Steel pipe stamping and punching machine

A technology for punching machines and steel pipes, which is applied in the field of steel pipe stamping devices, can solve the problems of affecting the punching efficiency and pass rate, the difficulty of controlling the punching distance, and the inconvenience of adjusting the punching machine, so as to improve the punching efficiency and ensure the efficiency And qualified rate, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

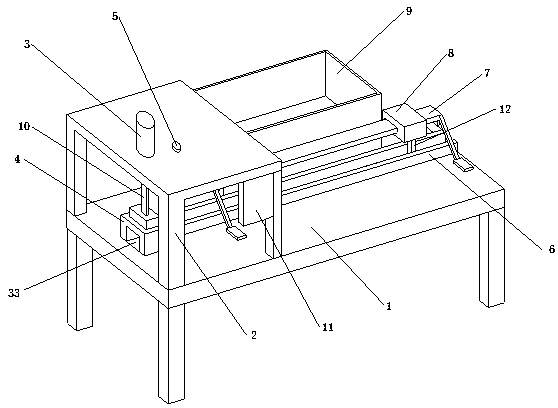

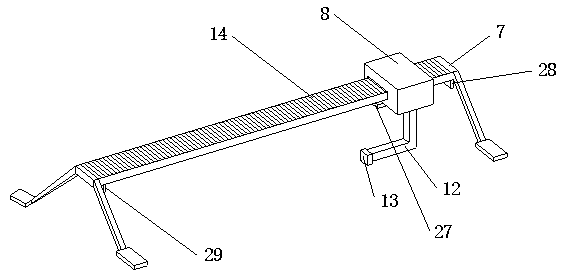

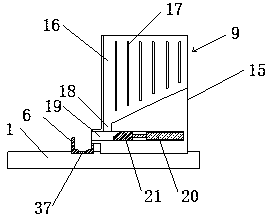

[0029] Embodiment: a kind of steel pipe stamping punching machine, as attached Figure 1-8As shown, it includes a workbench 1, a fixed frame 2 is arranged above the workbench 1, a first cylinder 3 vertically downward is embedded on the fixed frame 2, and a positioning frame 4 is arranged below the first cylinder 3; The extended end of a cylinder 3 is provided with a stamping plate 10, and the bottom of the stamping plate 10 is provided with a punching tool 22; U-shaped guide plate 6 is arranged, and the top of U-shaped guide plate 6 is provided with sliding frame 7, and sliding frame 7 is provided with sliding mechanism 8, and the bottom of sliding mechanism 8 is connected with the push rod 12 that stretches into U-shaped guide plate 6 inner cavity, pushes The end of the rod 12 is connected with a push block 13; one side of the U-shaped guide plate 6 is provided with a pipe delivery device 9; the fixed frame 2 is embedded with a laser displacement sensor 5 above the U-shaped g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com