Patents

Literature

58results about How to "High degree of full automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-automatic poker machine

InactiveCN102580307AAvoid misidentificationHigh degree of full automationCard gamesEngineeringWaiting time

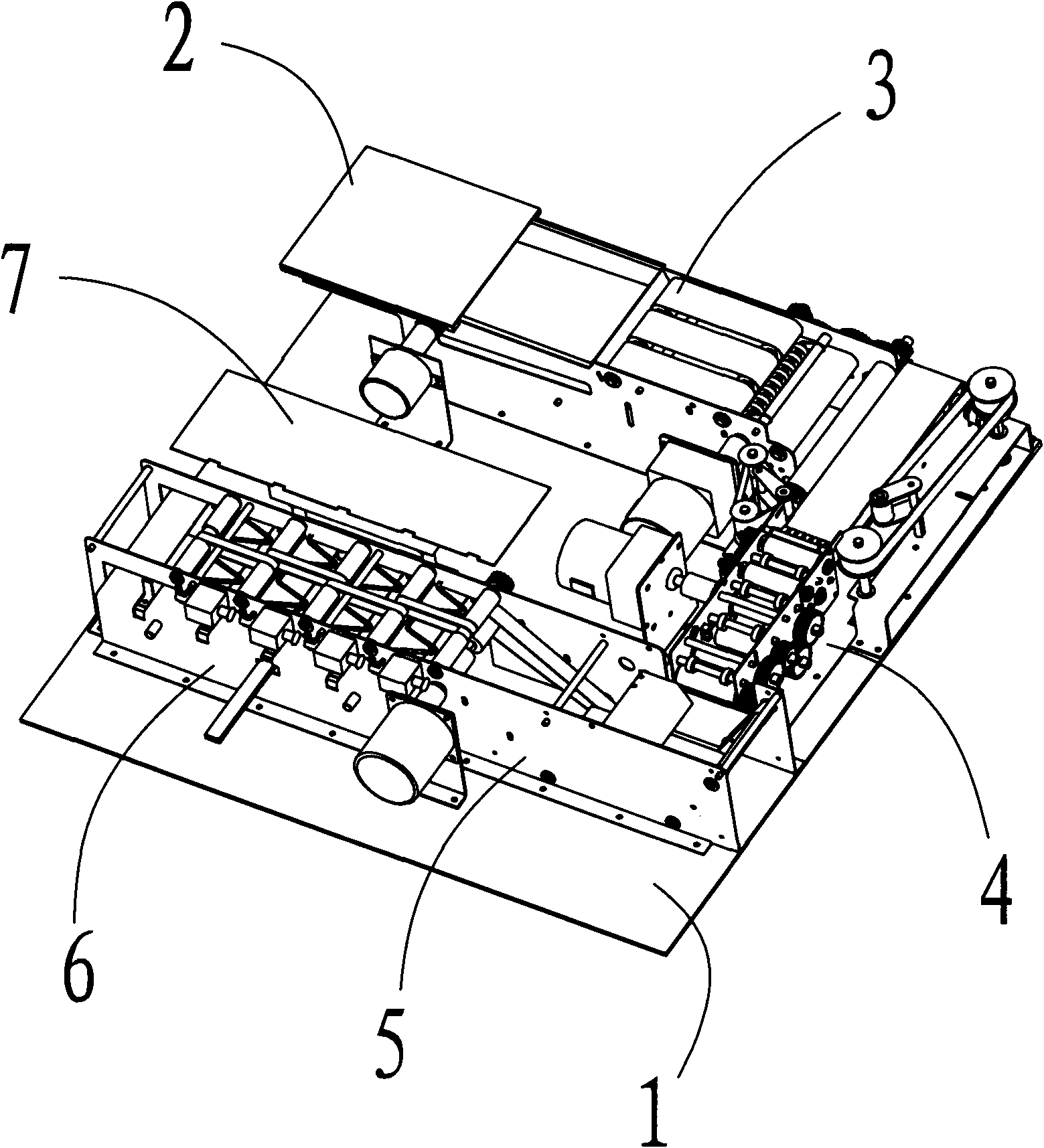

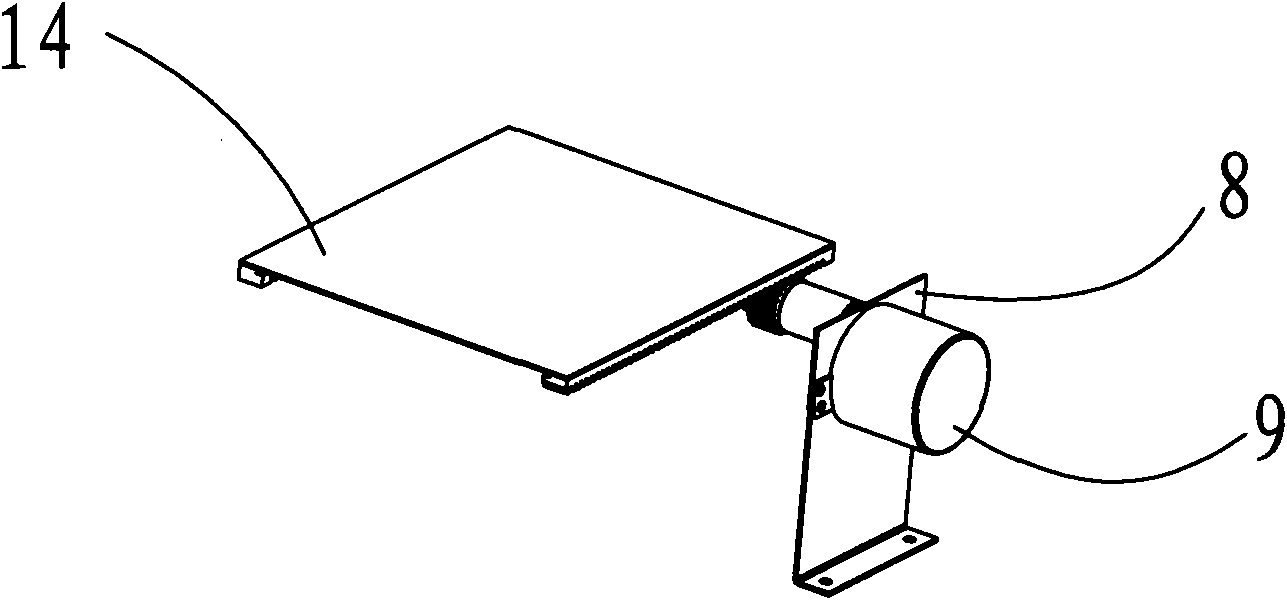

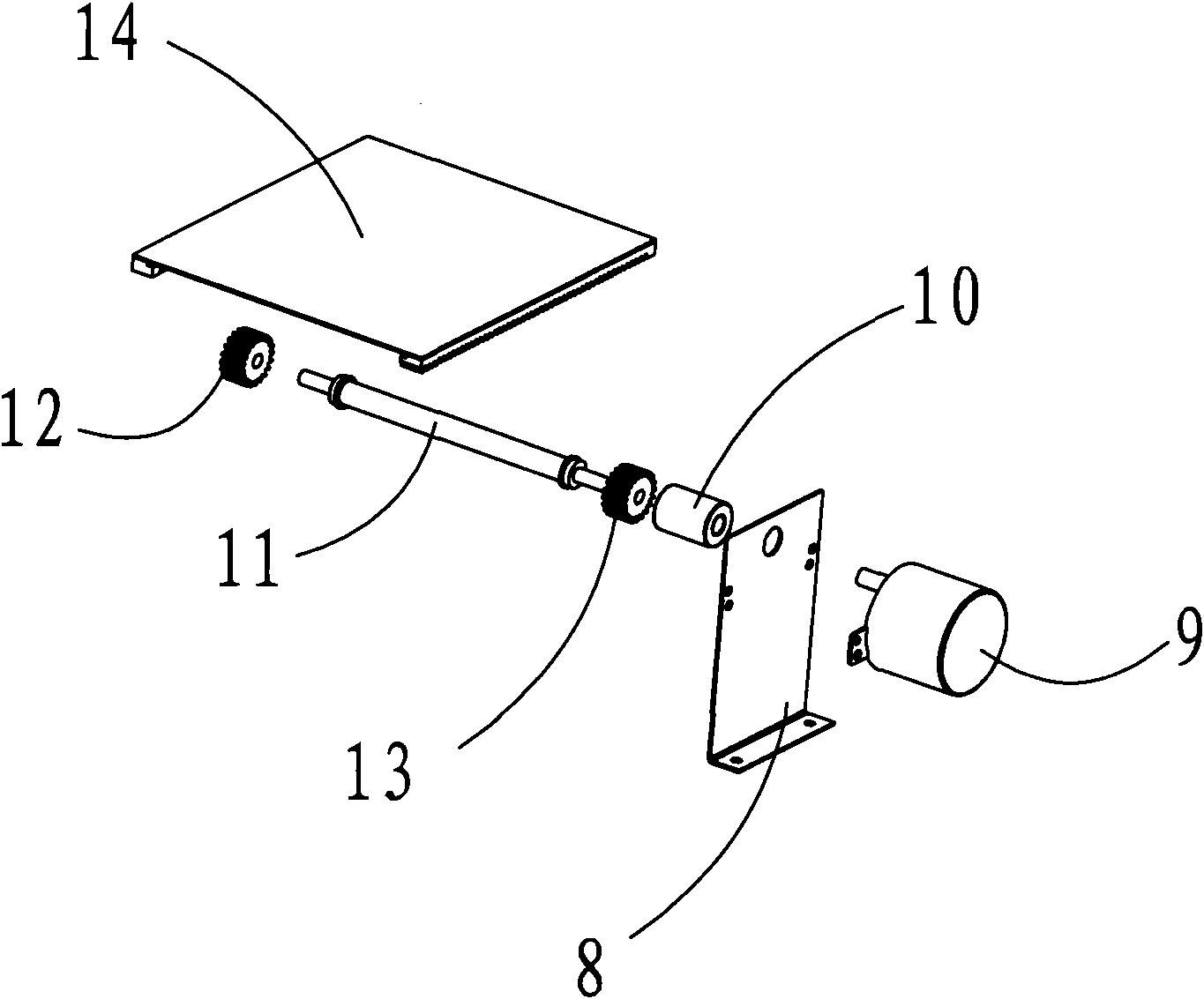

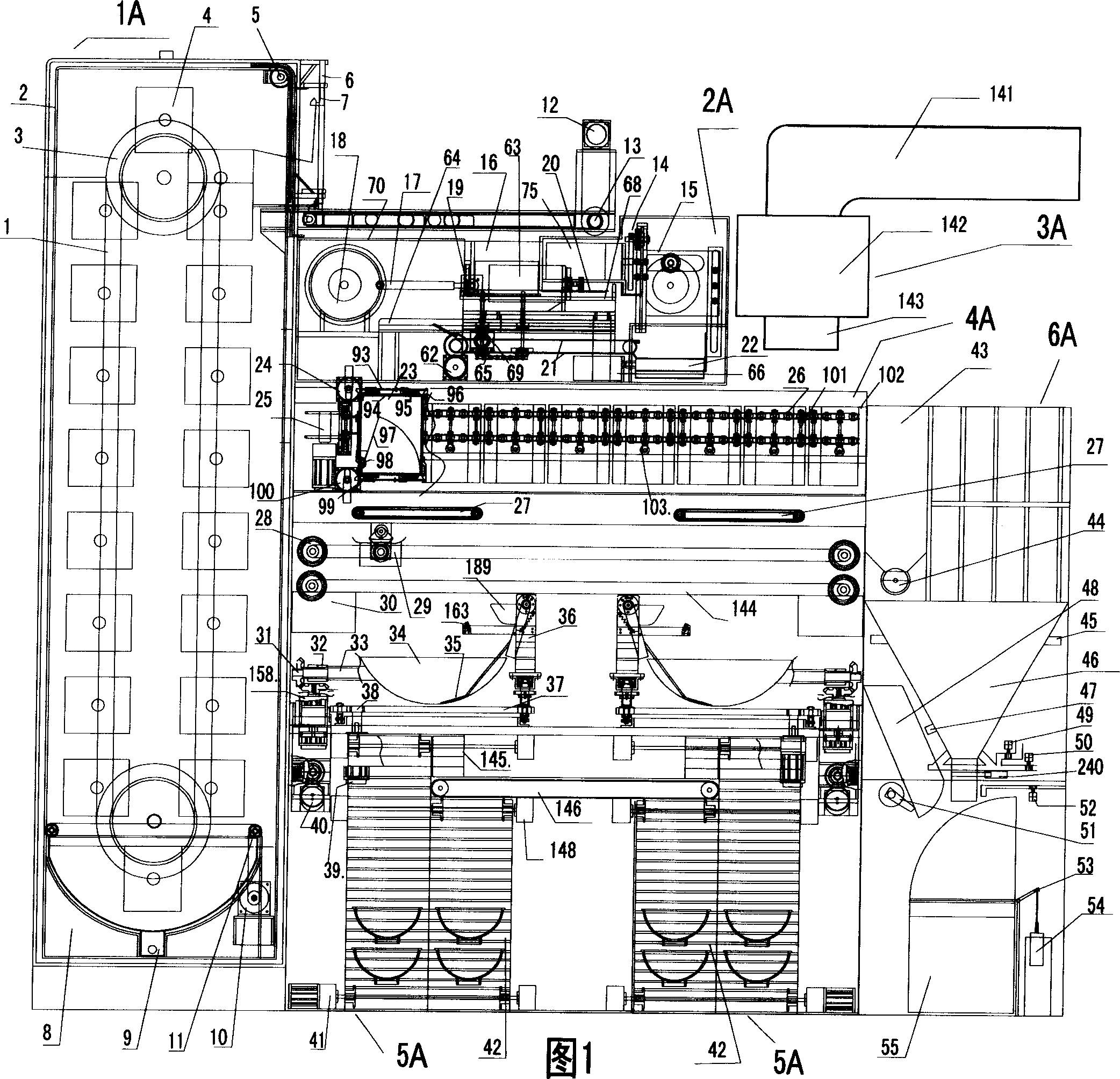

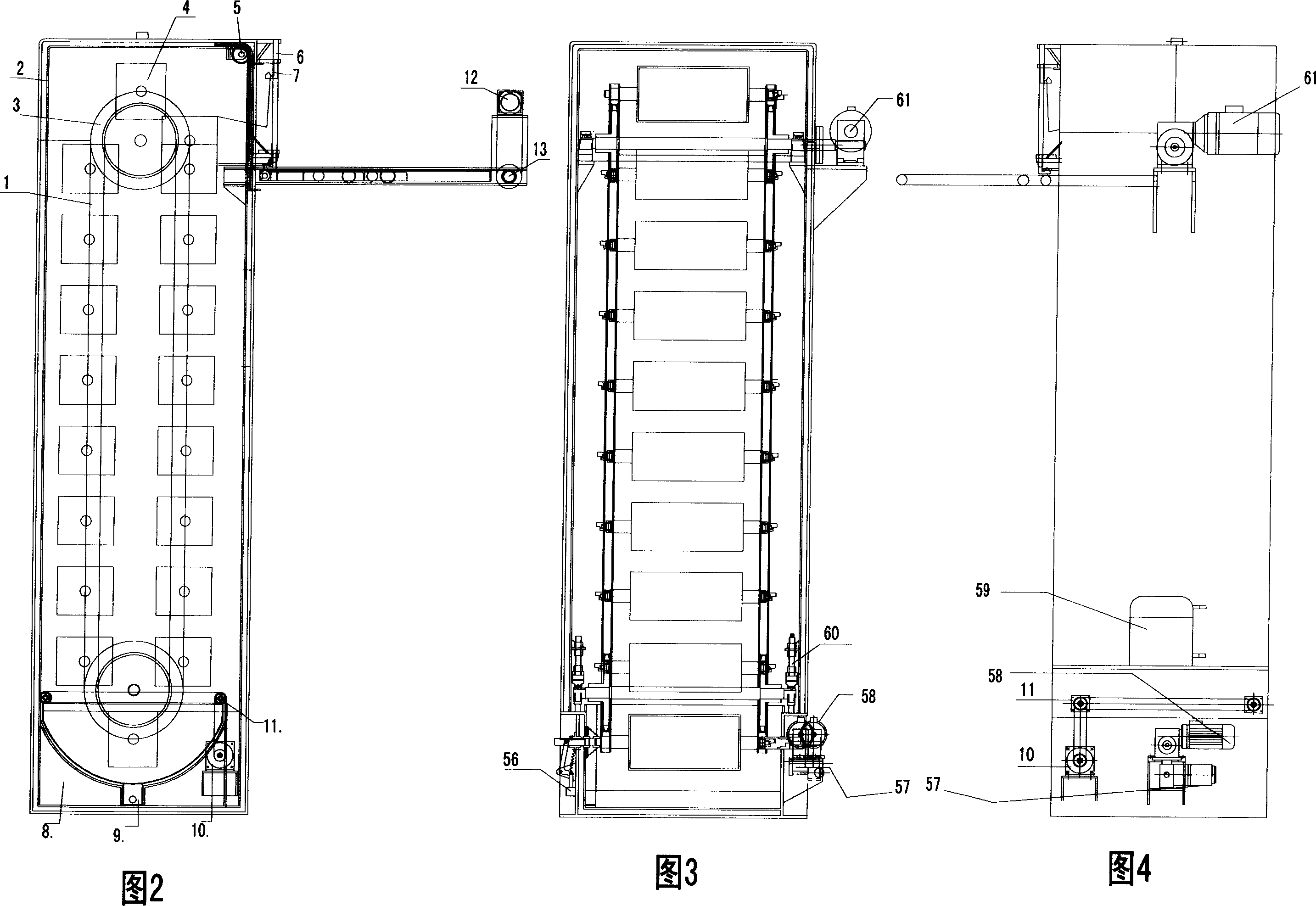

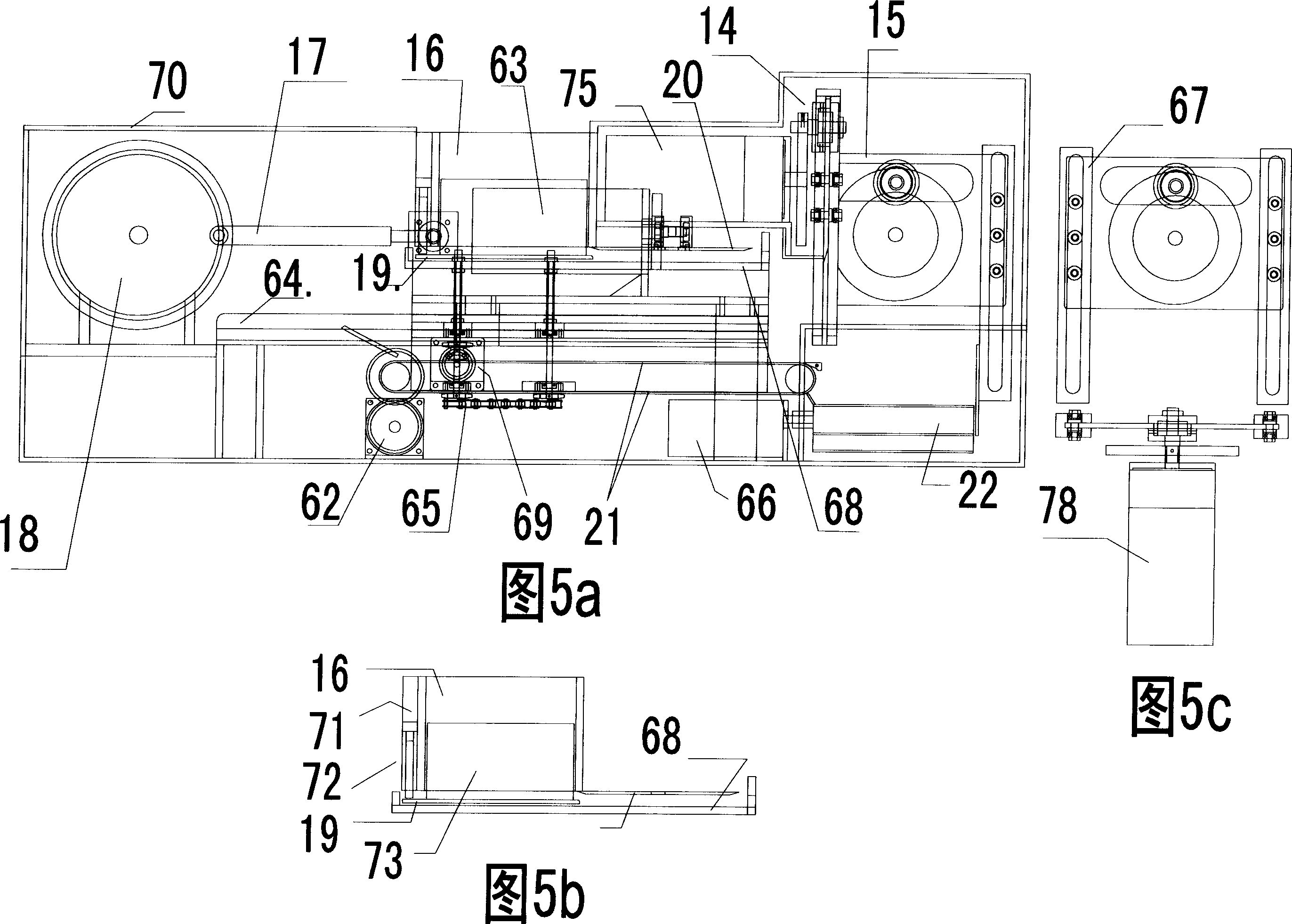

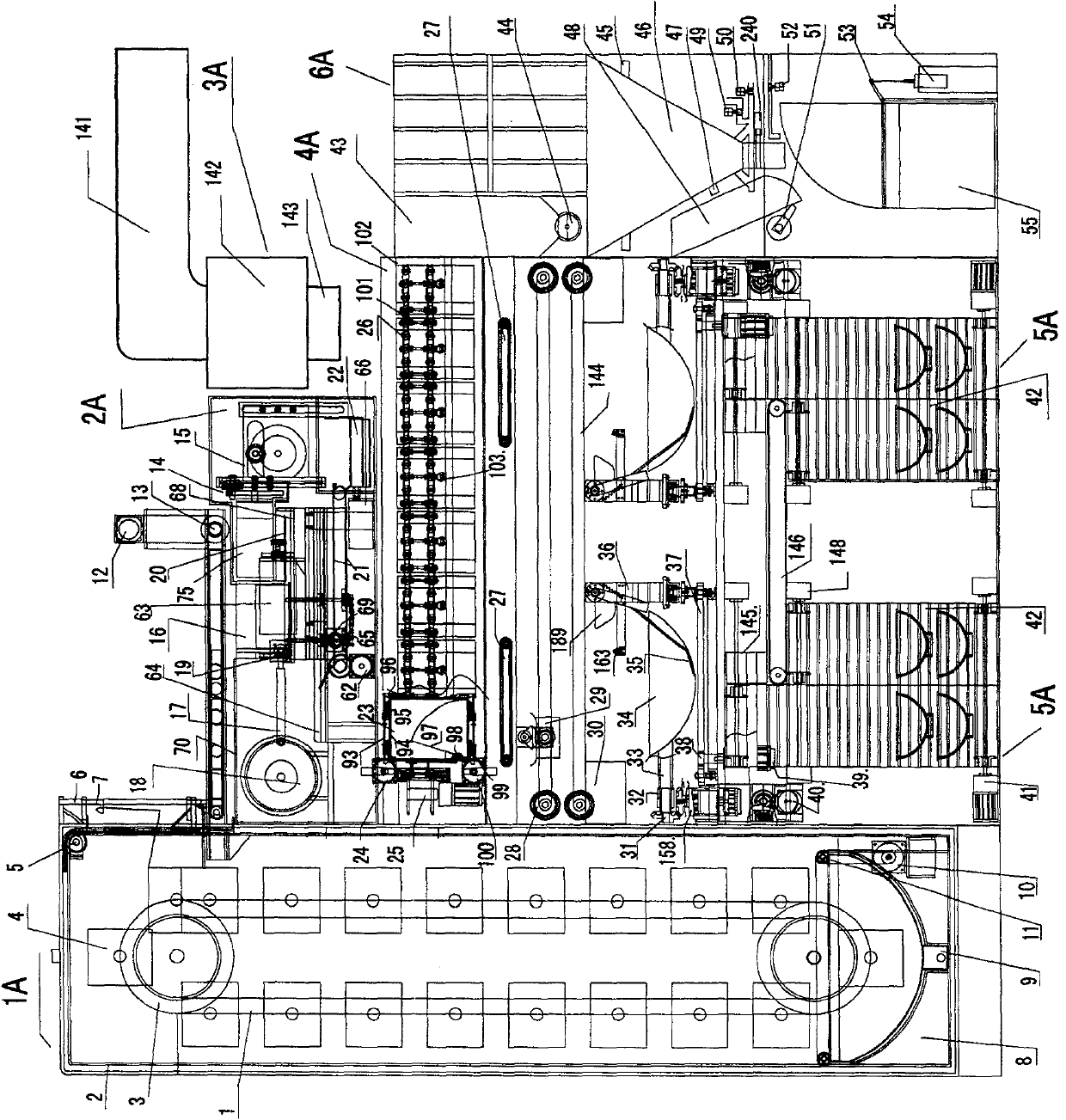

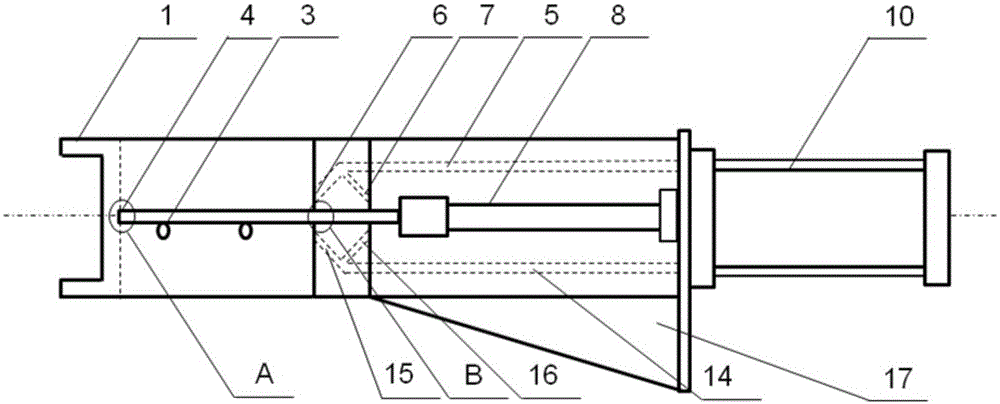

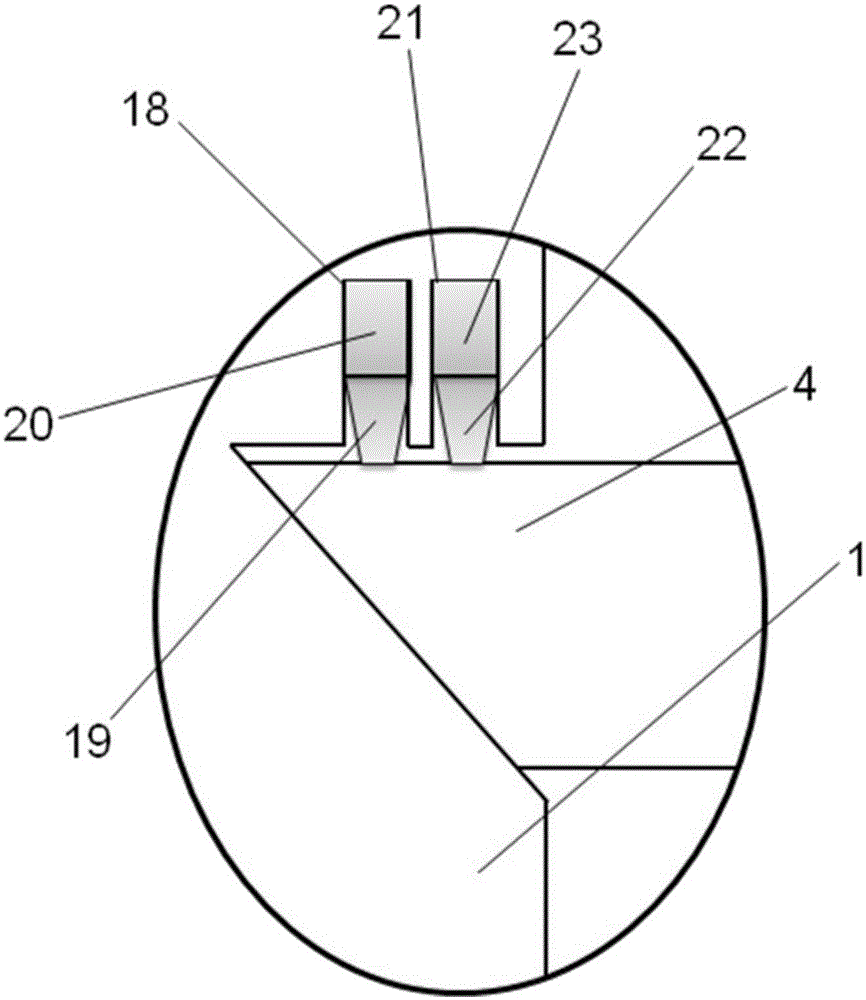

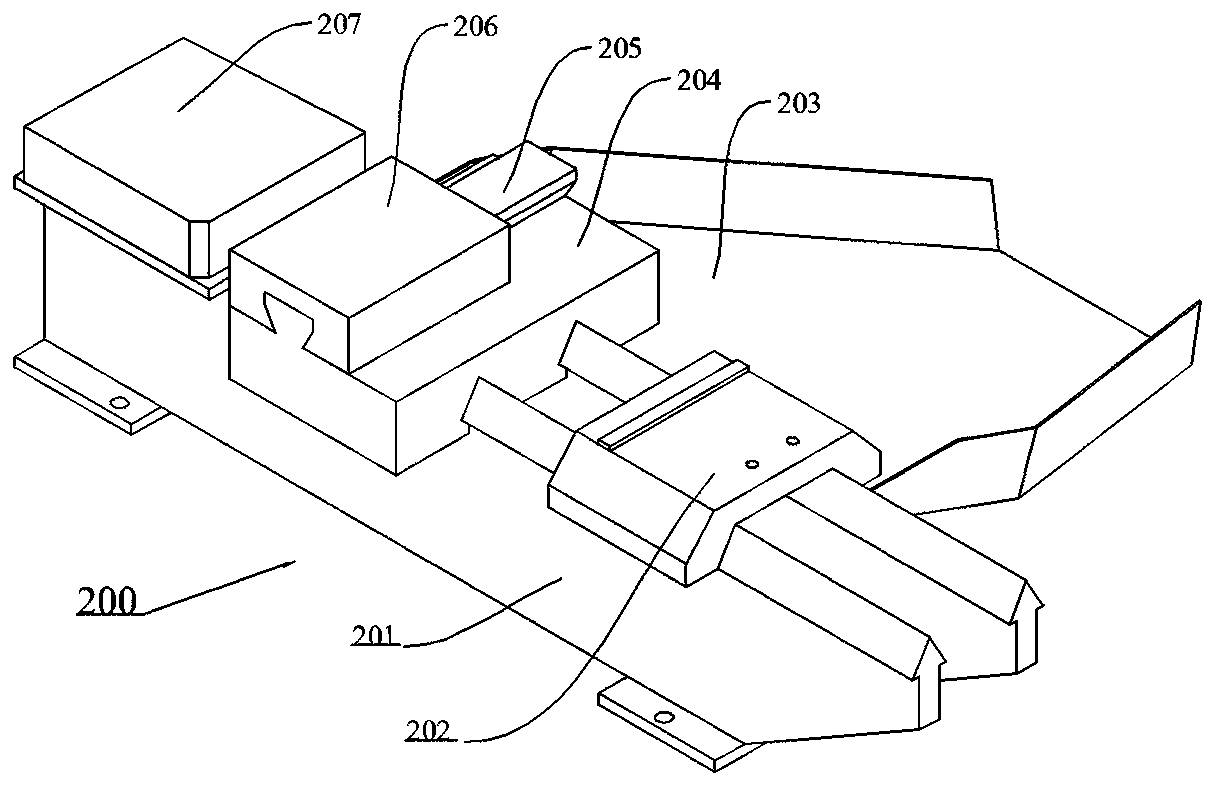

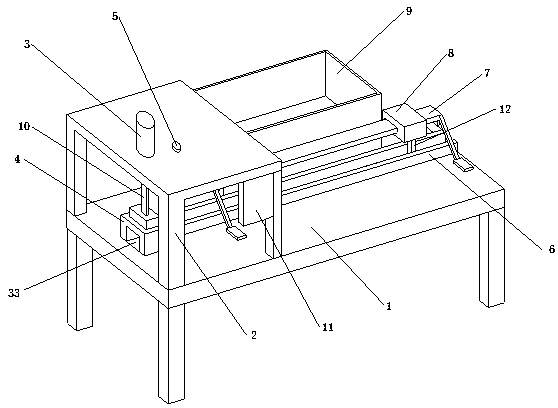

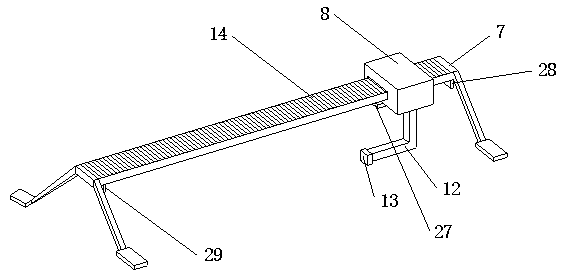

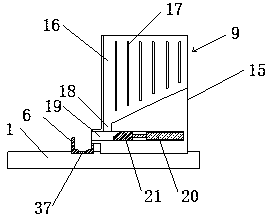

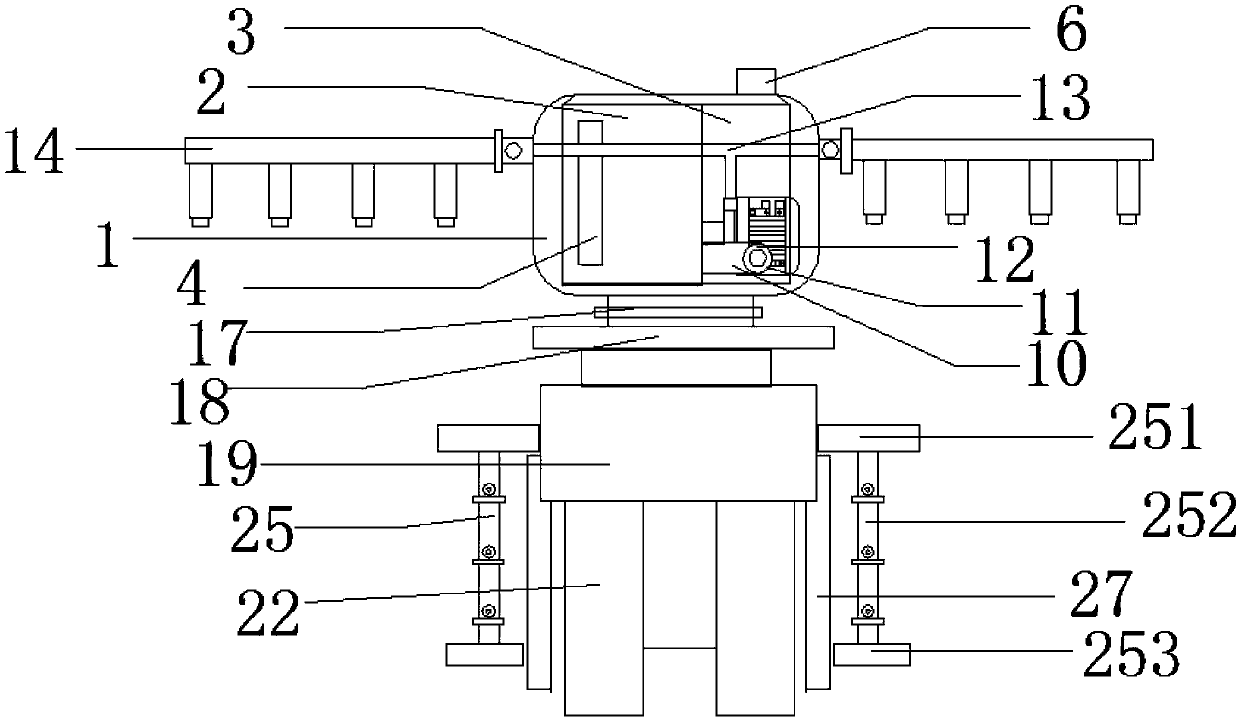

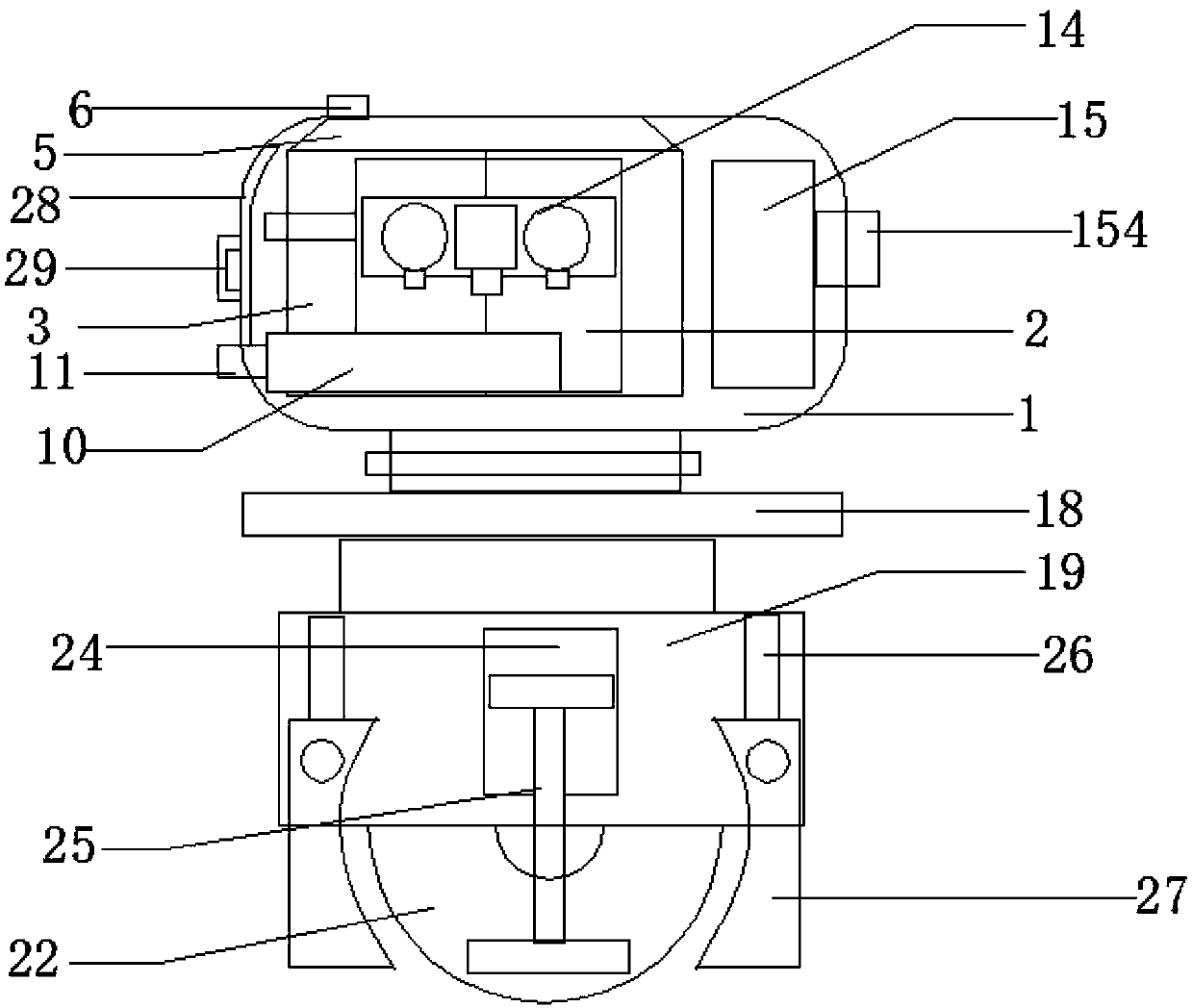

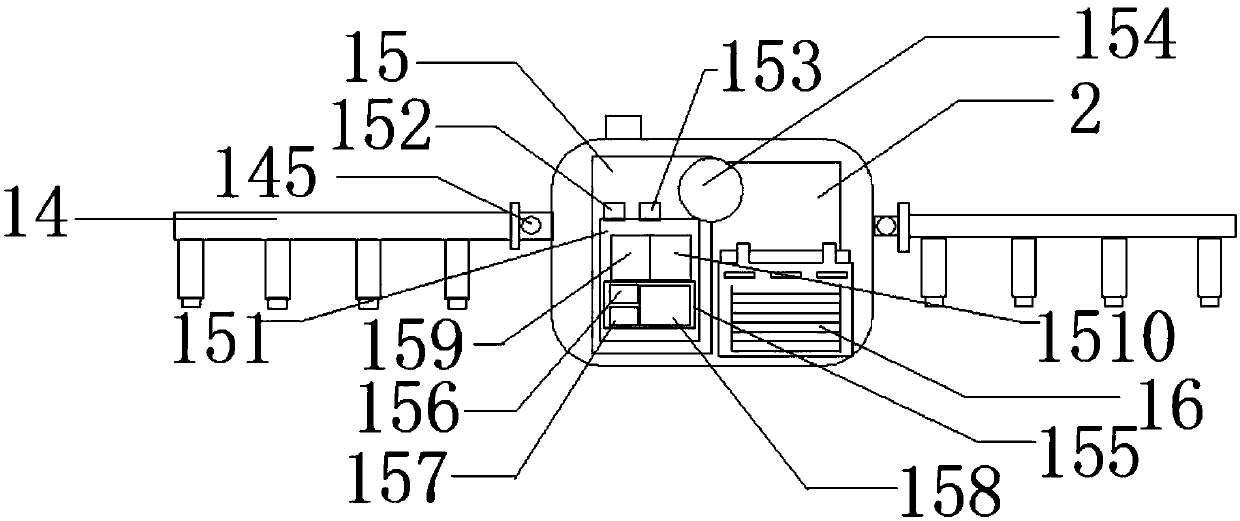

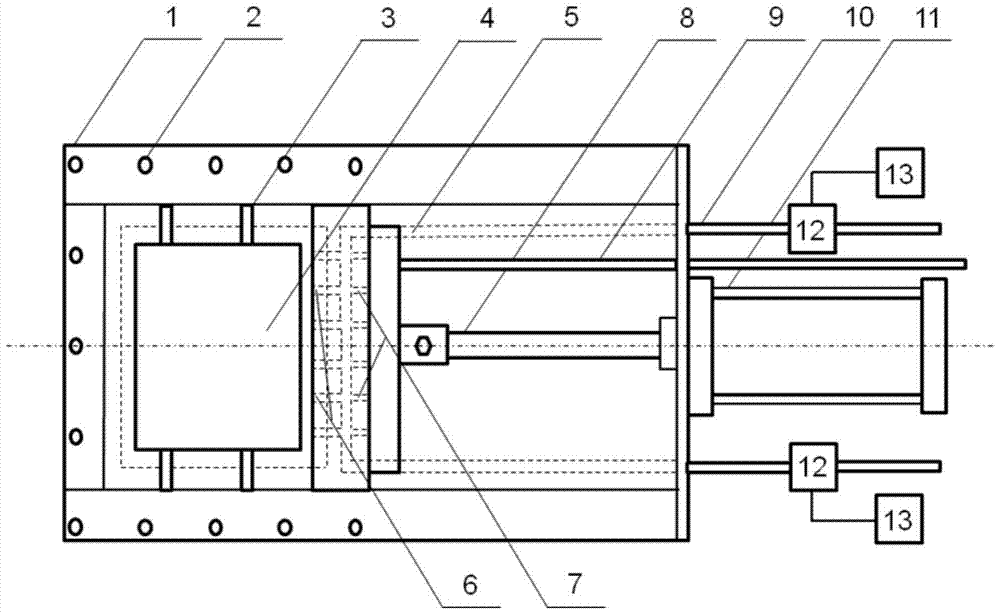

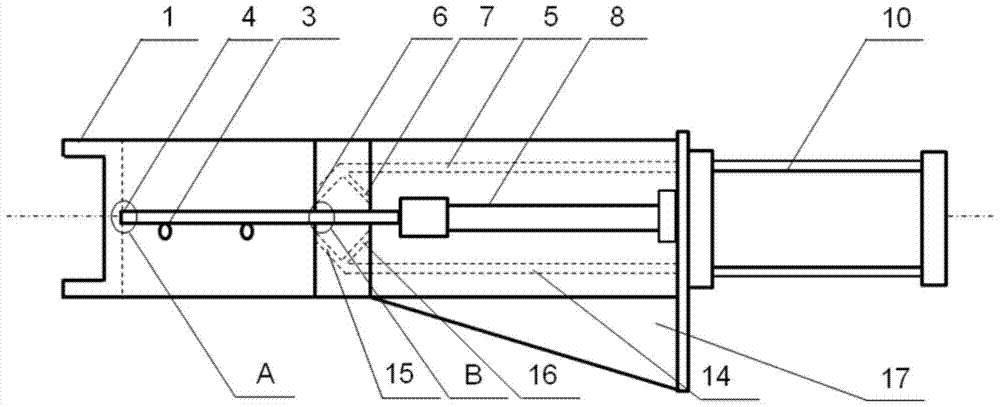

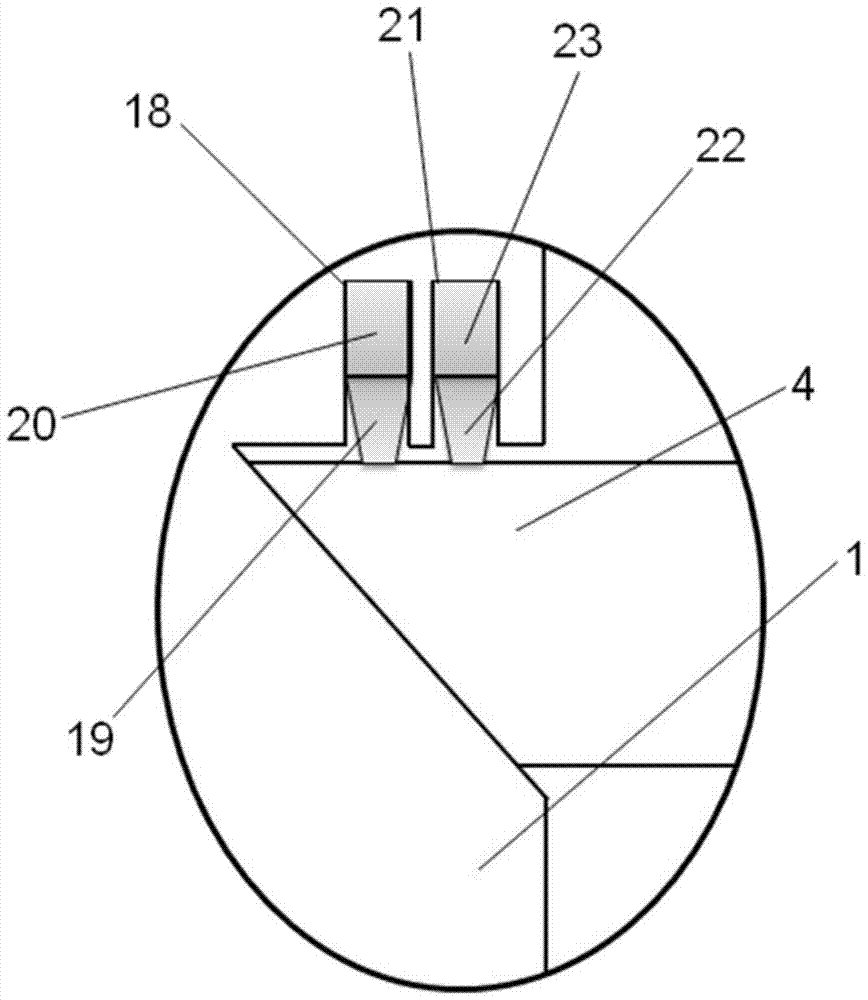

The invention relates to a full-automatic poker machine, which comprises a mounting bottom plate and a plurality of support legs. A card inlet is disposed on the mounting bottom plate, card cutting and primary card distributing equipment is arranged at one end of the card inlet, card sorting and secondary card distributing equipment is arranged at the other end of the card cutting and primary card distributing equipment, card flopping and dealing equipment is disposed at the other end of the card sorting and secondary card distributing equipment, card pushing equipment is arranged at the other end of the card flopping and dealing equipment, and card lifting equipment is disposed on one side of the card pushing equipment. When the full-automatic poker machine works, disorder poker cards are primarily separated by the aid of the card cutting and primary card distributing equipment, then are adjusted to face the same direction and separated from each other by the card sorting and secondary card distributing