Novel full-automatic down filling machine

A fully automatic and new technology, applied in textile and papermaking, fiber processing, floc filling and other directions, can solve problems such as affecting the health of operators, polluting the working environment, and easy to fly around, achieving simple structure, simple and convenient operation, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following implementation. example.

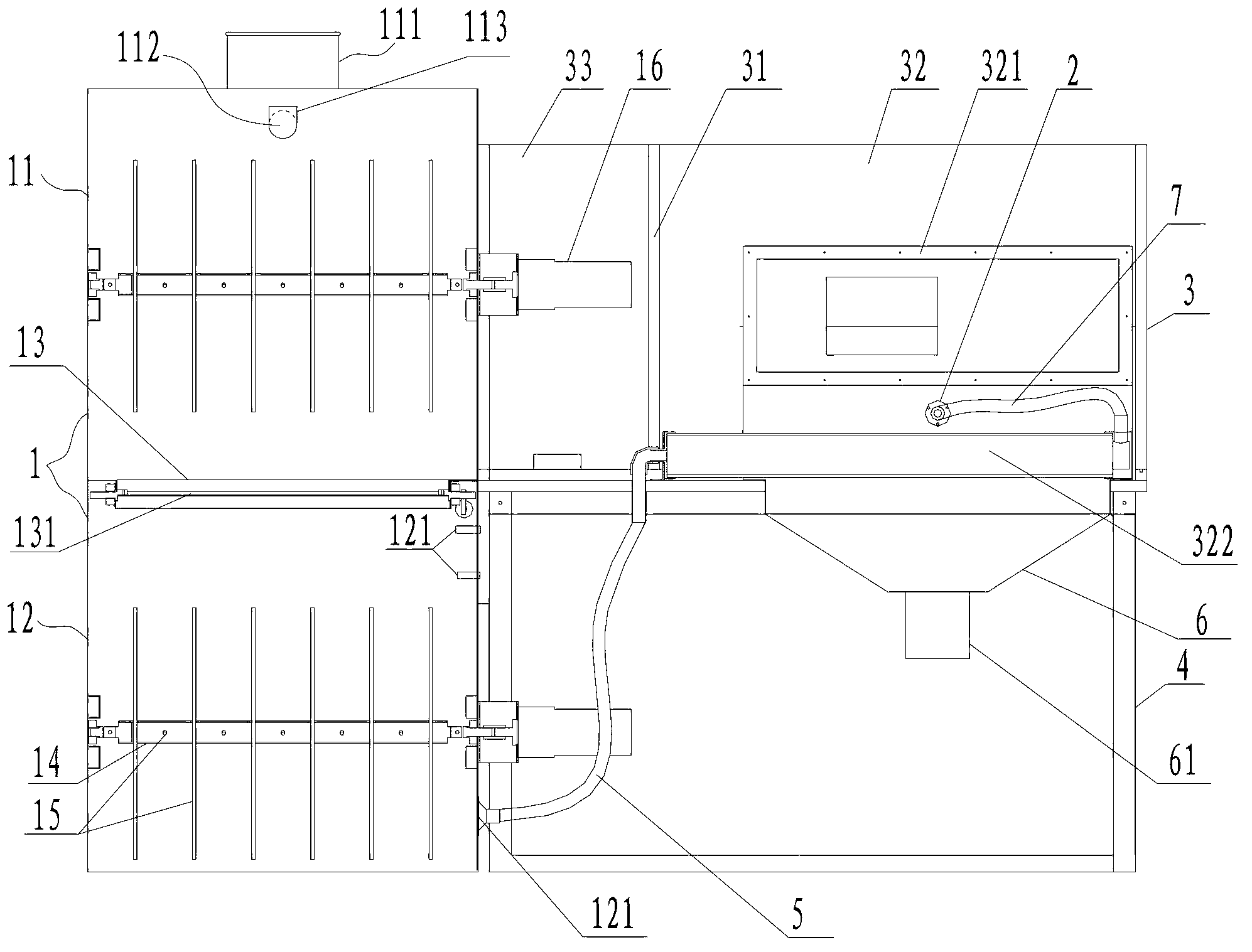

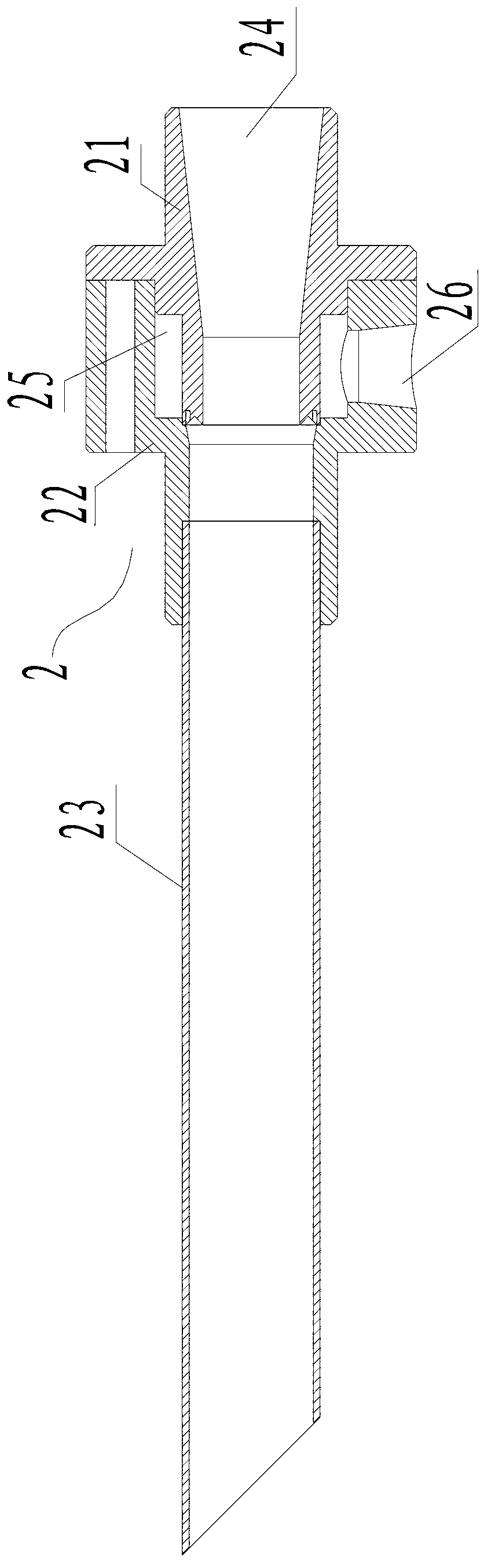

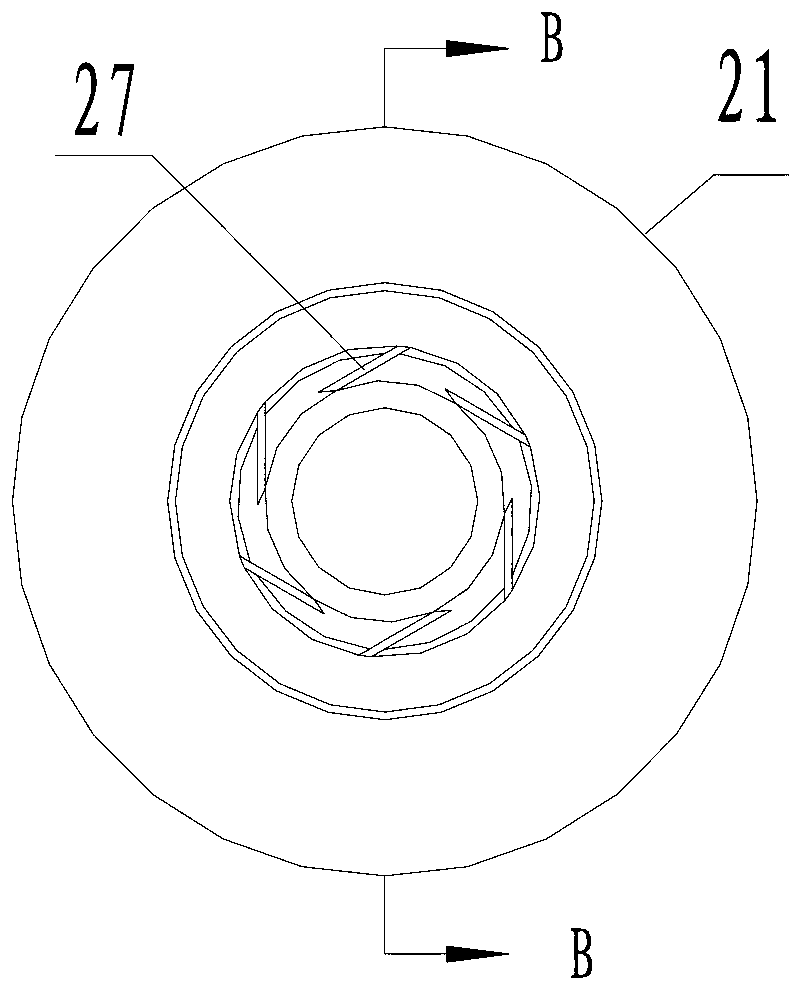

[0022] see figure 1 , This embodiment is described by taking a new type of double-station full-automatic cashmere filling machine as an example. Of course, multiple stations can be set as required. The new type of double-station automatic fleece filling machine includes a fan, a fleece storage box 1, a weighing device 311 and a fleece filling tube 2. The fleece storage box 1 is divided into an upper fleece box 11 and a lower fleece box 12. The top of the fleece box 11 is provided with There is a protruding air outlet 111, and the air outlet 111 is sleeved with a breathable filter cloth bag. A fleece opening 112 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com