Conveying track for bagged goods stacking production line

A technology for conveying tracks and production lines, applied to conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of easy wear and damage of conveyor belts, difficulty in effectively adjusting the speed and interval of goods, and inaccurate positions of goods, etc., to achieve Impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

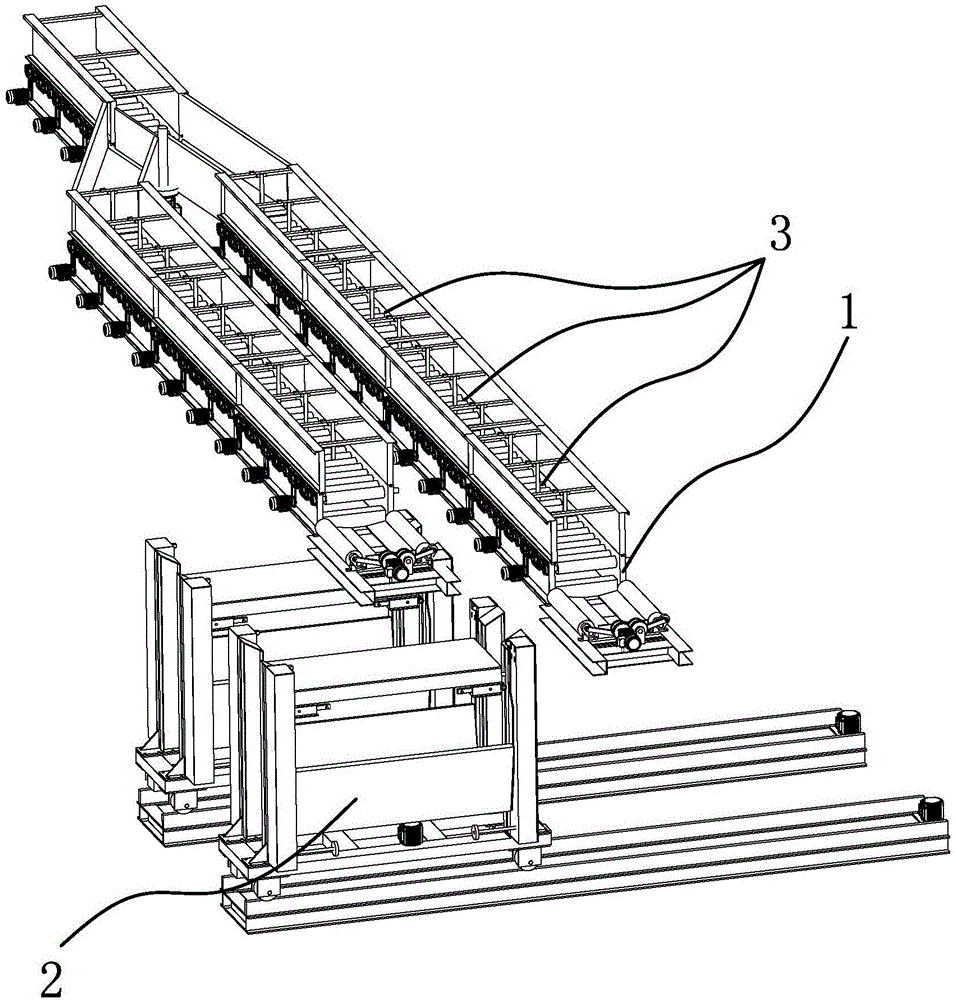

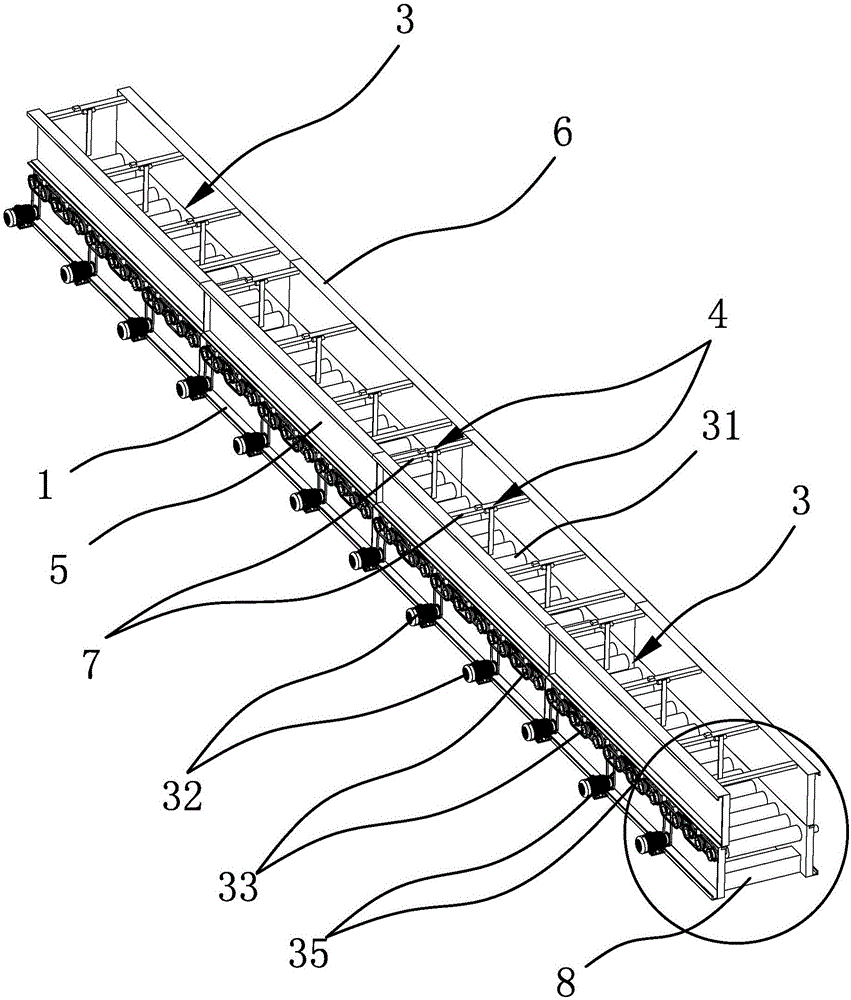

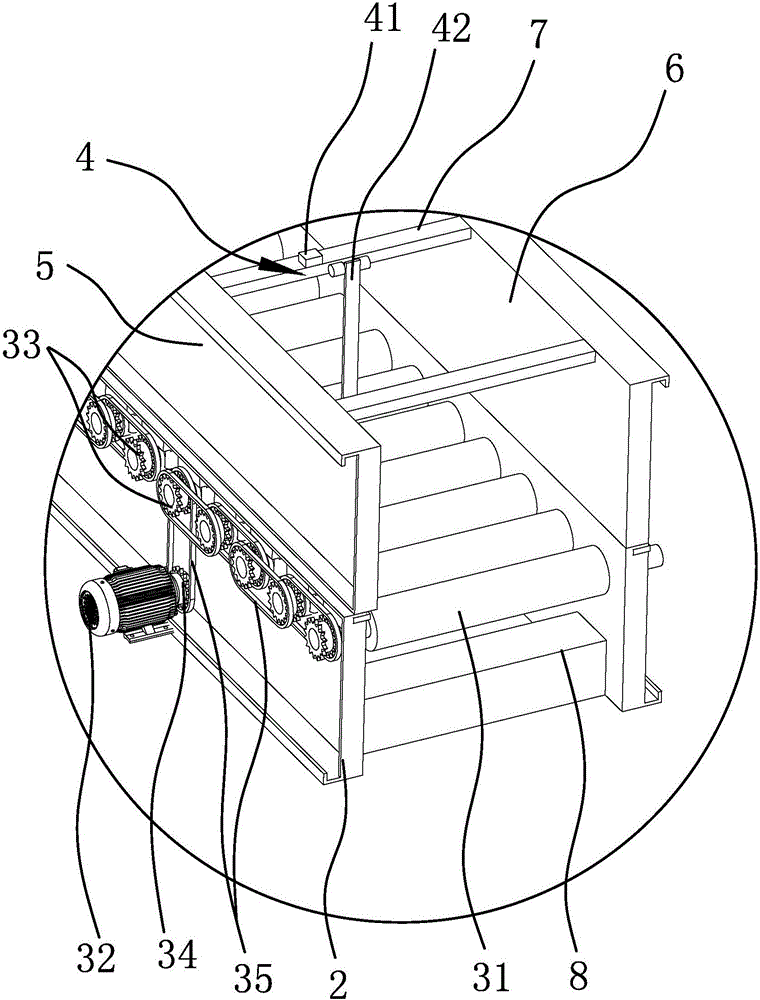

[0028] Such as figure 1 As shown, the conveying track is installed on the bagged goods stacking production line, one end is the entrance, and the other end is the exit. After the bagged goods are packaged, they enter the conveying track from the entrance of the conveying track, and unload from the exit of the conveying track into the conveyor. Load the trolley 2. Such as figure 2 and image 3As shown, the conveying track includes two row mounting frames 1 arranged at intervals in parallel, and at least 3 sets of drive units 3 are sequentially arranged between the two row mounting frames 1 along the length direction of the row mounting frames 1, generally 5- 15 groups of driving units 3, 12 groups of driving units 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com