Full-automatic rack vertical quenching and horizontal tempering equipment

A fully automatic, vertical technology, applied in the direction of quenching device, heat treatment equipment, furnace type, etc., can solve the problems of low efficiency, large distortion, poor working environment, etc., to reduce production costs, improve service life, and save space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

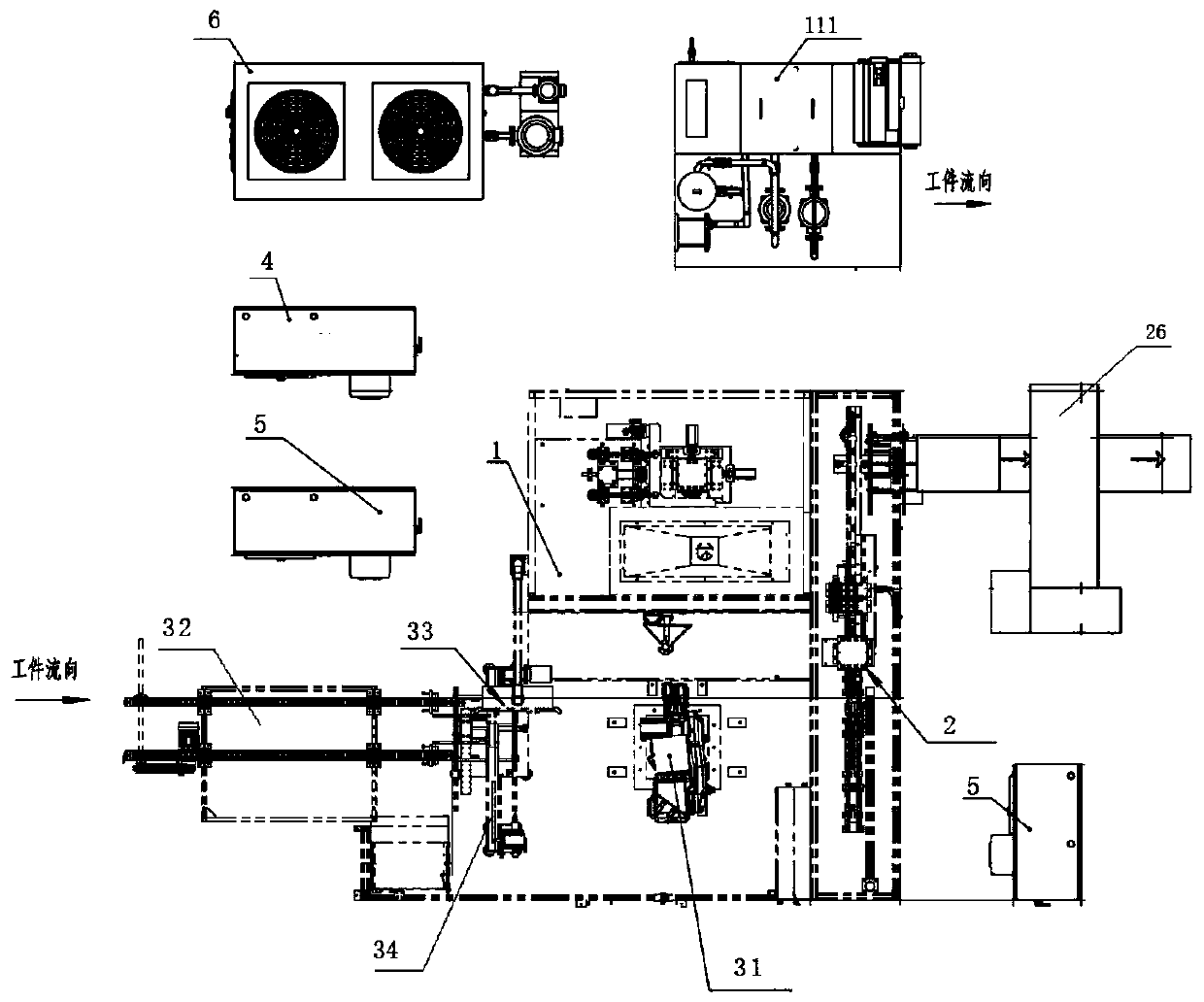

