Lathing device for iron core of efficient motor without end plate at two ends and machining method thereof

A technology of turning processing and endless plate, applied in metal processing equipment, turning equipment, turning equipment, etc., can solve the problems of affecting the appearance quality, unable to achieve aesthetic effects, wasting labor hours, etc., to avoid processing risks, product beauty, and saving The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

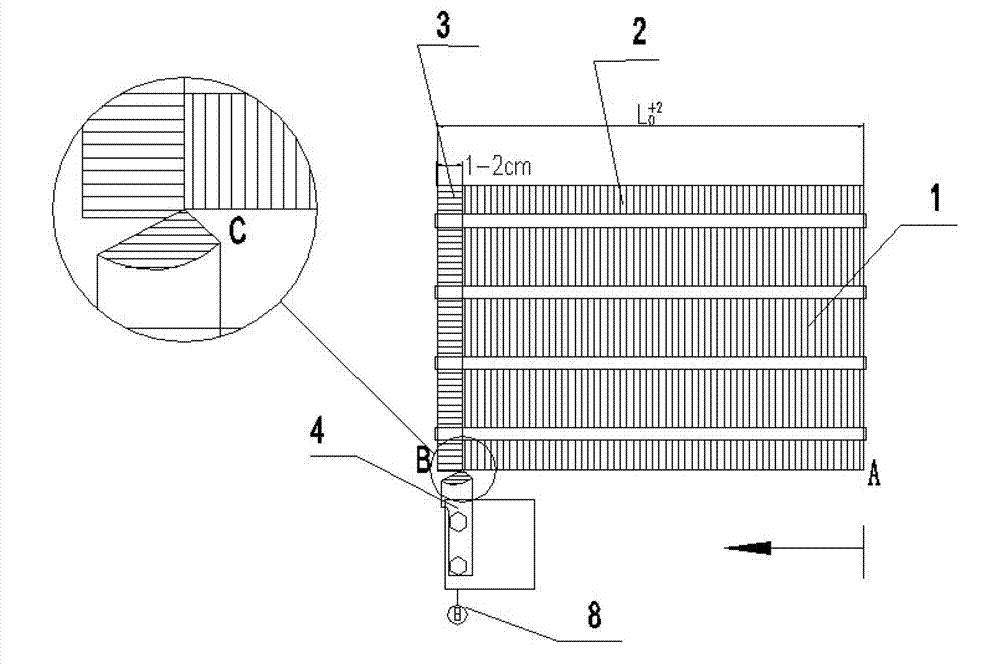

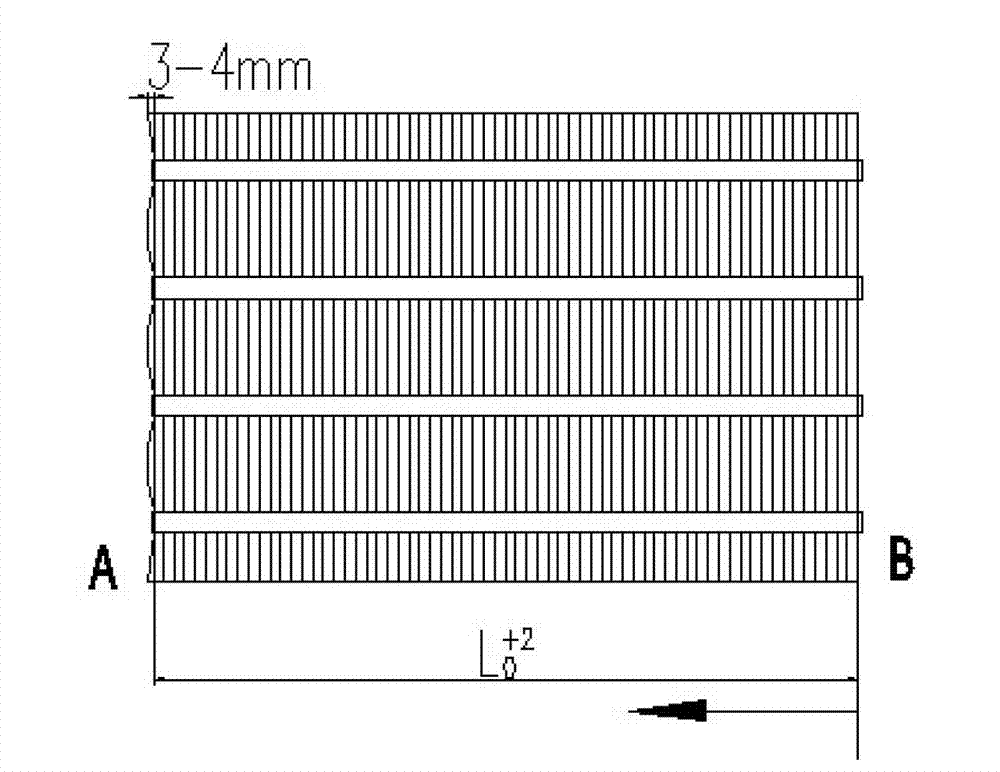

[0022] The accompanying drawings non-limitatively disclose a high-efficiency motor core turning method without end plates at both ends involved in the present invention. The technical processing scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] figure 1 It shows the running route of the turning tool, that is, the tool moves from the A end until the point C is 1-2cm away from the B end of the other end of the iron core. The scale size on the dial indicator 9 coincides with the beginning of the cutting tool, and it is only necessary to go in the opposite direction until it coincides with the forward turning process.

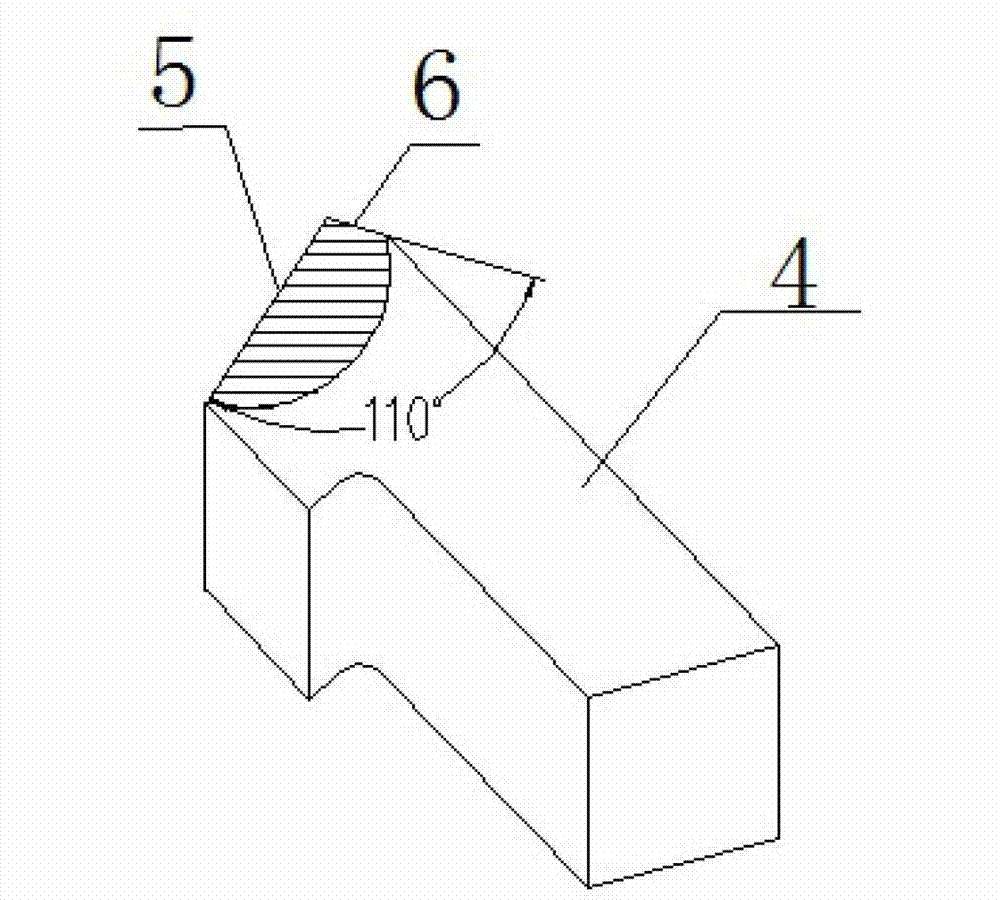

[0024] image 3 It is a schematic diagram of the structure of the turning tool. Make sure there are two cutting edges, that is, the first cutting edge and the second cutting edge. The faster the grinding, the better the turning effect. The angle between the two cutting edges is about 110o . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com