Online robot rolloff device for side body wheel covers

A technology of robots and side wheels, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of poor overall planning logistics, difficult maintenance and repair, and a small number of models in use, so as to save manufacturing costs, The effect of short debugging time and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

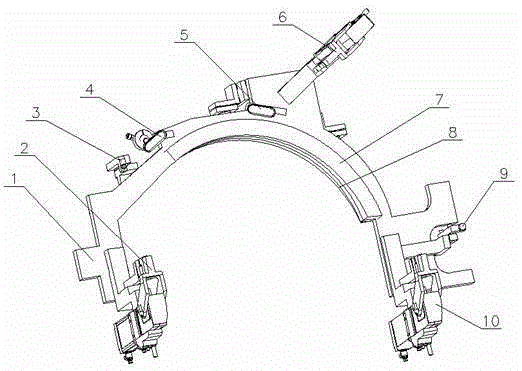

[0026] Such as figure 1 As shown, the side wheel cover online robot hemming device includes a base 1, three clamping mechanisms 2, 6, 10, two positioning pin mechanisms 3, 9, two suction cups 4, 5, and an upper bottom mold 7 and Lower bottom mold 8; positioning pin mechanisms 3,9 included on the device, clamping mechanisms 2,6,10, suction cups 4,5, upper bottom mold 7 and lower bottom mold 8 are all installed on the base 1, satisfying the The precision requirements of the hemming, all installation mechanisms are installed through the cooperation of pins and screws.

[0027] The clamping mechanisms 2, 6, and 10 are installed on the base 1 at intervals in the same direction. The clamping mechanism 2 corresponds to the position of the rear side sill of the wheel house of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com