Infrared temperature measurement method and infrared temperature measurement system

A technology of infrared temperature measurement and infrared detection device, which is applied in the field of infrared temperature measurement and infrared temperature measurement system, can solve the problems of interfering with infrared radiation propagation, weakening radiation intensity, and temperature measurement accuracy staying at 1%, etc., to achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

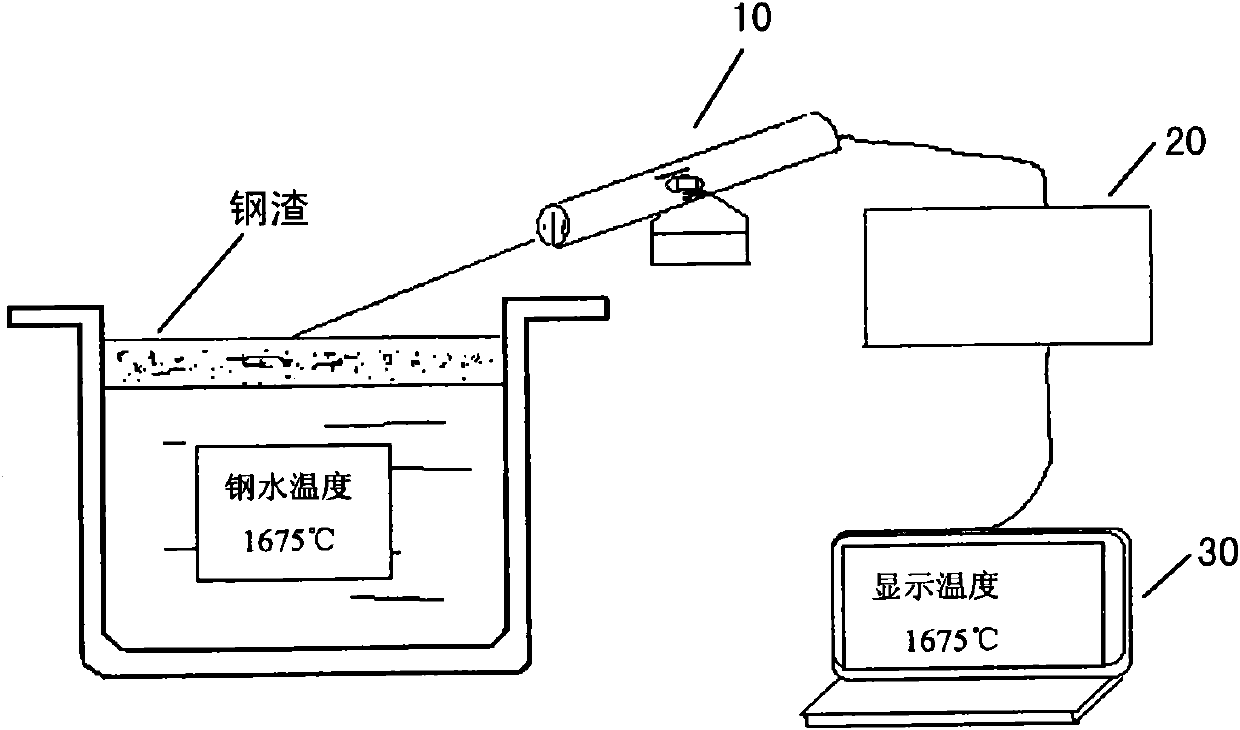

[0027] Infrared temperature measurement physical model of the present invention

[0028] The existing infrared temperature measurement method is based on the relationship between the radiation energy of the measured radiation object and the temperature of the radiation object. The infrared temperature measurement physical model proposed by the present invention is based on the relationship between the radiation energy emitted by the radiating object and received by the infrared temperature measuring device and the temperature of the radiating object.

