Method for preparing two-dimensional atomic crystal new material by supercritical fluid

A two-dimensional atomic crystal, supercritical flow technology, applied in the direction of polycrystalline material growth, crystal growth, chemical instruments and methods, etc., can solve the problem that the same quality standard of graphene cannot be reached, large-scale production cannot be promoted, and preparation methods are single, etc. problem, to achieve the effect of mild conditions, controllable number of layers, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

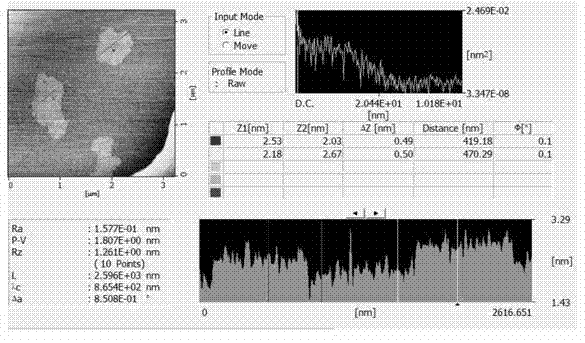

[0030] A method for preparing a new two-dimensional atomic crystal material using a supercritical fluid, the method adopts a device such as figure 1 As shown, it includes a carbon dioxide cylinder 1, a cooling device 2, a carbon dioxide pump 3, a pressure controller 4, a high-pressure reaction kettle 5, and a pressure relief sample collection tank 6. When in use, add 50 mg of hexagonal boron nitride powder into the autoclave 5 . The autoclave temperature was set at 45 °C. Carbon dioxide is pumped into the autoclave 5 through the carbon dioxide pump 3, and the pressure in the autoclave is controlled at 15MPa. The material stays in the autoclave 5 for 120 minutes, and the pressure is released at a rate of 0.2 atm / s to collect the product. Through atomic force microscope test and characterization, the large-scale hexagonal boron nitride thin film with tens of microns and less than 10 atomic layers in the product is more than 30%, and its characterization photos are as follows ...

Embodiment 2

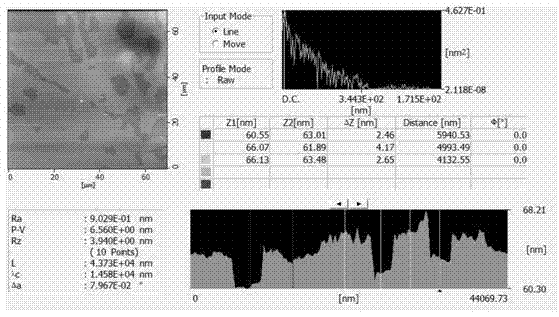

[0032] Add 50 mg of hexagonal boron nitride powder into the autoclave 5 . The autoclave temperature was set at 45 °C. Carbon dioxide is pumped into the autoclave 5 through the carbon dioxide pump 3, and the pressure in the autoclave is controlled at 15MPa. The material stays in the high-pressure reactor 5 for 120 minutes, 60W ultrasonic vibration is applied to the supercritical system for 30min, and the pressure is released at a rate of 0.2atm / s. The product is collected and characterized by atomic force microscopy. The hexagonal boron nitride film below the layer is greater than 60%, and there is a monoatomic layer boron nitride film, and the photo of its characterization is as follows figure 2 shown.

Embodiment 3

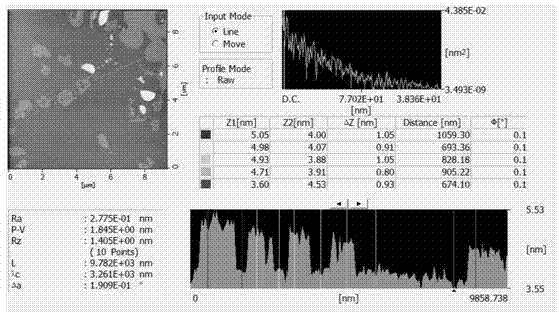

[0034] Add 50 mg of hexagonal boron nitride powder into the autoclave 5 . The autoclave temperature was set at 45 °C. Carbon dioxide is pumped into the autoclave 5 through the carbon dioxide pump 3, and the pressure in the autoclave is controlled at 15MPa. The material stays in the high-pressure reactor 5 for 120 minutes, 30min 60W ultrasonic oscillation is applied to the supercritical system, and the system is repeatedly pressurized and depressurized 5 times at a depressurization rate of 0.2atm / s. The collected product is characterized by atomic force microscopy. The product Medium and large-scale hexagonal boron nitride films with less than 5 atomic layers in the order of tens of microns are more than 56%, and monoatomic layer boron nitride films show a relatively large proportion, about 14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com