Preparation method of graphite alkene like tungsten disulfide nanometer sheet

A technology of tungsten disulfide and graphene, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as weak van der Waals force, achieve low cost, high product output rate, and simple and easy-to-control production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Put 0.5gWO 3 Mix with 4.92g of thiourea and grind it with a mortar for 45 minutes, put the ground powder into a porcelain boat for later use; increase the temperature of the tube furnace to 850℃, and pour nitrogen into the tube furnace; in the tube furnace When the temperature is stable at 850℃, open the flange at the outlet end of the tube furnace, and quickly push the porcelain boat into the central hot zone of the tube furnace for 1 hour; then, after the tube furnace is naturally cooled to room temperature, remove the tube furnace Flanges at both ends, take out the porcelain boat to obtain black powder, that is, graphene-like tungsten disulfide nanosheets.

Embodiment 2

[0019] Put 0.5gWO 3 Mix with 3.3g of thiourea and grind with a mortar for 30 minutes, put the ground powder into a porcelain boat for later use; increase the temperature of the tube furnace to 800°C, and let in nitrogen; the temperature in the tube furnace is stable at 800°C Open the flange at the outlet end of the tube furnace, and quickly push the porcelain boat into the central hot zone of the tube furnace for 30 minutes; then, after the tube furnace is naturally cooled to room temperature, black powder, ie, graphene-like disulfide, is obtained Tungsten nanosheets.

Embodiment 3

[0021] Put 0.5gWO 3 After mixing with 6.6g of thiourea, grind it with a mortar for 60 minutes, put the ground powder into a porcelain boat for later use; increase the temperature of the tube furnace to 900°C, and blow in nitrogen; the temperature in the tube furnace is stable at 900°C Open the flange at the outlet end of the tube furnace, and quickly push the porcelain boat into the central hot zone of the tube furnace for 60 minutes; then, after the tube furnace is naturally cooled to room temperature, black powder is obtained, that is, graphene-like disulfide Tungsten nanosheets.

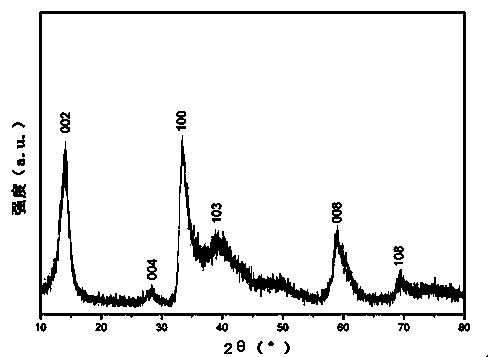

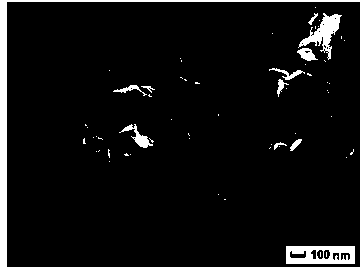

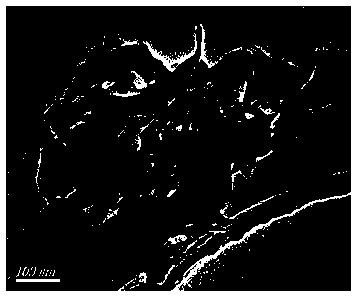

[0022] figure 1 XRD pattern of the prepared product, the product is pure WS 2 Hexagonal crystal figure 2 For the SEM photo of the prepared product, it can be clearly seen that a large number of ultra-thin nanosheets are formed without agglomeration, and the thickness of the nanosheets is 3-5 nm; image 3 In the TEM photograph of the prepared product, many graphene-like nanosheets can be seen, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com