Multi-joint robot geometric dimension accuracy calibration device and method based on standard gauge

A technology of multi-joint robots and geometric dimensions, which is applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of affecting detection and correction accuracy, limiting practicability, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

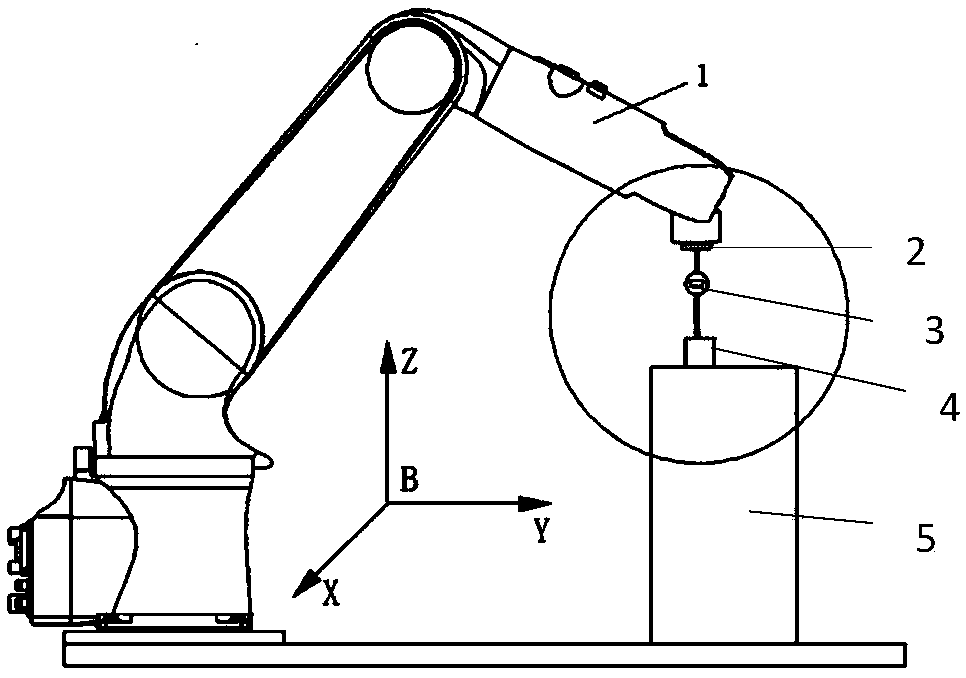

[0082] Taking the KUKA-KR210-2700 robot as an example, the geometric dimension accuracy calibration device of the multi-joint robot manipulator based on the standard measuring tool, the calibration device includes the dial gauge 3 and the standard gauge block 4, the dial gauge 3 and the method at the end of the robot 1 The blue plate 2 is rigidly connected, and the accuracy of the dial indicator 3 is 0.001mm;

[0083] The standard gauge block 4 is fixed on the workbench 5, and the surface machining accuracy Ra<1.6 of the standard gauge block 4, the geometric dimension (mm) of the standard gauge block 4 is: 100*100*100 (long *Width Height);

[0084] Then, adjust the robot 1 so that the top of the dial indicator 3 fixed on the flange plate 2 at the end of the robot 1 is perpendicular to but not in contact with the surface to be tested of the standard gauge block 4 .

