Silicon nitride ceramic substrate of copper-clad plate and preparation method thereof

A technology of copper clad laminate and nitrided ceramic silicon, which is applied in the field of silicon nitride ceramics and its preparation, and can solve the problems of reducing the effective life of devices and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

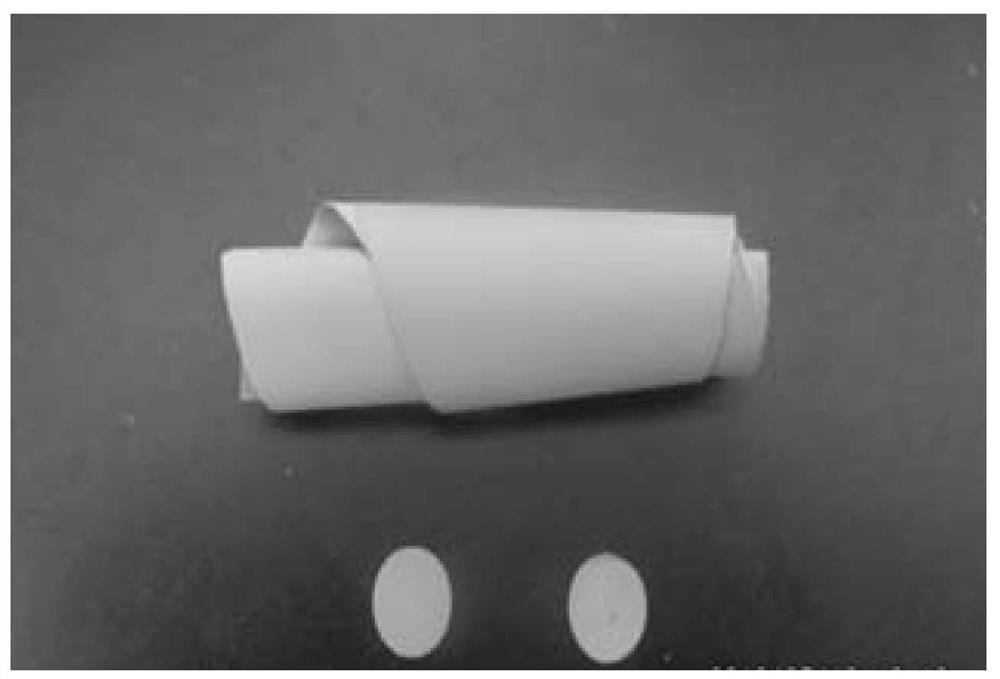

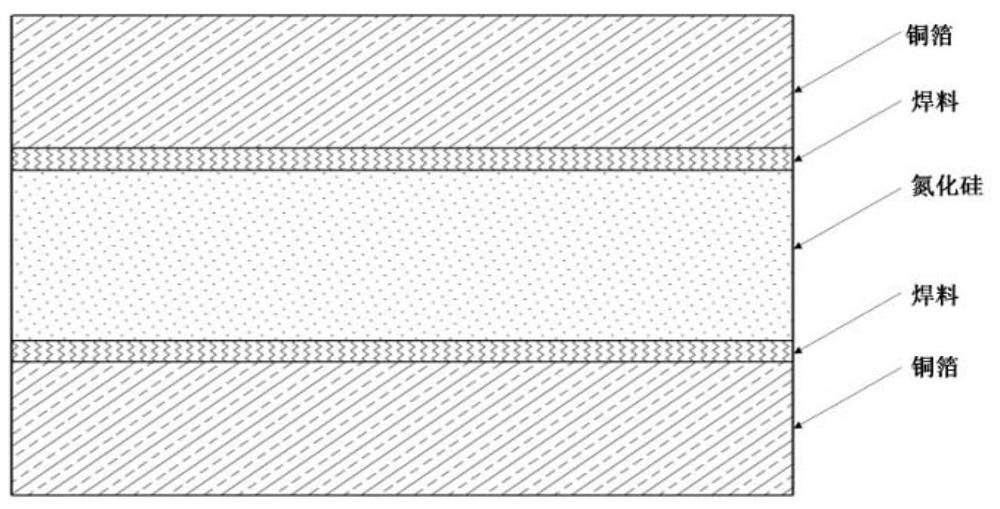

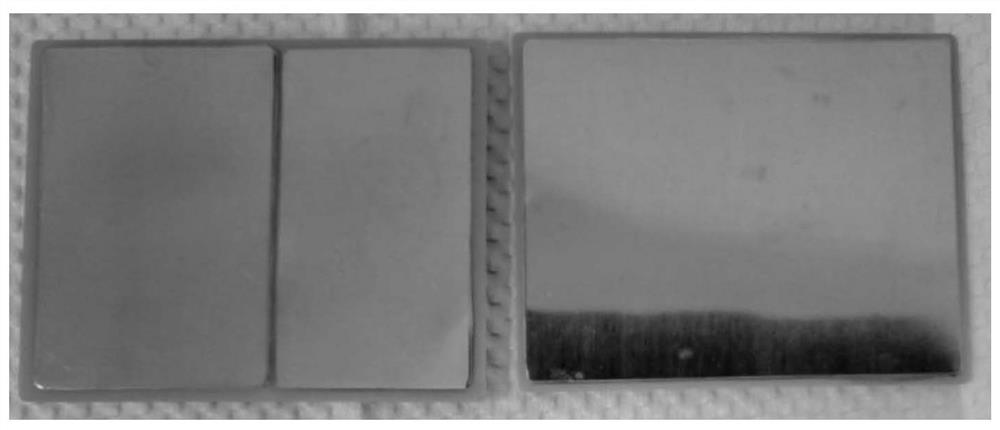

Image

Examples

preparation example Construction

[0050] The preparation method of the silicon nitride ceramic material specifically comprises the following steps: mixing materials under a protective atmosphere and forming a green body, pretreatment under a reducing atmosphere, sintering under a nitrogen atmosphere and controlling the sintering system.

[0051] Mixing under protective atmosphere. The original powder, sintering aid Y 2 o 3 The powder and the MgO powder are added into an airtight container with absolute ethanol as a solvent, mixed evenly under the protection of a protective atmosphere, and then dried to obtain a mixed powder. Alternatively, the original powder, sintering aid Y 2 o 3 The powder and the MgO powder are placed in a closed container, then absolute ethanol is added as an organic solvent, PVB is used as a binder, and then mixed evenly under the protection of a protective atmosphere to obtain a mixed slurry. Wherein, the binder can be 5-9 wt% of the total mass of the original powder + sintering aid...

Embodiment 1

[0071] First, 95g Si 3 N 4 Powder, 5g sintering aid powder (Y 2 o 3 : MgO=1.2:2.5, molar ratio), 1g castor oil, 1g PEG, 70g absolute ethanol and 200g silicon nitride grinding balls are put into the lined polyurethane ball milling tank with atmosphere protection function, and after sealing the ball milling tank cover, pump them out sequentially. Vacuum, N 2 In a protective atmosphere, the slurry was obtained after ball milling and mixing for 6 hours; 5g PVB and 3g DBP were further added to the above slurry, and the 2 Under the protection of the atmosphere, the uniform slurry was obtained after ball milling for 6 hours; secondly, the slurry was vacuum degassed for 6 hours, and the 2 Under the protection of the atmosphere, the substrate green body is tape-casted, and the thickness of the substrate green body is d±0.05mm (d=0.2~2.0); again, the formed substrate green body is cut into the required shape and placed in a BN crucible, and It is packed into a carbon tube furnace; ...

Embodiment 2~5

[0074] Specific parameters such as the ratio of raw materials, composition of sintering aids, pretreatment process, and sintering process are shown in Table 1. The process refers to Example 1. The composition and properties of the prepared materials are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com