An automatic corner protector wrapping machine

A corner protection and machine closing technology, applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of low efficiency and high labor intensity, and achieve the effect of liberating labor and improving the degree of full automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with regard to specific accompanying drawings.

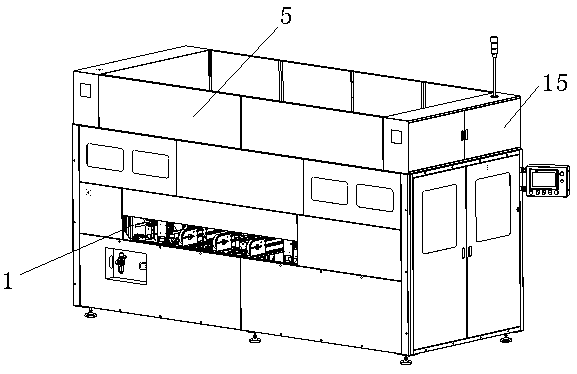

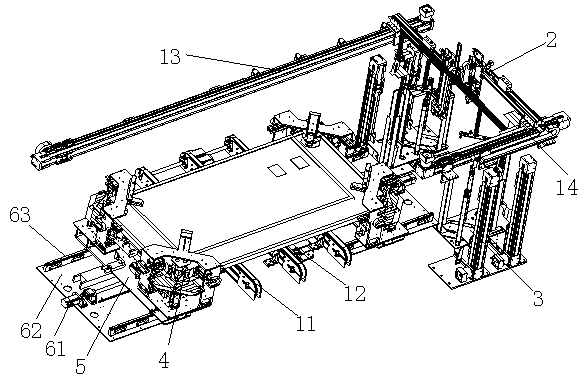

[0024] Such as figure 1 and figure 2 An automatic corner wrapping machine is shown, including a frame 1, an assembly line 11 arranged on the frame 1 for automatic product delivery, and a correcting mechanism 12 for positioning the product, which is set above the frame 1 There are two X1 shafts 13 and X2 shafts 14 of the same height. On the X1 shafts 13 and X2 shafts 14, a stepping motor 61 drives a feeding mechanism, and a bin storage mechanism 3 is arranged below the feeding mechanism. , the two sides of the assembly line 11 are provided with a cladding mechanism 4, wherein:

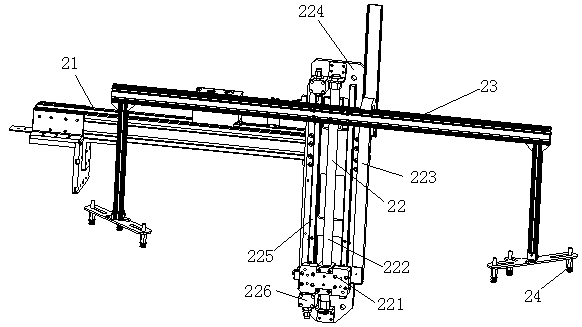

[0025] Such as image 3 As shown, the feeding mechanism is composed of a beam 21, a lifting cylinder 22 arranged on the beam 21, and a suction cup assembly driven by the lifting cylinder 22;

[0026] Such as Figure 4 As shown, the bin storage mechanism 3 has four groups, and each group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com