equipment, then by the aid of the card flopping and dealing equipment, the single poker cards with front surfaces facing upwards and downwards are adjusted so that the front surfaces of the single poker cards face upwards or downwards in a unified manner and the single poker cards are dealt, the poker cards are pushed to specified positions by the card pushing equipment, and finally are lifted to a tabletop by the card lifting equipment, and card cutting and dealing actions are completed. The full-automatic poker machine brings convenience for reducing labor intensity of game, waiting time is shortened, and simultaneously, automation degree of the machine is improved.

Owner:陈雄兵

Full automatic cooking robot system

ActiveCN101006833AShorten the timeSave social resourcesFood preparationRobotic systemsLogistics management

This invention relates to a robot system capable of completing different kinds of kitcheneering affairs automatically by timing. the robot system comprise automatic multifunctional intellectualized subsystem integrated with washing vegetable, dishes, sterilization, storage and perservation; automatic multifunctional vegetable cutter subsystem; automatic intellectualized cooking and compounding subsystem and oil fume pumping system; automatic cooking subsystem; automatic rice cooking subsystem; intellectualized automatic cooking digital menu software controls subsystem. The system establishes an only recognition coding, specifically to a robot system applicable for common household kitchen, restaurant kitchen, logistics kitchen, and automatic snack service. The invention can save time spent on cooking affairs, reduce labor cost, save a great deal of social resource and money spent on cooking affair.

Owner:李卫红

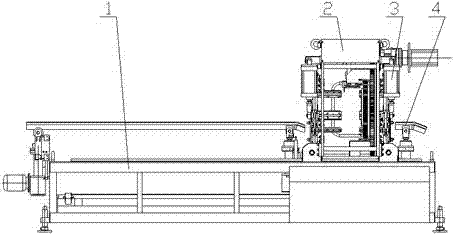

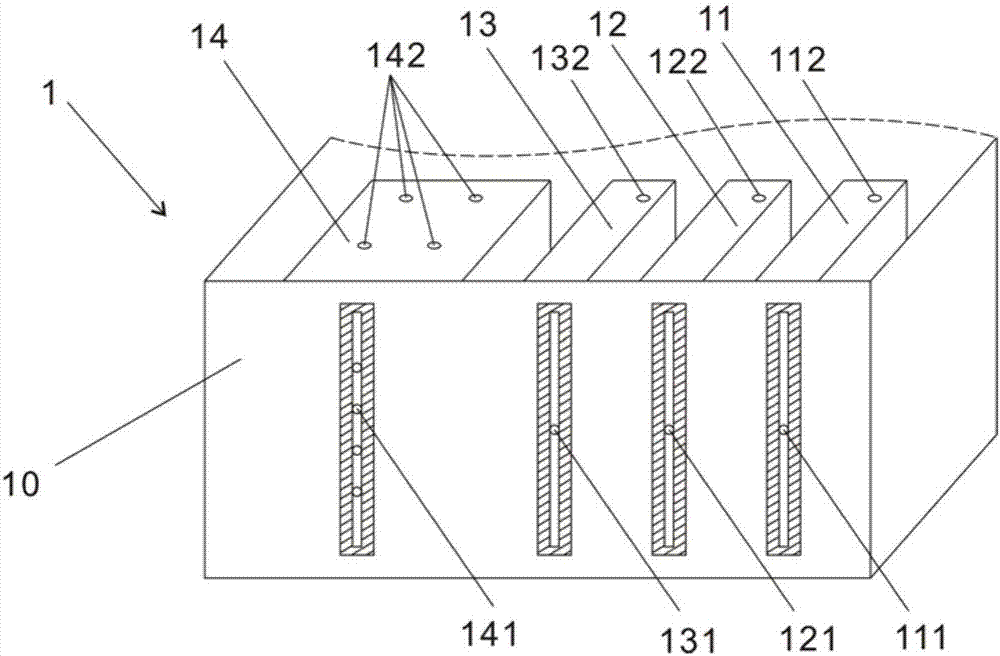

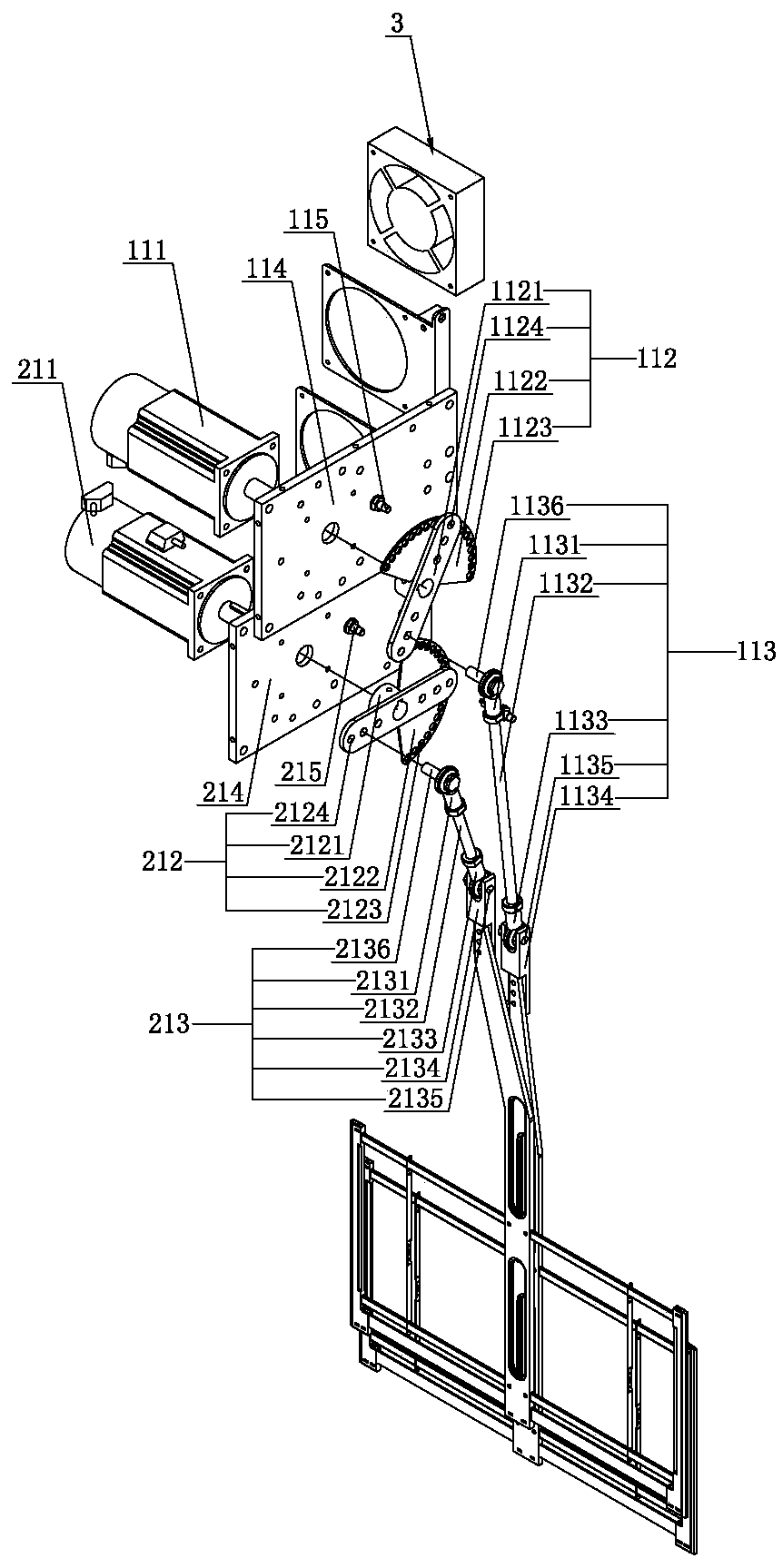

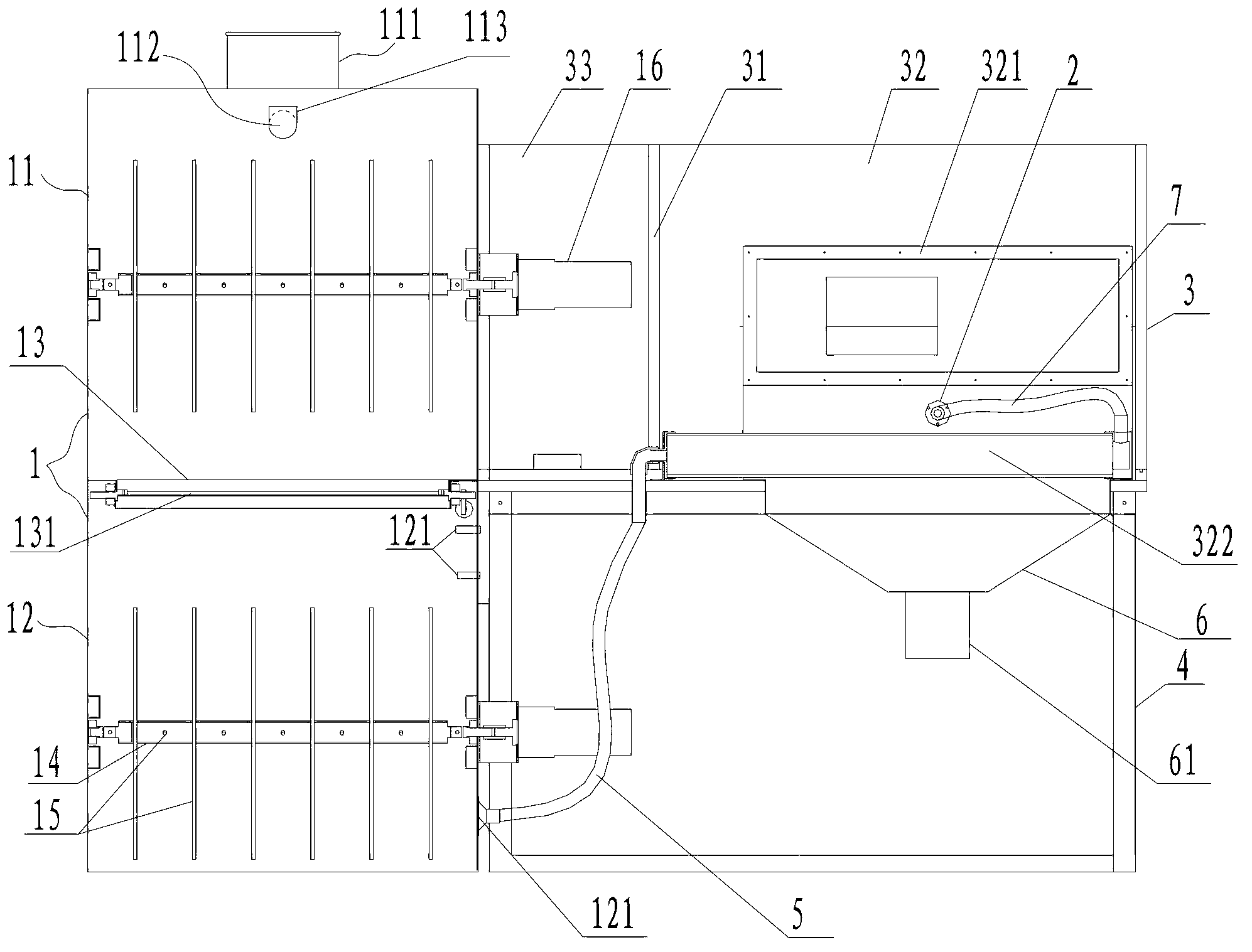

Full-automatic multi-trim-strip sewing equipment

ActiveCN107190425ASimple structureSewn flatWorkpiece carriersWork-feeding meansEngineeringSewing machine

