Welding device and method for assembling optical fiber gyro

A fiber optic gyroscope and welding device technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of incomplete electromagnetic shielding effect, inaccurate output of fiber optic gyroscope, etc., to achieve magnetic shielding effect, The effect of preventing the deformation of structural parts and the simple and compact structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings.

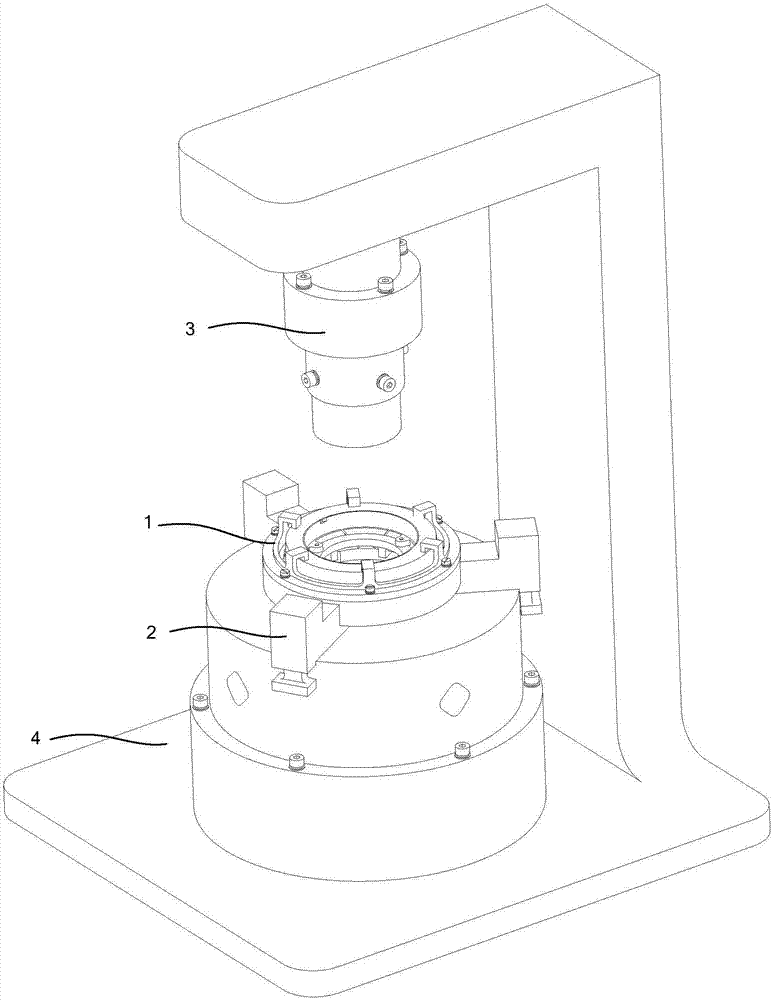

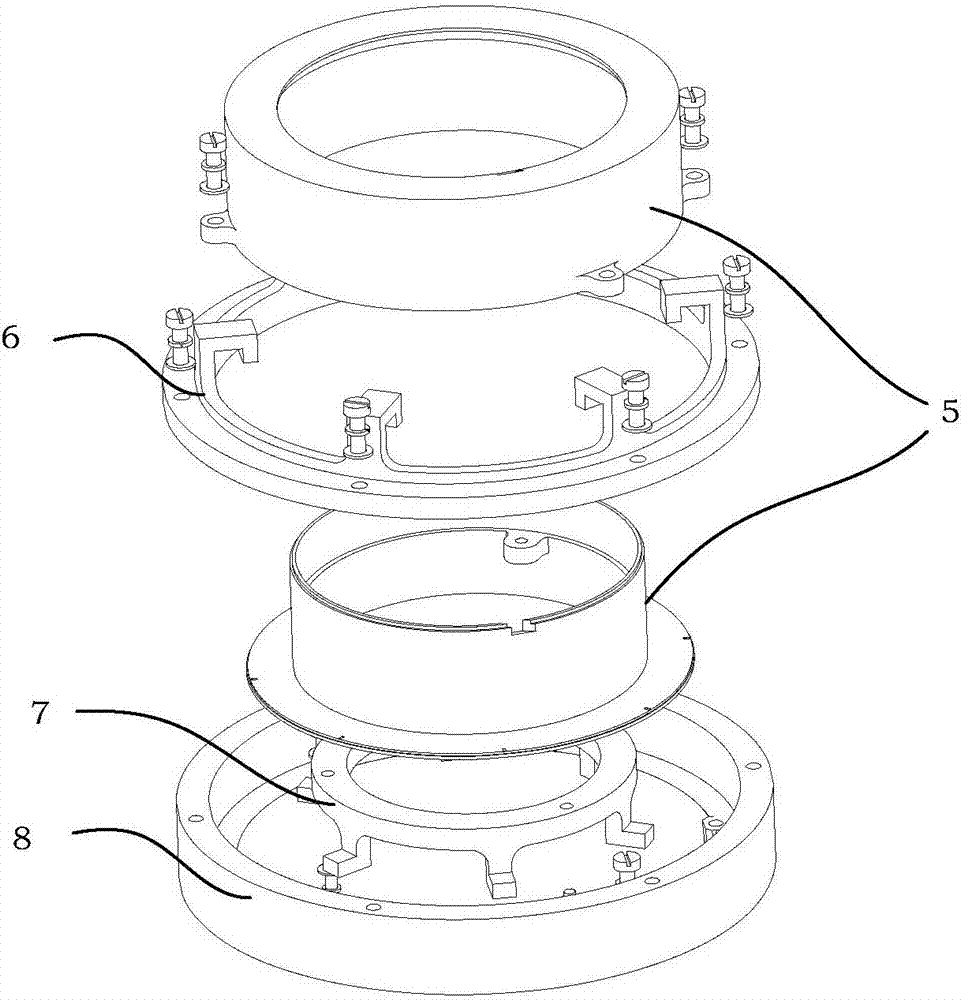

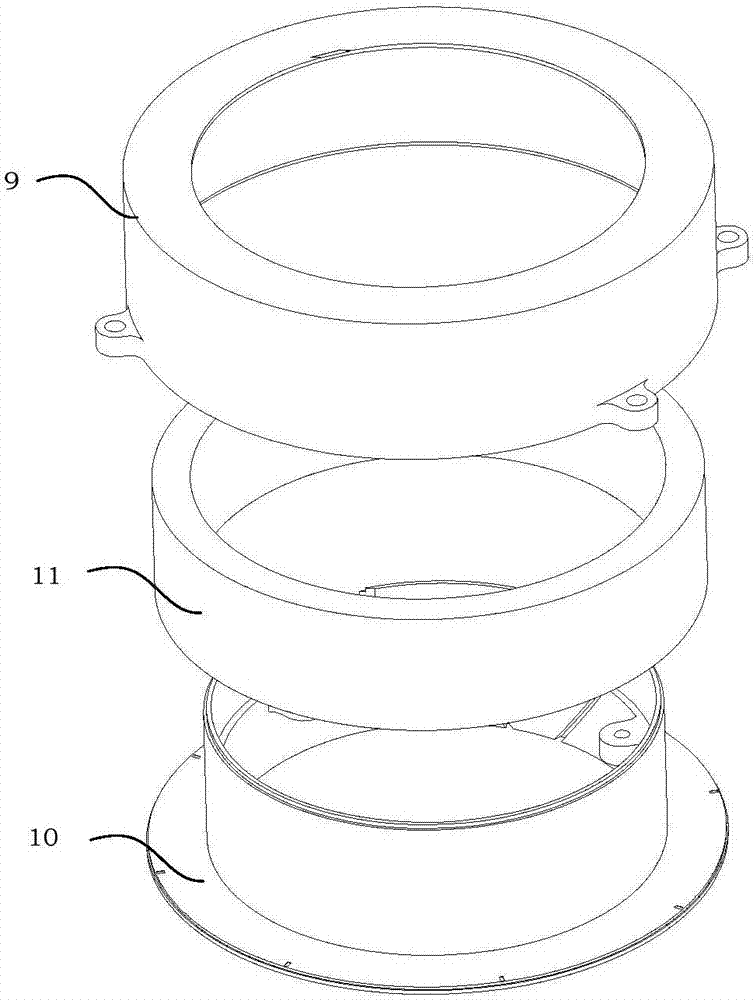

[0043] Welding device of the present invention is used for welding fiber optic gyroscope assembly 5, such as image 3 The structural explosion diagram of the fiber optic gyroscope assembly 5 shown, the fiber optic gyroscope assembly 5 consists of Figure 4 , Figure 4A , Figure 4B Shown gyroscope upper cover 9, Figure 5 , Figure 5A , Figure 5B The gyro base 10 shown with Figure 6 The illustrated fiber optic ring assembly 11 is constructed.

[0044] The gyroscope upper cover 9 is a hollow circular cover, the inner wall of the hollow circular cover is relatively thin, and the inner side and the lower end of the upper end are respectively limited bosses. The bosses vary in thickness and width. There are four external mounting bosses on the outer bottom of the gyro upper cover 9, and the bosses have four mounting through holes. Due to structural cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com