Device of measuring movement duration of tapered wedge of mold

A movement and mold technology, applied in forming tools, manufacturing tools, metal processing, etc., can solve the problems of slow wedge movement, parts grabbing, and affecting stamping automation production efficiency, etc., to achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

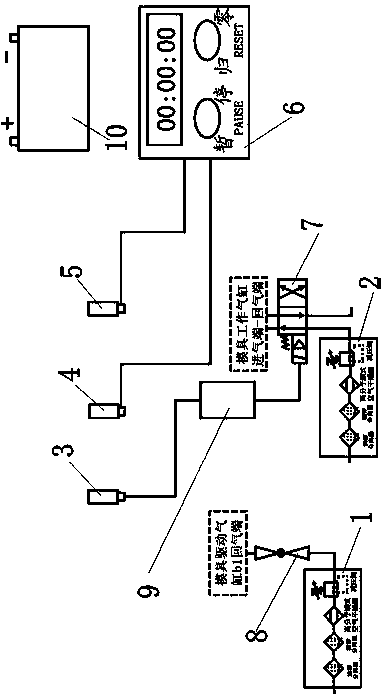

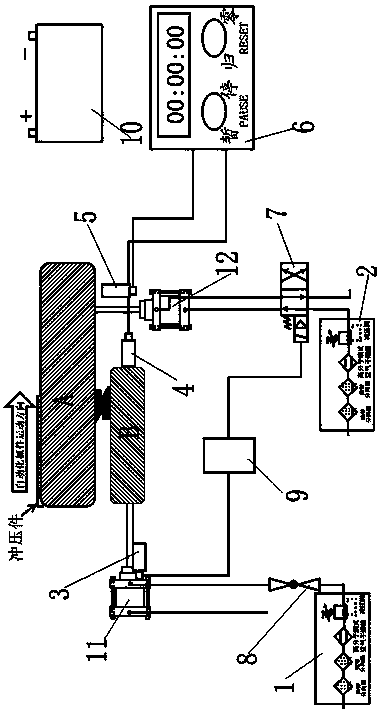

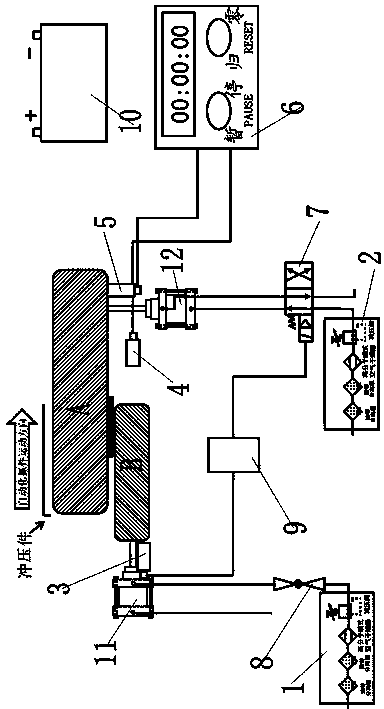

[0024] see Figure 1 to Figure 3 As shown, a device for measuring the movement time of the mold wedge, including a first pneumatic triplex 1, a second pneumatic triplex 2, a second proximity sensor 3, a first proximity sensor 4, a third proximity sensor 5, and a timer 6 , two-position four-way electromagnetic reversing valve 7, ball valve 8, relay 9 and power supply 10, the first pneumatic triple piece 1 is connected with the first mold cylinder 11 through the ball valve 8 and the pipeline, the second proximity sensor 3 and the first proximity sensor 4 are respectively arranged at both ends of the mold wedge B, the second proximity sensor 3 is connected to the second mold cylinder 12 through the relay 9, the two-position four-way electromagnetic reversing valve 7 and the wire, and the first proximity sensor 4 is connected to the timer through the wire 6 connection, the third proximity sensor 5 is set at the lower end of the mold wedge A and is connected to the timer 6 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com