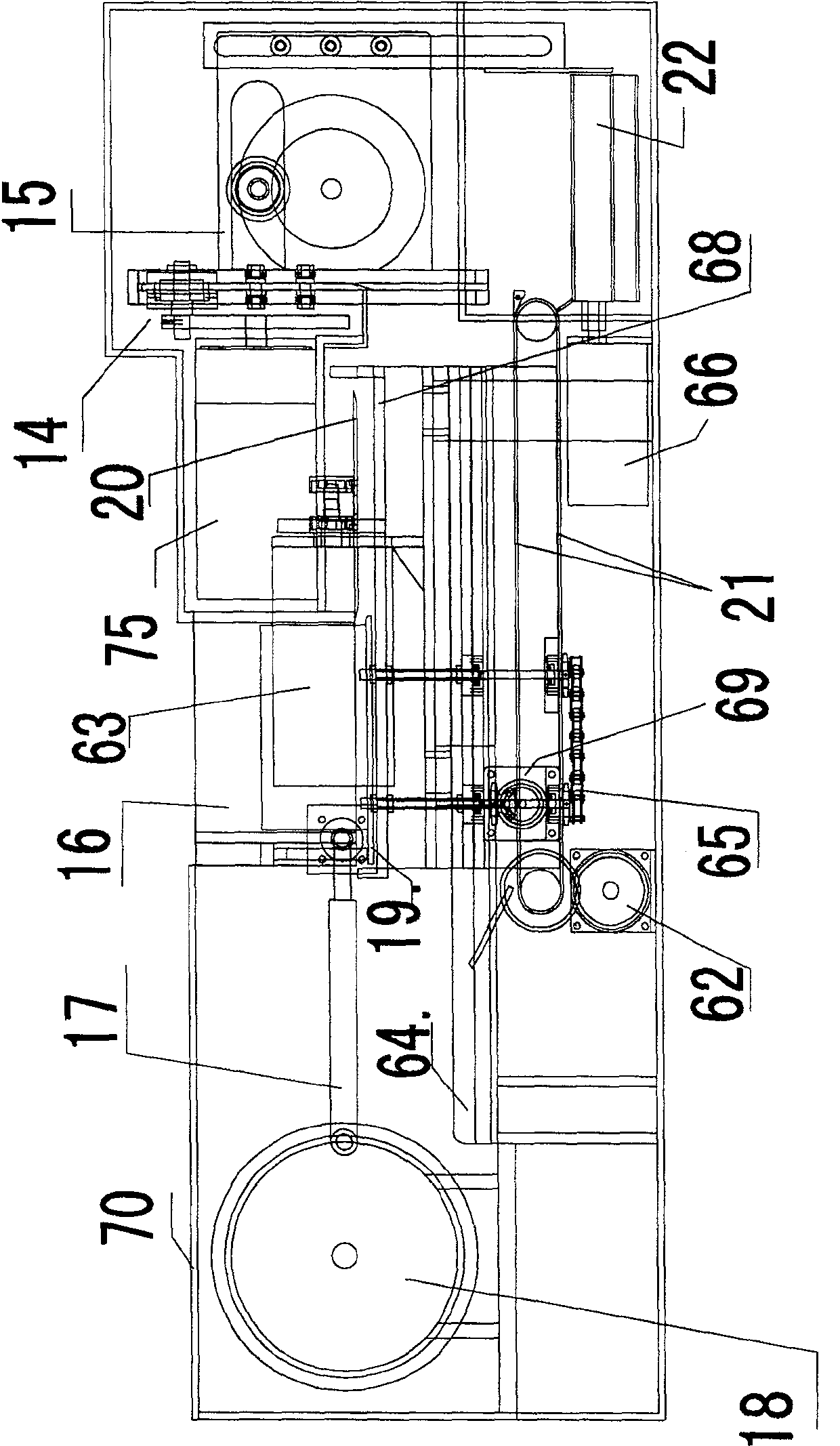

The invention discloses full-automatic multi-trim-strip sewing equipment. The full-automatic multi-trim-strip sewing equipment comprises a sewing device, wherein the sewing device comprises a multi-needle sewing machine, a trim-strip feeding device, a first work platform, an upper tug assembly and a lower tug assembly. The full-automatic multi-trim-strip sewing equipment is characterized by further comprising a feeding device, and lower tugs of the lower tug assembly are driving wheels. The feeding device comprises a discharging table assembly, a feeding table assembly, pressing foot assemblies, and a pressing foot two-stage driving assembly. A discharging panel of the discharging table assembly is arranged on a discharging shelf in a way of moving front and back, and a feeding table panel of the feeding table assembly is fixedly arranged on a feeding table mounting shelf. The feeding table surface is communicated with a first panel and a discharging panel of the first work platform. The pressing foot assemblies comprise pressure feet. The pressure feet are arranged above the discharging panels, a feeding table panel, and the first panel in a way of moving left and right through the pressing foot two-stage driving assembly, and are used for delivering fabric of to-be-sewed trim-strips located on the discharging panel to the first panel through the feeding table panel after pressing the fabric.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

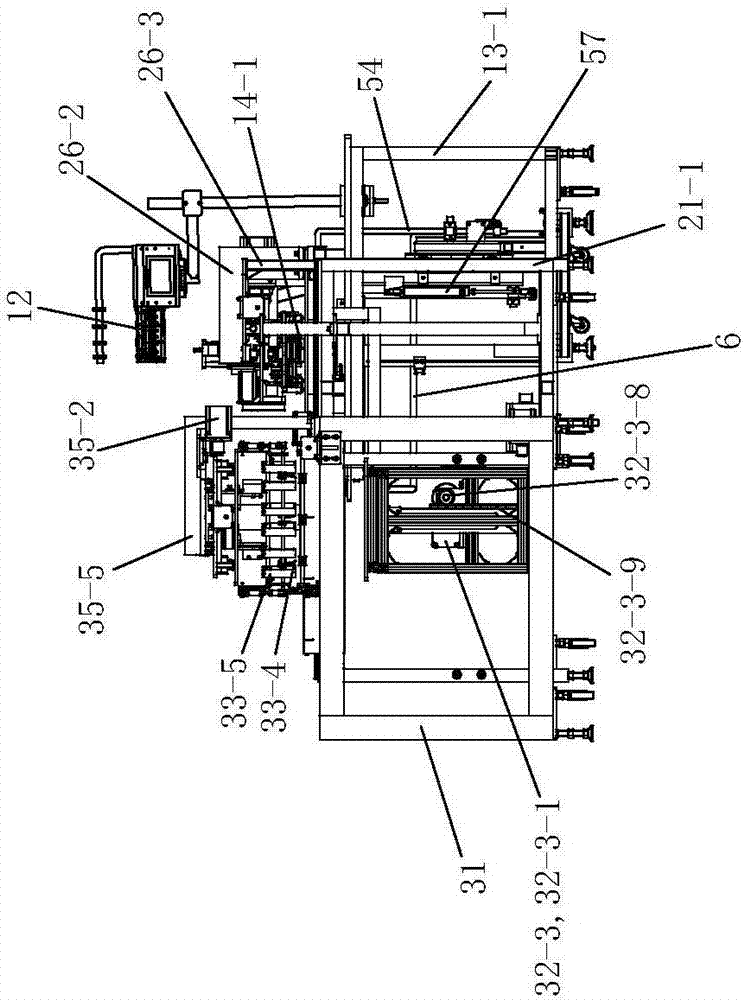

Automatic variable diameter chipless cutting machine

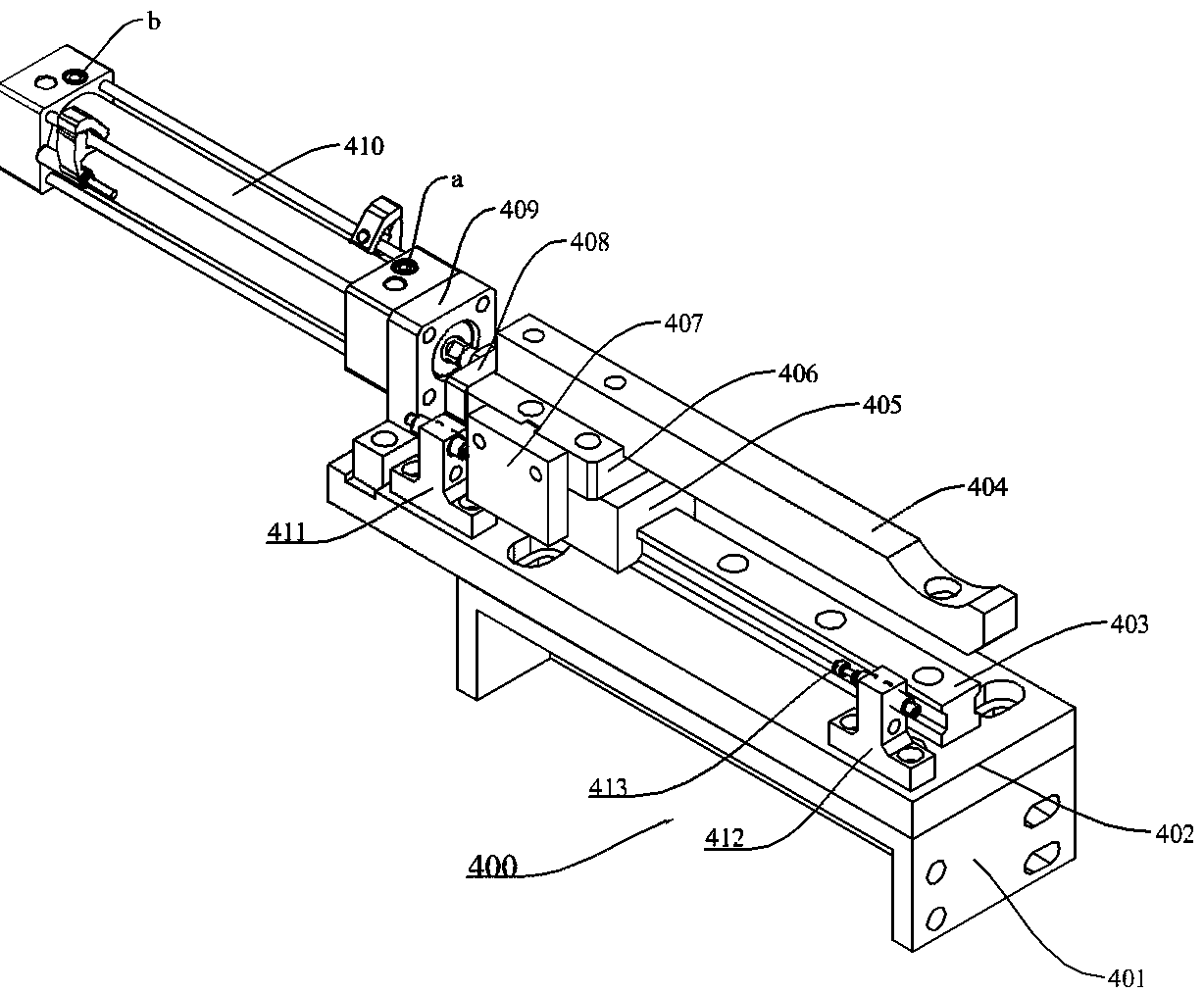

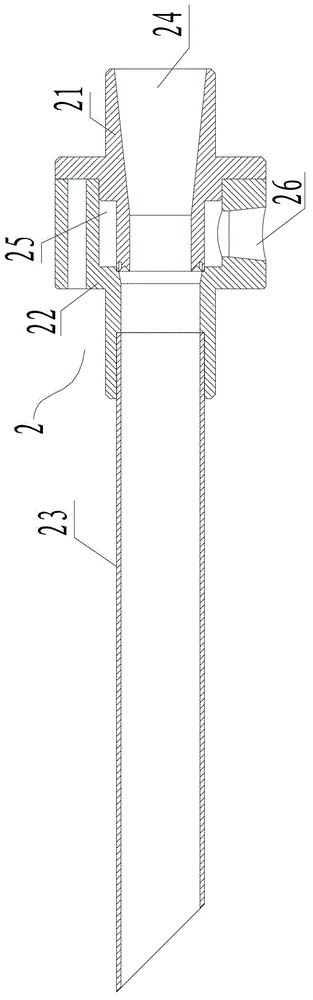

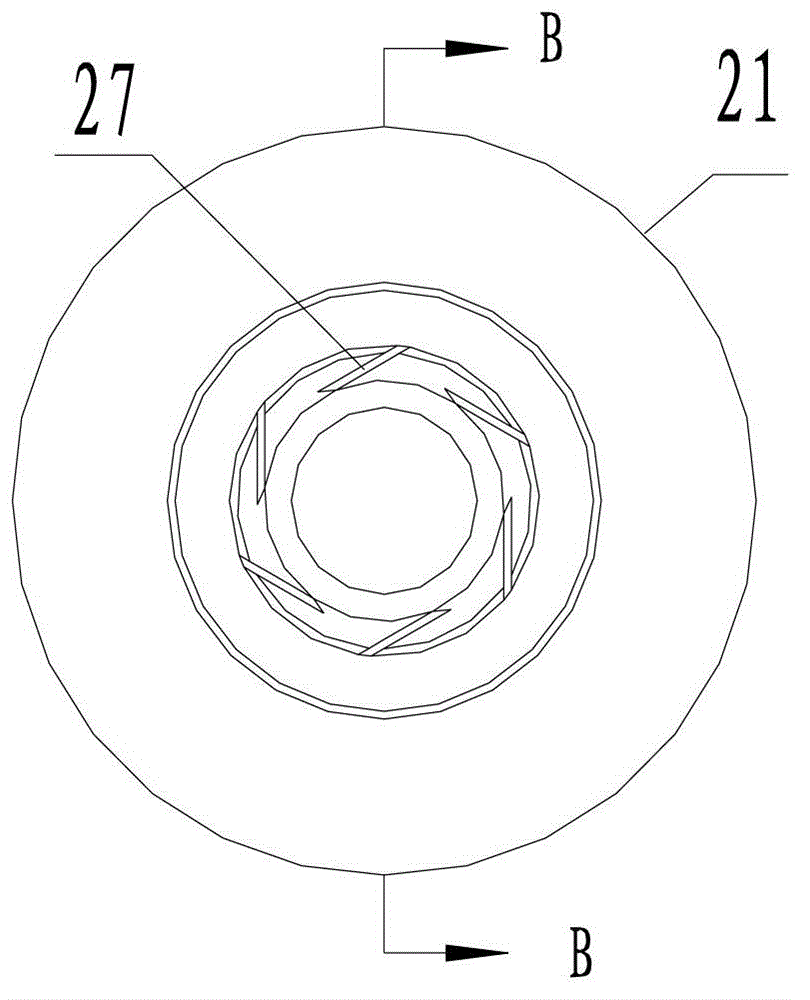

InactiveCN102452097AHigh degree of full automationCompact structureMetal working apparatusSpiteHuman–machine interface

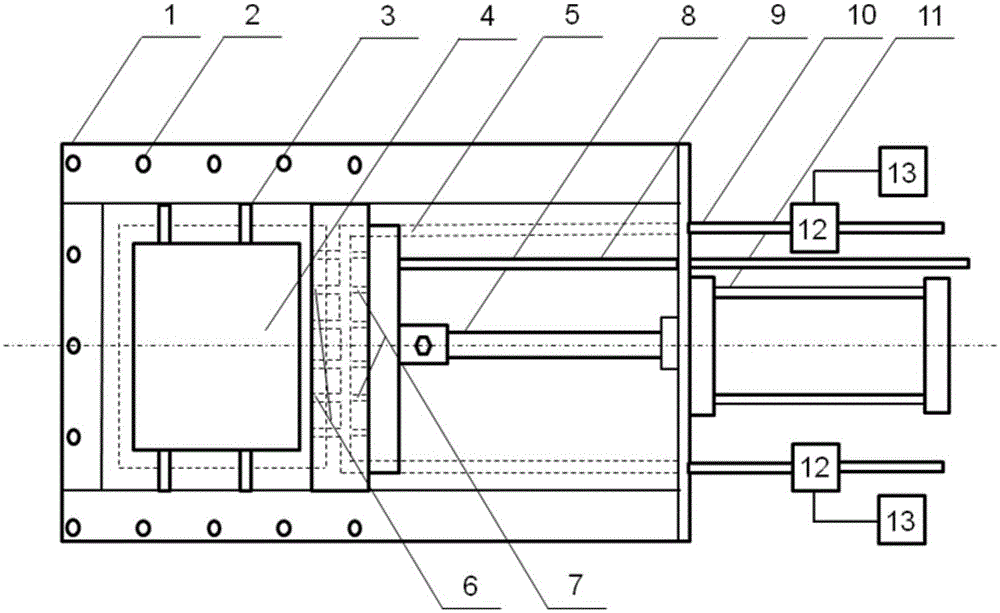

The invention relates to the related technical field of pipe cutting equipment, in particular to an automatic variable diameter chipless cutting machine, which comprises a frame, and a supporting mechanism, a clamping mechanism and a rotating mechanism arranged on the frame in turn, wherein the clamping mechanism comprises a clamping bottom plate with a clamping through hole, and a clamping cylinder, a front turning arm and a plurality of clamping force arms, which are arranged on the clamping bottom plate; and the front end of each clamping force arm is provided with a clamping block, and the rear end of each clamping force arm is provided with a clamping rotating shaft, a force applying shaft and a stressed shaft. In spite of the change of specifications of pipes, the clamping device can adapt to a pipe clamping range; and clamp blocks are not required to be changed, and a clamping cylinder mounting position design ensures that force generated by the cylinder is exerted maximally in a linked multi-point clamping mechanism, so that pipes with the maximum diameter are clamped. The machine has high full automation degree, compact and concise structure, safe and reliable electric control and ideal human-computer interface, and is easy and convenient to operate; and the online automation of the cutting machine is realized by a programmable logic controller (PLC).

Owner:GUANGDONG LIANSU MACHINERY MFG

Full automatic cooking robot system

This invention relates to a robot system capable of completing different kinds of kitcheneering affairs automatically by timing. the robot system comprise automatic multifunctional intellectualized subsystem integrated with washing vegetable, dishes, sterilization, storage and perservation; automatic multifunctional vegetable cutter subsystem; automatic intellectualized cooking and compounding subsystem and oil fume pumping system; automatic cooking subsystem; automatic rice cooking subsystem; intellectualized automatic cooking digital menu software controls subsystem. The system establishes an only recognition coding, specifically to a robot system applicable for common household kitchen, restaurant kitchen, logistics kitchen, and automatic snack service. The invention can save time spenton cooking affairs, reduce labor cost, save a great deal of social resource and money spent on cooking affair.

Owner:李卫红

Anti-jamming pneumatic slide plate gate of pulverized coal pipeline and work method based on anti-jamming pneumatic slide plate gate

ActiveCN105135034ASolve the jamAvoid influenceOperating means/releasing devices for valvesSlide valveAnti jammingCoal pipeline

The invention discloses an anti-jamming pneumatic slide plate gate of a pulverized coal pipeline and a work method based on the anti-jamming pneumatic slide plate gate. The anti-jamming pneumatic slide plate gate comprises a rectangular frame which is connected with the pulverized coal pipeline through fixing bolts, wherein a slide plate which can block airstreams in the pulverized coal pipeline is arranged in the center of the rectangular frame; the rectangular frame comprises a front side frame, a rear side frame, a left side frame and a right side frame; the left and right side frames are separately provided with a sliding rail, so that the slide plate can slide along the sliding rails of the rectangular frame; the slide plate is connected with a slide plate draft device; asymmetrical chevron air passages are arranged above the rear side frame; symmetrical chevron air passages are arranged below the rear side frame; the air passages are all connected with compressed air pipelines; the compressed air pipelines are connected with a compressed air source; electromagnetic valves are arranged on the compressed air pipelines; the electromagnetic valves are connected with compressed air control systems; and in processes of inserting the slide plate into the rectangular frame and pulling the slide plate out of the rectangular frame, dust accumulated on the upper part, the lower part, the front part and the rear part of the slide plate is cleaned through airstreams in the compressed air pipelines, so that the problem of jamming of the slide plate caused by large friction force of the dust is solved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

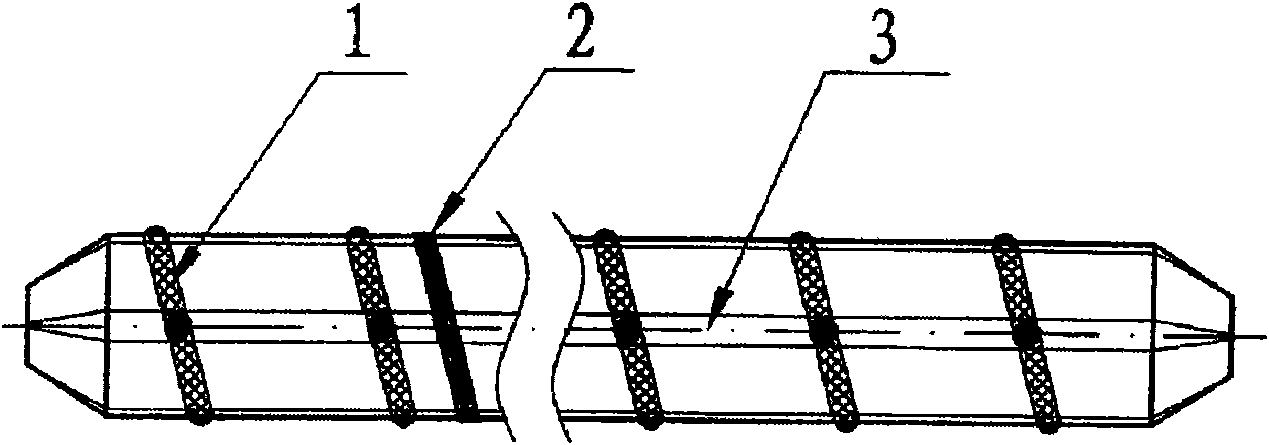

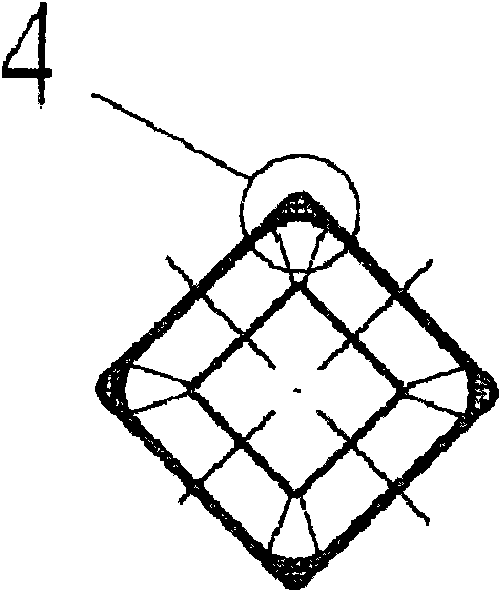

Helical plastic wire flexible shaft for reducing noise and manufacturing method thereof

ActiveCN101956753AExtended service lifeCancel noiseShaft for rotary movementEngineeringWork in process

The invention discloses a helical plastic wire flexible shaft for reducing the noise and a manufacturing method thereof, belonging to the field of mechanical transmission components. The helical plastic wire flexible shaft is characterized in that multiple steel wires are helically wound on the surface of a shaft core in layers; one steel wire at the outermost layer is replaced by a plastic wire; the flexible shaft wound therefrom is shaped through square upsetting; the plastic wires formed on the square surface and the sides opposite the angle are convex to be tightly matched in square-hole parts. The specific manufacturing method comprises the steps of: dismantling one steel wire of the common flexible shaft which undergoes heat treatment, and synchronously placing a plastic covered steel wire or a pure plastic wire to manufacture a semi-finished helical plastic-wire flexible shaft; carrying out square upsetting on the semi-finished helical plastic-wire flexible shaft; dragging, with a fixed length, the semi-finished helical plastic-wire flexible shaft to a burring device to remove the burrs generated in the square upsetting process; and dragging, with a fixed length, the semi-finished helical plastic-wire flexible shaft to a cutting device to cut off the flexible shaft from the square upsetting position, so as to manufacture a finished helical plastic-wire flexible shaft. The invention has simple product structure, can greatly reduce and even eliminate the occurrence of the noise, prolongs the service life of the flexible shaft, and has the advantages of simple manufacturing process and high degree of automation.

