Thickness detecting method for tempered glass membrane of mobile phone screen

A tempered glass film and thickness detection technology, which is applied in the mechanical field, can solve problems such as inaccurate detection results, low degree of automation, and complicated mechanism, and achieve the effects of improving the degree of full automation, avoiding instability, and high detection efficiency

Active Publication Date: 2018-06-29

SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In view of the above deficiencies, the present invention provides a mobile phone screen toughened glass film thickness detection device, which effectively solves the problems of complex mechanism, low degree of automation, inaccurate detection results, and low efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0040] Based on the above-mentioned device, a method for implementing a mobile phone screen tempered glass film thickness detection device includes the following steps:

[0041] A. The workpiece to be detected is transported to the position of the preliminary detection component 100 via the conveyor belt, and the material transfer component 200 sucks the workpiece to be detected onto the preliminary detection component 100;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

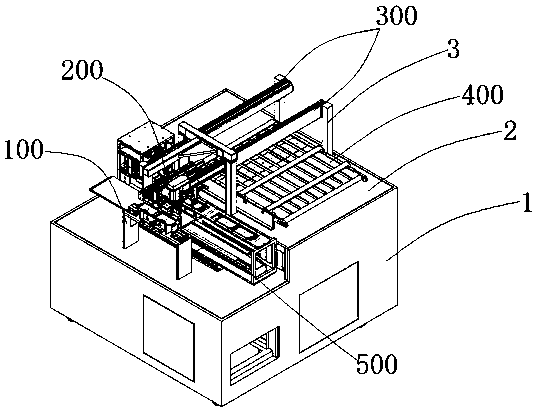

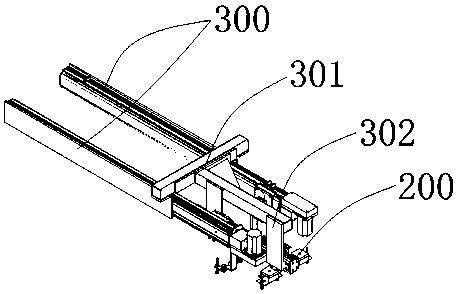

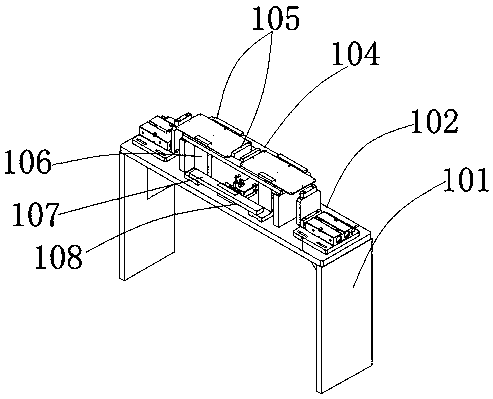

Athickness detecting method for a tempered glass membrane of a mobile phone screen comprises the following steps: conveying a to-be-detected workpiece to a primary detection assembly (100) through a conveyor belt; sucking the to-be-detected workpiece onto the primary detection assembly (100) through a material moving assembly (200); correspondingly controlling a Y-direction aligning adapting plate(107) and an X-direction aligning adapting plate (113) to move through a second cylinder (112) and a first cylinder (110); adjusting the position of the to-be-detected workpiece in a storing groove;clamping the to-be-detected workpiece; primarily detecting the to-be-detected workpiece through sensing heads which are mounted on inner sides of the Y-direction aligning adapting plate (107) and theX-direction aligning adapting plate (113); controlling the Y-direction aligning adapting plate (107) and the X-direction aligning adapting plate (113) to release the to-be-detected workpiece through the second cylinder (112) and the first cylinder (110); moving the to-be-detected workpiece from the material transferring assembly (200) to a displacing assembly (500); sucking the to-be-detected workpiece onto a workpiece positioning plate (508) through a second vacuum chuck (208); controlling a jig mounting rack (506) to move on a third guide rail (505) through a first rodless cylinder; conveying the to-be-detected workpiece to a thickness detection assembly (600); detecting the to-be-detected workpiece through the thickness detection assembly (600); storing data after detection; and suckingthe to-be-detected workpiece onto a production line assembly (400) for feeding through a first vacuum chuck (312) on a horizontal feeding assembly (300).

Description

technical field [0001] The invention relates to the field of machinery, in particular to a device for detecting the thickness of a tempered glass film on a mobile phone screen and a detection method thereof. Background technique [0002] Whether the thickness of the film is uniform is the basis for testing various properties of the film. Obviously, if the thickness of a single-layer film is uneven, it will not only affect the tensile strength and barrier properties of the film, but also affect the subsequent processing of the film. For thin-film pipe fittings, the uniformity of thickness is more important. Only when the overall thickness is uniform can its blast resistance be improved. In addition, reasonable control of the thickness of the product will not only improve product quality, but also reduce material consumption and improve production efficiency. . Therefore, whether the thickness of the film is uniform, whether it is consistent with the preset value, and whethe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B21/08

CPCG01B21/08

Inventor 张玉开

Owner SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com