Welding online monitoring system

A monitoring system and welding torch technology, applied in the field of welding online monitoring system, can solve the problems of simple function, difficult installation, high cost, etc., and achieve the effect of improving automation, reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

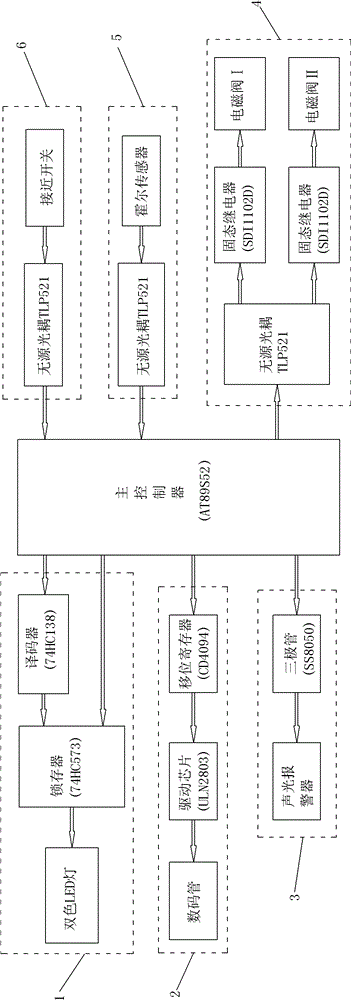

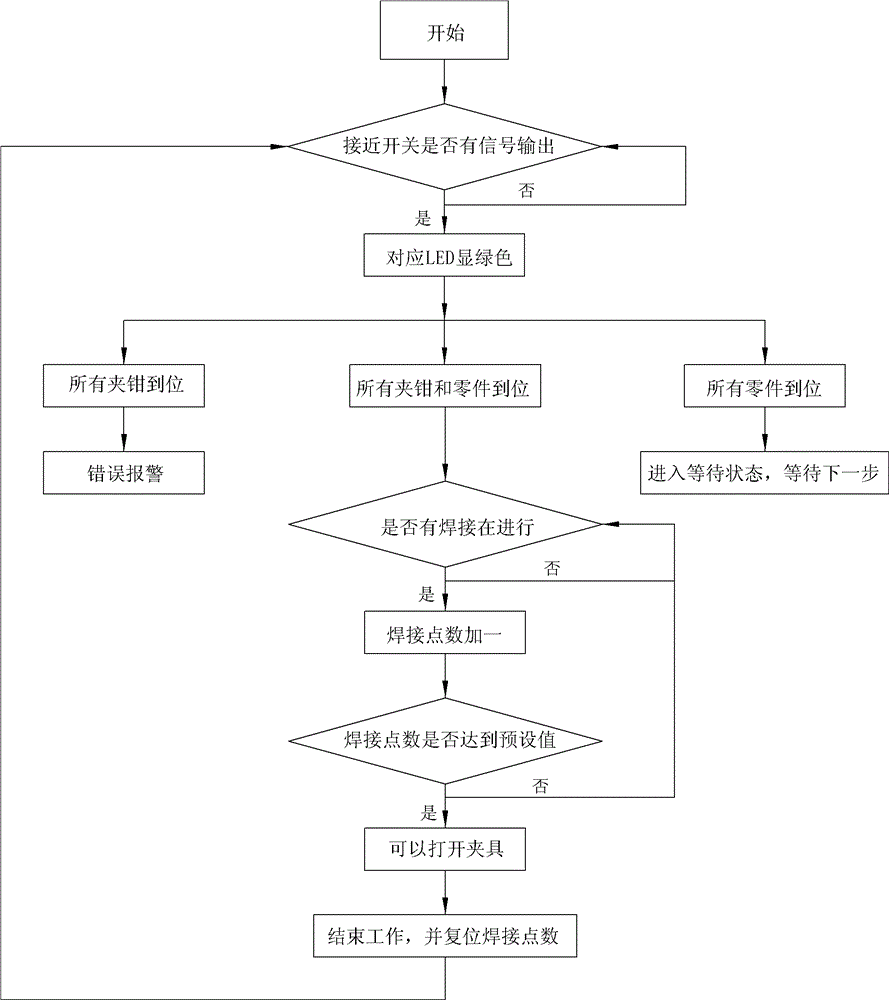

[0025] Such as figure 1 As shown, the welding online monitoring system of the present invention includes a main controller and a positioning detection module 6 respectively connected to the main controller, a welding torch magnetic detection module 5, an alarm module 3, a fixture control module 4, and a panel LED module 1. Nixie tube display module 2. In this embodiment, the main controller is AT89S52. Of course, the main controller is also other single-chip microcomputers with performance similar or identical to AT89S52.

[0026] Described location detection module 6 comprises the proximity switch that is installed on the welding fixture to detect position information and is connected between the proximity switch and the master controller and passes the signal that proximity switch collects to the passive optocoupler TLP521 of master controller, proximity switch The status information of the welding fixture and parts is collected and transmitted to the main controller, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com