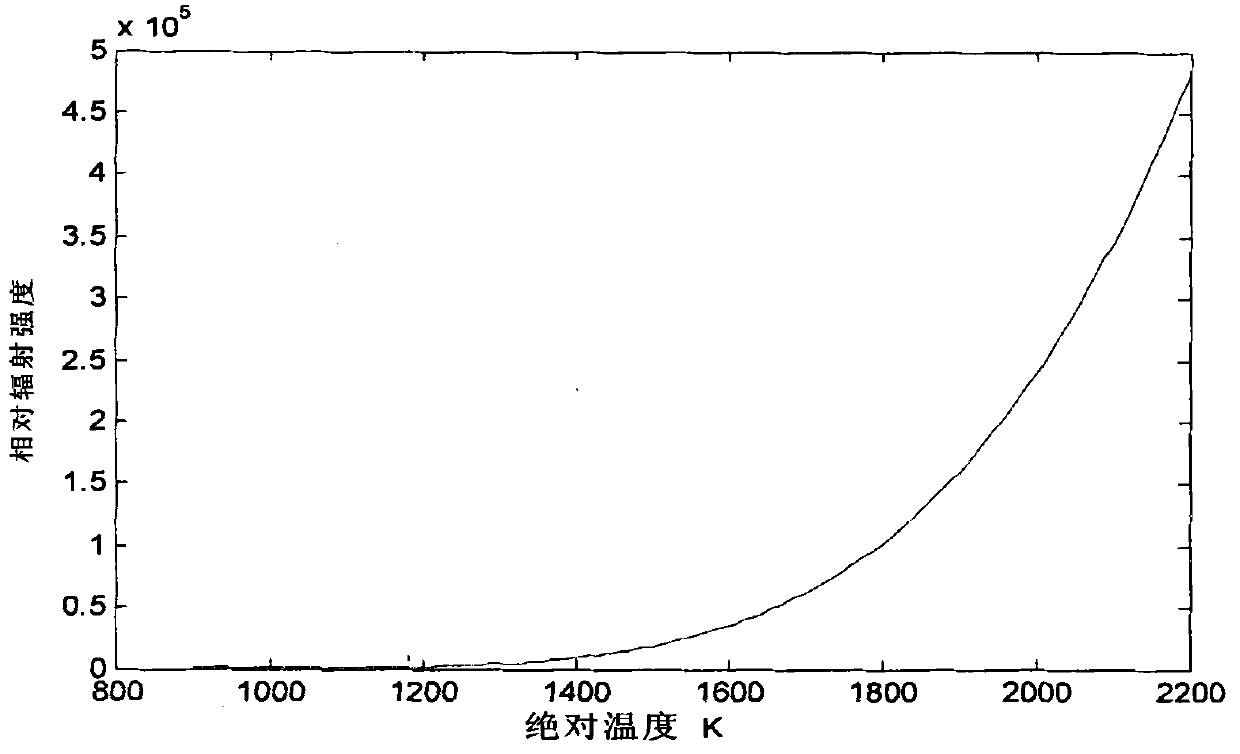

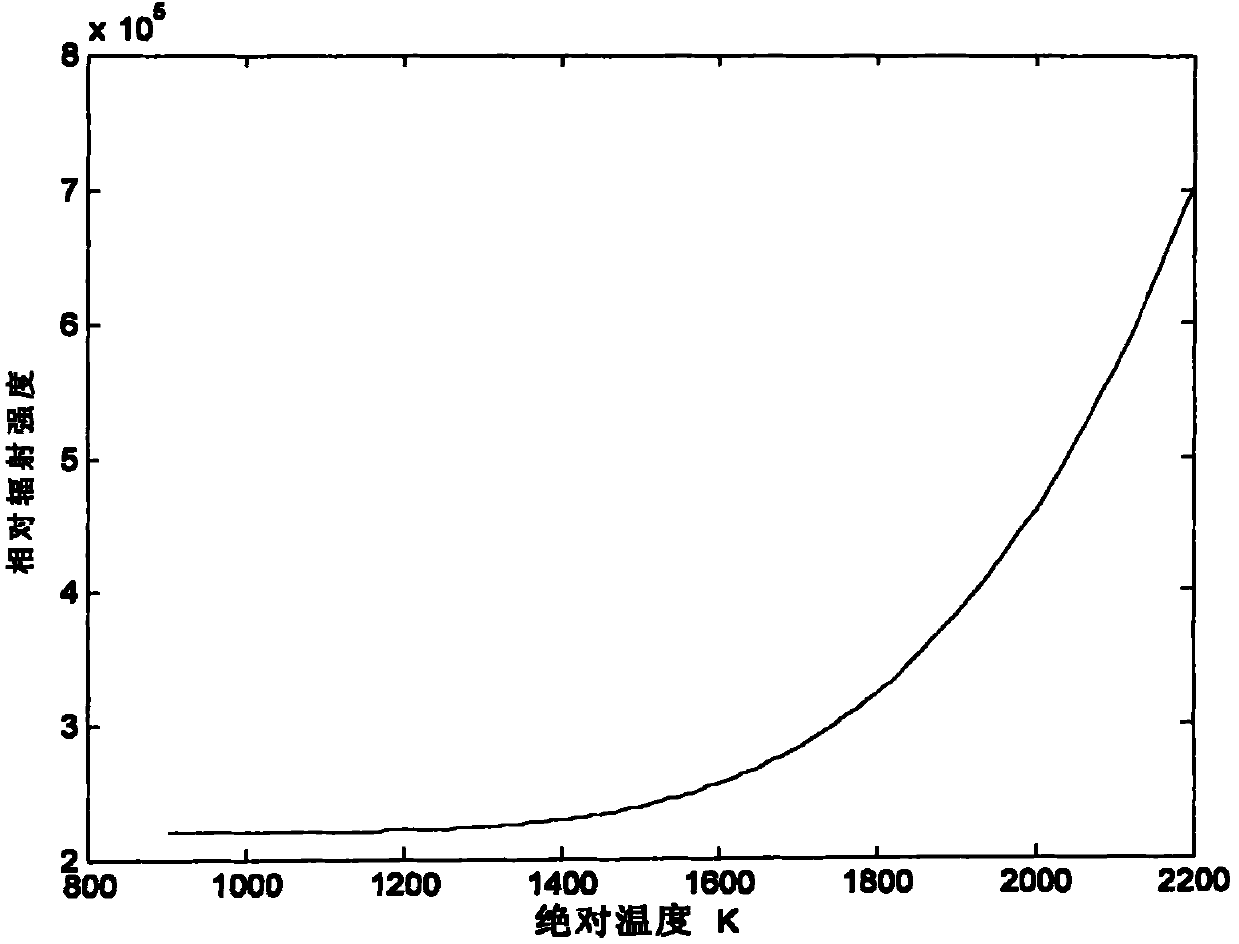

[0029] The traditional infrared temperature measurement method uses the Planck formula In the formula, W(λ, t) is the black body radiation intensity, λ is the radiation wavelength, t is the absolute temperature, c 1 , c 2 is a constant. This is the thermal radiation formula for a black body. The difference between the measured object and the black body is that the emissivity of the measured object is greater than zero and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com