Owner:上海高齐汽车配件有限公司

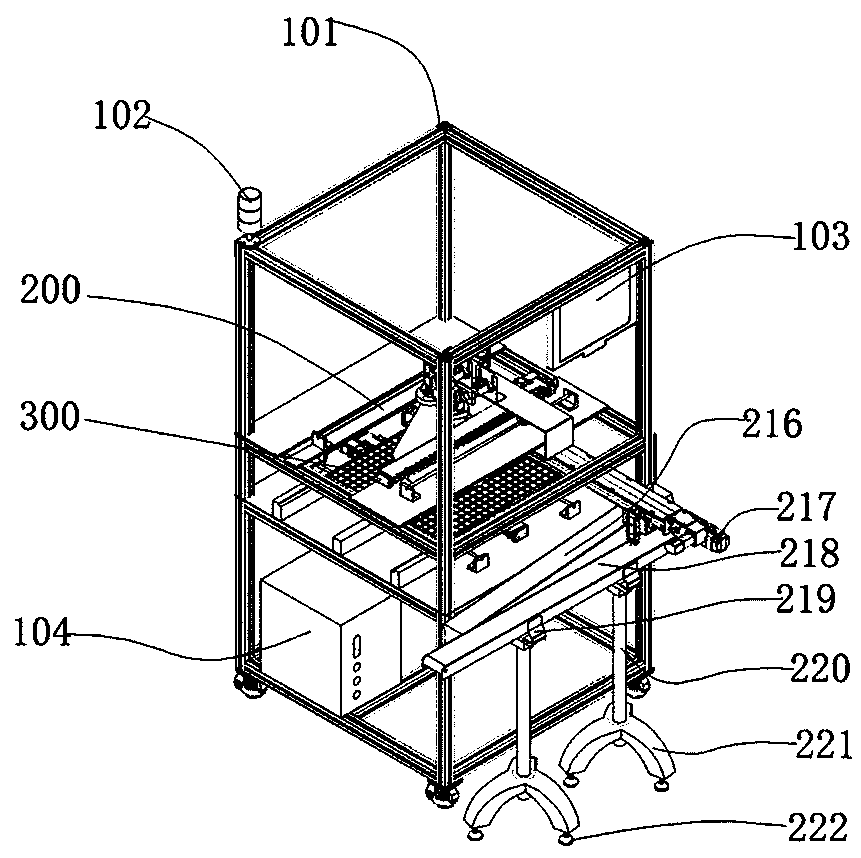

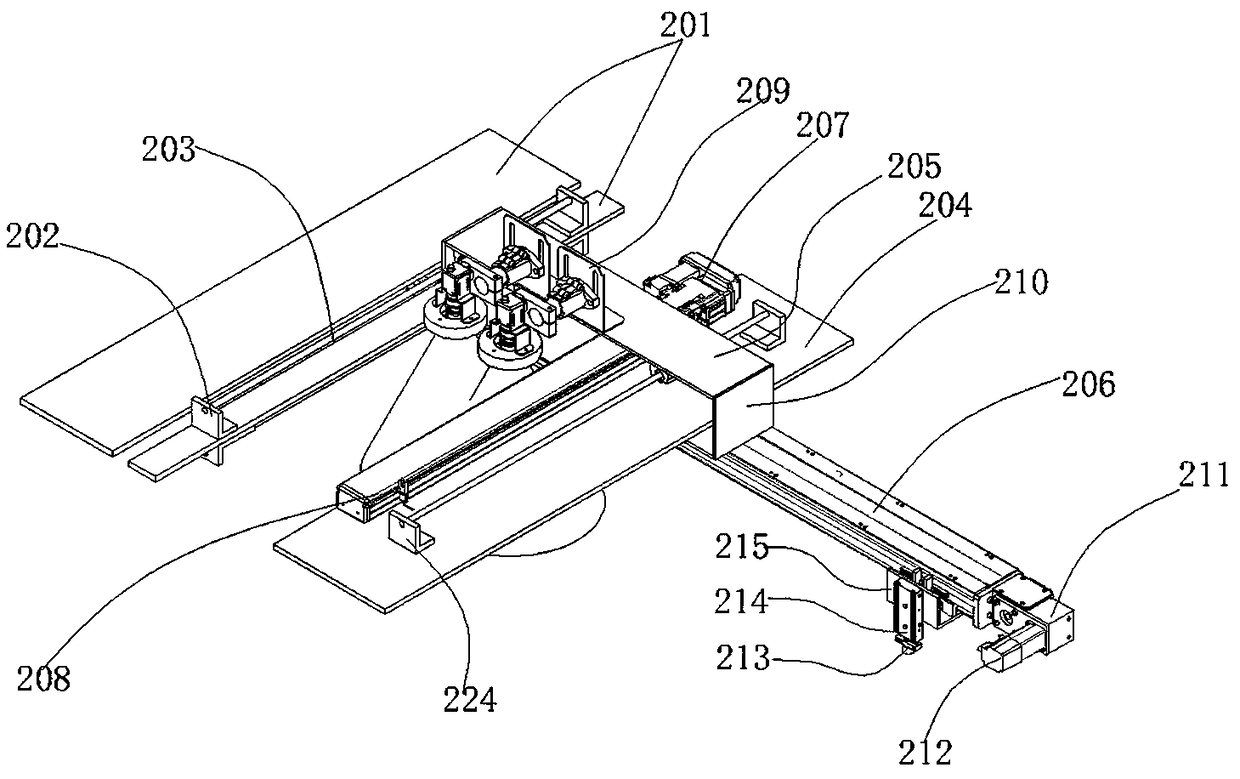

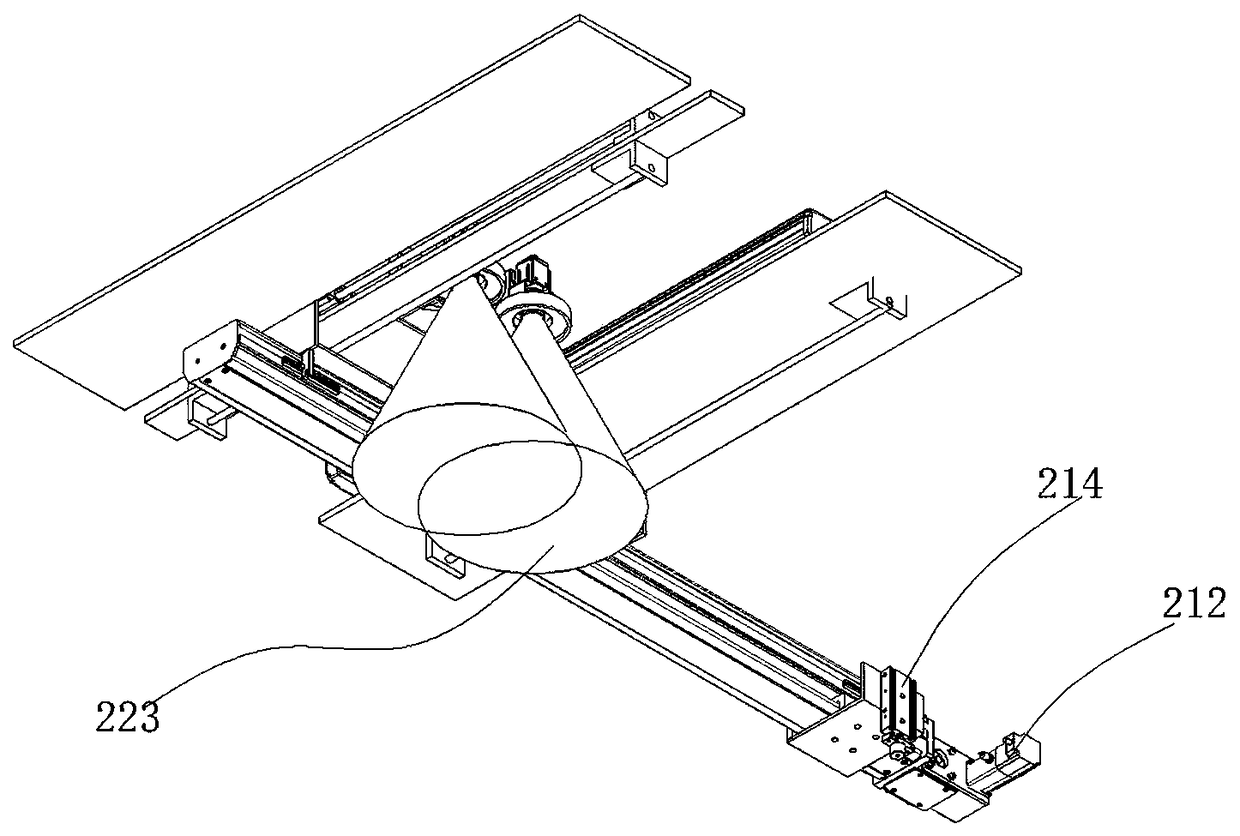

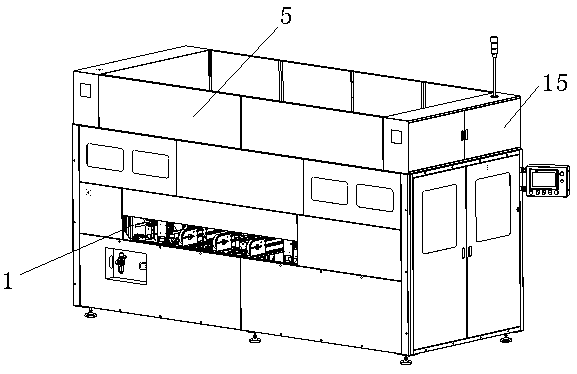

Camera detection device and detection method thereof

The invention discloses a camera detection device which comprises an outer frame. A control panel, a detection unit, a material shifting unit and an electricity box control unit are sequentially arranged in the outer frame from top to bottom. The problems that a camera detection device is complex in equipment structure and large in equipment occupation space are effectively solved; and the cameradetection device provided by the invention is simple and compact in structure, high in full-automatic degree, and high in detection efficiency.

Owner:成都中嘉微视科技有限公司

Related application method of voice-operated pen container

InactiveCN109050124AAdjustable heightAdjustable lighting angleWriting accessoriesElectric circuit arrangementsSlide plateEngineering

The invention discloses a related application method of a voice-operated pen container. The pen container is composed of a pen container device and a lighting device. The pen container device comprises a machine body. The machine body is internally provided with a cavity with an opening facing rightwards. A barrel for holding writing pens is slidably arranged in the cavity. A placement cavity withan opening facing upwards is arranged in the barrel. A concentric-square-shaped upper sliding plate penetrating up and down is slidably arranged in the placement cavity. An upper connecting rod is fixedly arranged on the front end surface of the upper sliding plate. The upper sliding plate is internally provided with a sliding groove with an opening facing downwards. The sliding groove is provided with sliding guide grooves with openings being formed oppositely in a lateral symmetry mode. A lower sliding plate is arranged at the position, in the placement cavity, of the lower side of the upper sliding plate. During operation, application is convenient, the height of the pen container is not limited, the pen container can accommodate pens of various height specifications, and is shrinkableand small in size and floor space, and the height and illumination angle of an illumination lamp can be adjusted, and the overall device is high in full-automation degree, good in linkage, low in energy consumption, environmentally friendly, practical, multifunctional and convenient to use.

Owner:王静娜

Automatic notching device for filter net of liquid reservoir

The invention discloses an automatic notching device for a filter net of a liquid reservoir. The device comprises a base and a vibrating feeding device. A motor is arranged on the lower portion of thebase, a fixing device is arranged on the upper portion of the base, and a feeding device, a pressing device, a notching device and a forming blanking device are arranged on the fixing device. The problem that the filter net can be manufactured through a multi-step process is effectively solved, the processes of bending and machining of a mounting groove can be automatically completed through thedevice only by welding a filter net support and a filter net piece in the manufacturing process, the structure is simple, the working efficiency is improved, manpower and material resources are saved,the production cost is reduced, the full automation degree is high, and the production efficiency is greatly improved.

Owner:HANSHAN RUIKE METAL CO LTD

Steel pipe stamping and punching machine

PendingCN108941312AImprove processing efficiencyHigh degree of automationMetal-working feeding devicesMetal working apparatusPunchingFixed frame

The invention discloses a steel pipe stamping and punching machine. The steel pipe stamping and punching machine comprises a workbench. A fixed frame is arranged on the upper portion of the workbench.A first cylinder arranged vertically downwards is inlaid in the fixed frame. A locating frame is arranged below the first cylinder. The extension end of the first cylinder is provided with a stampingplate. The bottom of the stamping plate is provided with a punching tool. The stamping plate extends into an inner cavity of the locating frame. One side of the locating frame is provided with a U-shaped guide plate. A sliding frame is erected above the U-shaped guide plate. The sliding frame is provided with a sliding mechanism. The bottom of the sliding mechanism is connected with a push rod extending into an inner cavity of the U-shaped guide plate. The end of the push rod is connected with a push block. A pipe feeding device is arranged on one side of the U-shaped guide plate. A laser displacement sensor is inlaid in the position, located above the U-shaped guide plate, of the fixed frame. The steel pipe stamping and punching machine has the advantages of being high in machining efficiency and automation degree, facilitating control and adjustment on the punching distance, saving a great deal of labor force and ensuring the punching efficiency and the qualified rate.

Owner:HAIYAN HUITONG INTELLIGENT FURNITURE CO LTD

Novel automatic pesticide spraying monitoring device

InactiveCN107660529AImprove work efficiencyReduce wasteInsect catchers and killersAgricultural scienceRoad surface

The invention discloses a novel automatic pesticide spraying monitoring device, and relates to the technical field of agricultural machinery. The device comprises a pesticide spraying control box, a first pesticide box is fixedly connected to the bottom end of the middle of the interior of the pesticide spraying control box, a second pesticide box is fixedly connected to the outer wall of one sideof the first pesticide box, both the first pesticide box and the second pesticide box are internally provided with surplus detector, pesticide transfer passing boxes are fixedly connected to the topends of the first pesticide box and the second pesticide box, and an independent feed opening is formed in the top end of the pesticide spraying control box. Through the novel automatic pesticide spraying monitoring device, the problems are solved that current field pesticide spraying is low in automation and work efficiency and thus human resources are wasted to a certain extent, the labor intensity of workers is reduced, the stability of the device is improved at the same time, the device is suitable for work on uneven roads of a field, and the applicability of the device is improved.

Owner:湖州吴兴升浪生态农业有限公司

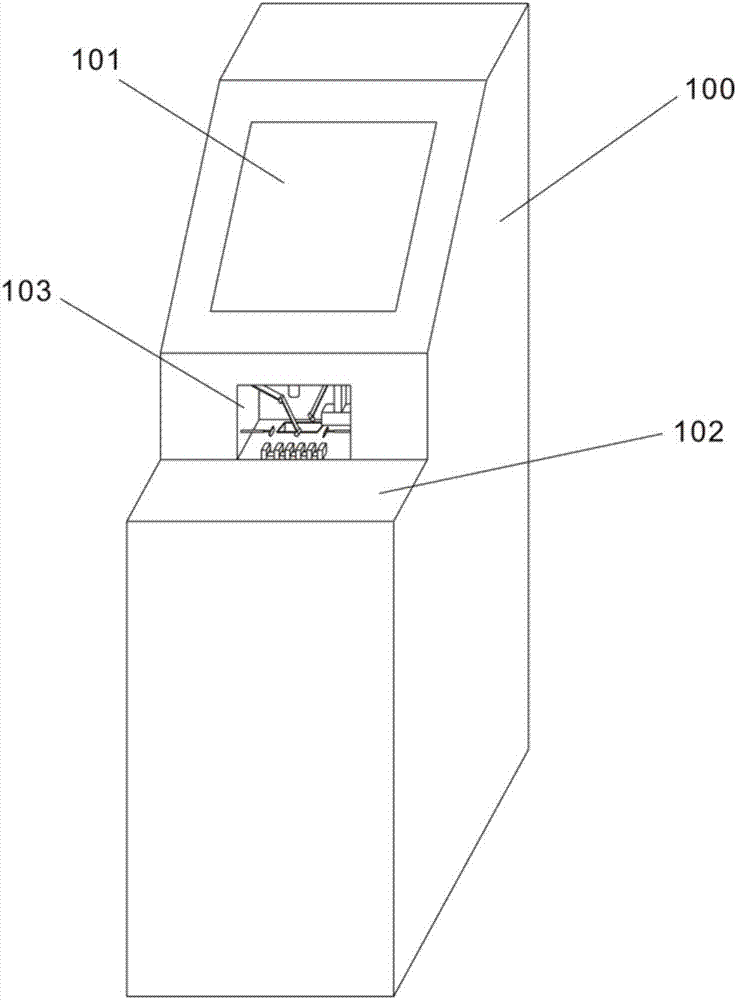

Nail polish nozzle, nail polish box, manicure vending machine and manicure technology

PendingCN107307564ASave spaceFast printingApparatus for meter-controlled dispensingManicure/pedicureSpray nozzlePulp and paper industry

The invention discloses a nail polish nozzle, a nail polish box, a manicure vending machine and a manicure technology, and the nail polish nozzle comprises four nail polish nozzles which are arranged in the nail polish box; the nail polish box comprises nail polish accommodation cavities and polish inlets, and the nail polish accommodation cavities are communicated with the nail polish nozzles; the manicure vending machine comprises a machine body, a touch display screen and a working table, and the working table further comprises a palm placing table and a manicure operation table which are separated by a closing door, and the palm placing table is located at the front end and the manicure operation table is located at the rear end. According to the manicure machine, the printing speed is high, cleaning, trimming, polishing, jet printing and drying can be completed by one step, the dead corner problem is avoided, and the manicure machine has the advantages that the full automation degree is high, layering outgoing of polish can be realized, and the printing effect is improved greatly.

Owner:SHENZHEN ZHUOBANGYUAN TECH CO LTD

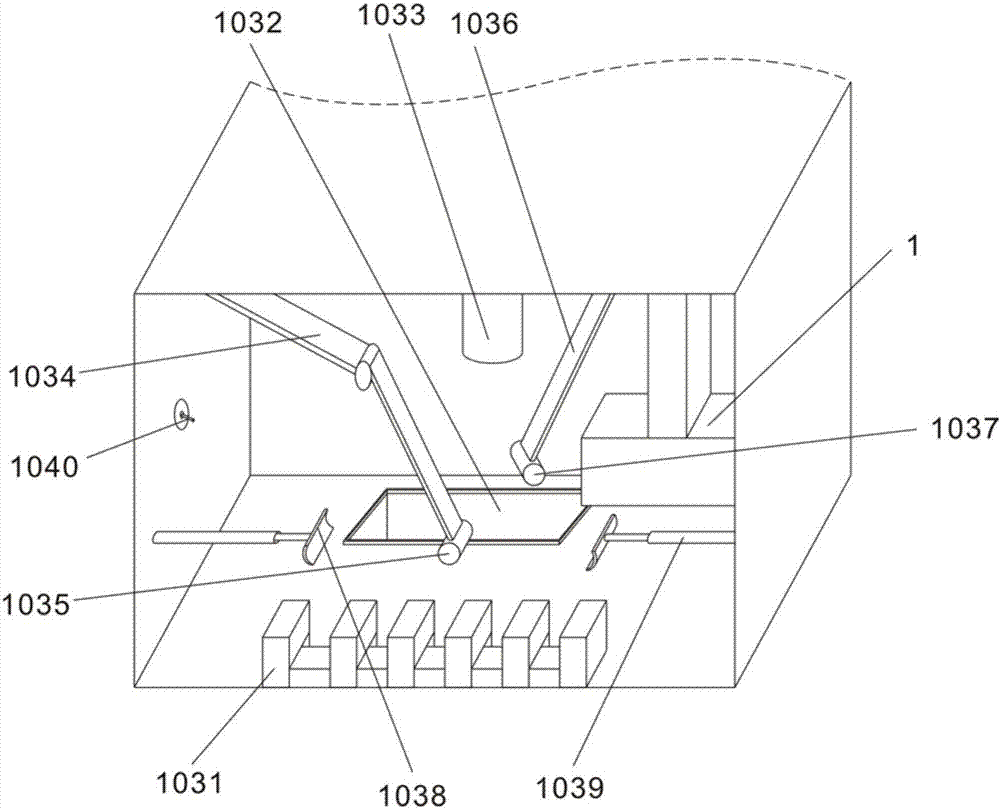

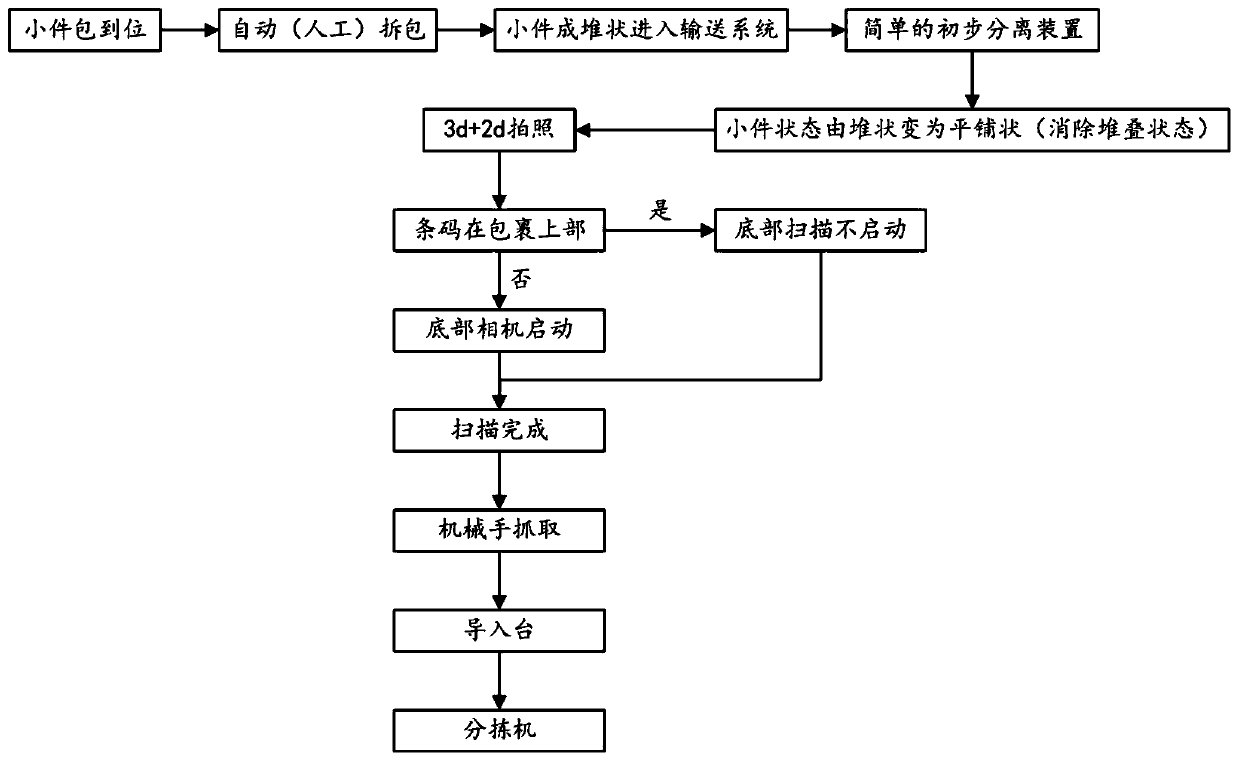

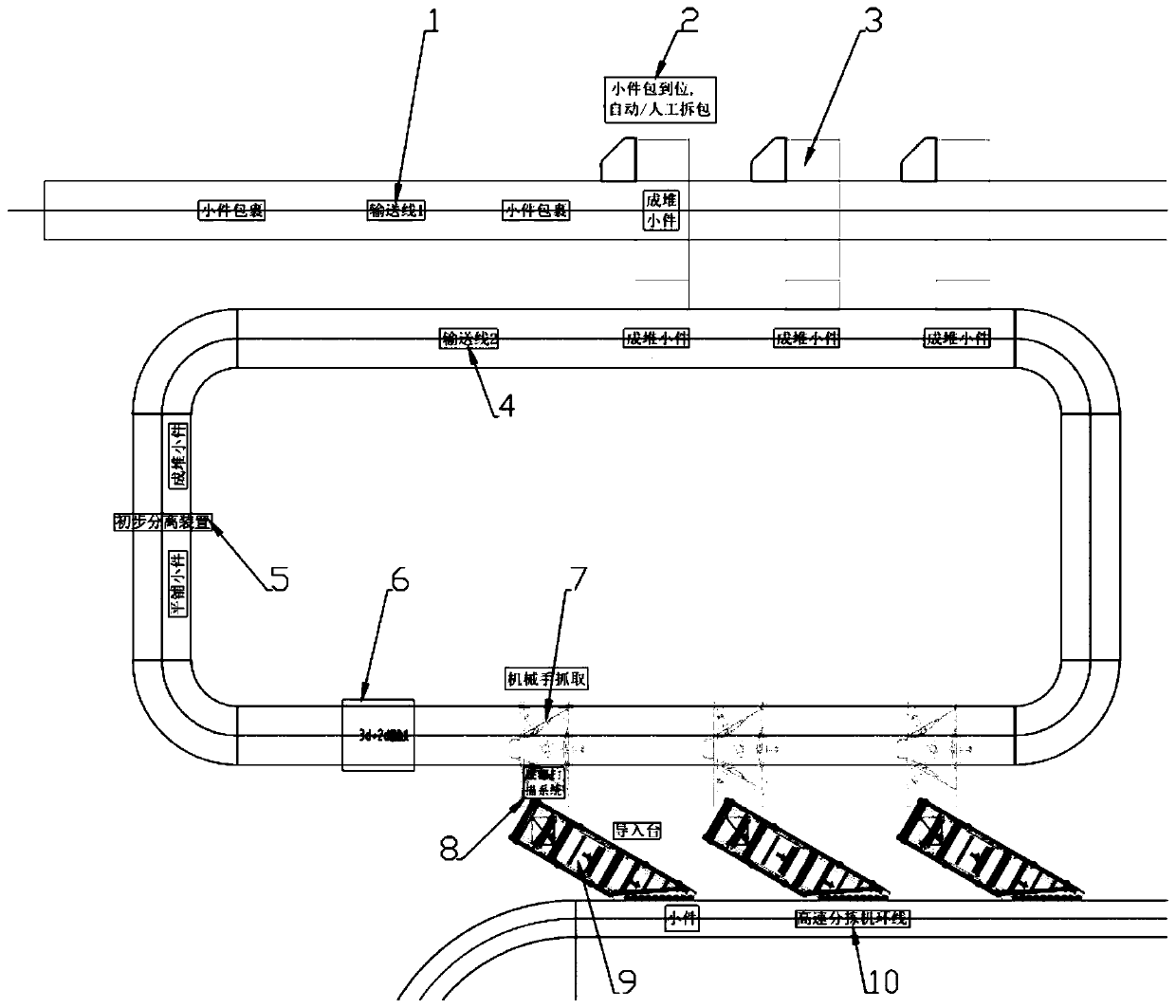

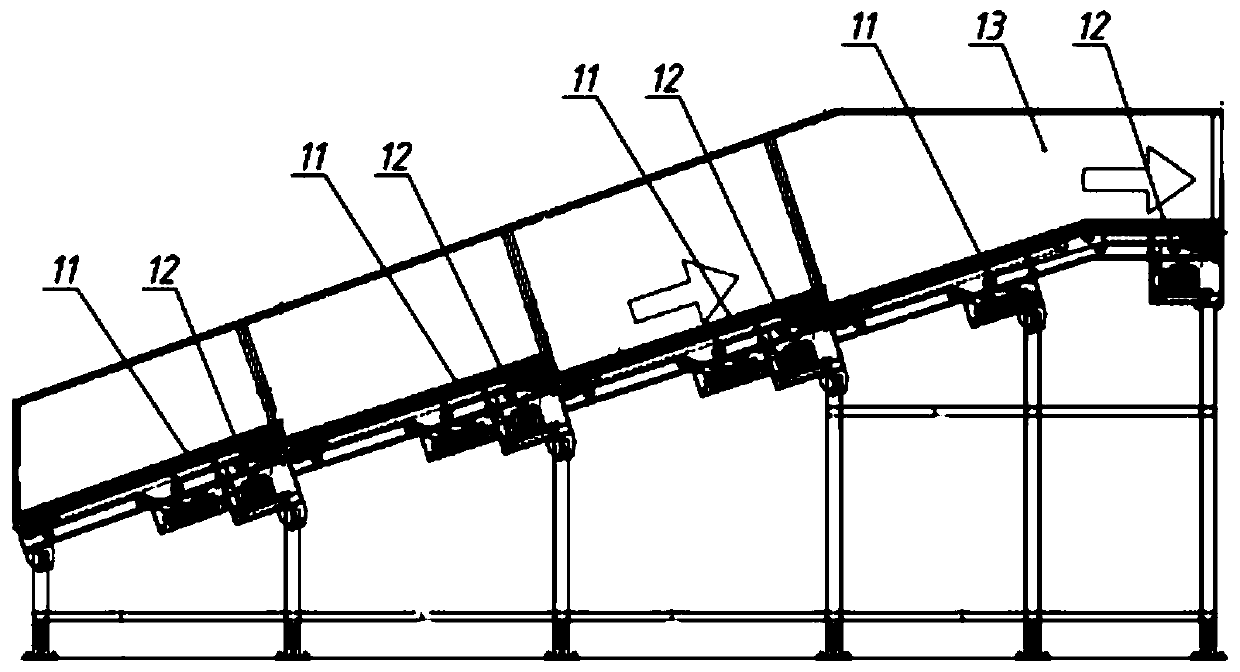

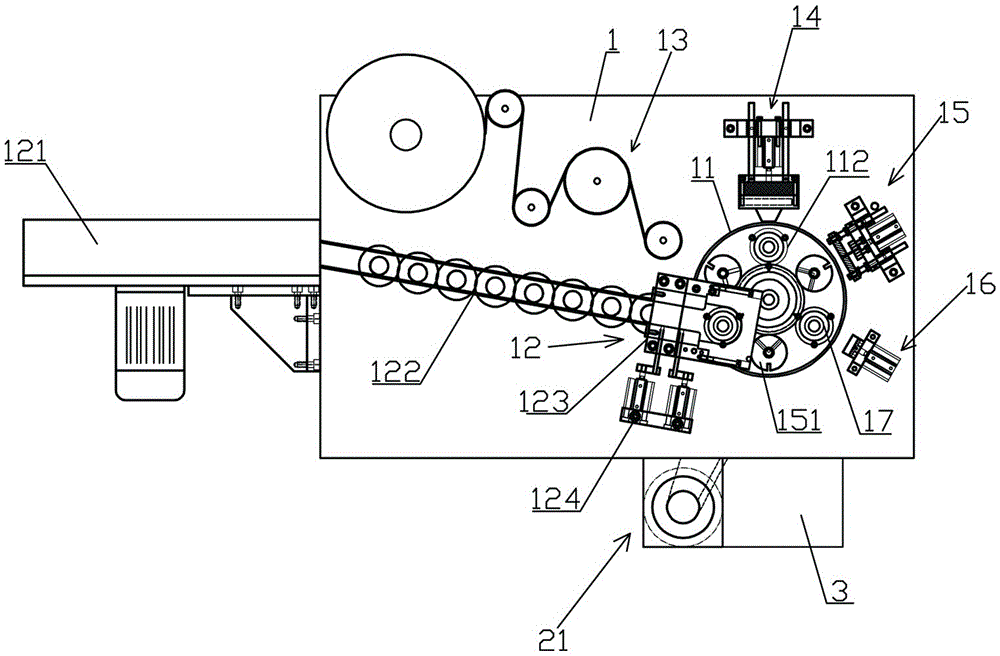

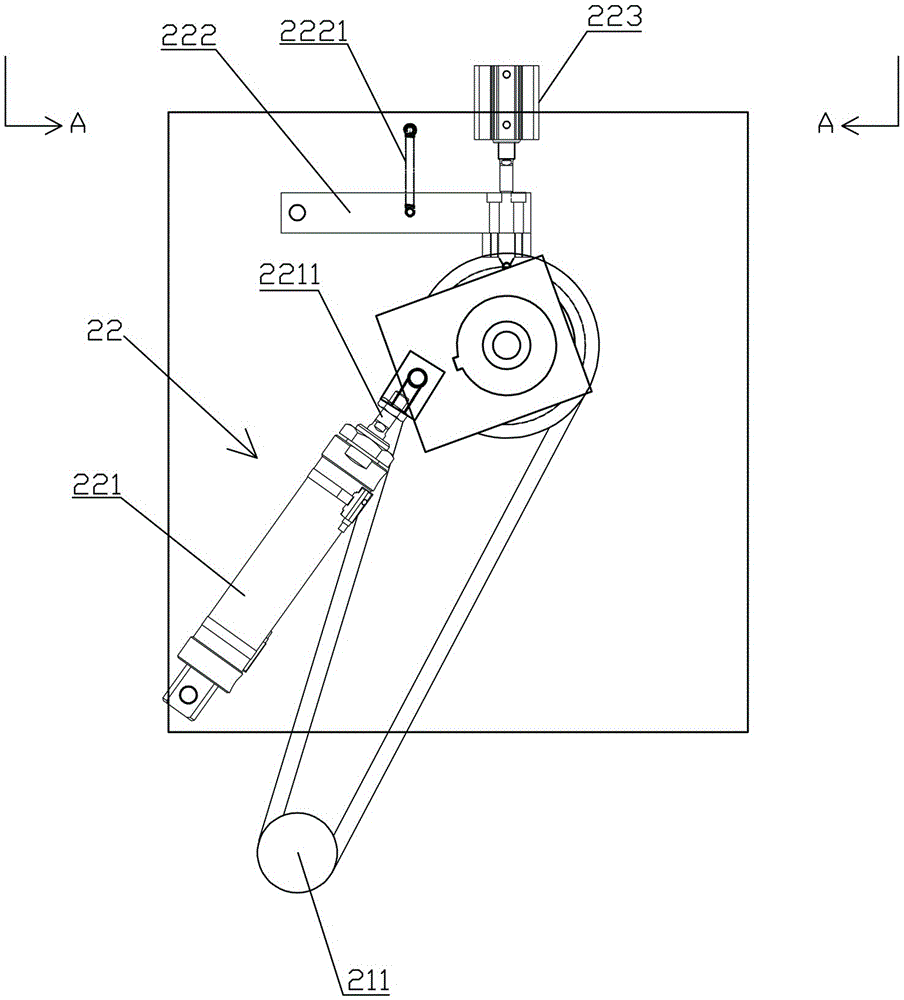

Automatic parcel feeding and sorting control method

ActiveCN111282827AImprove execution speedImprove sorting efficiencySortingRobot handAgricultural engineering

The invention provides an automatic parcel feeding and sorting control method. According to the automatic parcel feeding and sorting control method, an automatic separation procedure is set before parcels are fed into a sorting machine, a manual parcel one-by-one feeding mode is omitted, and a mechanical separation device and a cyclic parcel feeding mode are adopted, so that the operation pressureof parcel one-by-one feeding after unpacking is eliminated, the one-by-one scanning recognition and parcel feeding rate and accuracy are improved, the number of workers for feeding parcels and the load of the workers are effectively reduced, and the high-speed operating and sorting efficiency of the sorting machine is ensured fundamentally. The automatic parcel feeding and sorting control methodcomprises the following steps of (1) goods unpacking, specifically, dismantling goods conveyed from a first conveying line into small goods parcels at an unpacking unit; (2) separation, specifically,conveying piles of unpacked goods parcels to a separation unit to be separated in a spreading state on the conveying line; (3) scanning, specifically, scanning codes through a 3d+2d vision unit, inputting external dimension data of all the goods, and establishing follow-up sorting tasks through generated coordinate information; (4) parcel feeding, transferring the goods to a sorting machine lead-in unit through a manipulator grabbing unit; and (5) sorting, specifically, feeding the goods into the conveying line of the sorting machine through the sorting machine lead-in unit until the sorting task is completed.

