Magnetic coupling energy-carrying reverse communication method for underground measurement while drilling

A technology of reverse communication and measurement while drilling, used in signal transmission systems, instruments, electrical components, etc., can solve the problems of vulnerable cables and connectors, high manual repair and maintenance costs, and poor reliability of data transmission. To achieve the effect of saving equipment maintenance and personnel maintenance costs, convenient power supply, and improving the effective transmission distance of signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

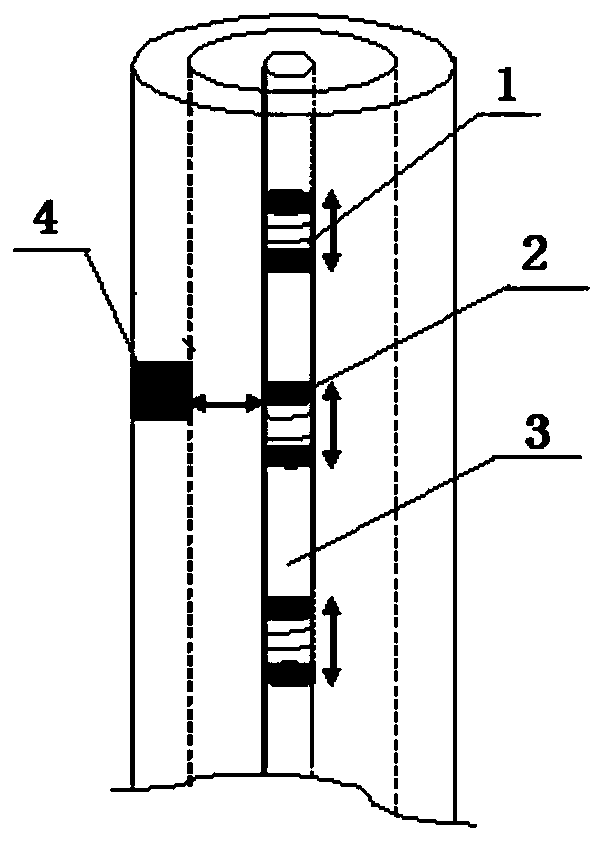

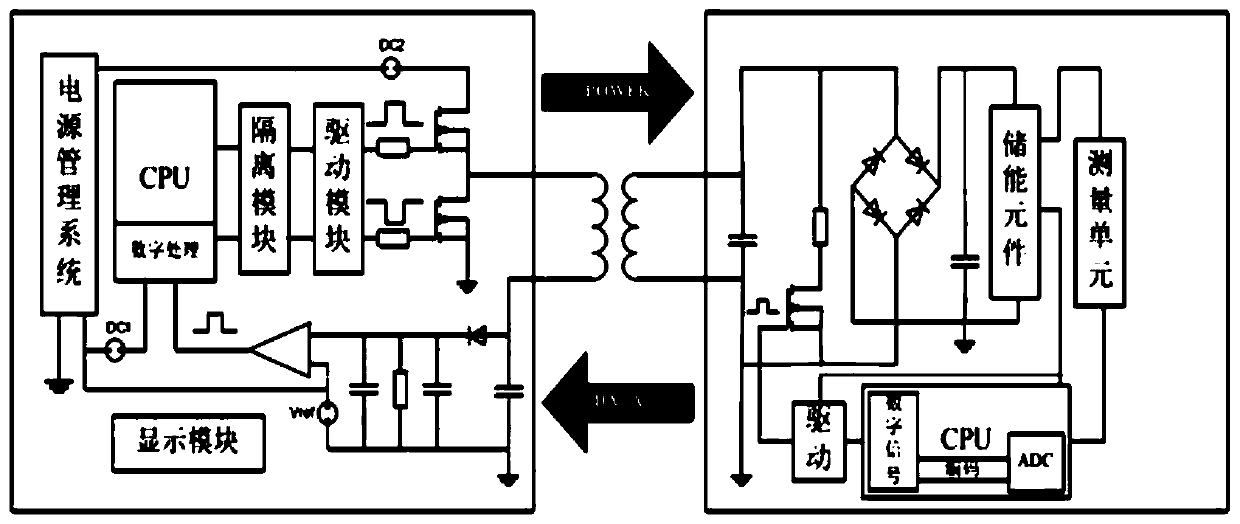

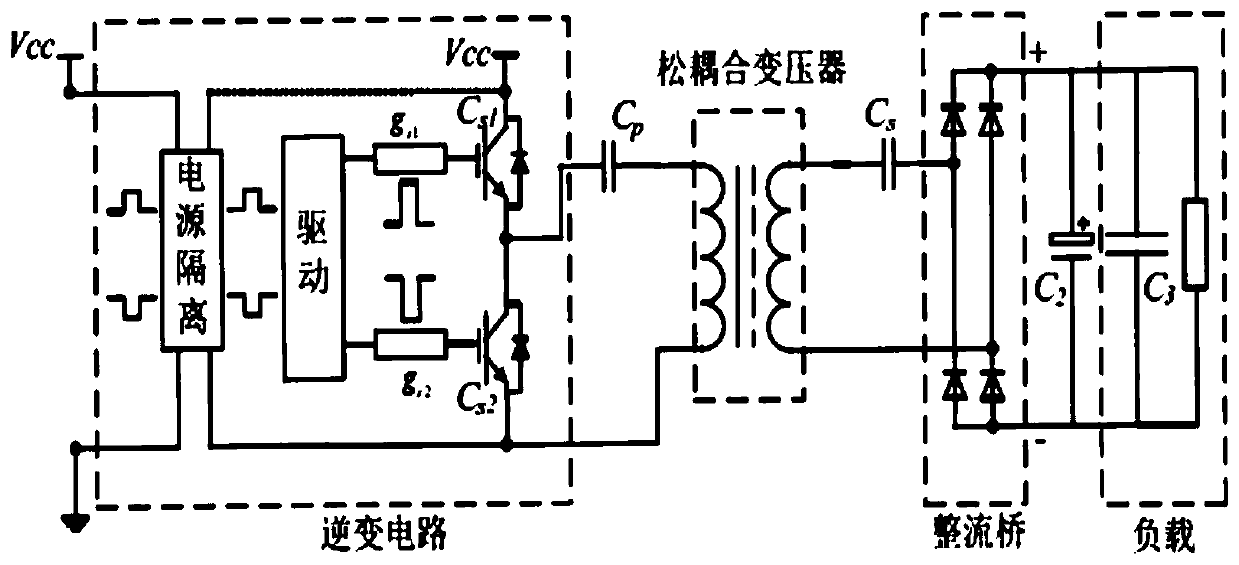

[0053] This embodiment will specifically describe the specific process of downhole measurement while drilling and the components of each part of the device by the magnetic coupling reverse communication and energy carrying method. first combined with figure 1 , giving the steps of wireless magnetic coupling reverse communication and energy carrying method for downhole measurement while drilling:

[0054] Step 1: The generator nipple drives the drill bit to rotate for downhole drilling operations.

[0055] Step 2: The geological parameter sensor located in the probe sub-section 1 at the upper end of the screw measures the real-time well deviation, azimuth, tool surface and other geological parameter signals, and transmits them to the main control circuit sub-section 3 through the wireless magnetic coupling communication and the energy-carrying device 4; at the same time , the engineering parameter sensor located in the measuring drill collar also transmits real-time measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com