High-precision thermal expanding method for high-strength steel pipes

A high-precision, high-strength technology, which is applied in the field of thermal processing, can solve the problems that the normal temperature diameter expansion process cannot meet the requirements and use requirements, and achieve simple and practical expansion methods, increase the scope of use, and improve roundness and straightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

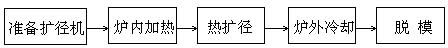

Method used

Image

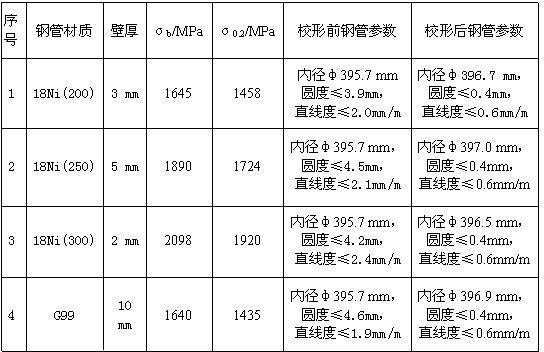

Examples

Embodiment 1

[0027] Embodiment 1 adopts the steel pipe of T250 material, and the mechanical property of material: tensile strength σ b 1700MPa, yield strength

[0028] σ 0.2 It is 1600MPa, the wall thickness is 5mm, the inner diameter of the steel pipe is φ395.7mm, the length is 970mm, the roundness is ≤4.6mm, and the straightness is ≤2.6mm / m.

[0029] The manual spray gun evenly sprays graphite emulsion on the surface of the outer module of the expanding machine; the pipe delivery trolley sends the steel pipe into the heating furnace, and after filling with argon for 10 minutes, 2500Hz intermediate frequency heating, heating at room temperature to 200°C within 3 minutes, keeping it warm for 5 minutes, and removing water Impurities such as steam and oil. Rapidly heat up to 700°C in 4 to 6 minutes, stop heating after 2 minutes of heat preservation, open the movable furnace door, move the expanding machine forward into the heating furnace, insert the outer module into the steel pipe, expan...

Embodiment 2

[0030] Embodiment 2 adopts the tapered steel pipe of T300 material, and the mechanical property of material: tensile strength σ b 2100 MPa, yield strength σ 0.2 It is 1900 MPa, the wall thickness is 4 mm, the inner diameter of the tapered steel pipe: small head φ393.1mm, large head φ430.1mm, length 940mm, roundness ≤ 4.3mm, straightness ≤ 2.8mm / m.

[0031] Spray graphite emulsion on the surface of the outer module with a manual spray gun; send the steel pipe into the heating furnace with argon for 10 minutes, and then heat it with 3000 Hz intermediate frequency, heat it at room temperature to 200°C within 2 minutes, and keep it warm for 4 minutes to remove water vapor and oil stains, etc. For impurities, quickly heat to 800°C in 5-6 minutes, keep warm for 2 minutes, and stop heating. Open the door of the movable heating furnace, and the expanding machine moves forward to enter the heating furnace. The outer module is inserted into the steel pipe, and the inner diameter of the...

Embodiment 3

[0032] Embodiment 3 adopts the tapered steel pipe of 16Co14Ni10Cr2Mo material, and material mechanical properties: tensile strength σ b 1749 MPa, yield strength σ 0.2 1598 MPa, wall thickness 8 mm, inner diameter of steel pipe: small head φ420.2mm, large head φ455.3mm, length 940mm, roundness ≤ 5.0mm, straightness ≤ 3.0mm / m.

[0033] Spray graphite emulsion on the surface of the outer module with a manual spray gun; send the steel pipe to the heating furnace with argon for 10 minutes, and then heat it with 2000 Hz intermediate frequency, heat it at room temperature to 200°C within 4 minutes, and keep it warm for 8 minutes to remove water vapor and oil stains, etc. Impurities. Rapidly heat to 750°C in 7 minutes, keep warm for 2 minutes, and stop heating. Open the movable heating furnace door, the expanding machine moves forward to enter the heating furnace, the outer module is inserted into the steel pipe, and the inner diameter of the expansion type is expanded to φ423mm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com