Automatic pallet filler of commutator

A technology of tray loading machine and commutator, which is applied in the direction of conveyor objects, transportation and packaging, etc., which can solve the problems of low efficiency, unguaranteed tray quality, and heavy labor of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

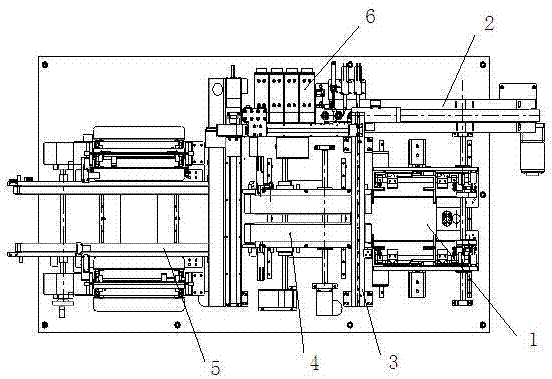

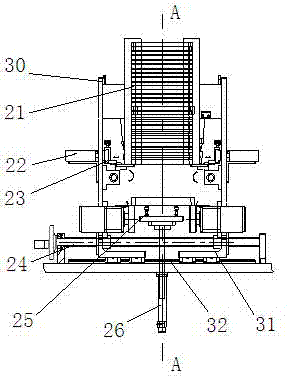

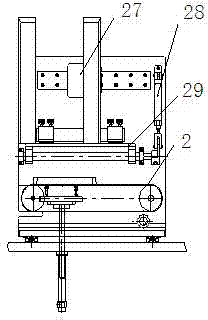

[0021] As shown in the figure, a commutator automatic disk loading machine is equipped with a workbench, which is characterized in that the workbench is equipped with a disk dividing mechanism 1, a feeding belt line 2, an electric cylinder translation grabbing mechanism 3, and an automatic distance changer. Belt line 4 and discharge storage mechanism 5, wherein: sub-disc mechanism such as figure 2 image 3 As shown, there are plastic tray fixture 21, clamping cylinder 22, material holding claw 23, manual adjustment screw 24, sucker plate 25, disc cylinder 26, sliding locking block 27, rotating plate driving cylinder 28 and 90-degree rotating support The plate 29, the plastic tray fixture 21 and the clamping cylinder 22 are respectively connected with the large brackets 30 on both sides, the drag claw 23 is connected with the clamping cylinder 22, the large bracket 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com