Loading device based on six-degree-of-freedom parallel mechanisms

A technology of loading device and degrees of freedom, applied in railway vehicle testing and other directions, can solve the problems of inability to measure the pose of the specimen, unreliable output value of the acceleration sensor, low precision, etc., to simplify investment, improve accuracy, and improve measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

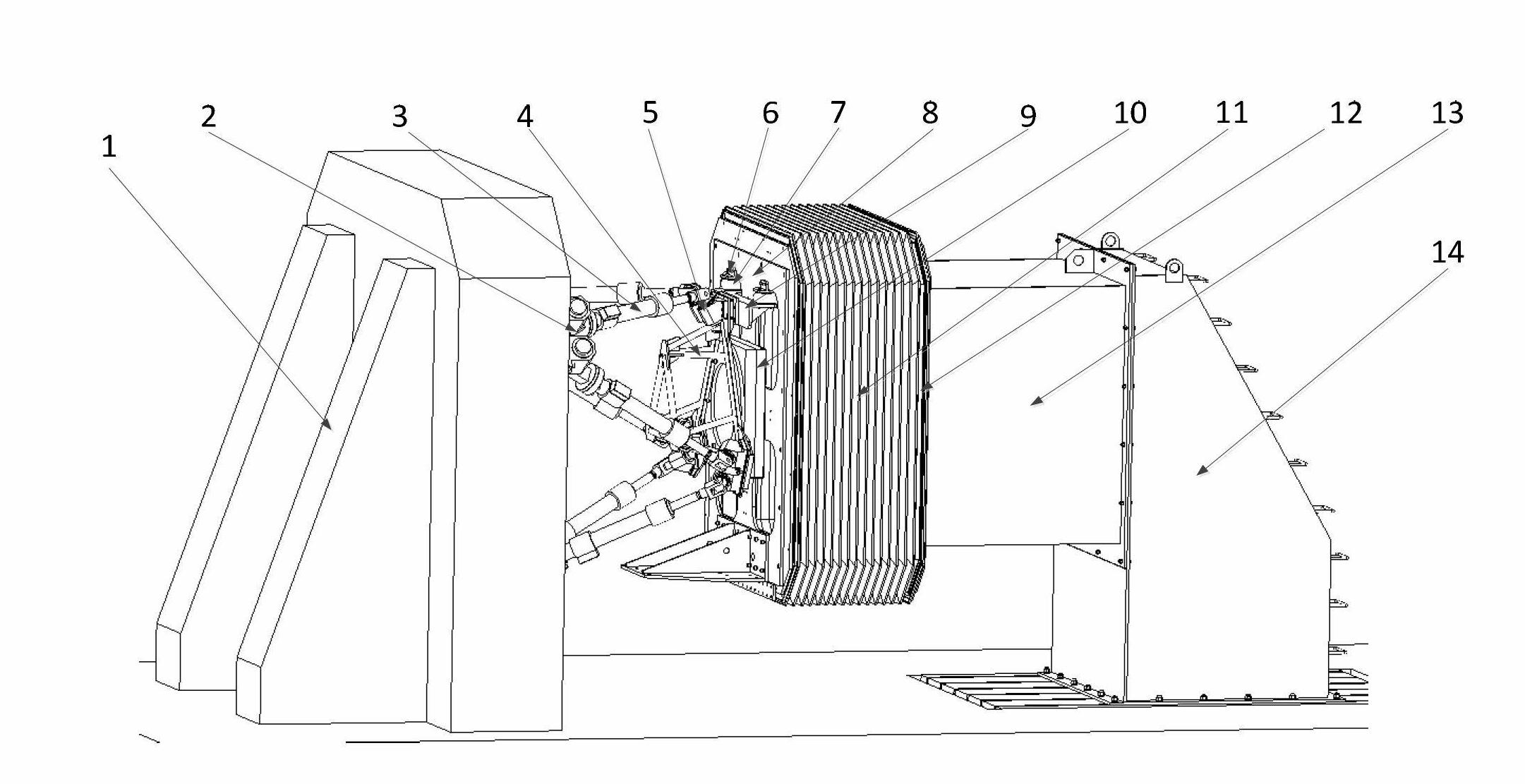

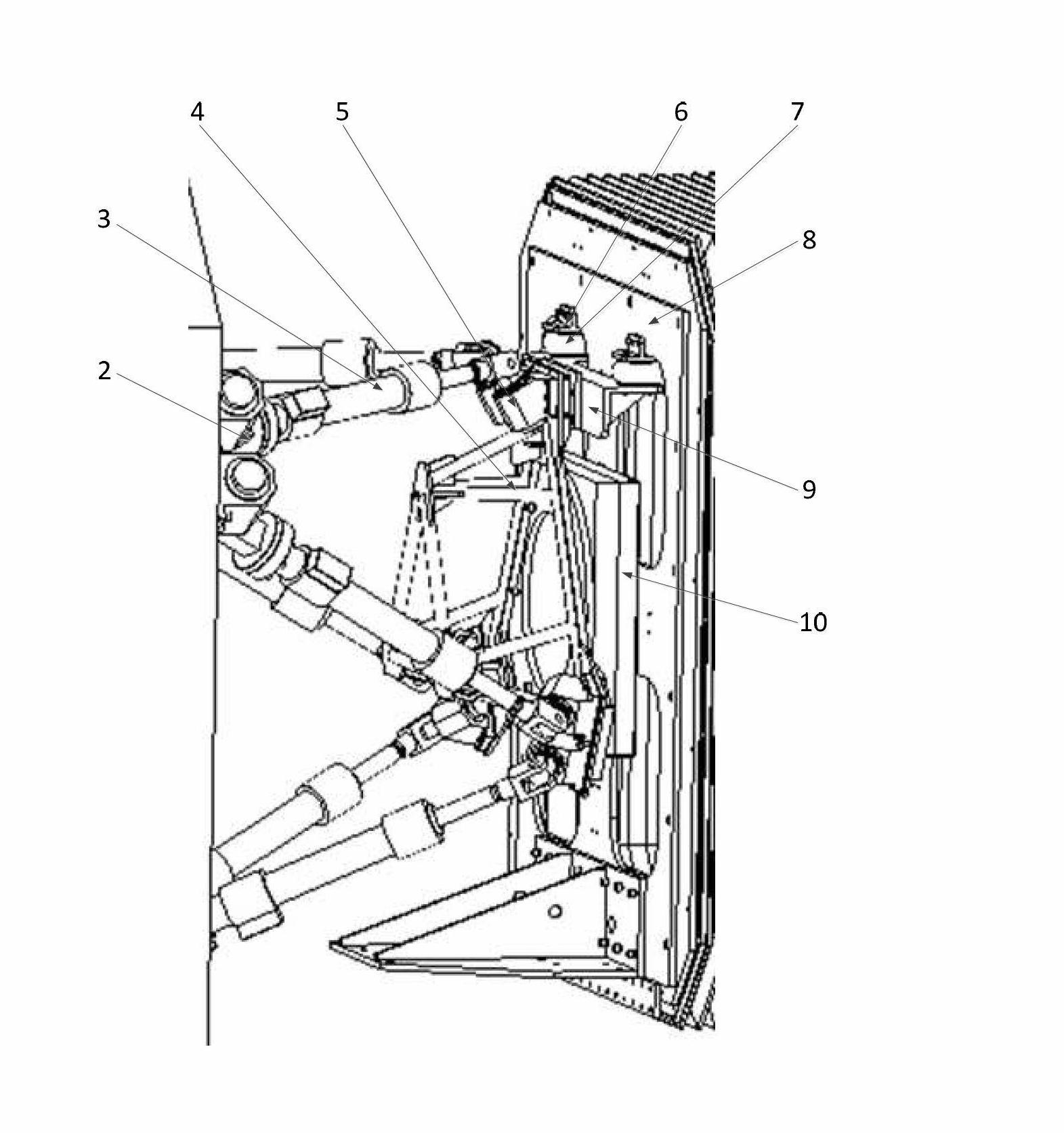

[0019] like figure 1 and 2 As shown, the present invention is a loading device based on a six-degree-of-freedom parallel mechanism. The device is arranged on the foundation and includes a front reaction force foundation 1, a six-degree-of-freedom parallel mechanism, a gravity balance mechanism, a force measuring mechanism and a rear reaction force foundation 14. , the six-degree-of-freedom parallel mechanism includes a lower hinge support 2 connected with the front reaction force base 1, a hydraulic actuator 3 connected with the lower hinge support 2 at one end, and a motion platform 4 connected with the other end of the hydraulic actuator 3 ; Described gravity balance mechanism includes air spring 7 connected with motion platform 4 through bracket 9, front end transition plate 8 connected with air spring 7 through connecting frame 6; Described force measuring mechanism includes sensor 10 on motion platform 4, The sensor 10 is connected to the front end transition plate 8; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com