Owner:QINGDAO KENGIC AUTOMATION EQUIP CO LTD

A fully automatic raw material tape splitting machine

ActiveCN103449264BEasy to controlRealize fully automated operationWebs handlingWinding machineControl system

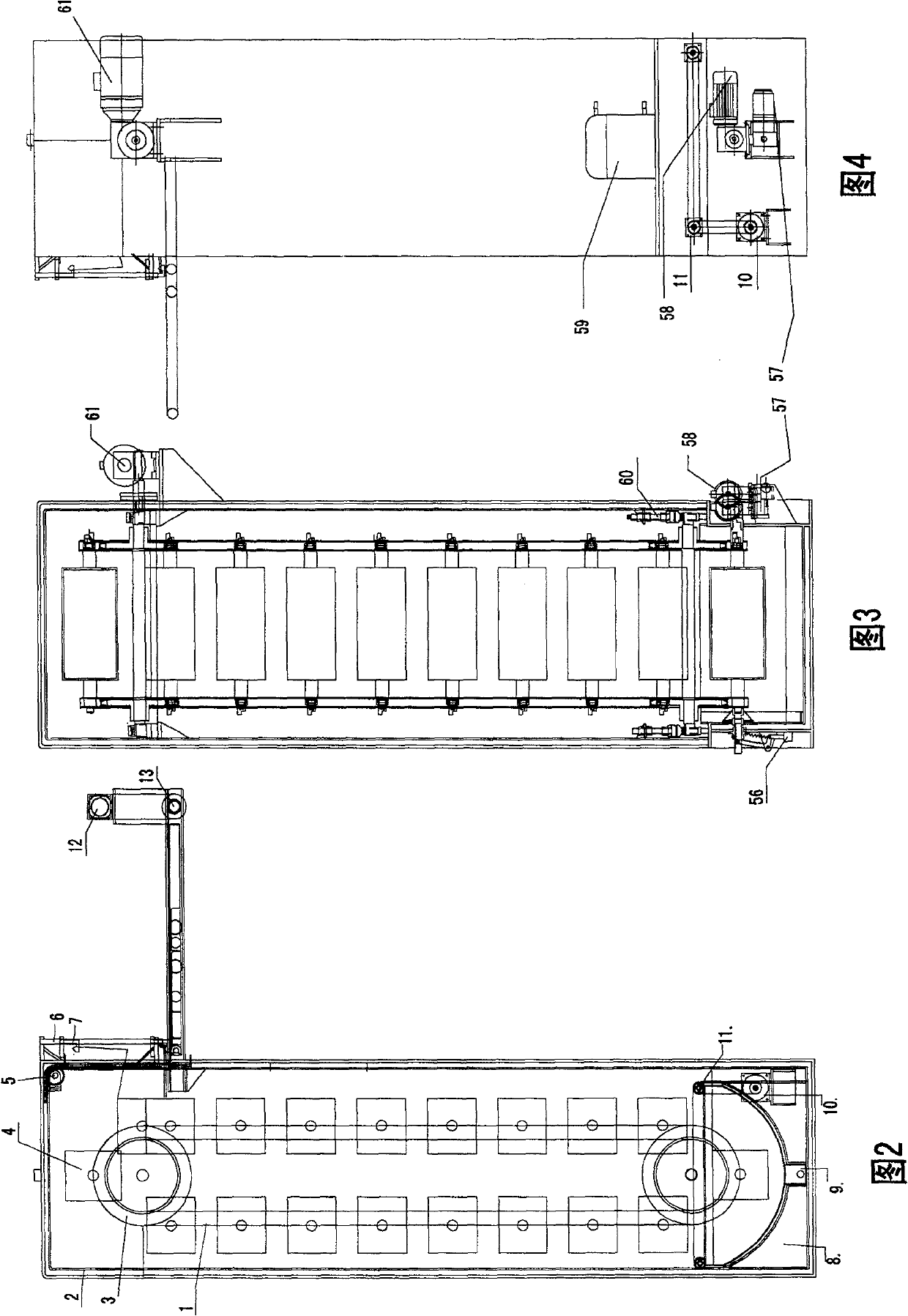

The invention disclose a full-automatic thread seal tape roll separator which comprises a frame body, a power driving mechanism and a control system, wherein a rotatable scale division rotary table is mounted on the frame body; a central rotating shaft and three rotating shafts are arranged on the scale division rotary table; the central rotating shaft is used for driving the scale division rotary table to rotate, and the three rotating shafts are uniformly distributed along the circumference of the scale division rotary table and can rotate independently; a roll core supplying device, a feeding device, a bonding device, a cutting-off device, a tail pressing device and an unloading device of thread seal tapes are sequentially mounted on the frame body on the outer side of the scale division rotary table in the clockwise direction; the roll core supplying device is used for automatically supplying roll cores for the rotating shafts of the scale division rotary table; the feeding device is used for conveying the thread seal tapes to the roll cores on the scale division rotary table and winding; the bonding device is used for bonding the thread seal tapes on the roll cores; the cutting-off device is used for cutting off the thread seal tapes; the tail pressing device is used for pressing the cutting-off thread seal tapes. The full-automatic thread seal tape roll separator has the advantages that the full-automatic operation of thread seal tape roll separation is achieved, the rolled length of the thread seal tapes is controlled accurately, and the production efficiency is improved.

