Weighing system having high precision quantification process

A high-precision, weighing value technology, applied in the direction of weighing, measuring devices, automatic feeding/discharging weighing equipment, etc., can solve the problems of insufficient repeatability of feeding methods and weighing values beyond the control range, etc. , to achieve the effects of smooth production line, easy control of precision, and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

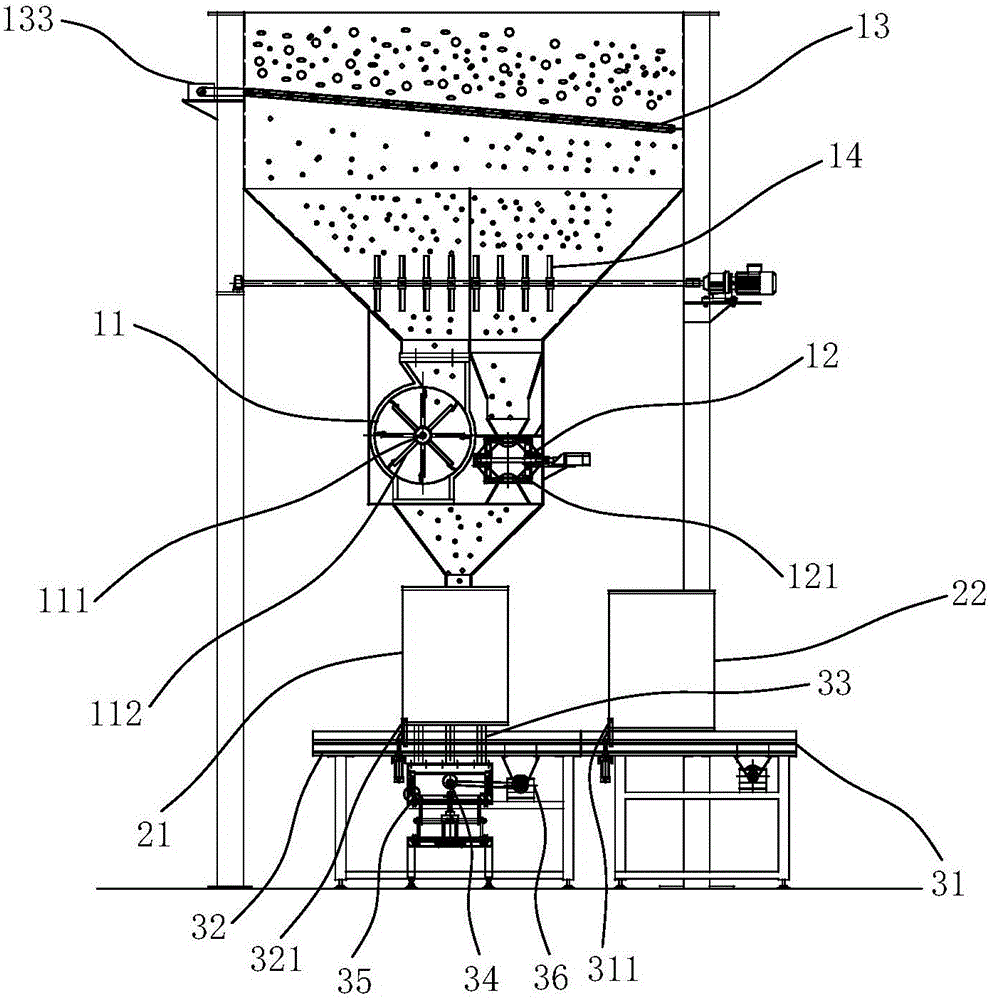

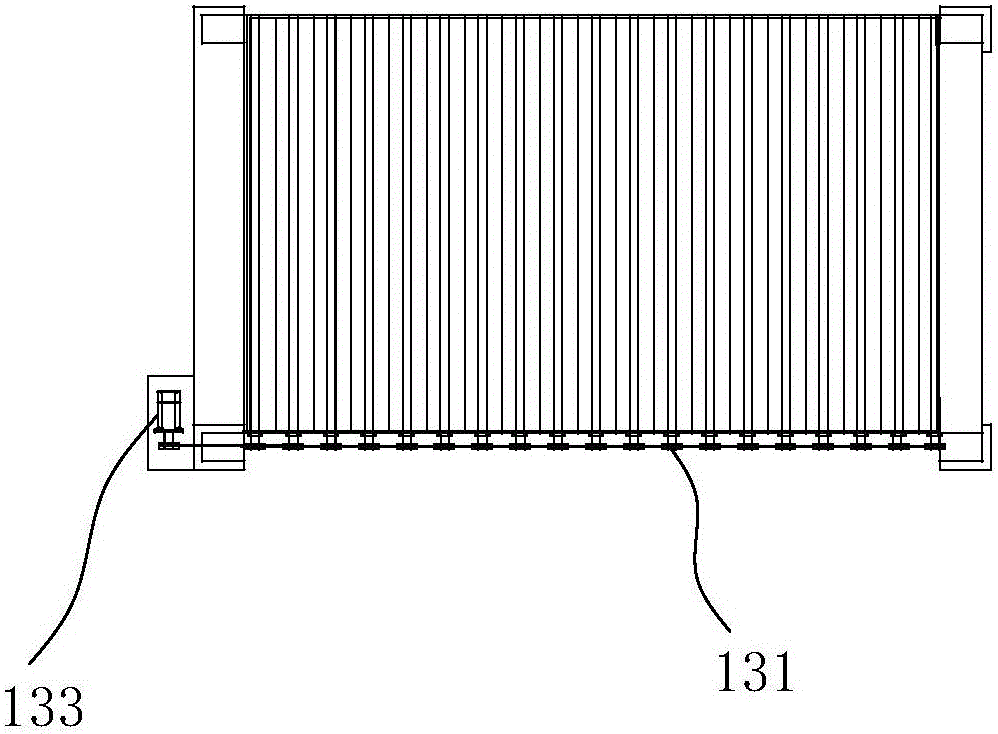

[0036] Now describe in detail the structural features of the present invention in conjunction with the accompanying drawings, as shown in the accompanying drawings:

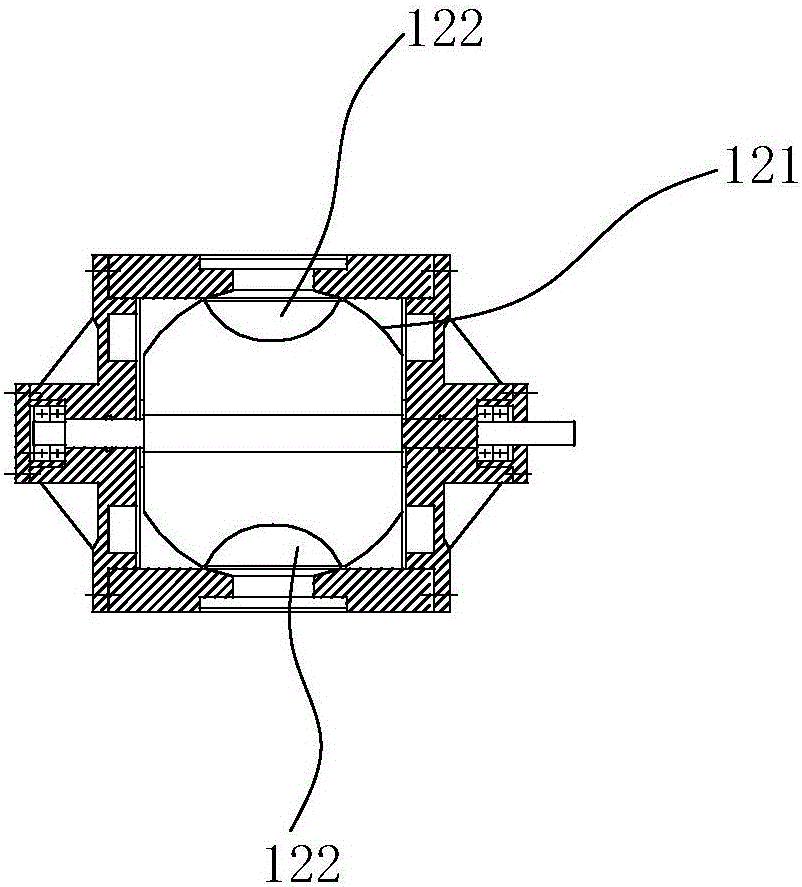

[0037] When feeding, the present invention firstly feeds through the first feeding mechanism 11. When the weight of the material in the previous packaging container 21 reaches the initially set weighing value, the first feeding mechanism 11 stops feeding, and the plug valve mechanism Execute closing action to prevent material drop. Then start the second feeding mechanism 12 to feed, when the weight of the material in the first packaging container 21 reaches the target set weighing value, the second feeding mechanism 11 stops feeding, and the second feeding mechanism 11 of the present invention passes through the spherical valve core part When 111 rotates, it drives the concave part 112 to rotate to convey the material, the spherical valve core part 111 rotates one circle, and the material in the concave part 112 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com