Preparation method of tungsten disulfide nanorods

A technology of tungsten disulfide and nanorods, which is applied in chemical instruments and methods, nanotechnology, tungsten compounds, etc., can solve the problems of uneven particle size of nanorods, poor controllability of shape, and influence on application, and achieve layered The effect of obvious structure, low cost and high anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Dissolve 0.18g CTAB in 70ml of distilled water, then add 1.40g CS(NH 2 ) 2 , 0.725gNH 2 OH·HCl and 1.56g (NH 4 ) 2 WO 4 . After completely dissolving, add 2mol·L -1 Adjust the pH to around 6 with HCl. After stirring for 30 min, the mixture was transferred to a 100 ml stainless steel reaction kettle, placed in a vacuum drying oven at 180° C. for 24 h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly with deionized water and absolute ethanol, and finally dried at 80° C. for 10 h under vacuum to obtain a gray-black product powder, which was tungsten disulfide nanorods.

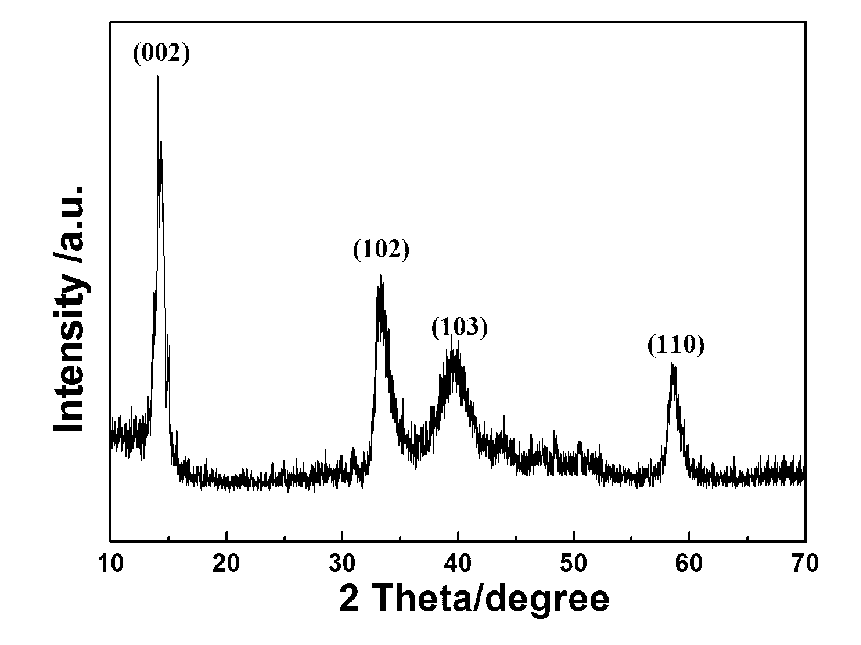

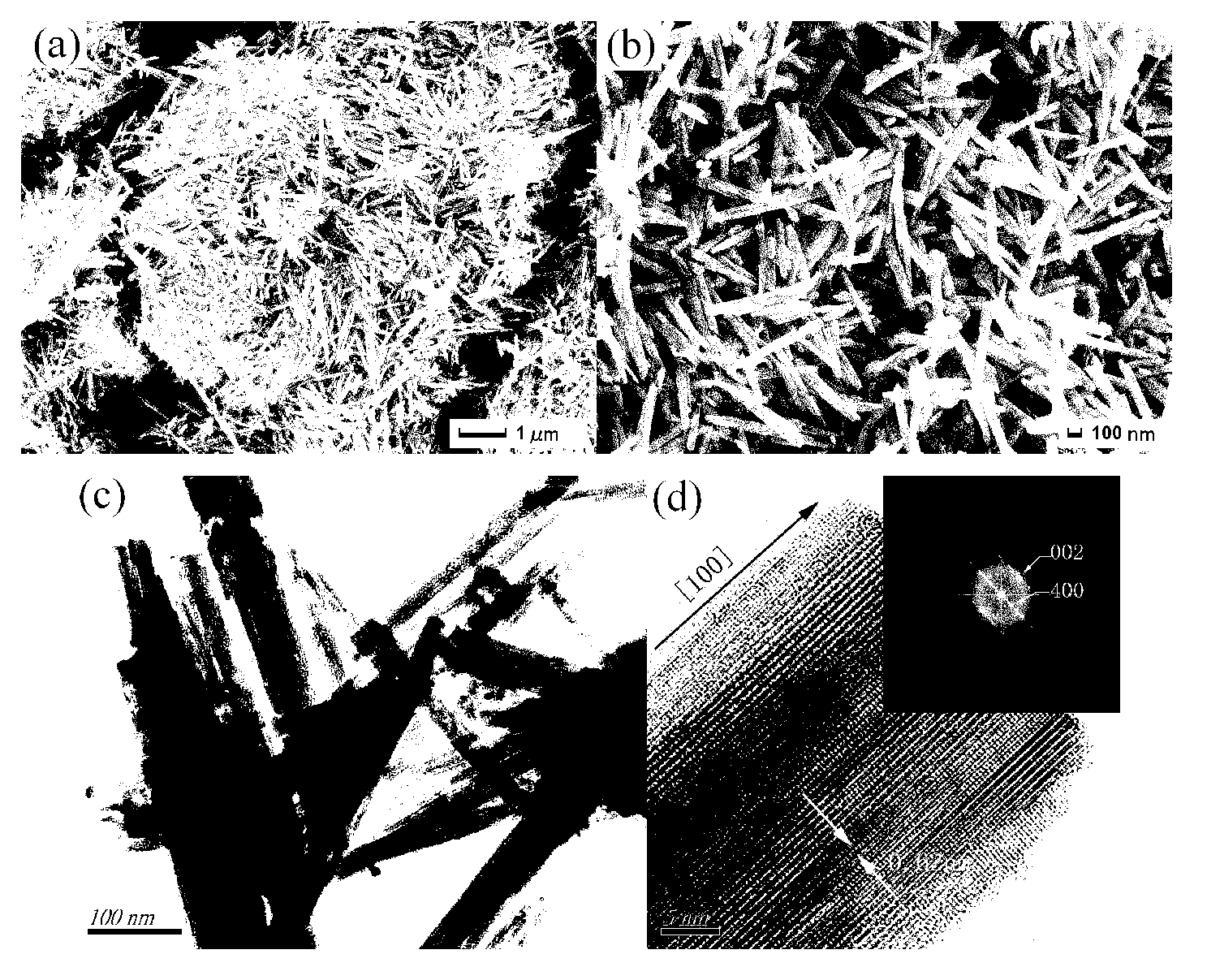

[0040] figure 1 The XRD pattern shows that the XRD peak position is consistent with the standard diffraction pattern (JCPDS84-1398), and the product is pure WS 2 Hexagonal crystal, the XRD peak of the (002) plane in the figure is very strong, while other peaks are weakened, indicating that WS 2 The hexagonal layered structure has...