Owner:FUJIAN CHUN FLAG MACHINERY IND & TRADE

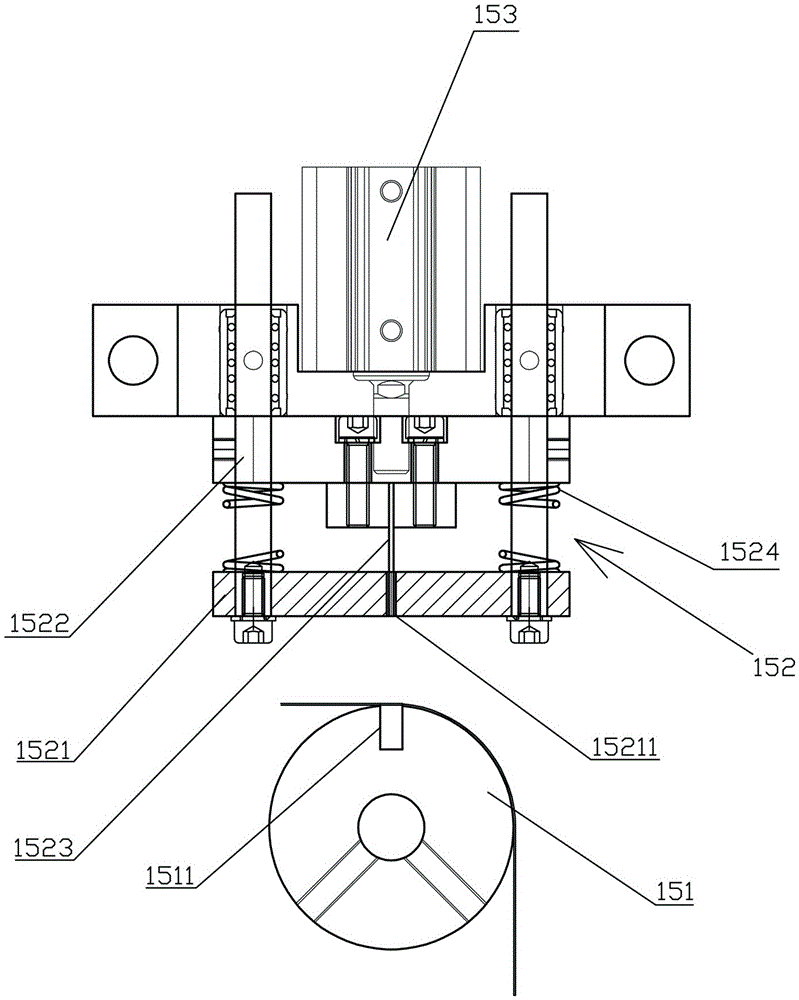

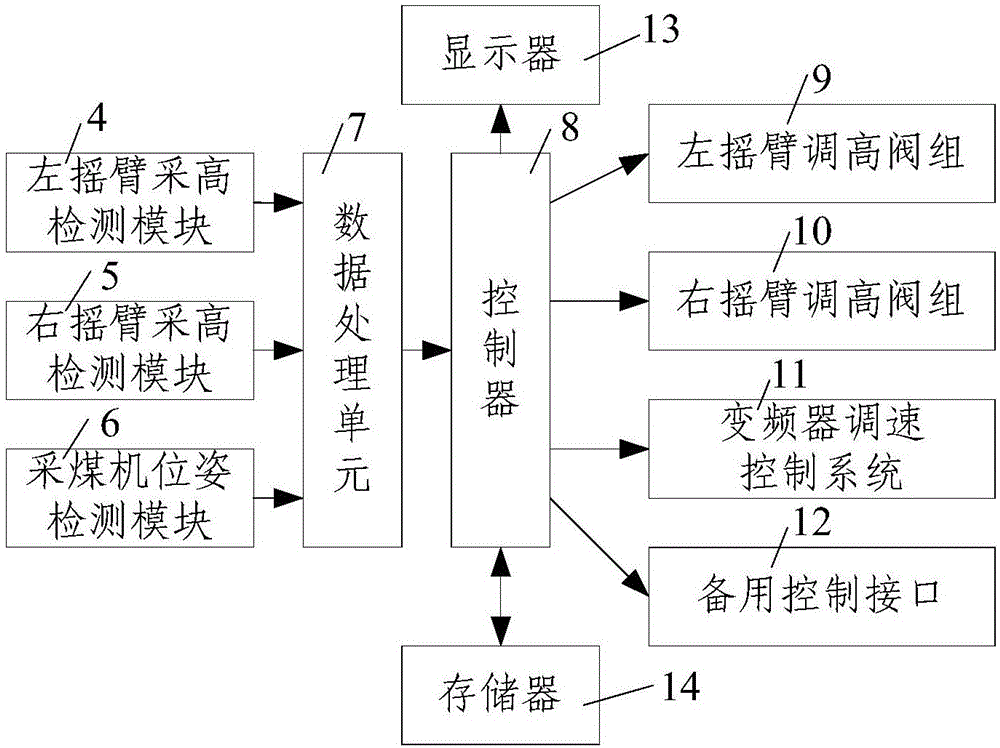

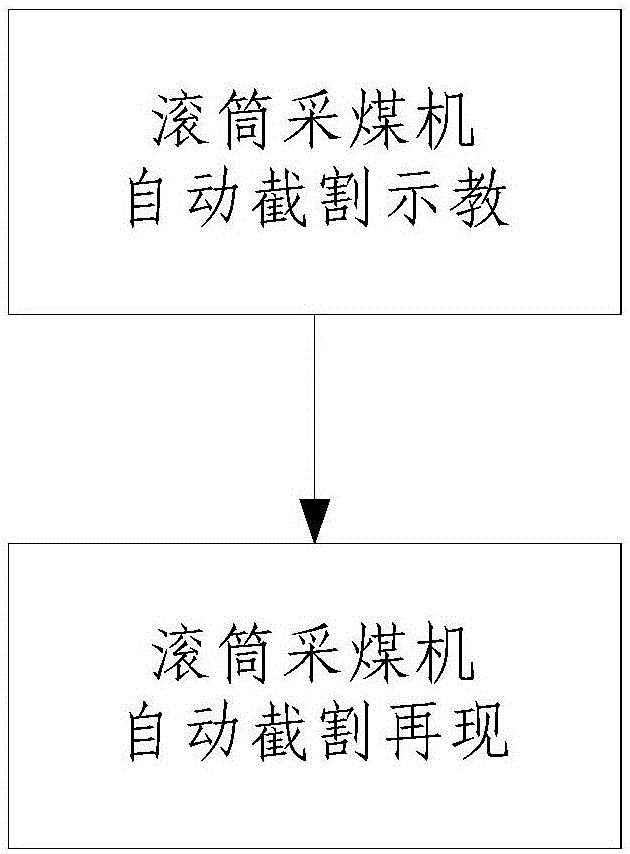

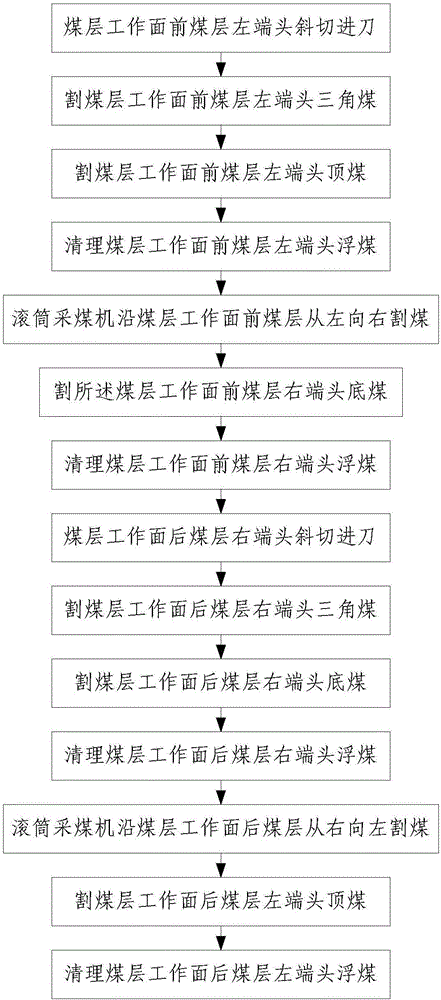

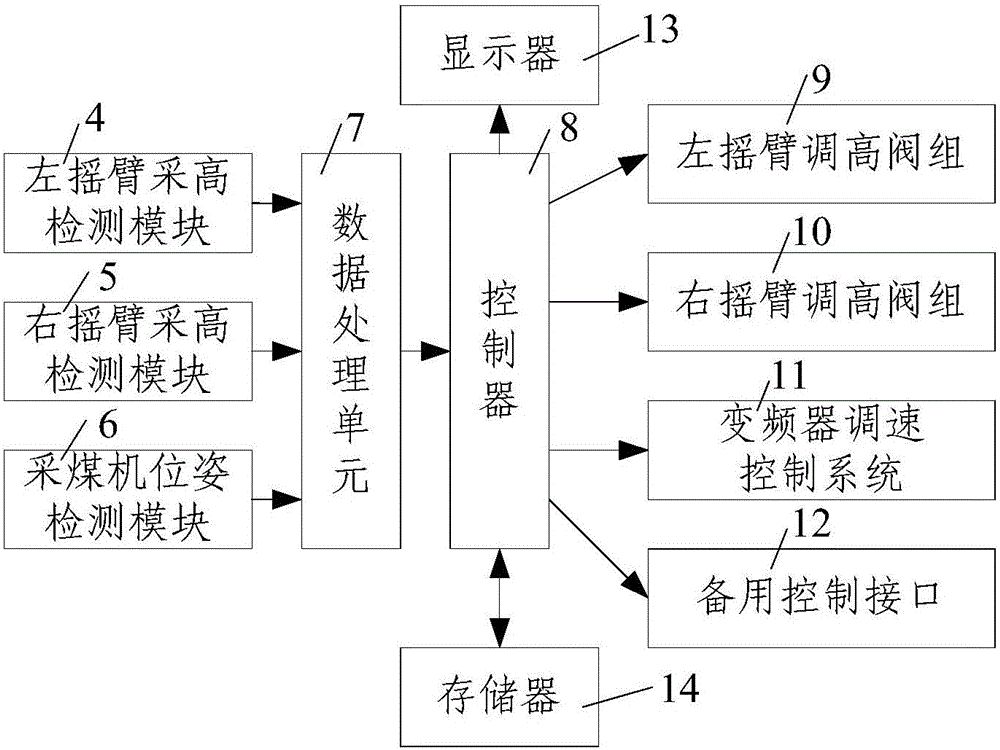

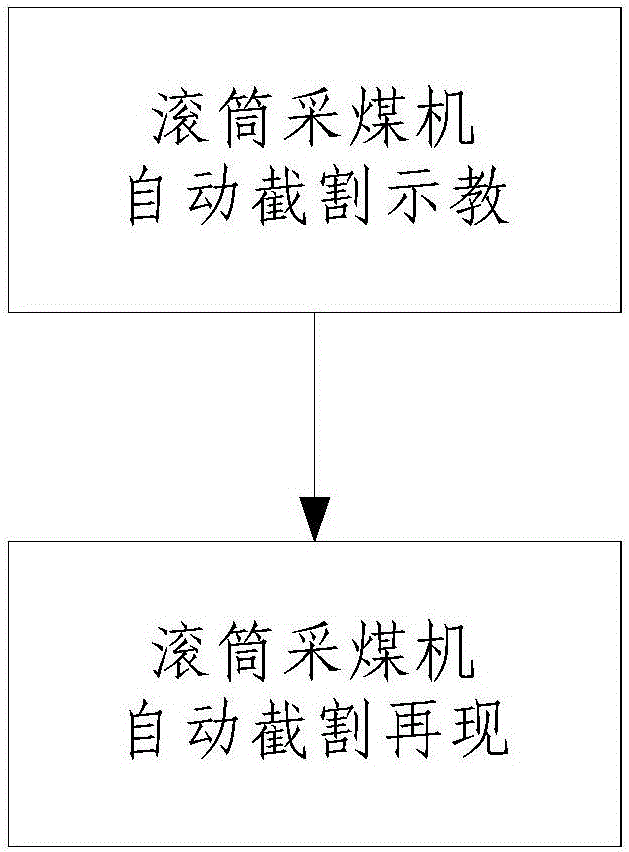

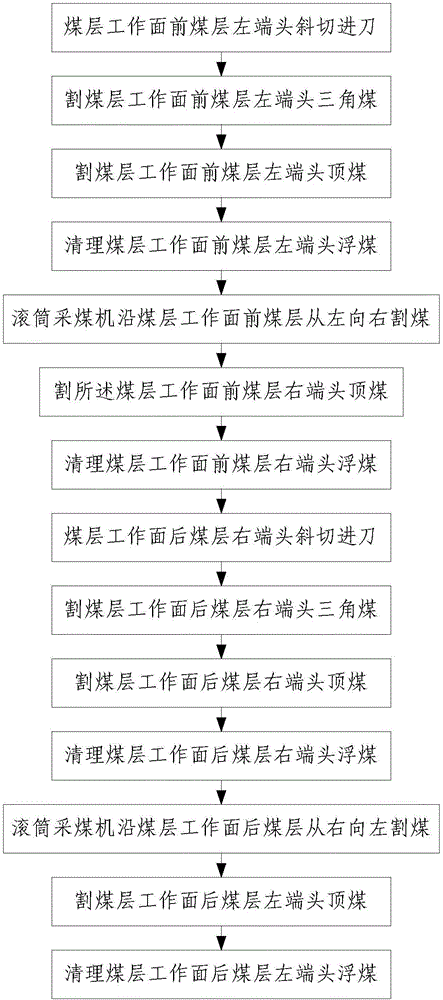

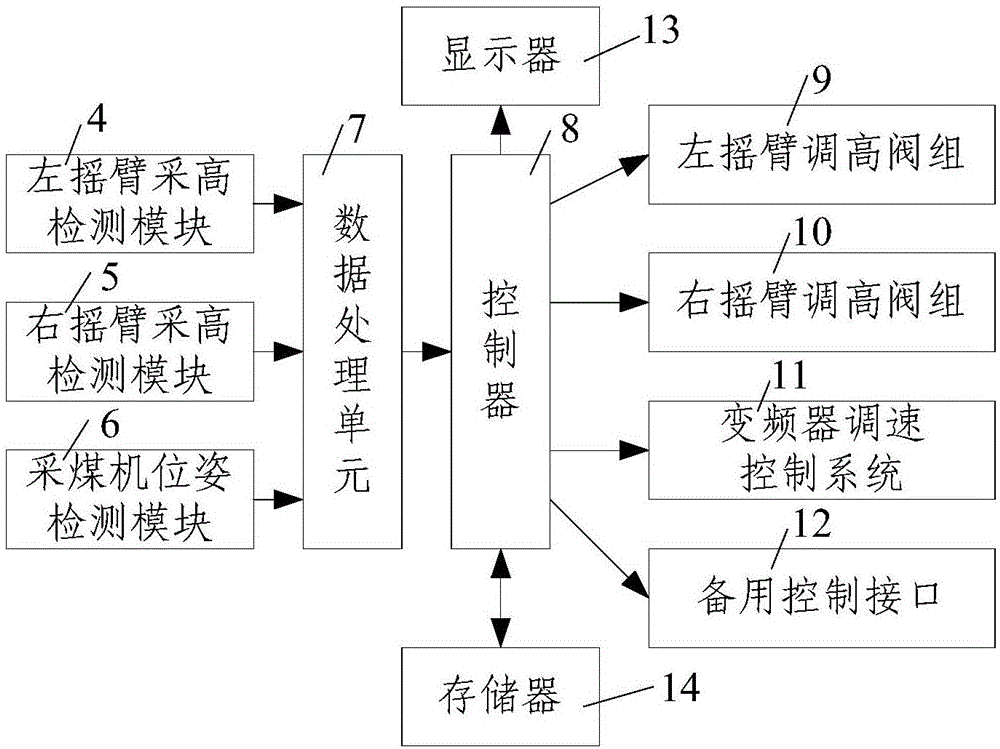

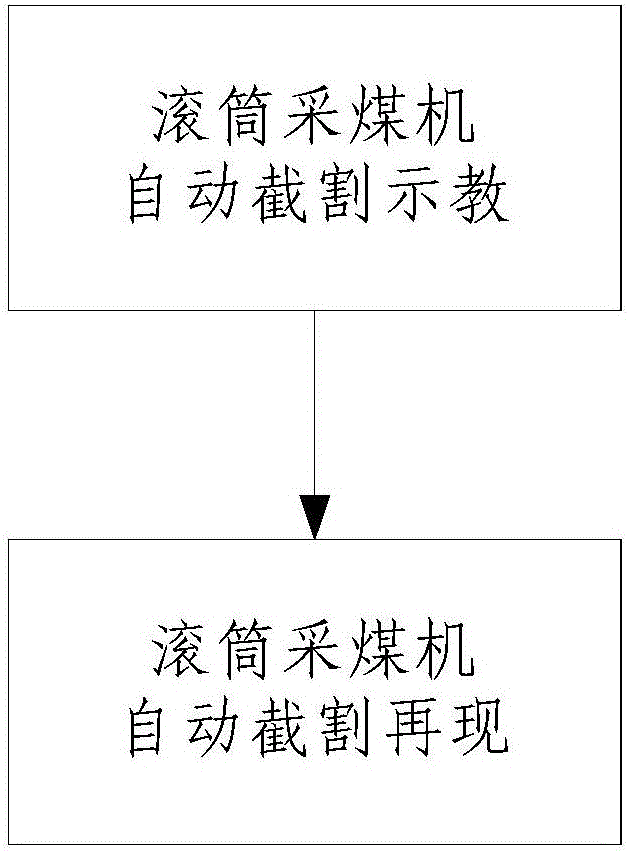

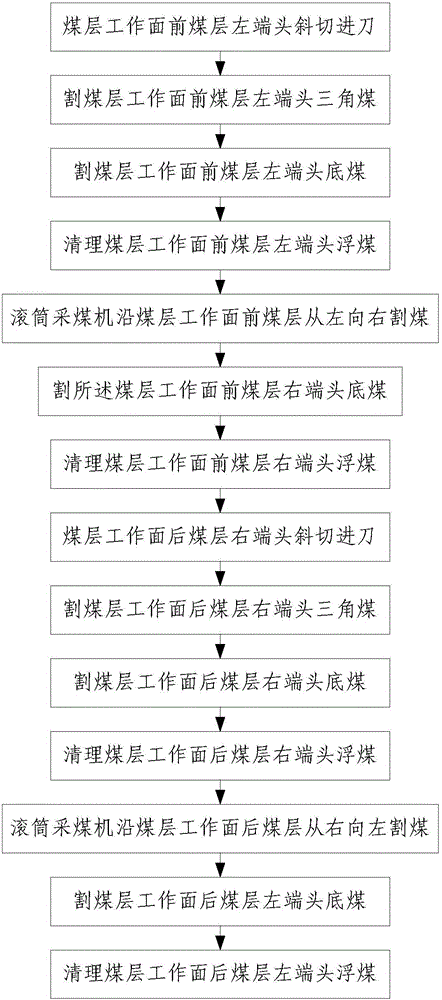

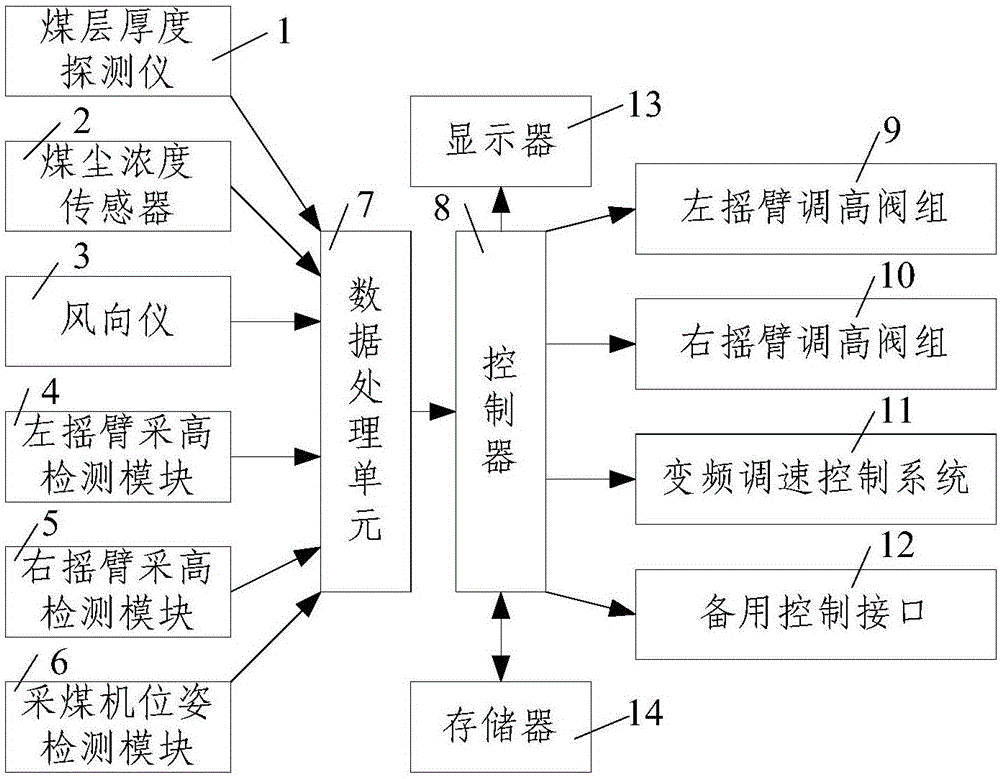

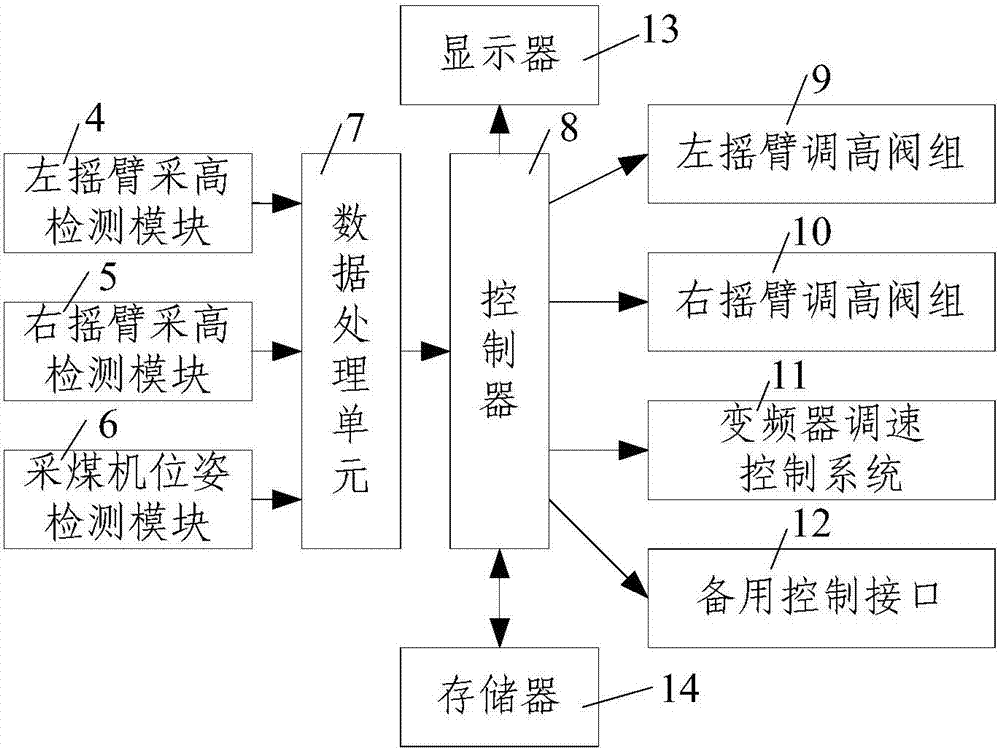

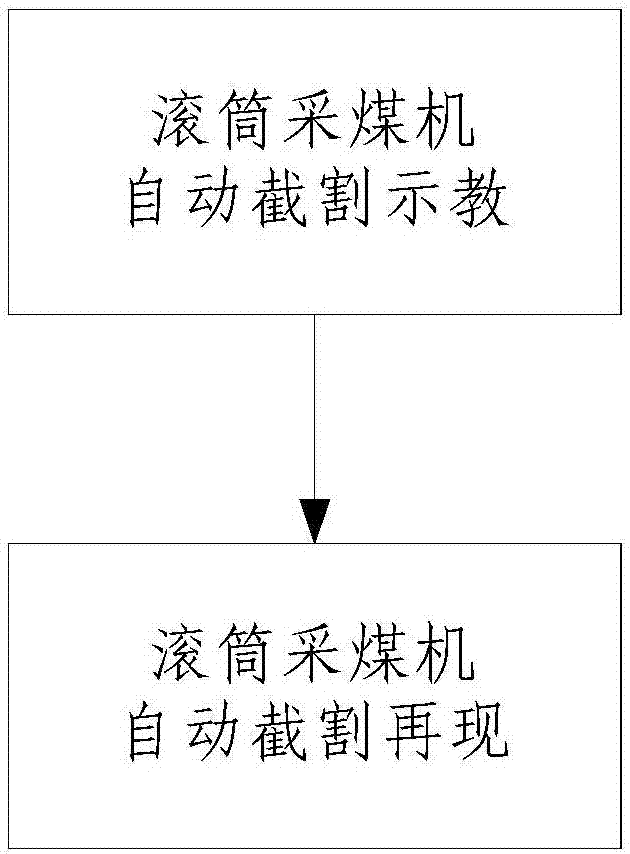

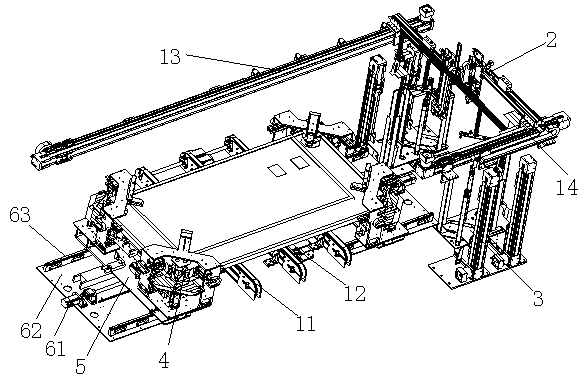

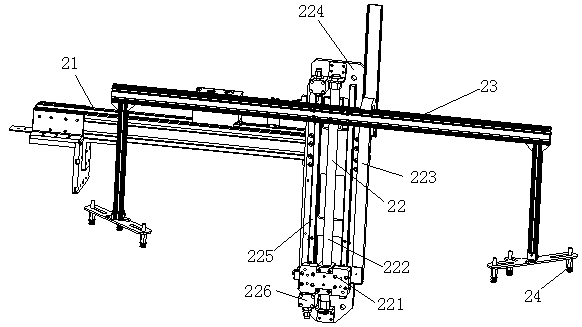

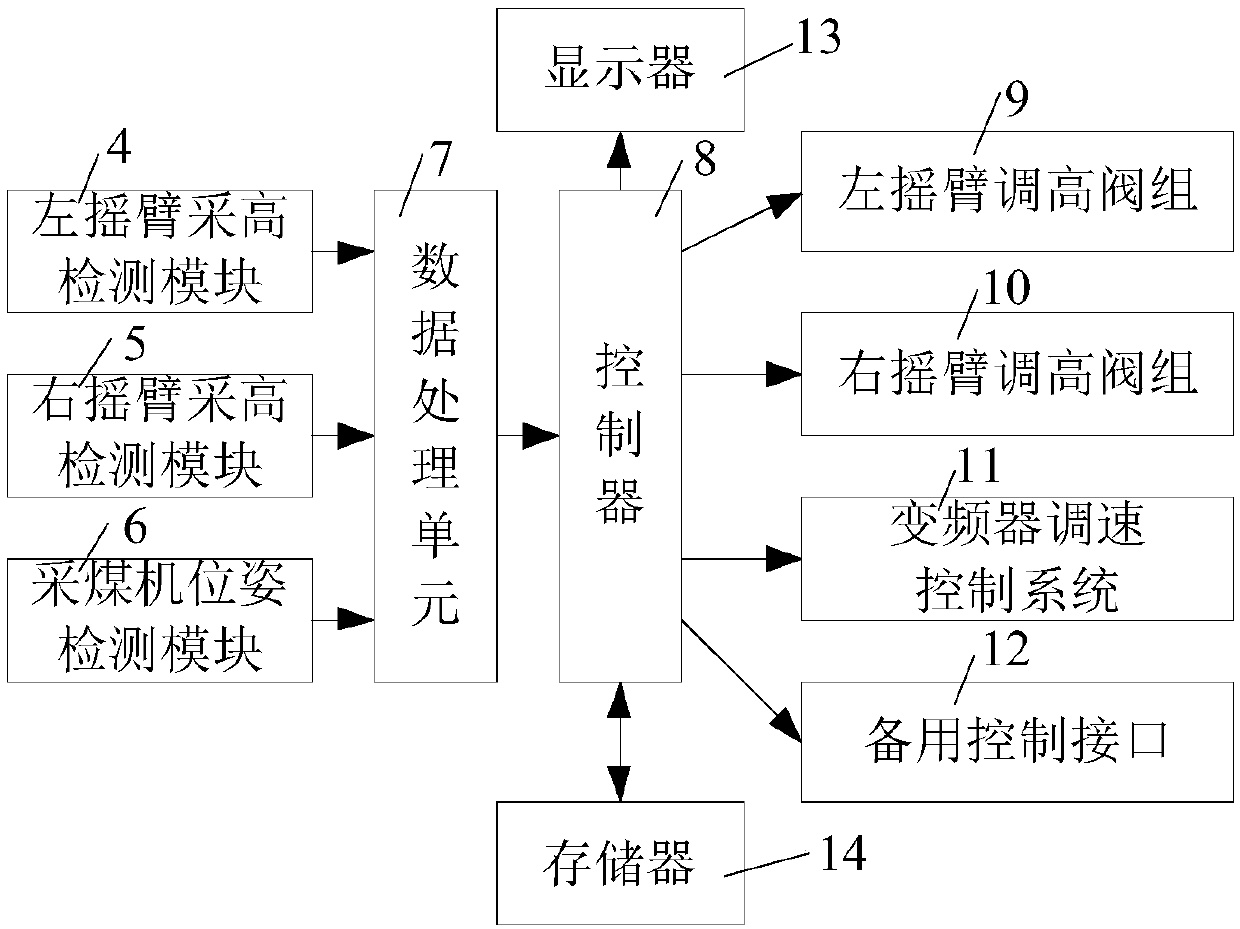

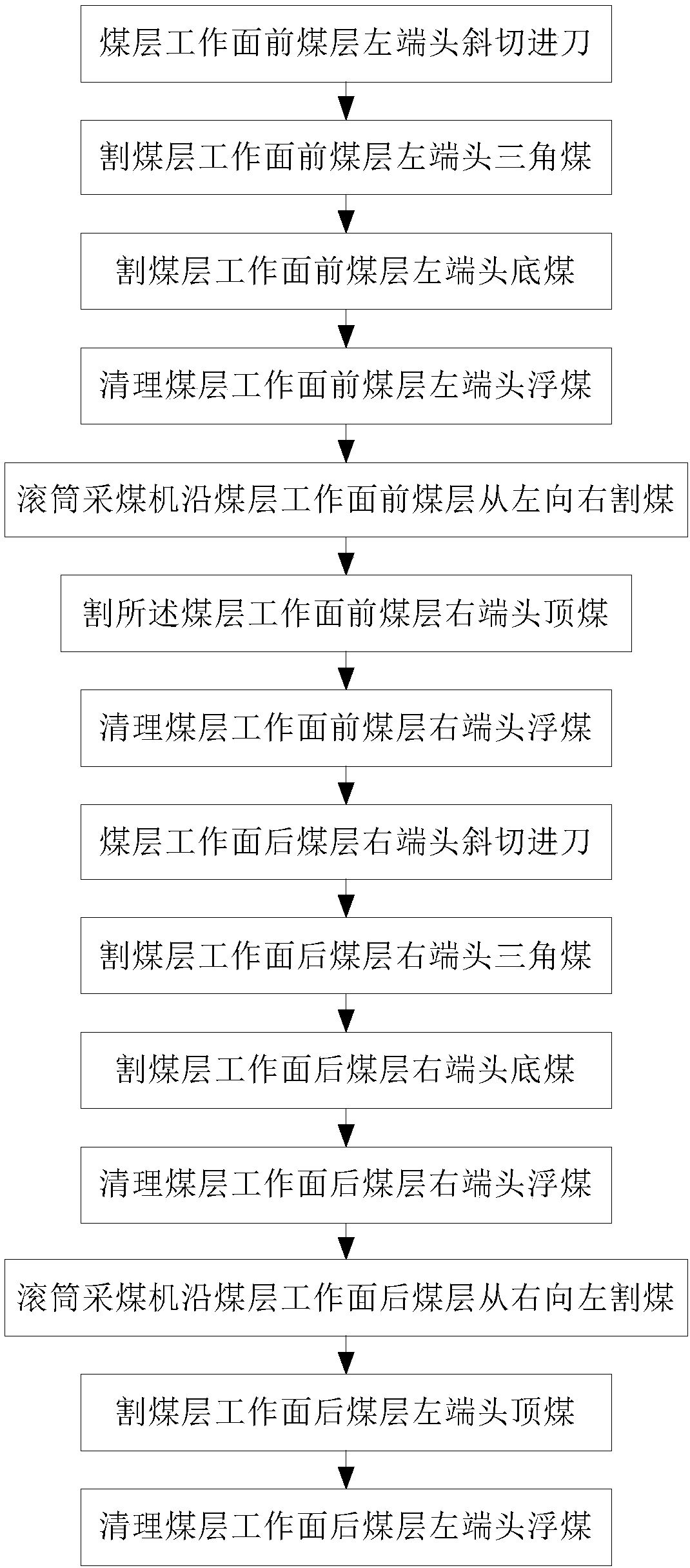

Control method of high-coal-dust thin coal seam shearer demonstration and representation of automatic cutting with wind direction

ActiveCN106194183AReasonable designRigorous method stepsSlitting machinesAutomatic controlControl system

The invention discloses a control method of high-coal-dust thin coal seam shearer demonstration and representation of automatic cutting with wind direction. The control method includes following steps: 1, demonstrating of automatic cutting of a drum shearer; 2, representing automatic cutting of the drum shearer: 201, initializing a drum shearer control system; 202, judging whether the drum shearer is positioned at the end or not; 203, representing automatic cutting of the left end of the drum shearer; 204, representing automatic cutting of the right end of the drum shearer. The high-coal-dust thin coal seam drum shearer cutting process with the wind direction is demonstrated and includes necessary processes during oblique-cutting feeding, triangular coal cutting, floating coal removing and coal cutting and mining during advancing of high-coal-dust thin coal seams with the wind direction, so that manual intervention is greatly reduced, automated coal mining requirements on coal mining process of the high-coal-dust thin coal seams with the wind direction are met, and full-automatic control efficiency is high.

Owner:XIAN COAL MINING MACHINERY

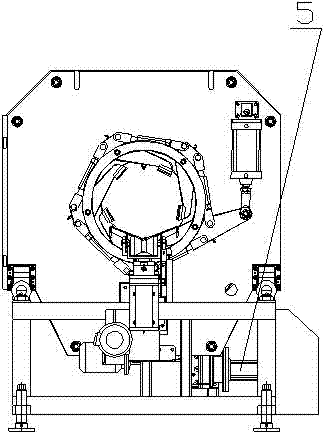

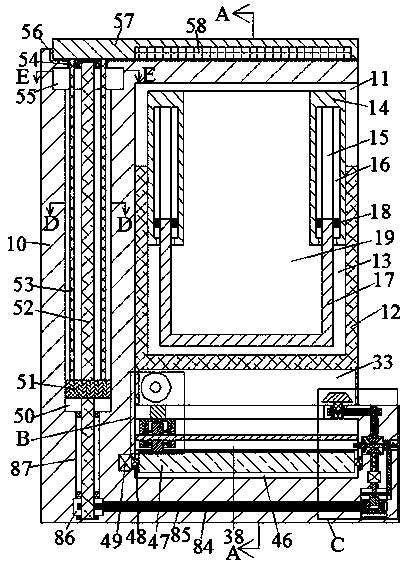

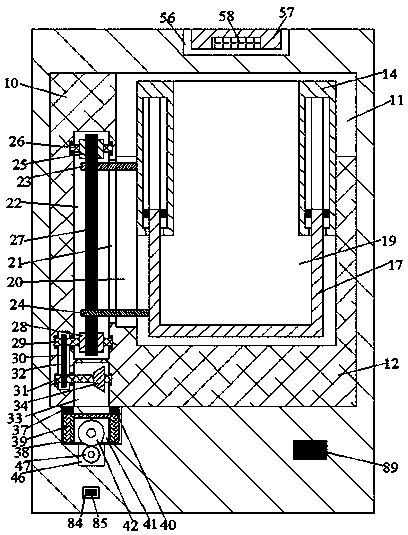

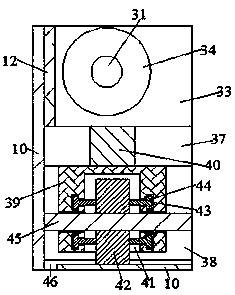

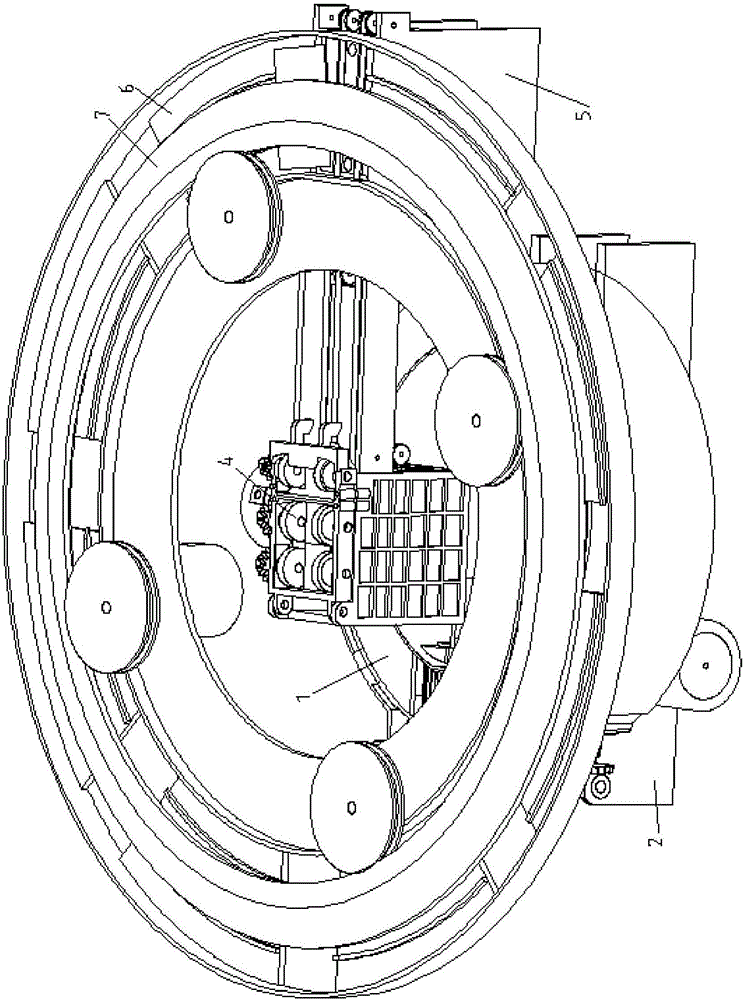

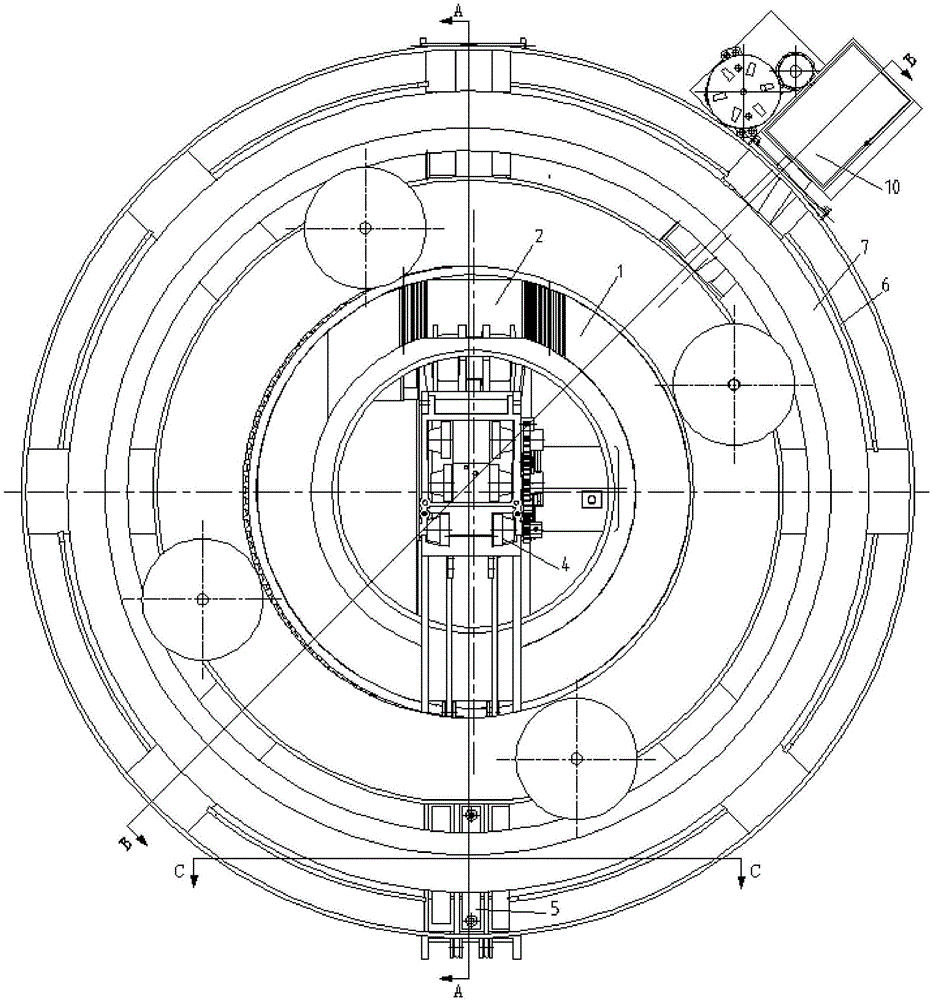

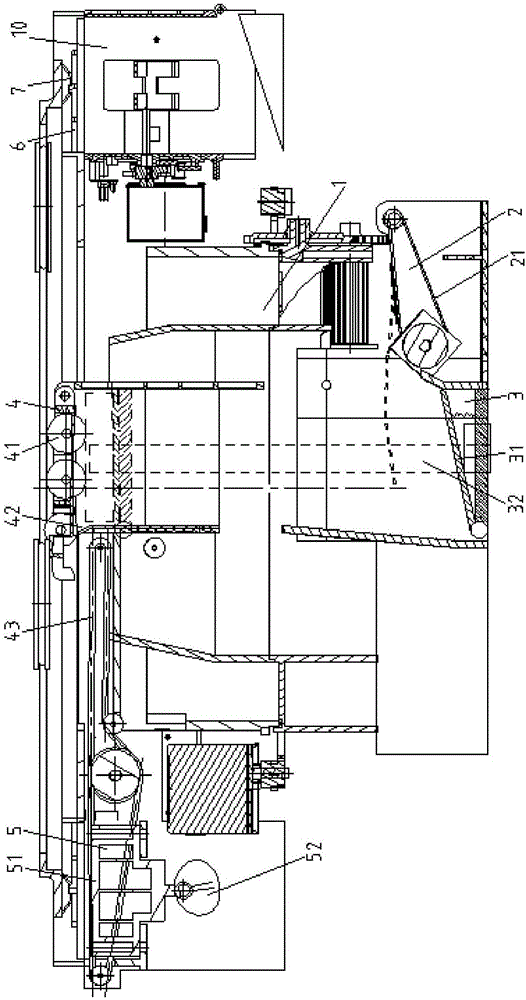

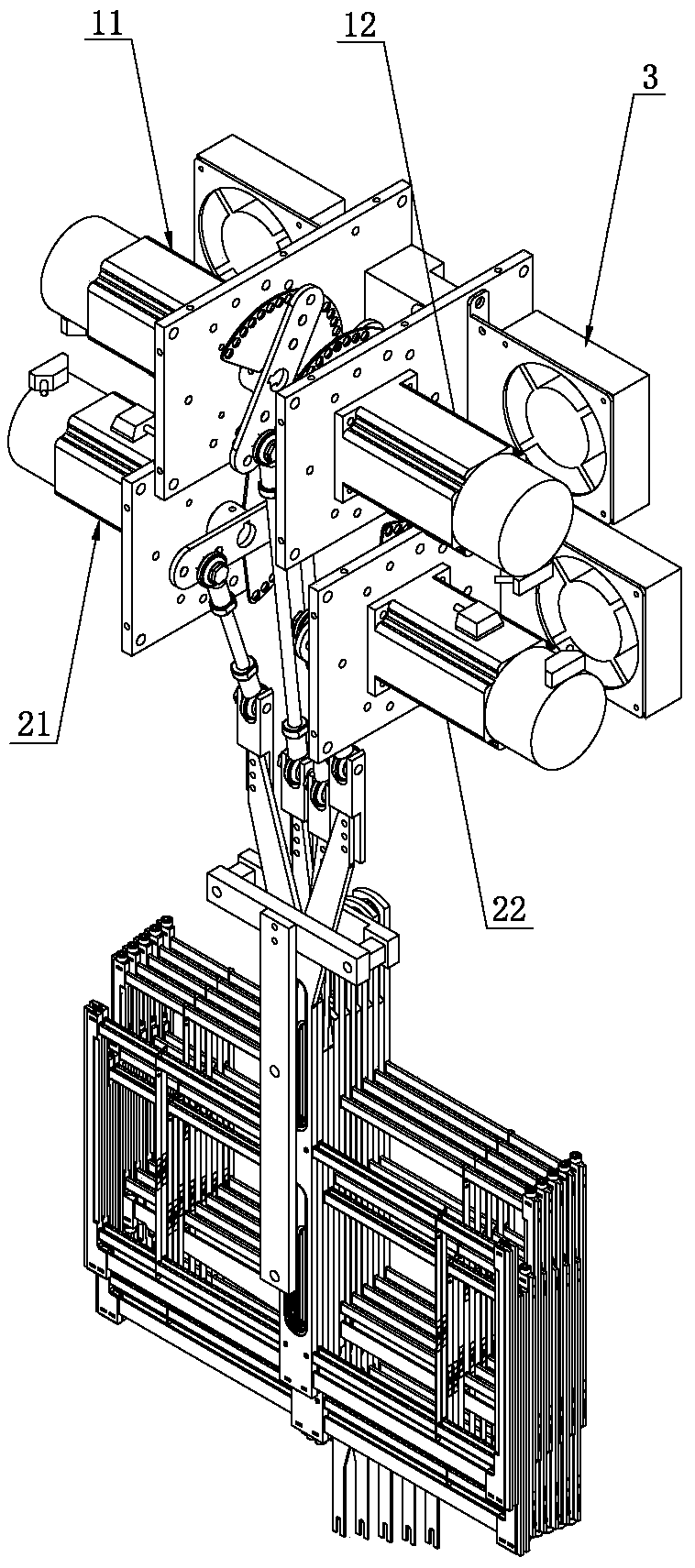

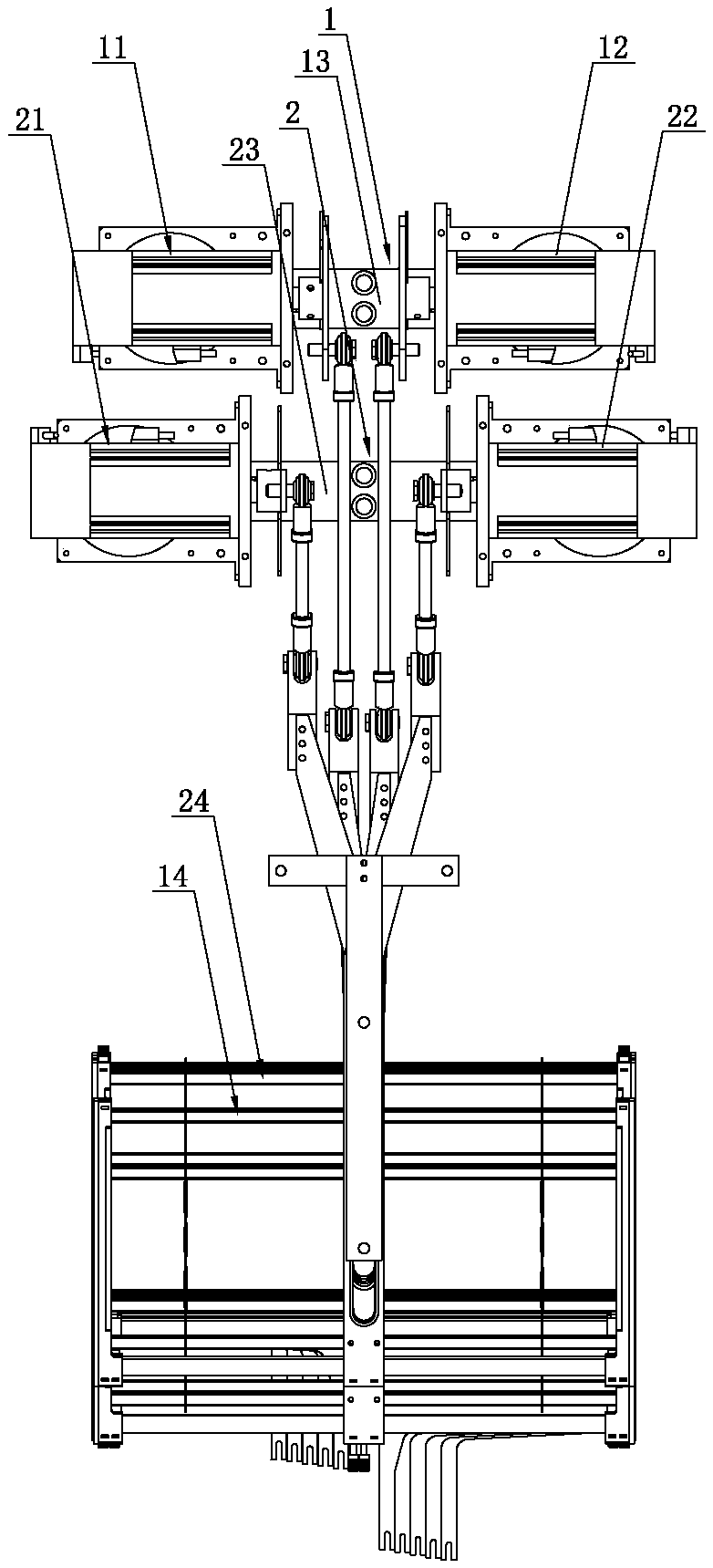

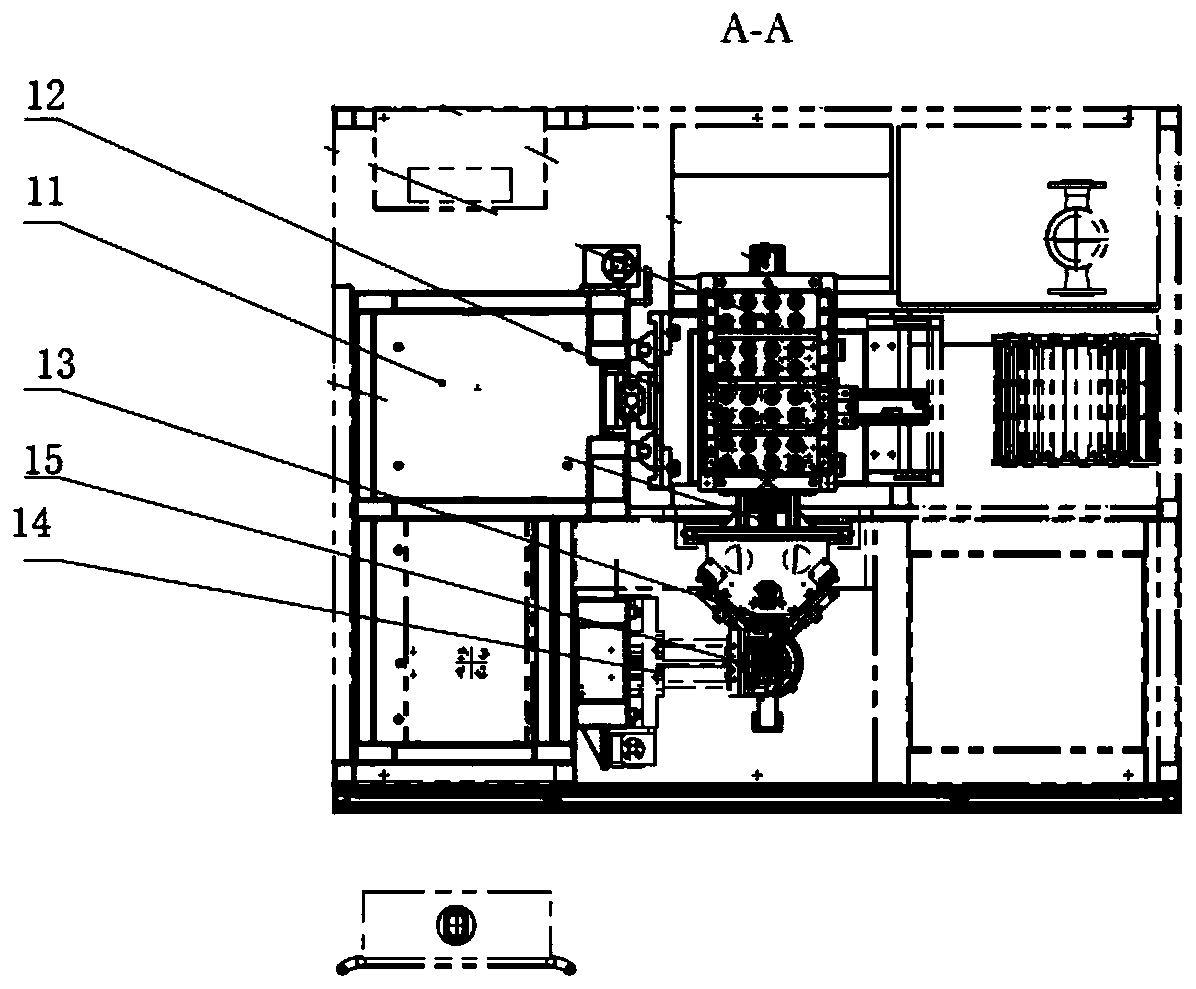

Automatic poker machine

PendingCN106110641AHigh degree of full automationAvoid identificationCard gamesEngineeringWaiting time

The invention discloses an automatic poker machine which comprises an annular shuffling box, a card distribution mechanism and a card sending mechanism, wherein the annular shuffling box is used for collecting and shuffling scattered poker cards and then stacking a poker card pile; a conveying device is connected below the annular shuffling box; a spring lifting platform is connected behind the conveying device; the card distribution mechanism capable of sending out poker cards is arranged above the lifting platform; the front end of a card conveying mechanism is engaged with an annular track; a friction belt for driving the poker cards conveyed by the card conveying mechanism to move along circumference of the annular track is arranged above the annular track; a card falling port allowing the poker cards to fall to the card sending mechanism is formed in the annular track; the card sending mechanism is used for sending the poker cards to specified card sending positions. The automatic poker machine is high in automation degree of mechanisms, simple in structure and convenient to use, and can reduce the game labor intensity and shorten the waiting time.

