Helical plastic wire flexible shaft for reducing noise and manufacturing method thereof

A technology of plastic wire and flexible shaft, which is applied in the direction of rotating motion shaft, etc., can solve the problems affecting the comfort of the driver of the vehicle or mechanical equipment, the wear of the square head of the flexible shaft and the square hole of the accessories, and the impact on the service life of the flexible shaft. The effect of high degree of automation, noise elimination and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is further described;

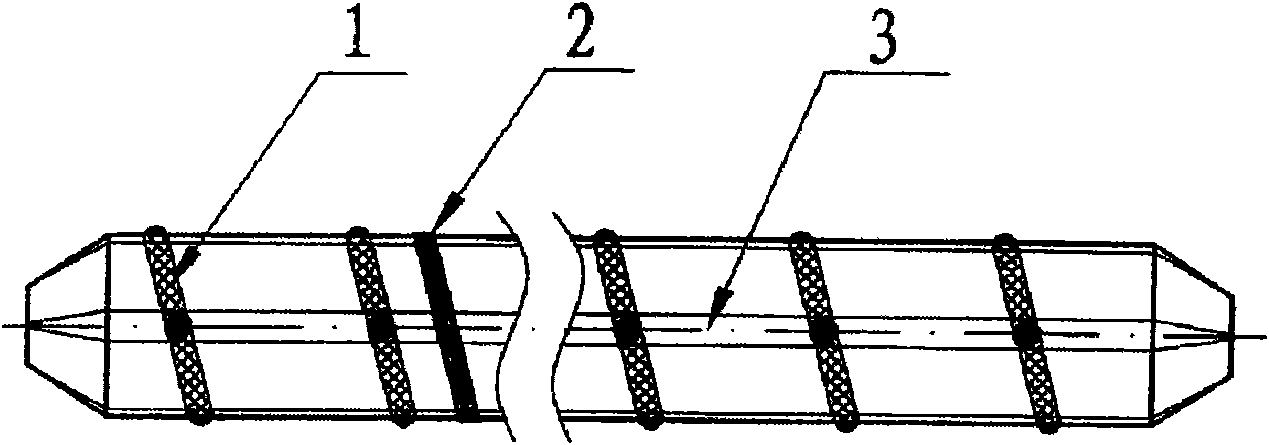

[0020] Refer to attached figure 1 , A spiral plastic wire flexible shaft for noise reduction, which consists of a shaft core, steel wire, and plastic wire. The steel wire is layered and spirally wound on the surface of the shaft core, and a plastic wire and multiple steel wires are spirally wound on the outermost layer of the flexible shaft.

[0021] The steel wire is a high-carbon steel wire, which is copper-plated, galvanized or phosphating-treated, and multiple steel wires are layered and spirally wound on the shaft core to improve the torsion resistance of the flexible shaft.

[0022] The plastic wire is a pure plastic wire made of engineering plastics with high wear resistance, or a plastic-coated steel wire with a steel wire inner core.

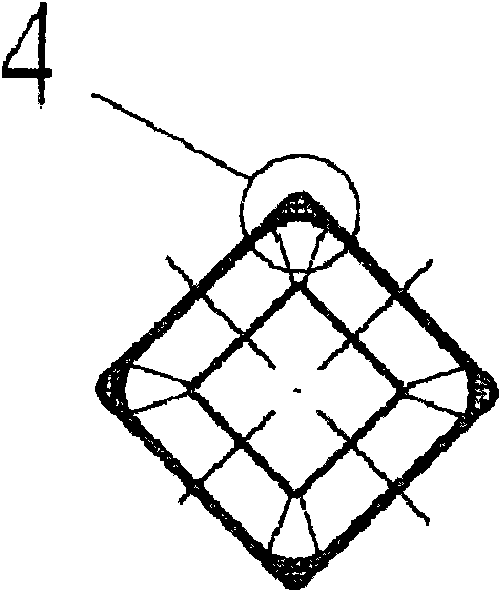

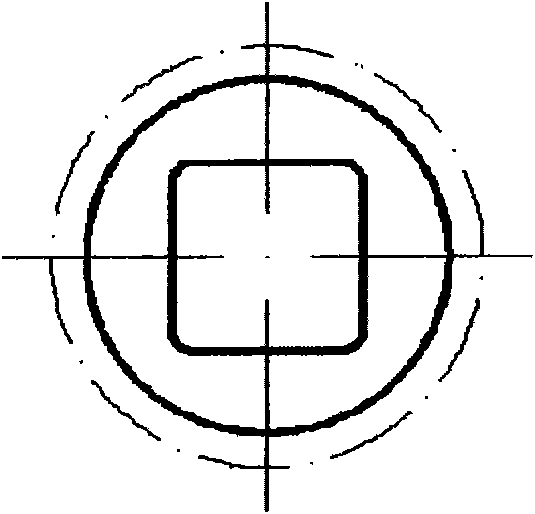

[0023] as attached figure 2 , with image 3 , the flexible shaft is fitted in the matching square hole parts with an interference t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com