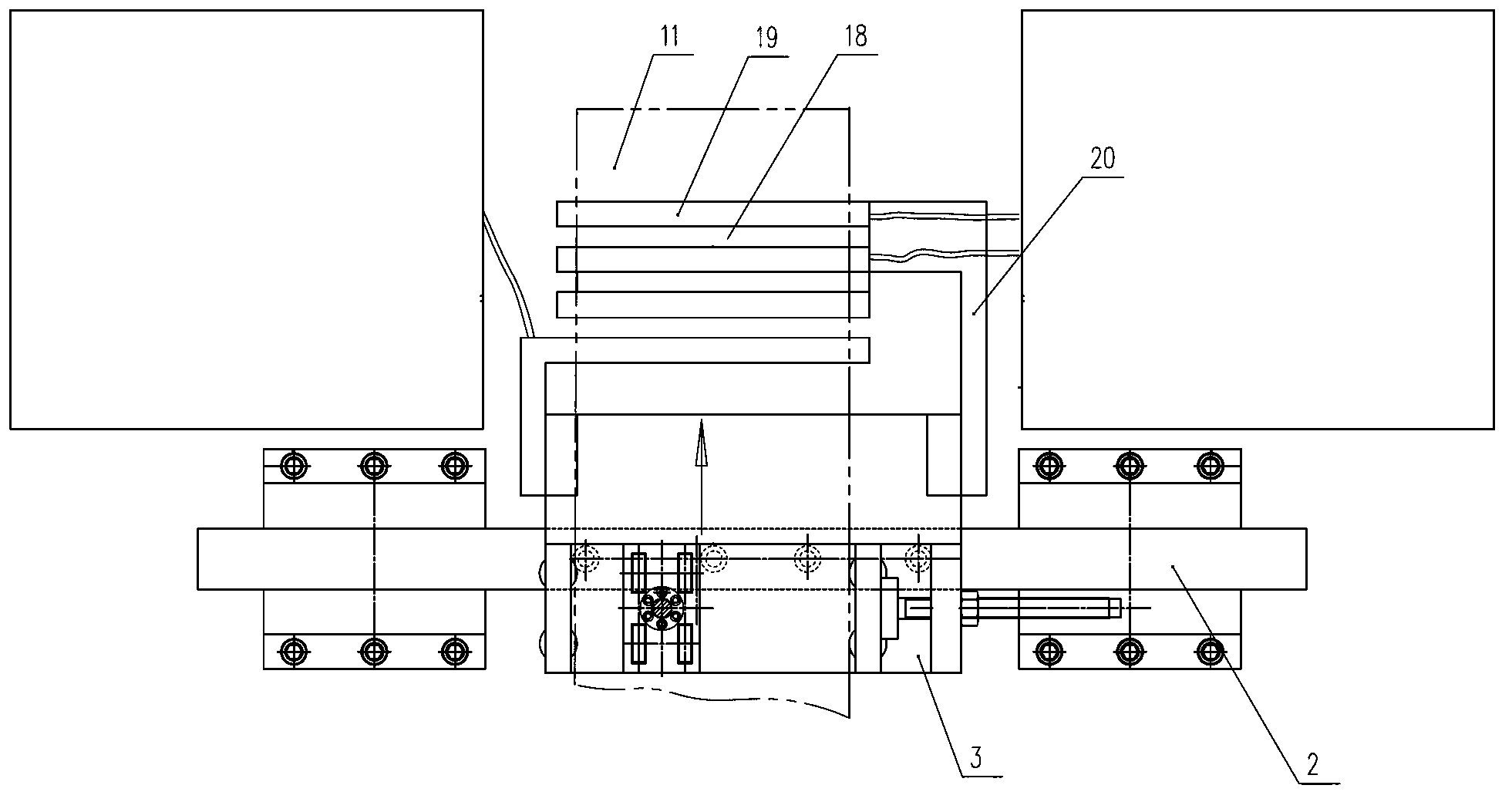

[0014] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0015] See Figure 1-Figure 3 , is a structural diagram of an embodiment of a follow-up intermediate frequency sensor of the present invention, including an induction head 18, a bracket 1, a floating beam 2 and a positioning device 3, the bottom of the floating beam 2 is provided with a bracket 1, and the upper part of the floating beam 2 is provided with a positioning device 3 , the positioning device includes a frame 4, a side guide roller 5, a support roller 6, an upper roller 7 and a side guide 2 8, the upper roller 7 is connected to the top of the frame 4 through an adjustment frame 9, and the side guide The roller table one 5 is connected to one side of the frame body 4 through the adjustment frame two 10, the support roller table 6 is arranged at the lower part of the frame body 4, the other side of the frame body 4 is provided with the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com