Owner:JIANGSU DANBOM MECHANICAL & ELECTRICAL

Multi-head heald frame servo control device

PendingCN111575865AImprove work efficiencyHigh degree of full automationCam shedding mechanismHealdsServo control

The invention relates to the technical field of ribbon looms, in particular to a multi-head heald frame servo control device. The multi-head heald frame servo control device comprises a first heald frame opening mechanism and a second heald frame opening mechanism. The first heald frame opening mechanism comprises a first mounting base, the first mounting base is provided with a first warp liftingheald frame assembly and a second warp lifting heald frame assembly, and the first warp lifting heald frame assembly comprises a first warp lifting servo motor. The first warp lifting servo motor isconnected with a first adjusting assembly, and the first adjusting assembly is connected with a first connecting rod assembly. The first connecting rod assembly is connected with a first warp liftingheald frame. The second heald frame opening mechanism comprises a second mounting base, the second mounting base is provided with a third warp lifting heald frame assembly and a fourth warp lifting heald frame assembly, the third warp lifting heald frame assembly comprises a second warp lifting servo motor, the second warp lifting servo motor is connected with a second adjusting assembly, the second adjusting assembly is connected with a second connecting rod assembly, and the second connecting rod assembly is connected with a second warp lifting heald frame. The multiple warp lifting heald frames are automatically controlled to move up and down through computer programming, and electronic control adjustment is convenient.

Owner:东莞高恩机械有限公司

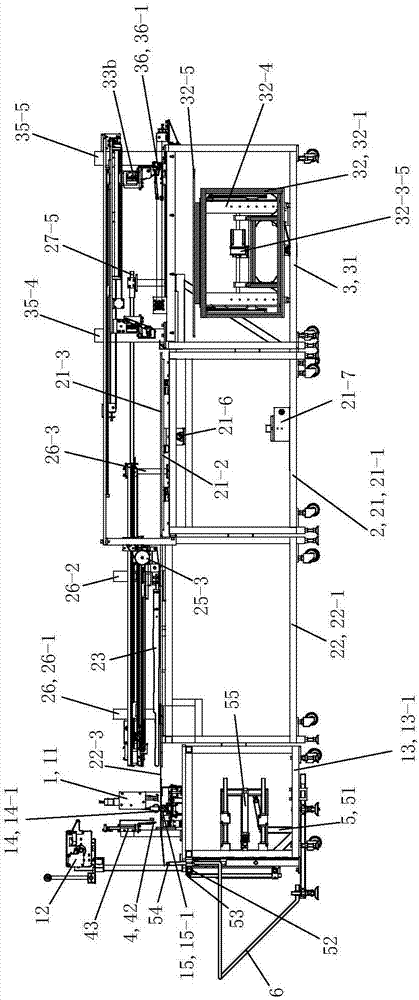

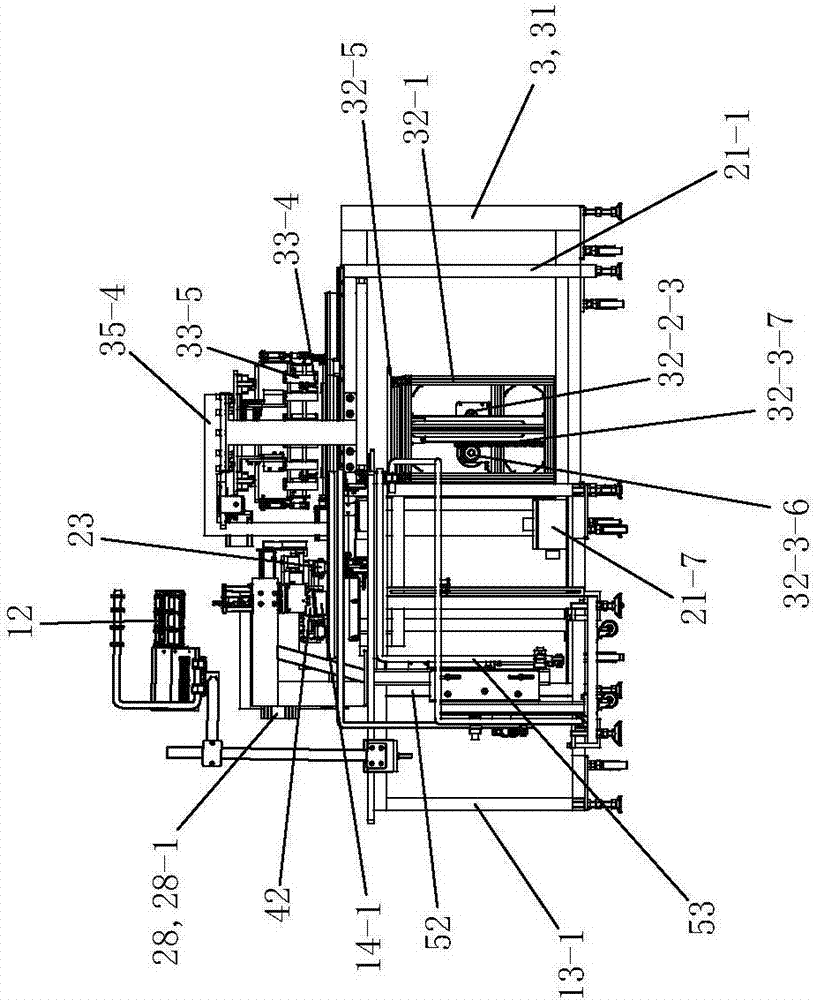

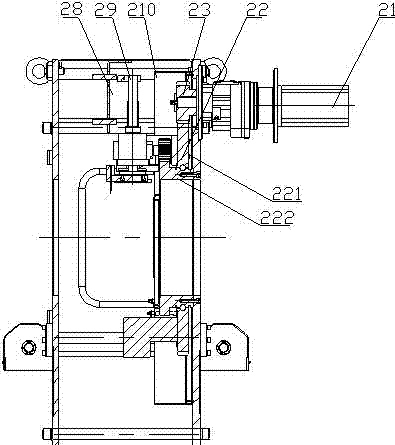

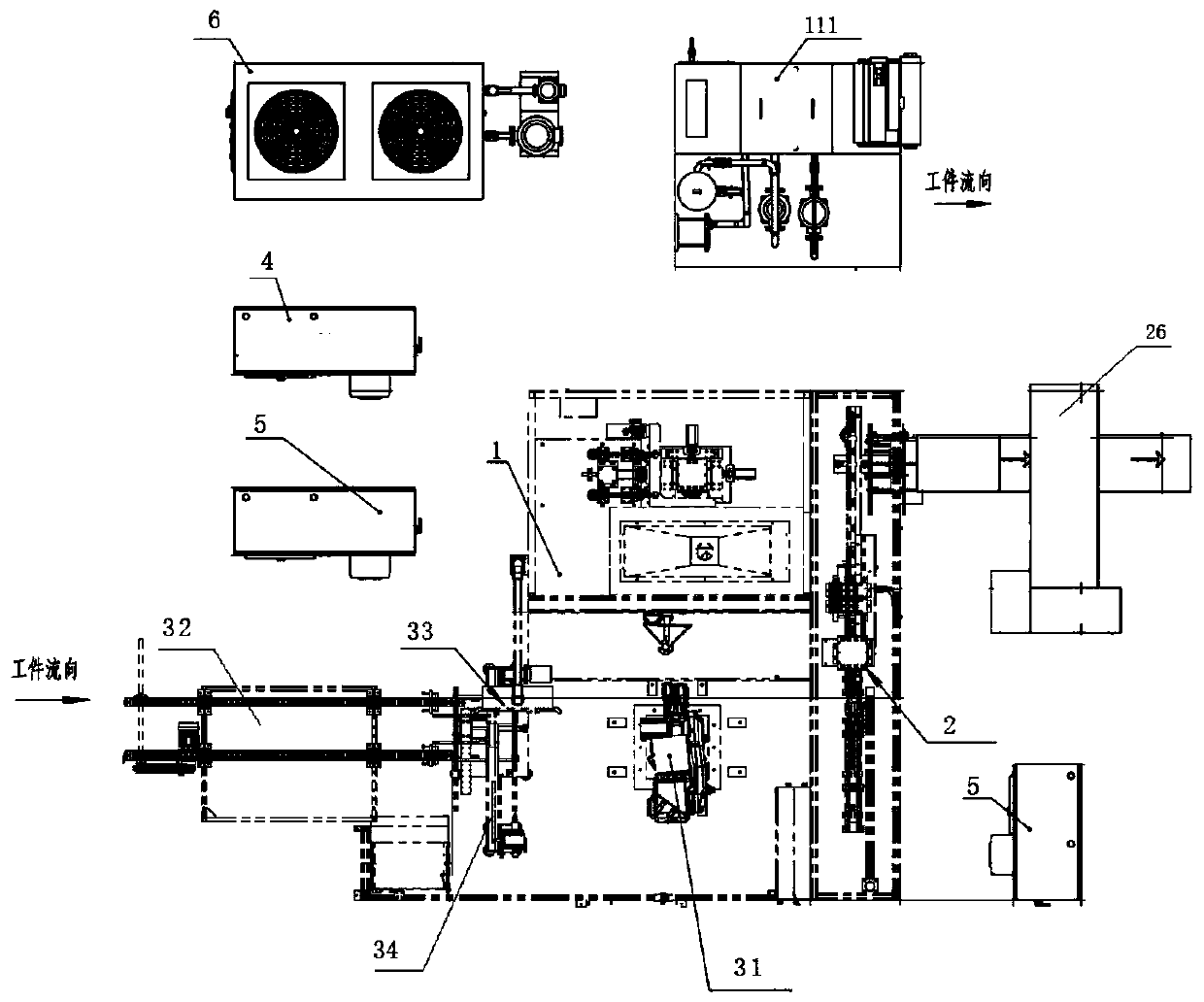

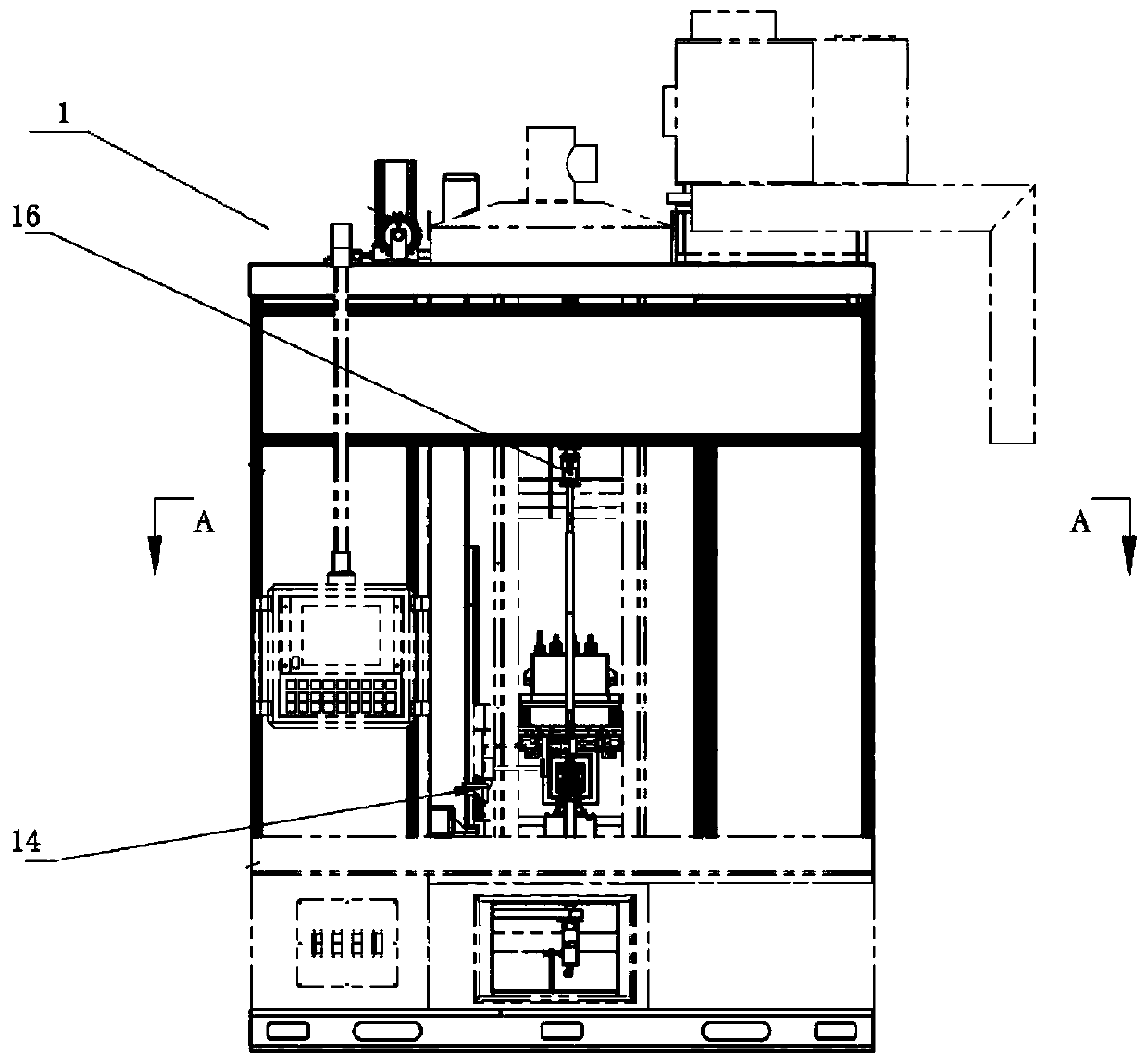

Full-automatic rack vertical quenching and horizontal tempering equipment

ActiveCN111172369AExtended service lifeReduce manufacturing costIncreasing energy efficiencyFurnace typesMachine toolControl system

The invention discloses full-automatic rack vertical quenching and horizontal tempering equipment and relates to the technical field of heat treatment machining equipment. The equipment comprises a vertical quenching machine tool, a horizontal tempering machine tool and an external carrying mechanism; the vertical quenching machine tool comprises a vertical machine body part, a sliding plate lifting part, a displacement tracking part, a machine tool tooth surface positioning part, a rotating main shaft part, an upper center part and a quenching load part; the horizontal tempering machine toolcomprises a horizontal machine body part, a tempering guide push rod part, a tempering pushing part, an active discharge part, a stepping blanking part and a tempering load part; and the equipment further comprises an electrical numerical control system, a power supply control system and a cooling system. The multi-functional integrated design can be realized for a rack in multiple stations of feeding storage, tooth surface positioning, workpiece two-dimensional code scanning, robot feeding and discharging carrying, vertical scanning quenching, horizontal scanning tempering, stepping discharging mechanisms and the like, unmanned operation is realized, and the equipment can be connected with client previous and next work procedures on line, and is high in full automation degree.

Owner:WUHAN HEATKING MACHINE ELECTRICAL EQUIP

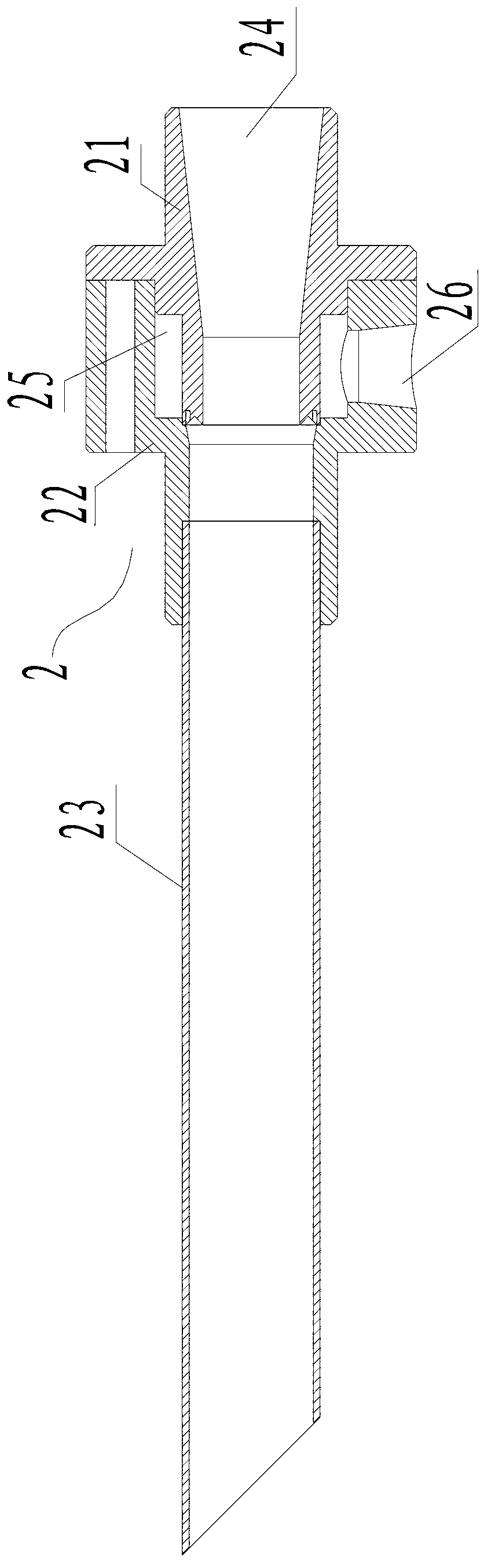

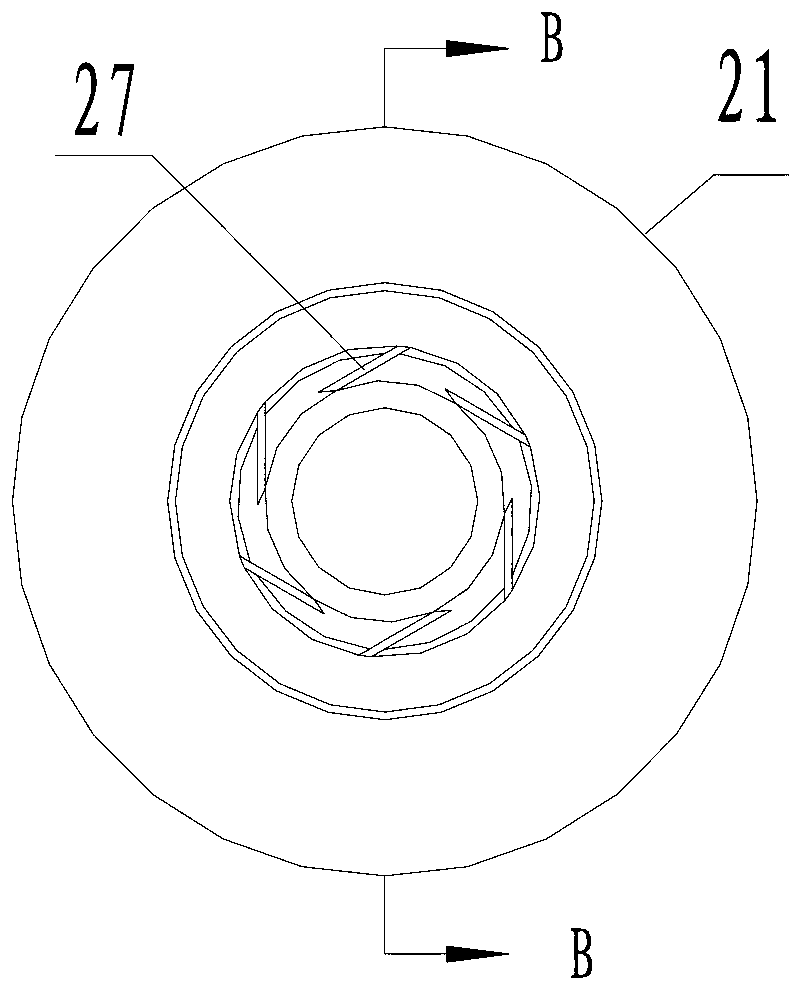

Novel full-automatic down filling machine

ActiveCN103320909AReduce energy consumptionHigh degree of full automationOakum treatmentLap jointEnergy consumption

The invention discloses a novel full-automatic down filling machine. The down filling machine comprises a fan, a down storage box, a weighing device and a down filling pipe, wherein the down filling pipe comprises an inner pipe, an outer pipe and a long pipe, a through down incoming hole is formed in the middle of the inner pipe, two steps are arranged at the front end of the inner pipe, a step is arranged at the rear end inside the outer pipe, the step at the rear end inside the outer pipe is in lap joint with the first step at the front end of the inner pipe in a sealing mode, an annular cavity is formed by the step at the rear end inside the outer pipe and the second step at the front end of the inner pipe, a gas inlet which is communicated with the annular cavity is arranged on one side of the outer pipe, a plurality of gas outgoing grooves which are communicated with the annular cavity are uniformly formed in the front end of the inner pipe and are formed in an inclined mode in the clockwise or anticlockwise direction, and the long pipe is connected with the front end of the outer pipe in a sealing mode. Compared with the prior art, the down filling machine has the advantages of being simple in structure, convenient to operate, high in working efficiency, low in energy consumption, low in labor intensity, uniform in down filling and high in down filling quality.

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

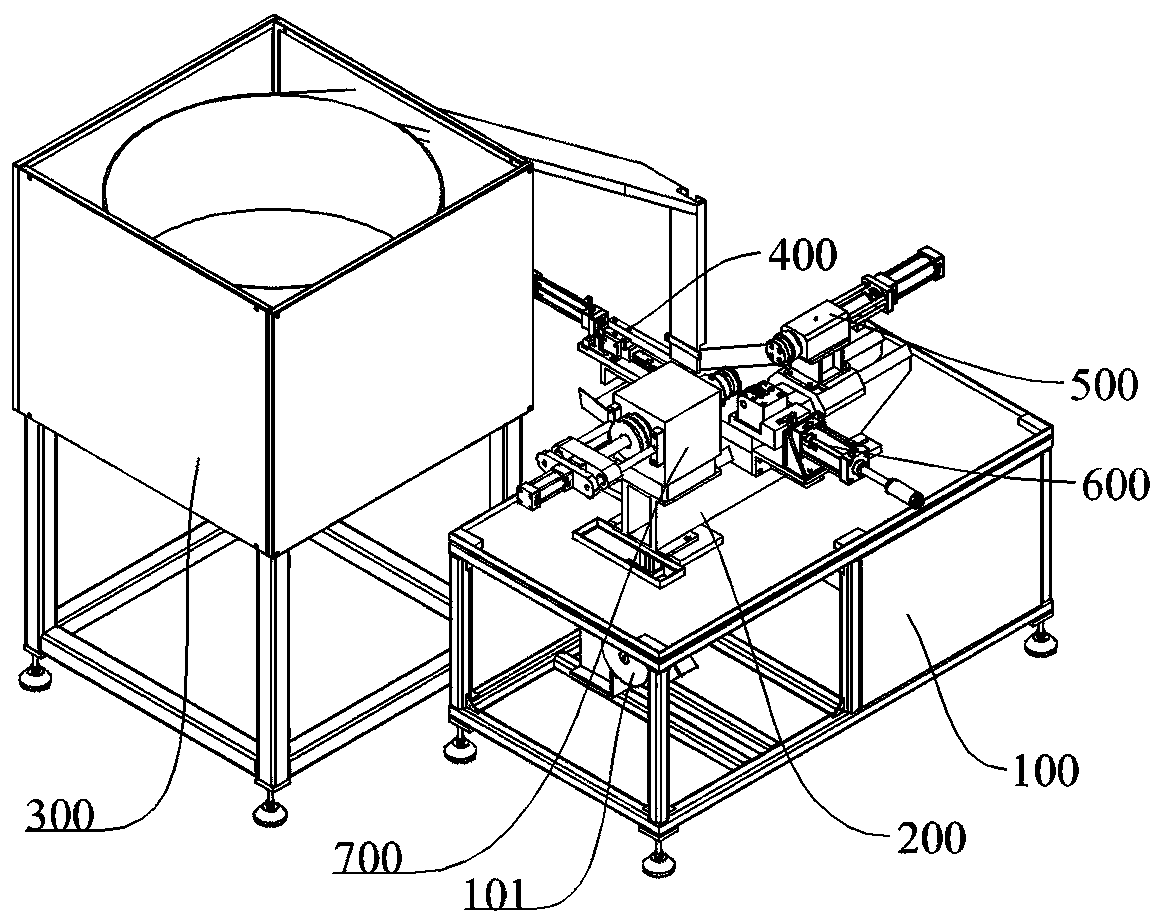

Thickness detecting method for tempered glass membrane of mobile phone screen

ActiveCN108225242AComprehensive testing dataAvoid the unstable type of manual adjustmentMeasurement devicesProduction lineEngineering

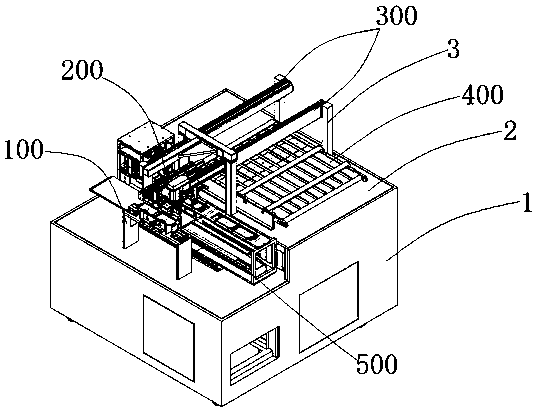

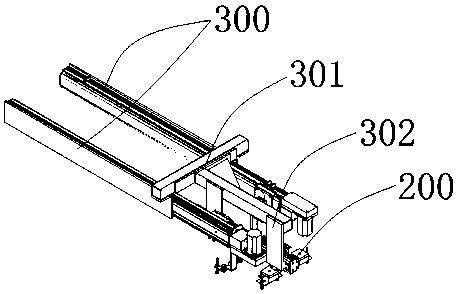

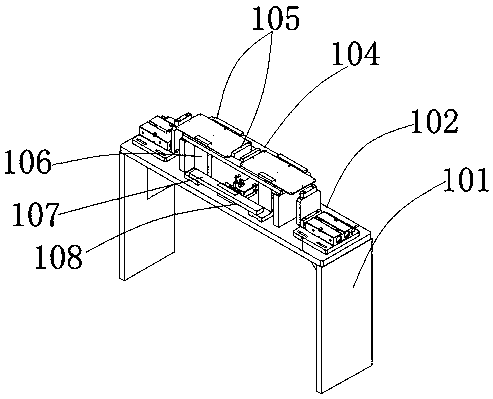

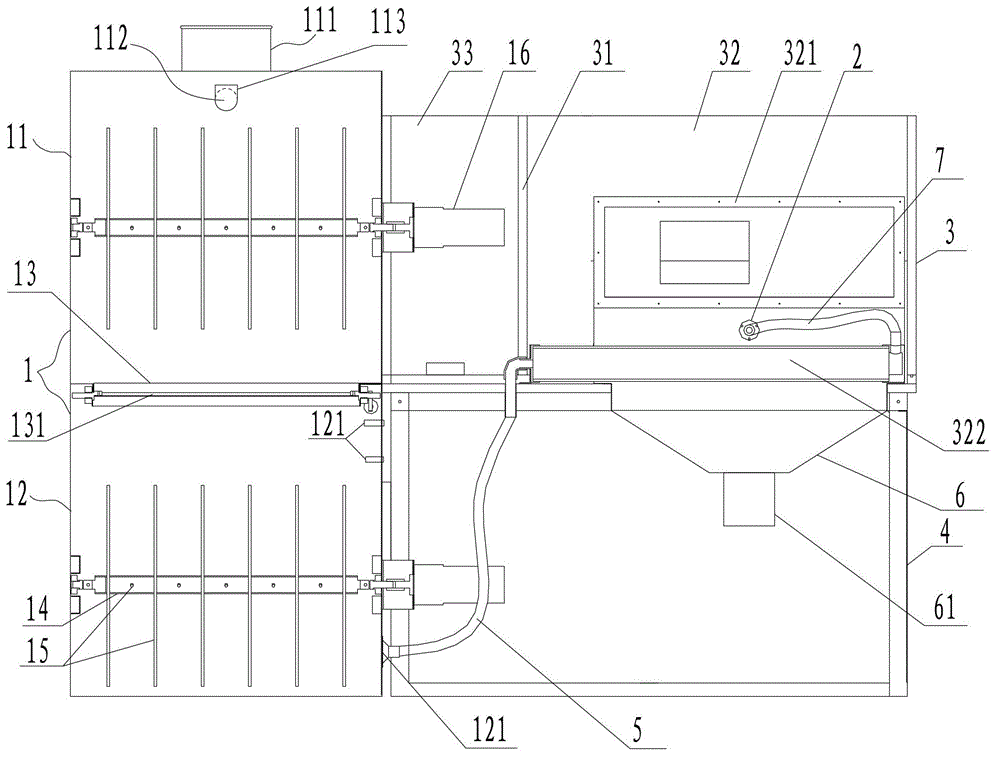

Athickness detecting method for a tempered glass membrane of a mobile phone screen comprises the following steps: conveying a to-be-detected workpiece to a primary detection assembly (100) through a conveyor belt; sucking the to-be-detected workpiece onto the primary detection assembly (100) through a material moving assembly (200); correspondingly controlling a Y-direction aligning adapting plate(107) and an X-direction aligning adapting plate (113) to move through a second cylinder (112) and a first cylinder (110); adjusting the position of the to-be-detected workpiece in a storing groove;clamping the to-be-detected workpiece; primarily detecting the to-be-detected workpiece through sensing heads which are mounted on inner sides of the Y-direction aligning adapting plate (107) and theX-direction aligning adapting plate (113); controlling the Y-direction aligning adapting plate (107) and the X-direction aligning adapting plate (113) to release the to-be-detected workpiece through the second cylinder (112) and the first cylinder (110); moving the to-be-detected workpiece from the material transferring assembly (200) to a displacing assembly (500); sucking the to-be-detected workpiece onto a workpiece positioning plate (508) through a second vacuum chuck (208); controlling a jig mounting rack (506) to move on a third guide rail (505) through a first rodless cylinder; conveying the to-be-detected workpiece to a thickness detection assembly (600); detecting the to-be-detected workpiece through the thickness detection assembly (600); storing data after detection; and suckingthe to-be-detected workpiece onto a production line assembly (400) for feeding through a first vacuum chuck (312) on a horizontal feeding assembly (300).