Embodiment 2

[0042] Dissolve 0.30g PEG600 in 70ml of distilled water, then add 1.40g CS(NH 2 ) 2 , 0.725gNH 2 OH·HCl and 1.56g (NH 4 ) 2 WO 4 . After completely dissolving, add 2mol·L -1 Adjust the pH to around 6 with HCl. After stirring for 30 min, the mixture was transferred to a 100 ml stainless steel reaction kettle, placed in a vacuum drying oven at 180° C. for 24 h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly with deionized water and absolute ethanol, and finally dried at 80° C. for 10 h under vacuum to obtain a gray-black product powder, which was tungsten disulfide nanorods.

Embodiment 3

[0044] Dissolve 0.17g SDBS in 70ml of distilled water, then add 1.40g CS(NH 2 ) 2 , 0.725gNH 2 OH·HCl and 1.56g (NH 4 ) 2 WO 4 . After completely dissolving, add 2mol·L -1 Adjust the pH to around 6 with HCl. After stirring for 30 min, the mixture was transferred to a 100 ml stainless steel reaction kettle, placed in a vacuum drying oven at 180° C. for 24 h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly with deionized water and absolute ethanol, and finally dried at 80° C. for 10 h under vacuum to obtain a gray-black product powder, which was tungsten disulfide nanorods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com