Embodiment 2

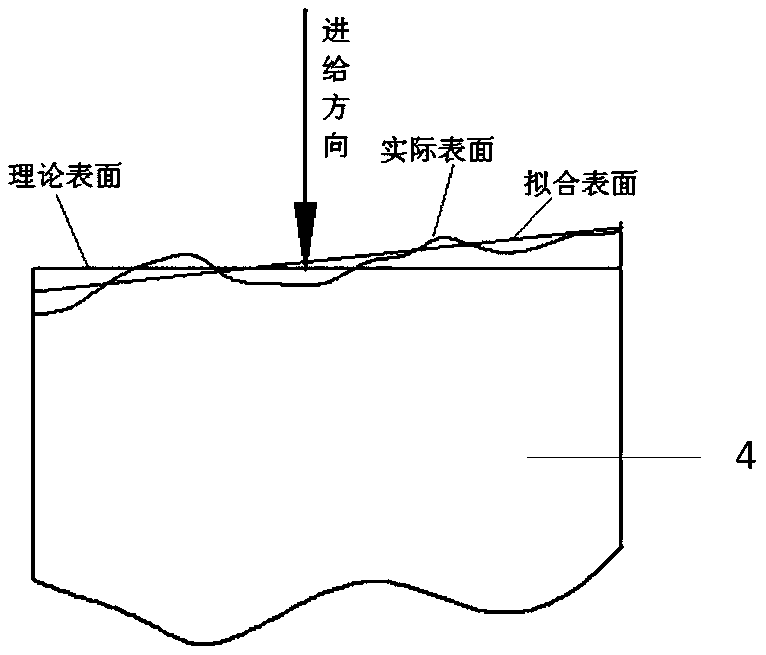

[0086] For the installation and commissioning of the calibration device in Embodiment 1, the standard gauge block coordinate system {P} is established with the upper left vertex on the upper surface of the standard gauge block 4 as the coordinate origin, and the standard gauge block 4 is fixed on the workbench 5, Adjust the standard gauge block 4 so that its three coordinate axes are respectively parallel to the X, Y, and Z axes in the robot base coordinate system {B}, wherein the Z axes of the two coordinate systems are opposite to each other,

[0087] Rigidly connect the flange plate 2 at the end of the robot 1 with the digital dial indicator 3, pay attention to the reliable connection to avoid the occurrence of small displacement, fix the standard gauge block 4 on the workbench 5, and adjust the workbench 5 and the standard gauge at the same time. The position of the gauge block 4 makes the three coordinate axes of the standard gauge block coordinate system {P} X, Y, and Z p...

Embodiment 3

[0090] Taking the KUKA-KR210-2700 robot as an example, the method for calibrating the geometric dimension accuracy of the multi-joint robot manipulator based on the standard measuring tool uses the calibration device for the geometric dimension accuracy of the multi-joint robot manipulator based on the standard measuring tool described in Embodiment 1, and includes the following step:

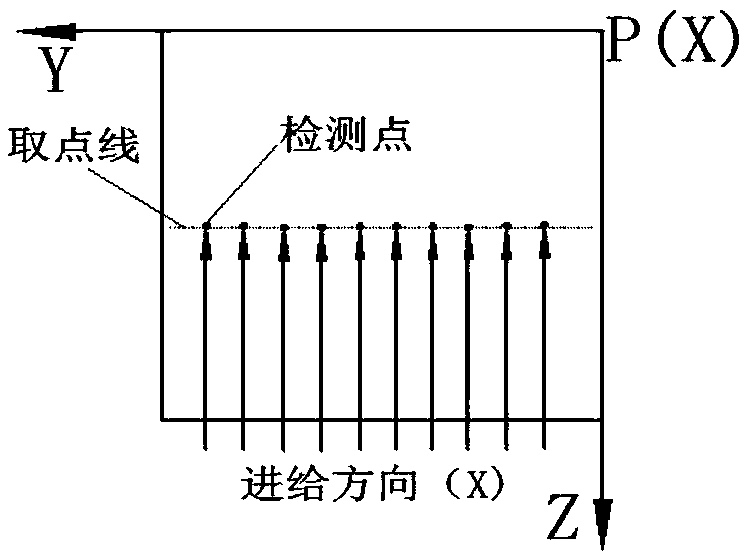

[0091] 1) Take point detection along the point-taking line of feeder X, Y, Z respectively, and determine the reading calculation value x of each detection point on the point-taking line of feeder X, Y, Z i 、y i ,z i (i=1,2,···10) and the calculated value of the rotation angle of each joint axis of the robot [(θ 1 ~θ 6 )i] X , [(θ 1 ~θ 6 )i] Y , [(θ 1 ~θ 6 ) i ] Z (i=1,2,...10);

[0092] Take points on the Y-P-Z surface of the standard gauge block, the point interval is 5mm, take 10 groups of points, feed each point along the X direction for 10 times and take the average value of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com