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

Novel full-automatic down filling machine

The invention discloses a novel full-automatic down filling machine. The down filling machine comprises a fan, a down storage box, a weighing device and a down filling pipe, wherein the down filling pipe comprises an inner pipe, an outer pipe and a long pipe, a through down incoming hole is formed in the middle of the inner pipe, two steps are arranged at the front end of the inner pipe, a step is arranged at the rear end inside the outer pipe, the step at the rear end inside the outer pipe is in lap joint with the first step at the front end of the inner pipe in a sealing mode, an annular cavity is formed by the step at the rear end inside the outer pipe and the second step at the front end of the inner pipe, a gas inlet which is communicated with the annular cavity is arranged on one side of the outer pipe, a plurality of gas outgoing grooves which are communicated with the annular cavity are uniformly formed in the front end of the inner pipe and are formed in an inclined mode in the clockwise or anticlockwise direction, and the long pipe is connected with the front end of the outer pipe in a sealing mode. Compared with the prior art, the down filling machine has the advantages of being simple in structure, convenient to operate, high in working efficiency, low in energy consumption, low in labor intensity, uniform in down filling and high in down filling quality.

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

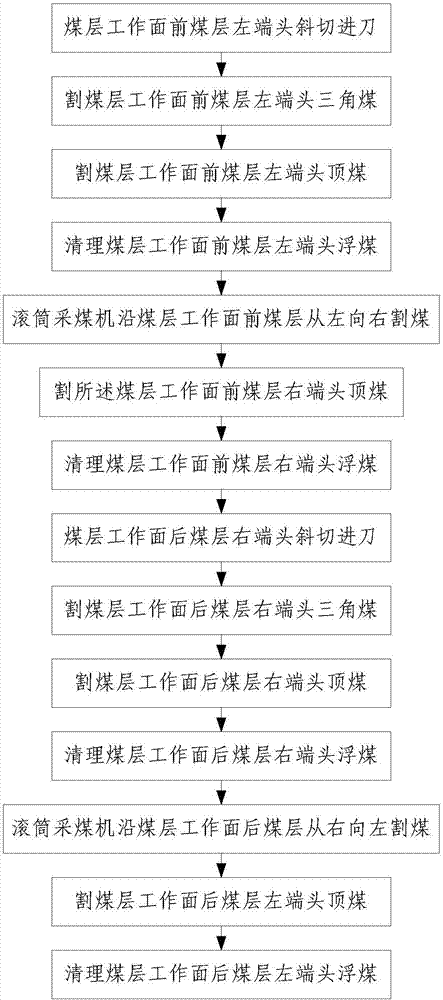

Automatic cutting control method for teaching playback of drum shearer for low coal dust thin coal seam

ActiveCN106150498AReasonable designRigorous method stepsSlitting machinesAutomatic controlControl system

The invention discloses an automatic cutting control method for teaching playback of a drum shearer for a low coal dust thin coal seam. The automatic cutting control method comprises the following steps: firstly, teaching automatic cutting of the drum shearer; secondly, playing back the automatic cutting of the drum shearer: 201, initializing a control system of the drum shearer; 202, judging whether the drum shearer is positioned at an end or not; 203, playing back the automatic cutting of the left end of the drum shearer; 204, playing back the automatic cutting of the right end of the drum shearer. According to the automatic cutting control method disclosed by the invention, the cutting process of the drum shearer for the low coal dust thin coal seam is taught, the necessary processes of performing beveling feed, triangular coal cutting, cleaning of float coal, coal cutting and coal mining in advancing on the low coal dust thin coal seam are covered, manual intervention is greatly reduced, the automatic coal mining requirement of the low coal dust thin coal seam on a coal mining technology is met, and the full-automatic control efficiency is high.

Owner:XIAN COAL MINING MACHINERY

Demonstration and playback control method for automatic cutting of drum shearer for medium-thickness coal seams

ActiveCN106150497AReasonable designRigorous method stepsSlitting machinesAutomatic controlControl system

The invention discloses a demonstration and playback control method for automatic cutting of a drum shearer for medium-thickness coal seams. The demonstration and playback control method includes 1, demonstration of automatic cutting of the drum shearer, and 2, playback of automatic cutting of the drum shearer. The step 2 includes 201, initializing a control system of the drum shearer; 202, judging whether the drum shearer is located at the tip or not; 203, playing back automatic cutting of the left end of the drum shearer; 204, playing back automatic cutting of the right end of the drum shearer. The demonstration and playback control method has the advantages that demonstration of the cutting process of the drum shearer for the medium-thickness coal seams covers necessary processes of bevel feeding, triangle coal cutting, float coal cleaning and coal cutting and excavating during travelling, so that manual interference is reduced greatly, automatic coal excavating requirements in coal excavation of the medium-thickness coal seams are met, and full-automatic control efficiency is high.

Owner:XIAN COAL MINING MACHINERY

A pulverized coal pipeline pneumatic sliding door that can prevent jamming and its working method

ActiveCN105135034BSolve the jamOvercome the defect of not being able to complete the final strokeOperating means/releasing devices for valvesSlide valveAnti jammingCoal pipeline

The invention discloses an anti-jamming pneumatic slide plate gate of a pulverized coal pipeline and a work method based on the anti-jamming pneumatic slide plate gate. The anti-jamming pneumatic slide plate gate comprises a rectangular frame which is connected with the pulverized coal pipeline through fixing bolts, wherein a slide plate which can block airstreams in the pulverized coal pipeline is arranged in the center of the rectangular frame; the rectangular frame comprises a front side frame, a rear side frame, a left side frame and a right side frame; the left and right side frames are separately provided with a sliding rail, so that the slide plate can slide along the sliding rails of the rectangular frame; the slide plate is connected with a slide plate draft device; asymmetrical chevron air passages are arranged above the rear side frame; symmetrical chevron air passages are arranged below the rear side frame; the air passages are all connected with compressed air pipelines; the compressed air pipelines are connected with a compressed air source; electromagnetic valves are arranged on the compressed air pipelines; the electromagnetic valves are connected with compressed air control systems; and in processes of inserting the slide plate into the rectangular frame and pulling the slide plate out of the rectangular frame, dust accumulated on the upper part, the lower part, the front part and the rear part of the slide plate is cleaned through airstreams in the compressed air pipelines, so that the problem of jamming of the slide plate caused by large friction force of the dust is solved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

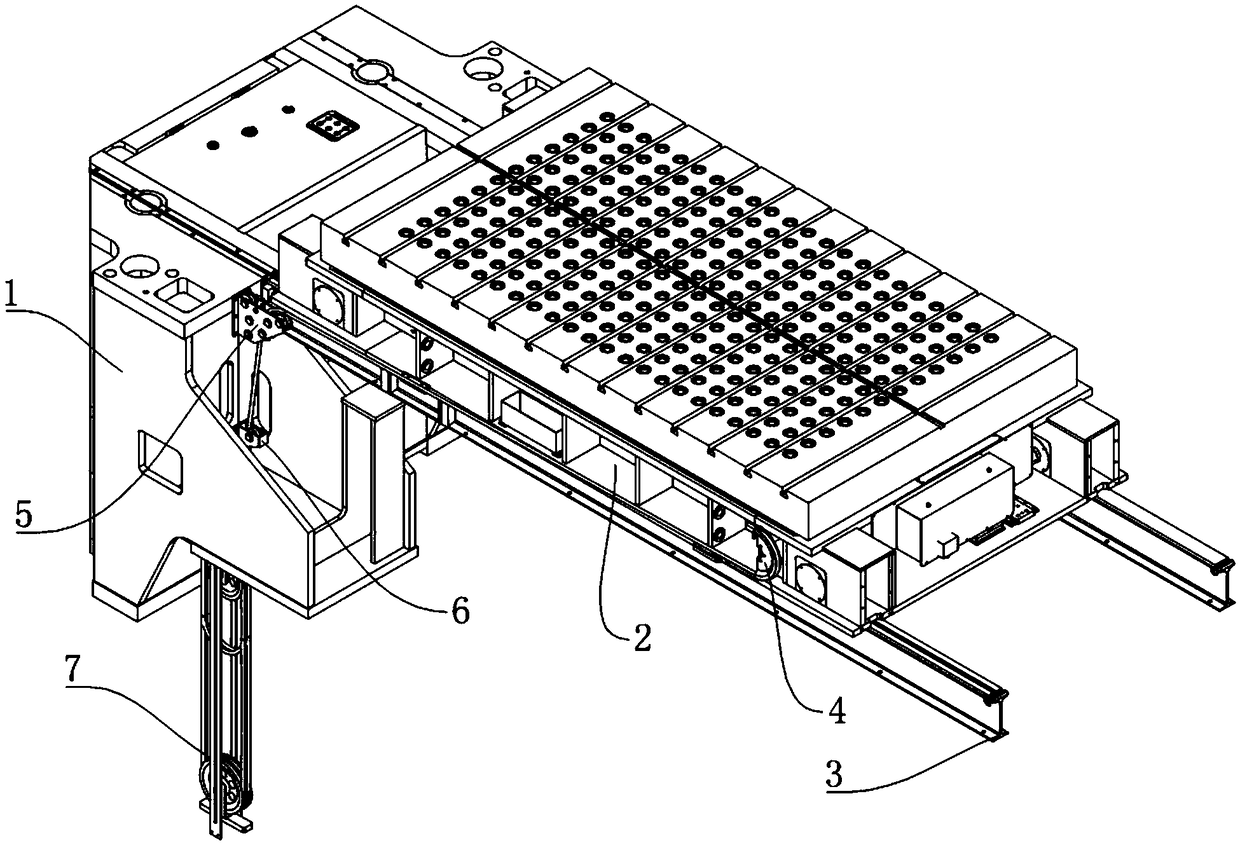

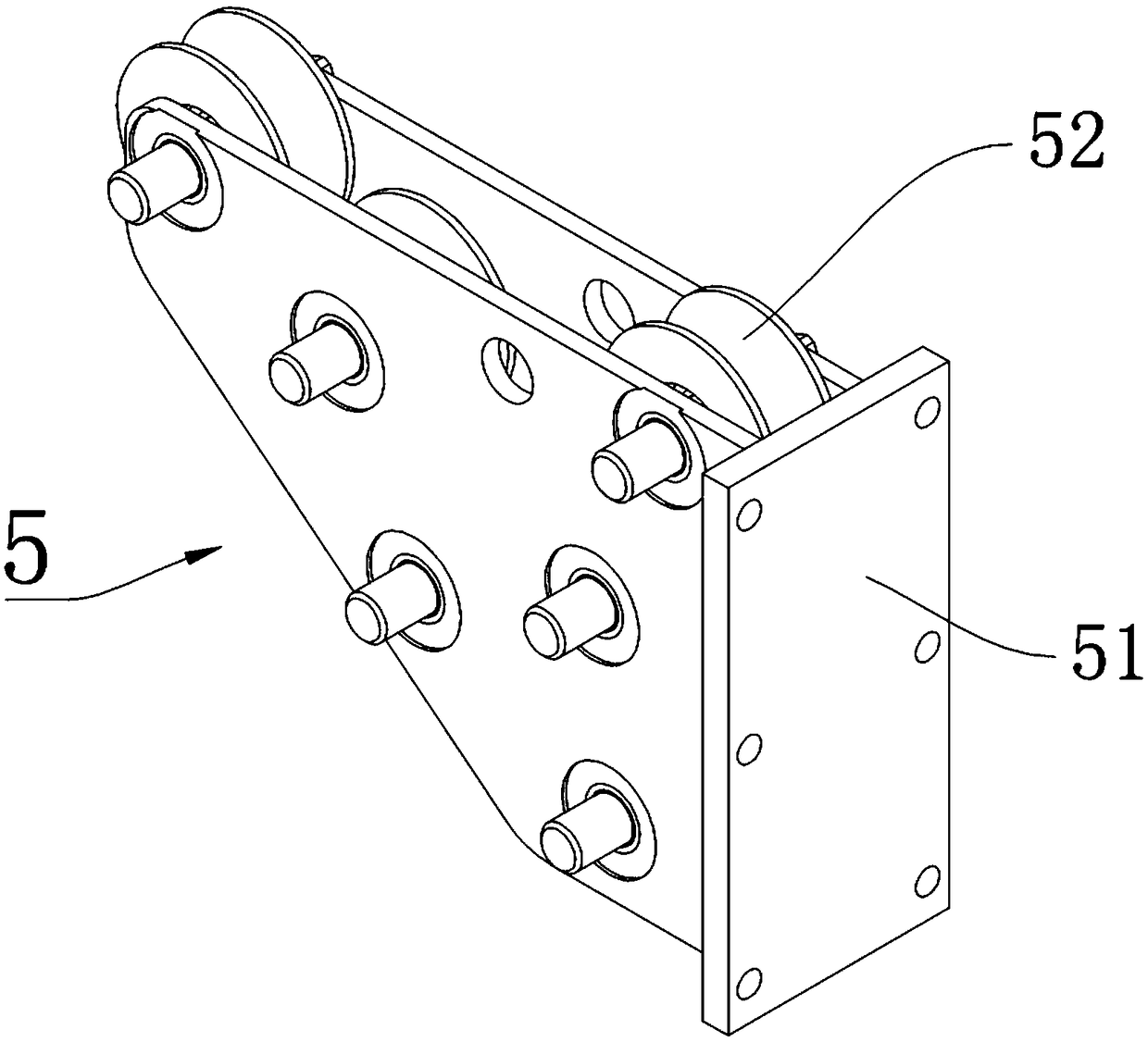

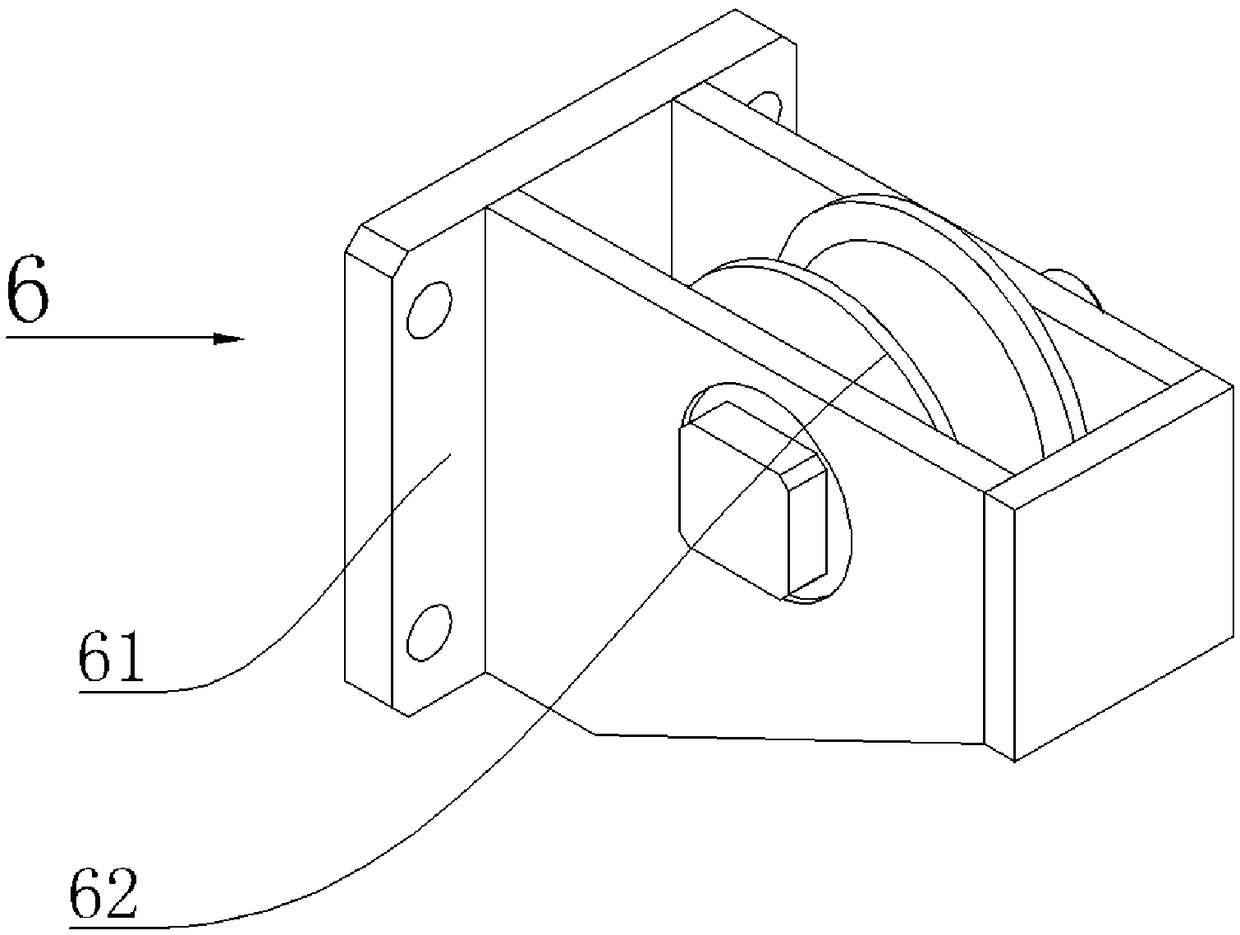

Automatic wire routing device and wire routing method for press workbench

ActiveCN107225789BSolve the problem of being exposed and easy to be damaged by collisionSmall footprintElectrical apparatusPressesAutomatic routingEngineering

The invention discloses a press machine workbench full-automatic cable arranging device. The press machine workbench full-automatic cable arranging device comprises a guide wire device (4), the guide wire device (4) is arranged on a moving workbench (2), the moving workbench (2) is mounted on a guide rail (3), and the guide rail (3) is arranged on a base (1) of the press machine. The press machine workbench full-automatic cable arranging device is characterized in that the base (1) is further provided with an upper guide wire device (5), a lower guide wire device (6) and a wire take-up device (7). The press machine workbench full-automatic cable arranging device and the cable arranging method thereof effectively solves the problem that a cable is exposed and prone to causing collision and damage, the occupied space of the exposed cable is greatly saved, the structure is simple, the working efficiency of the machine is improved, the manual wire take-up time is saved, and the degree of full automaticity is high.

Owner:江西埾鑫电气有限公司

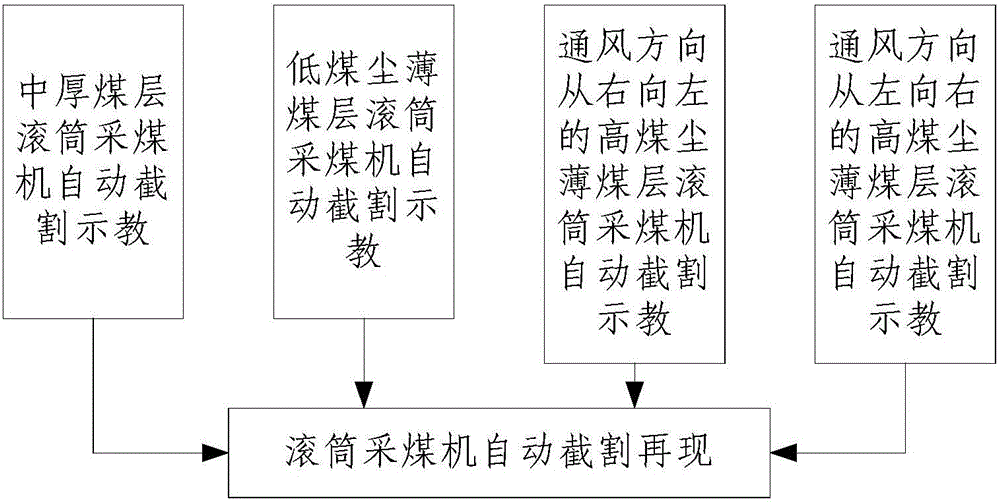

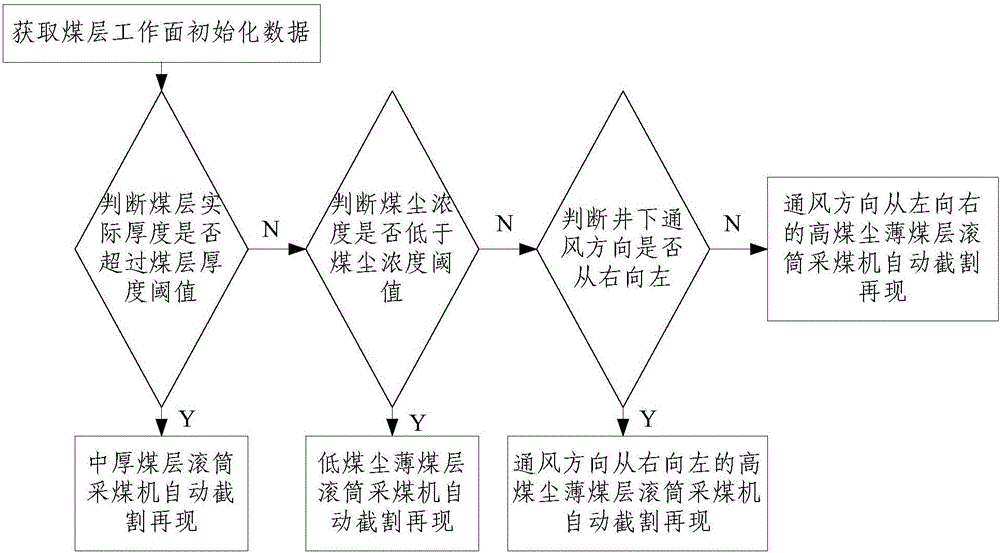

Control method for demonstration and representation of automatic cutting of drum shearer

ActiveCN106321097AReasonable designRigorous method stepsSlitting machinesAutomatic controlRight-to-left

The invention discloses a control method for demonstration and representation of automatic cutting of a drum shearer. The method comprises steps as follows: step 1, demonstration of automatic cutting of a drum shearer on the medium-thickness coal seam; step 2, demonstration of automatic cutting of the drum shearer on the low-coal-dust thin coal seam; step 3, demonstration of automatic cutting of the drum shearer on the high-coal-dust thin coal seam in the ventilation direction from right to left; step 4, demonstration of automatic cutting of the drum shearer on the high-coal-dust thin coal seam in the ventilation direction from left to right; step 5, representation of automatic cutting of the drum shearer: 501, acquisition of initialization data of a coal seam working face; 502, judgment of the type of the coal seam; 503, representation of automatic cutting of the drum shearer on the medium-thickness coal seam; 504, representation of automatic cutting of the drum shearer on the low-coal-dust thin coal seam; 505, representation of automatic cutting of the drum shearer on the high-coal-dust thin coal seam in the ventilation direction from right to left; 506, representation of automatic cutting of the drum shearer on the high-coal-dust thin coal seam in the ventilation direction from left to right. With the adoption of the method, multiple coal seam cutting processes are demonstrated, automatic coal mining requirements of different coal mining technologies are met, and the full-automatic control efficiency is high.

Owner:XIAN COAL MINING MACHINERY

Low coal dust and thin coal seam drum shearer teaching reproduction automatic cutting control method

ActiveCN106150498BReasonable designRigorous method stepsSlitting machinesAutomatic controlControl system

The invention discloses an automatic cutting control method for teaching playback of a drum shearer for a low coal dust thin coal seam. The automatic cutting control method comprises the following steps: firstly, teaching automatic cutting of the drum shearer; secondly, playing back the automatic cutting of the drum shearer: 201, initializing a control system of the drum shearer; 202, judging whether the drum shearer is positioned at an end or not; 203, playing back the automatic cutting of the left end of the drum shearer; 204, playing back the automatic cutting of the right end of the drum shearer. According to the automatic cutting control method disclosed by the invention, the cutting process of the drum shearer for the low coal dust thin coal seam is taught, the necessary processes of performing beveling feed, triangular coal cutting, cleaning of float coal, coal cutting and coal mining in advancing on the low coal dust thin coal seam are covered, manual intervention is greatly reduced, the automatic coal mining requirement of the low coal dust thin coal seam on a coal mining technology is met, and the full-automatic control efficiency is high.

Owner:XIAN COAL MINING MACHINERY

An automatic corner protector wrapping machine

ActiveCN108238318BHigh degree of full automationFree laborShock-sensitive articlesElectric machineryStructural engineering

Owner:苏州德睿联自动化科技有限公司

Automatic cutting control method for demonstration and reproduction of underground thin coal seam shearer with wind direction

ActiveCN106368700BReasonable designRigorous method stepsSlitting machinesAutomatic controlControl system

The invention discloses a coal cutter teaching and reproduction automatic cutting control method for a downhole thin coal seam with the wind direction. The method comprises the following steps that firstly, a drum coal cutter automatically cuts the coal seam for teaching; and secondly, the drum coal cutter automatically cuts the coal seam for reproduction, specifically, 201, a control system of the drum coal cutter is initialized, 202, whether the drum coal cutter is located at an end or not is judged; 203, the left end of the drum coal cutter automatically cuts the coal seam for reproduction, and 204, the right end of the drum coal cutter automatically cuts the coal seam for reproduction. The cutting process of the downhole thin coal seam with the wind direction through the drum coal cutter is taught, the necessary processes of beveling cutter inlet, triangular coal cutting, float coal removing and coal cutting and collecting during advancing of the downhole thin coal seam with the wind direction are covered, manual interference is greatly reduced, the automatic coal cutting requirement of the coal cutting technique for the downhole thin coal seam with the wind direction is met, and the full-automatic control efficiency is high.

Owner:XIAN COAL MINING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com