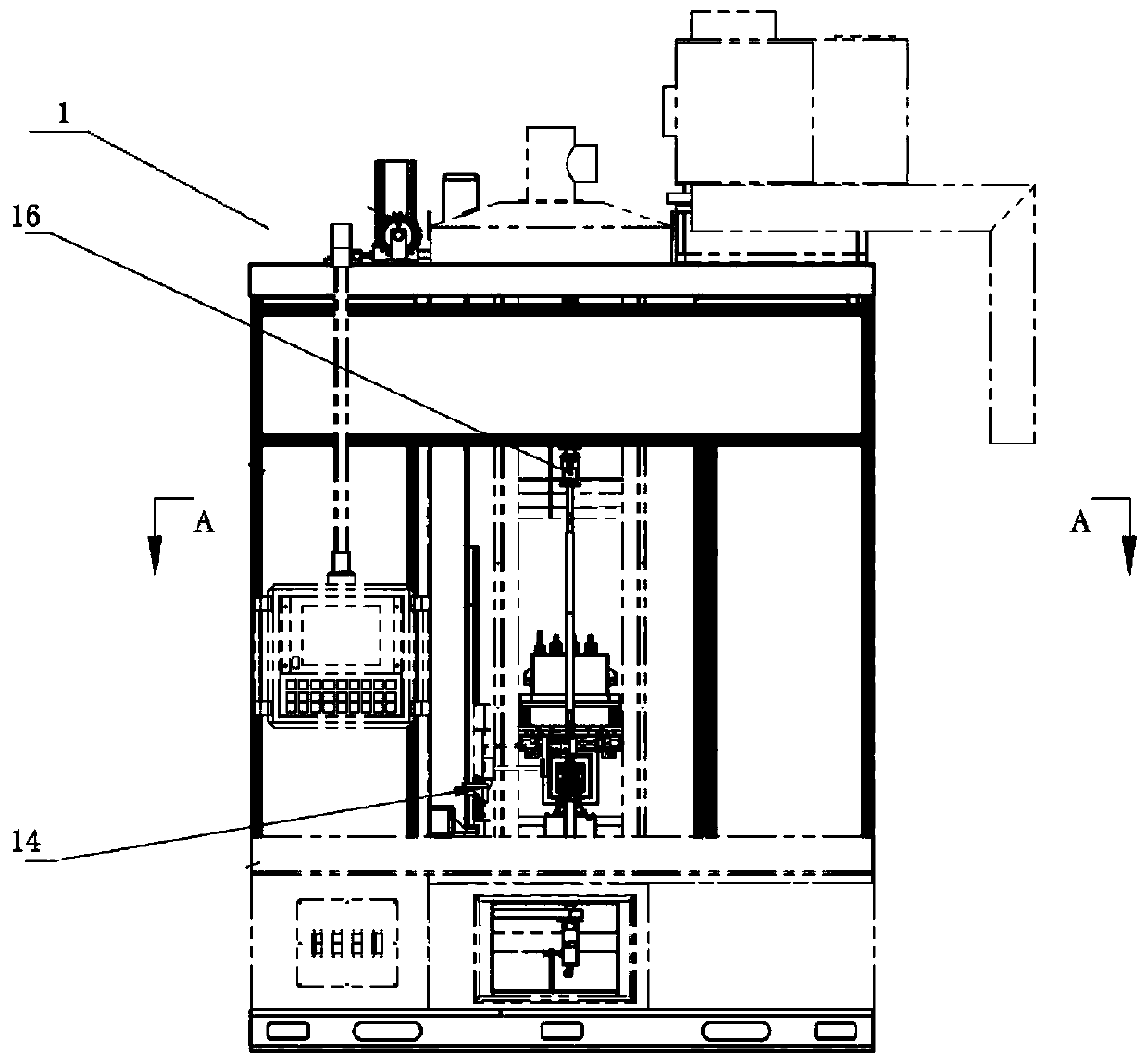

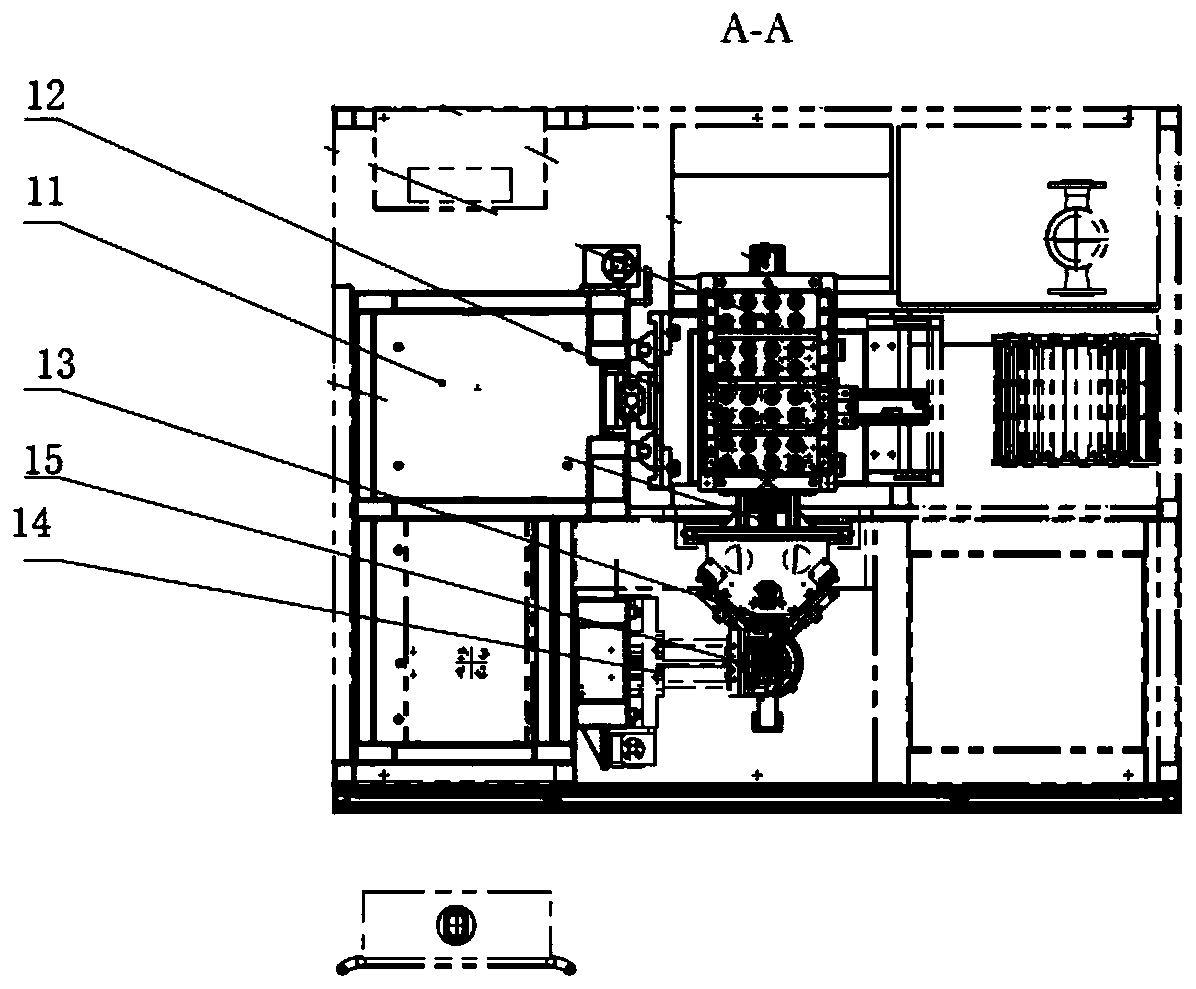

[0041] Such as Figure 1-5As shown, the present invention includes a vertical quenching machine tool 1, a horizontal tempering machine tool 2, and an external transport mechanism 3; Surface positioning part 14, rotating spindle part 15, upper top part 16, quenching load part; the horizontal tempering machine tool 2 includes a horizontal bed part 21, a tempering guide push rod part 22, a tempering pushing part 23, Active discharging part 24, stepping and unloading part 25, and tempering load part; the external handling mechanism includes a robot handling part 31, a feeding conveyor 32, a loading tooth surface positioning part 33, and a code scanning fixed tooth surface part 34 ; It also includes electrical numerical control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com