Laser welding method and device

A technology of laser welding and laser welding head, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of poor welding quality, achieve the effect of improving welding quality and preventing missing welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

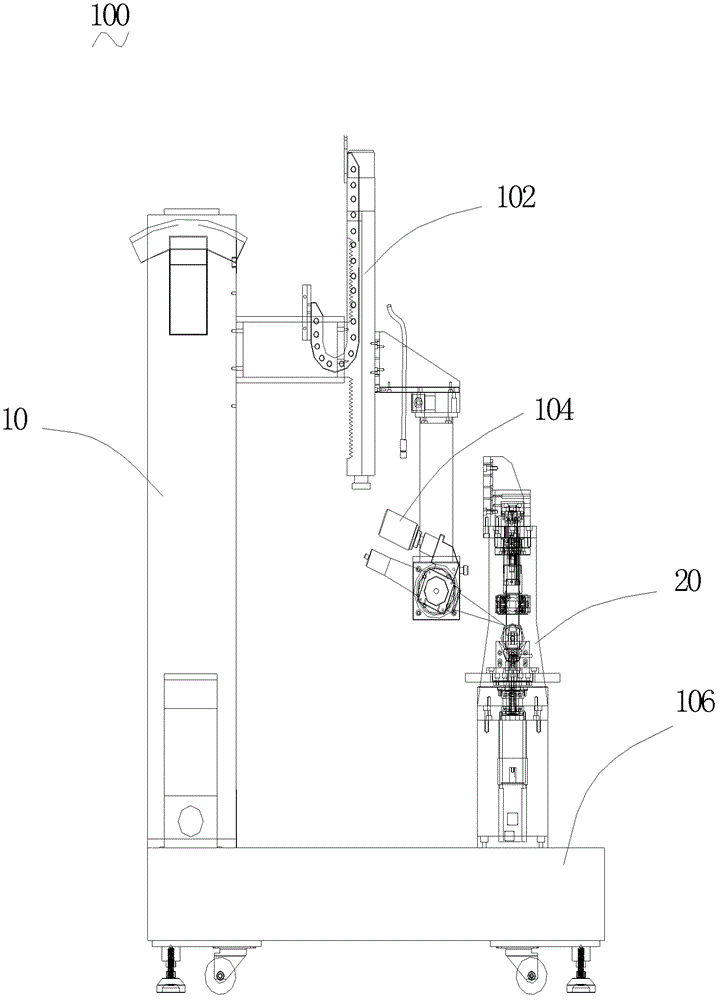

[0021] Based on the fact that laser welding technology can improve the welding quality between the main pipe and the branch pipe of the metal tee pipe, a laser welding method is proposed, which is suitable for welding between the main pipe and the branch pipe of the metal tee pipe, including the following steps:

[0022] a. Make the main pipe and branch pipe of the metal tee pipe ready for welding and rotate them;

[0023] b. The main pipe and the branch pipe are welded together using a laser welding head that performs linear reciprocating motion relative to the plane of rotation of the main pipe.

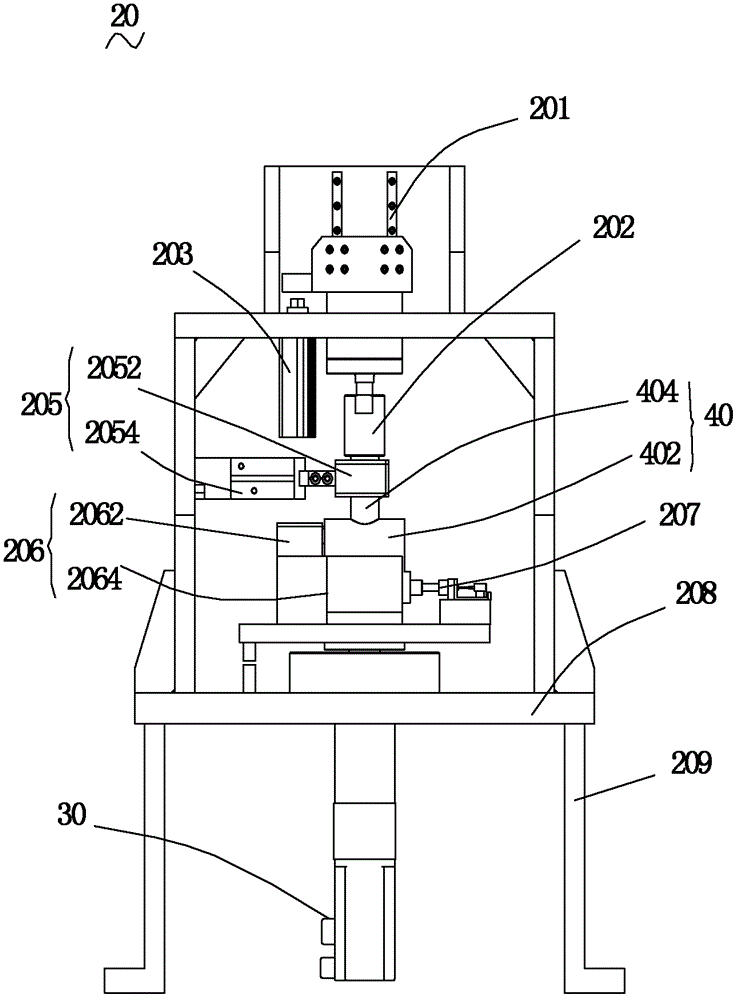

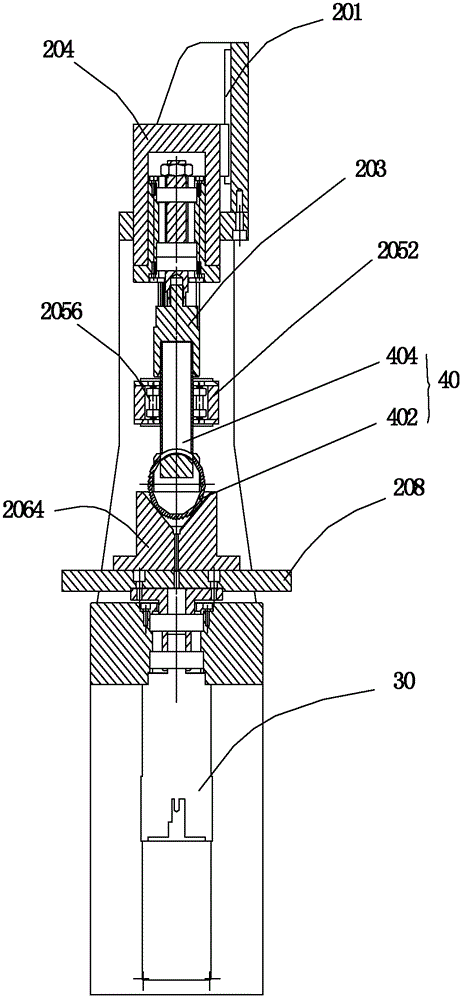

[0024] The laser welding method will be specifically described below in combination with specific embodiments. refer to Figure 1 to Figure 3 , the laser welding method specifically also includes the following steps:

[0025] S101 , a step of inserting the branch pipe 404 into a preset hole on the main pipe 402 . The branch pipe 404 is usually perpendicular to the main pipe 402 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com