Hydraulic control system of extruder and control method implemented by hydraulic control system

A hydraulic control system and extrusion press technology, applied in presses, manufacturing tools, machinery and equipment, etc., can solve the problems of difficult automatic and precise control, low component life, high operating costs, and reduce serious heat generation. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

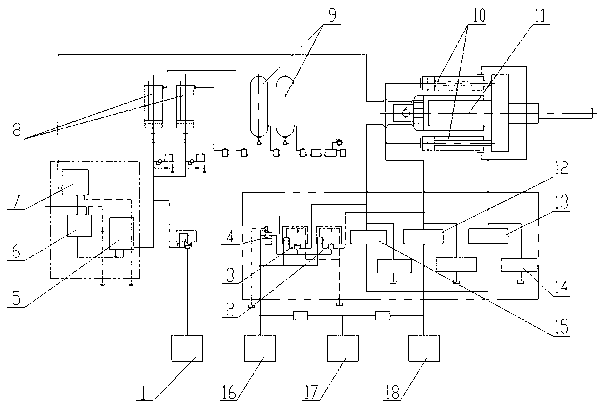

[0016] like figure 1 As shown, the extruder hydraulic control system provided by this embodiment can be applied to a wide range of extrusion speed and high precision requirements, including a high-pressure gas tank 9, a piston accumulator 8, an accumulator isolation valve 7, a proportional Flow valve 6, accumulator oil supply inlet valve 5, high-frequency response proportional valve 4, main cylinder inlet valve 3, side cylinder inlet valve 2, fluid replenishment variable pump 1 and multiple parallel inlet variable pumps 16, 17, 18; the high-pressure gas tank 9 communicates with the air inlet of the piston accumulator 8 through a pipeline to provide air pressure compensation when supplying oil to the piston accumulator 8; the oil outlet of the piston accumulator 8 passes through the pipeline, and passes through the Accumulator oil supply inlet valve 5, proportional flow valve 6, and accumulator isolation valve 7 communicate with the main cylinder 11 of the extruder; the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com