Transmission mechanism and 4D probe thereof

A transmission mechanism, 4D technology, applied in the field of probes, can solve the problems of short life, affect the precision requirements of the probe, reduce the life of the probe, etc., and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A 4D probe usually includes: a casing, a motor, a transmission mechanism, and a transducer core. Usually the casing is arranged outside the other components to play the role of support and protection. One end of the transmission mechanism is connected to the core of the transducer, and the other end is connected to the motor. The motor drives the core of the transducer to swing. In the prior art, due to the limitation of the structure of the transmission mechanism itself, the precision of the probe is limited. Reduced, in some high-precision applications, often can not meet the requirements.

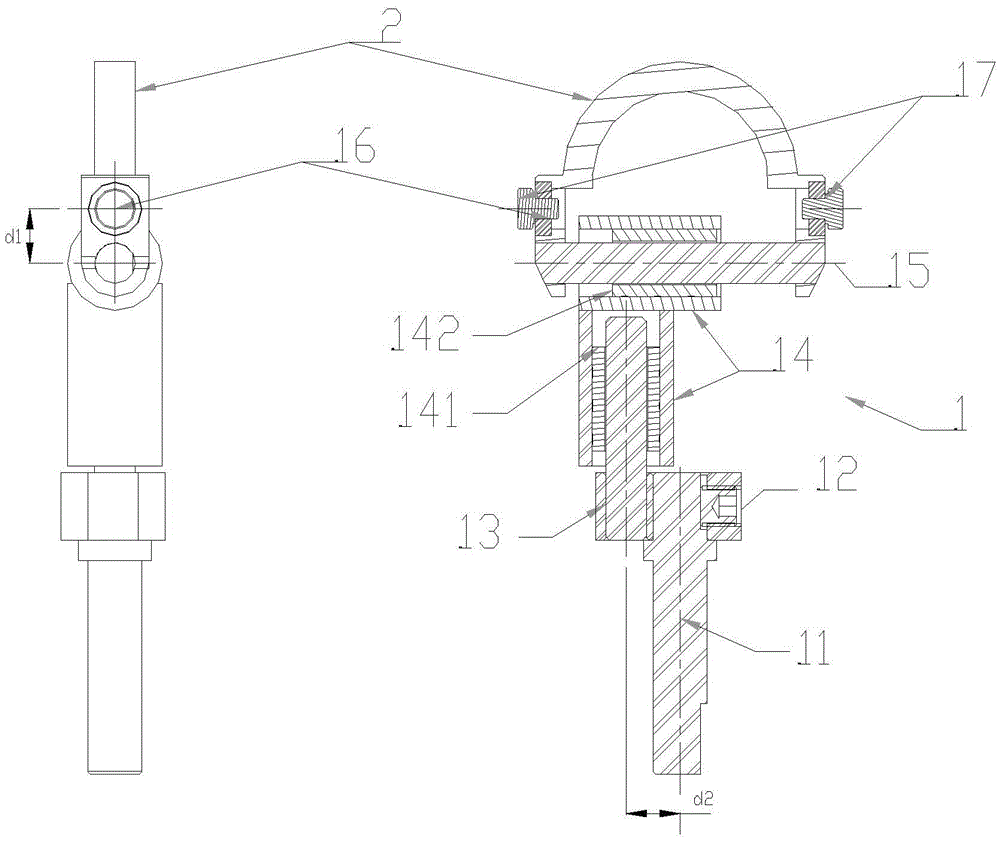

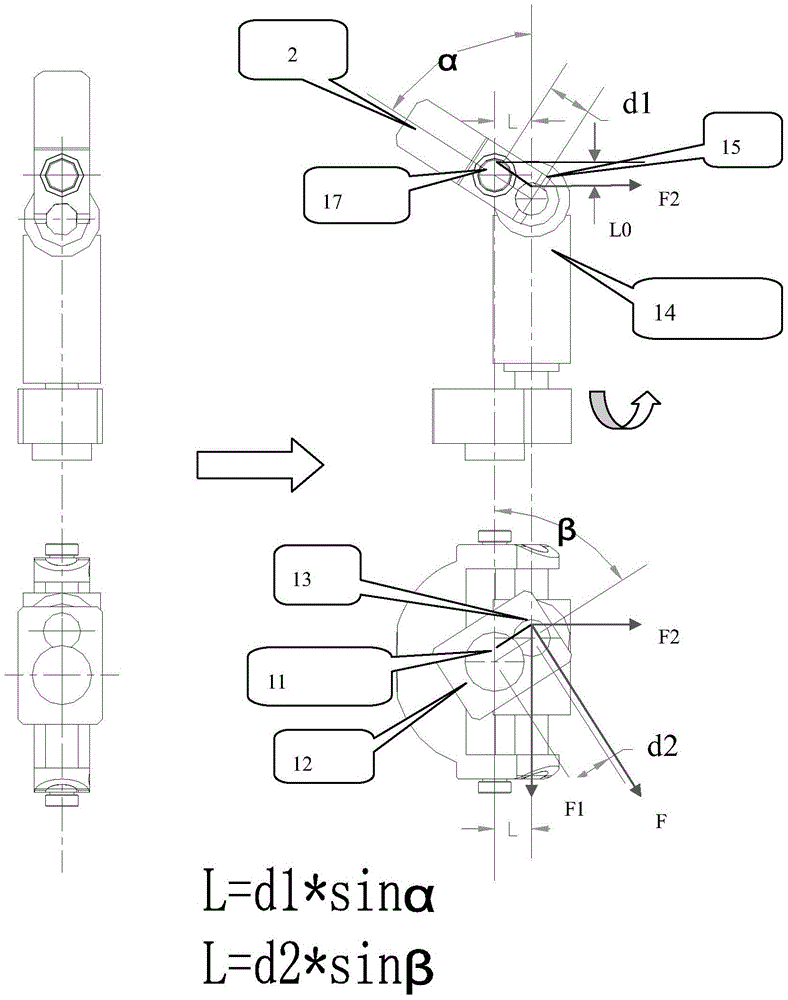

[0021] Such as figure 1 As shown, the present invention provides a 4D probe transmission mechanism 1 to solve the above problems. The 4D probe transmission mechanism includes: a first transmission shaft 11 , an eccentric connector 12 , a second transmission shaft 13 , a sliding sleeve 14 , a third transmission shaft 15 , at least one connector 16 , and at least one fixed shaft 1...

Embodiment 2

[0046] The present invention also provides a 4D probe, which includes: a casing, a motor, a transmission mechanism, and a transducer core. Usually the casing is arranged outside the other components to play the role of support and protection. One end of the transmission mechanism is connected to the core of the transducer, and the other end is connected to the motor, which is driven by the motor to drive the core of the transducer to swing.

[0047] The transmission mechanism is the transmission mechanism described in Embodiment 1, and the high precision requirement of the 4D probe can be achieved by using the probe of the above transmission mechanism. For the transmission mechanism, refer to Embodiment 1 for details, and details are not repeated here.

[0048] It should be noted that the above fixed connection includes detachable fixed connection, bonding, pre-integrated and so on. The detachable fixed connection may include detachable connections realized by various existi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com