Automatic parcel feeding and sorting control method

A control method and fast technology, applied in sorting and other directions, can solve the problems of reducing the sorting efficiency and capacity of the logistics system, requiring high quality of manual loading personnel, and increasing the pressure of scanning and sorting operations, so as to improve the overall Sorting efficiency and operating capacity, improving the overall sorting efficiency, and the effect of improving the sorting efficiency of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

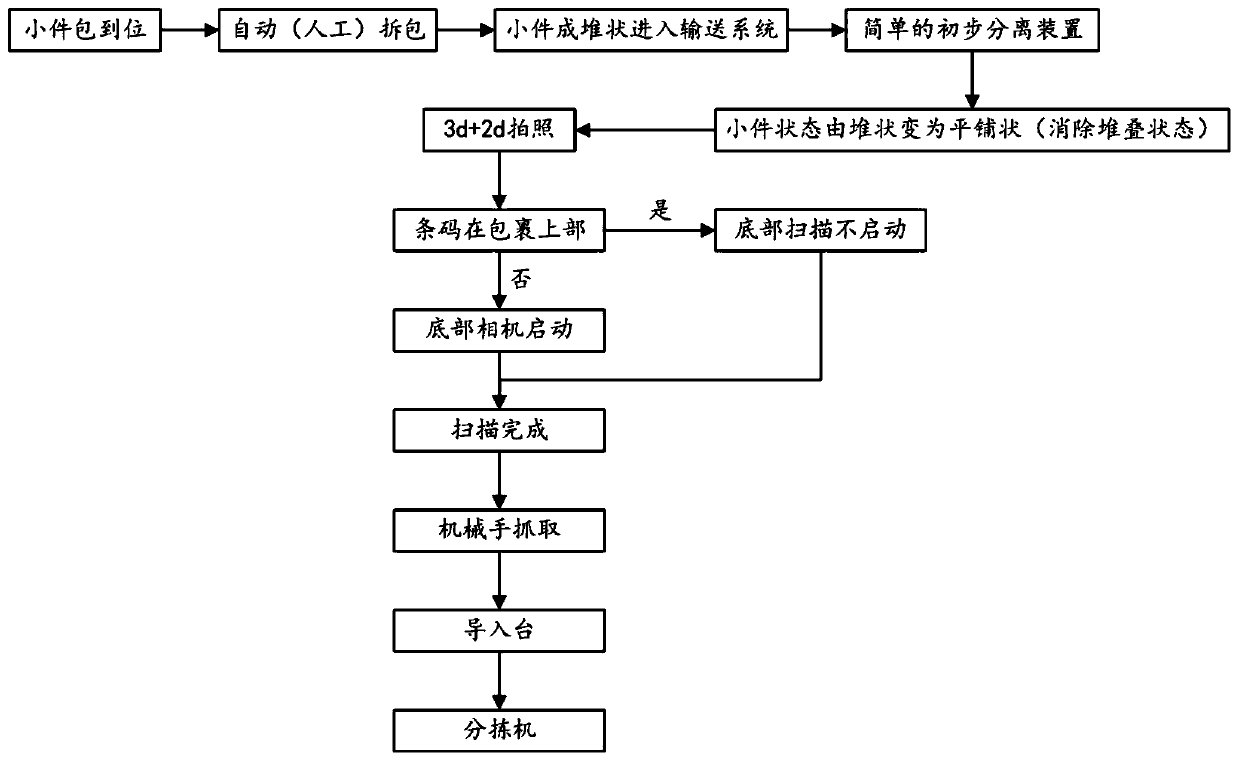

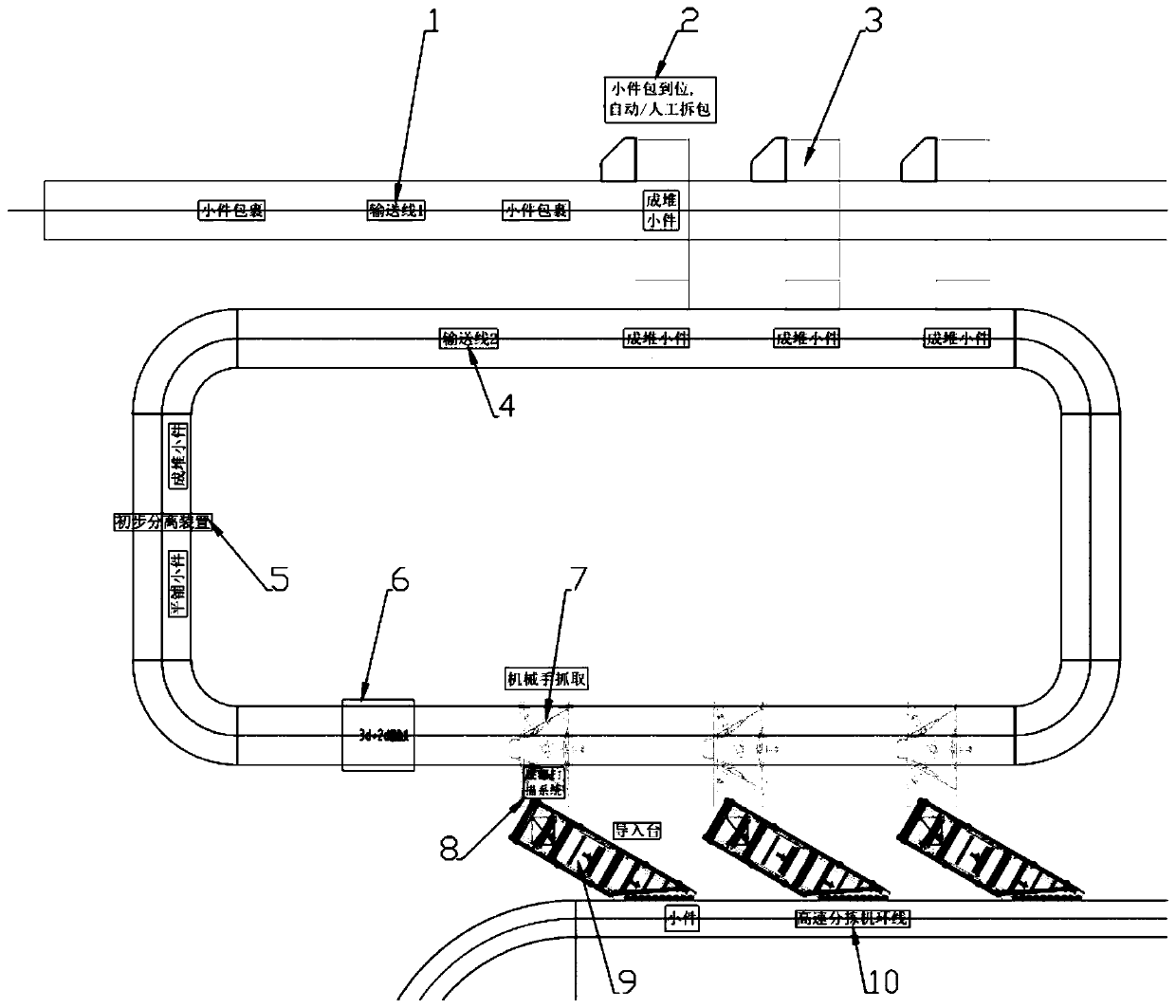

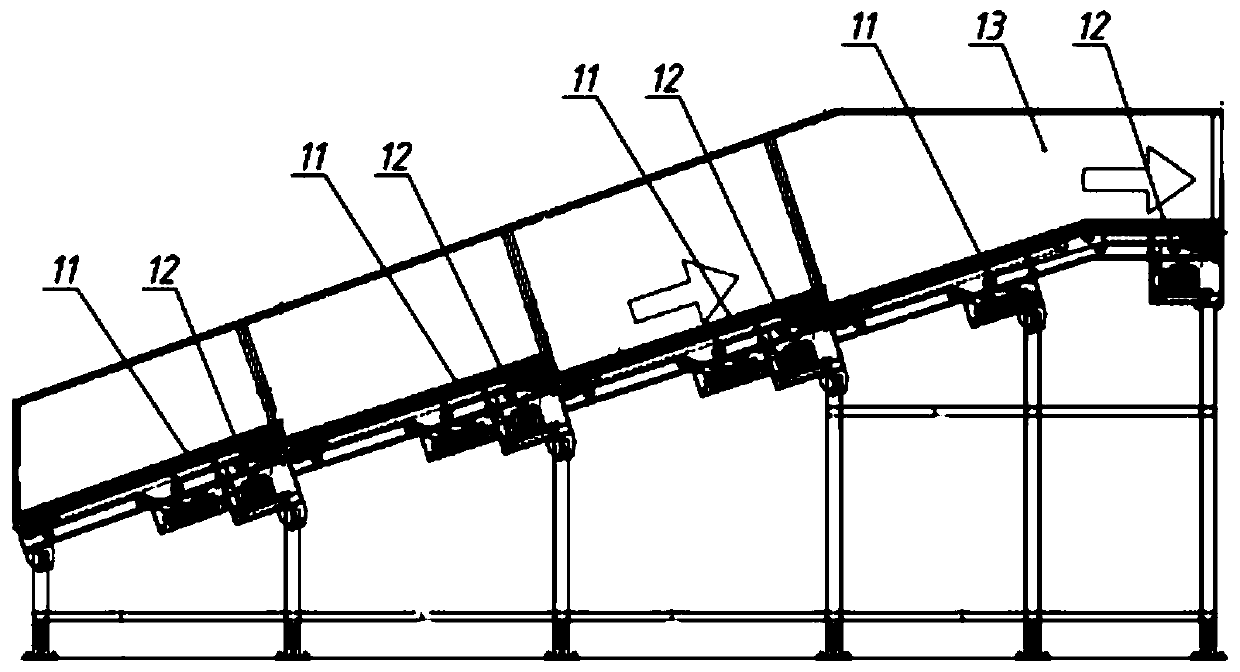

[0038] Example 1, such as figure 1 and figure 2 As shown, the automatic loading fast sorting control method described in this application adopts the following automatic loading device, that is, a first conveying line 1, an unpacking unit 2, an unpacking chute 3, and a separation unit 5 are arranged in sequence along the conveying direction , 3d+2d vision unit 6, manipulator grabbing unit 7, bottom scanning unit 8, sorter introduction unit 9, sorter 10.

[0039] Wherein, a separating unit 5 is set between the unpacking unit 2 and the 3d+2d visual unit 6;

[0040] Between the 3d+2d vision unit 6 and the sorter introduction unit 9, a manipulator grabbing unit 7 and a bottom scanning unit 8 are sequentially connected;

[0041] An annular conveying line 4 is arranged between the unpacking unit 2 and the bottom scanning unit 8, and the separating unit 5 forms a part of the endless conveying line 4;

[0042] The 3d+2d visual unit 6 and the manipulator grabbing unit 7 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com