Magneto-rheological hydraulic rubber air spring

A rubber air spring, magnetorheological fluid technology, applied in gas-liquid shock absorber, vibration suppression adjustment, non-rotation vibration suppression and other directions, can solve the problem of inability to achieve suspension control, achieve simple structure and strong temperature adaptability , the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

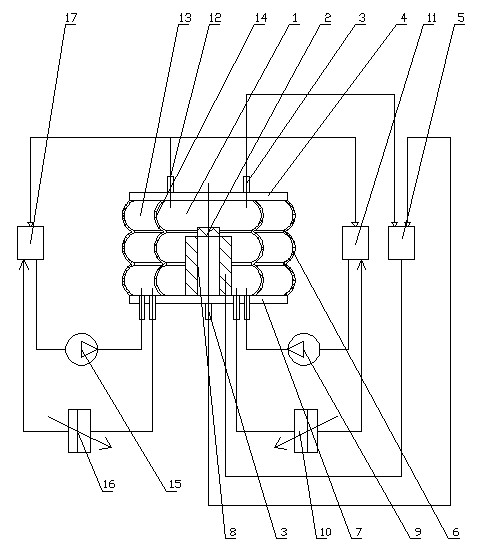

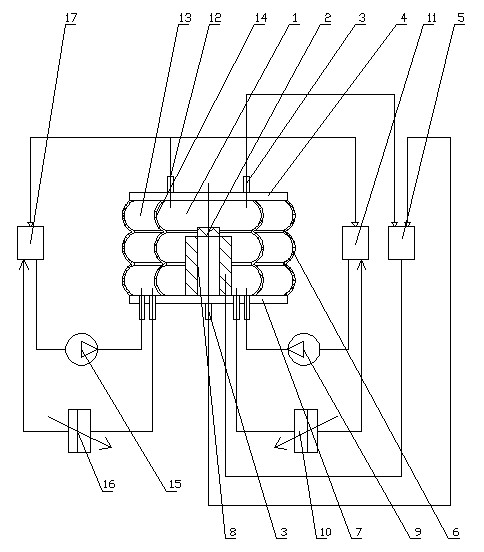

[0019] 1. Components and product structure:

[0020] 1) Magneto-rheological hydraulic rubber air spring, such as figure 1 Shown, be divided into inner and outer two layers of coaxially symmetrical rubber capsule rubber capsule 6 and rubber capsule 14, shape and material are similar to the rubber capsule of common rubber air spring. The interior of the inner layer rubber bag rubber bag 14 is a magneto-rheological fluid 1, the annular area cavity 13 between the inner layer rubber bag rubber bag 14 and the outer layer rubber bag rubber outer bag 6 is air, and the height limiter 2 and the upper and lower Composed of fixed sealing plates 4 and 7, the height limiter 2 is connected with the lower fixed sealing plate 7, and the inner and outer rubber bags are connected with the upper and lower fixed sealing plates;

[0021] 2) Magneto-rheological hydraulic adjustment system: composed of a magnetorheological hydraulic pump 9, a height sensor 12, a control module 11 and a controlla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com