Preparation method for large-area single-layer tungsten disulfide film based on atmospheric pressure chemical vapor deposition and product

A normal-pressure chemical vapor, tungsten disulfide technology, applied in the field of materials, can solve the problems of difficult repeated growth, inability to effectively control the dosage, difficult to control the size, number of layers and crystal quality of the tungsten disulfide film, and achieve the effect of repeated preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

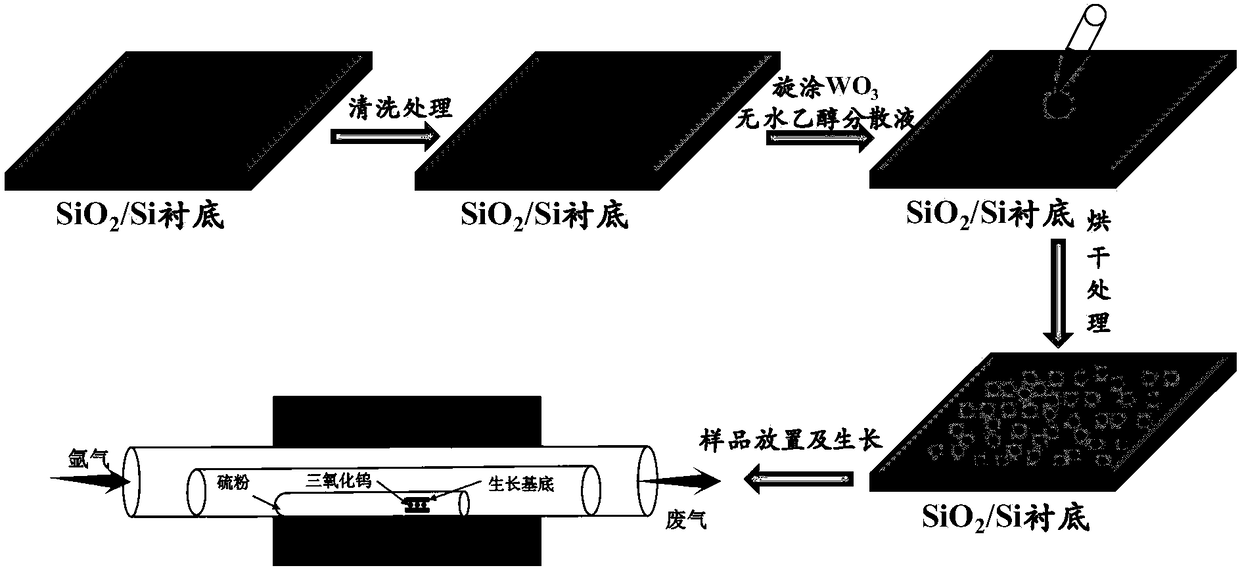

[0024] A method for preparing a large-area single-layer tungsten disulfide film based on atmospheric pressure chemical vapor deposition, the preparation process is as follows figure 1 shown, including the following steps:

[0025] (1) SiO 2 / Si substrate cleaning

[0026] 5 x 5mm SiO 2 / Si substrate is ultrasonicated in 50ml alcohol-deionized water-acetone-deionized water for 10 minutes to remove the dirt on the surface of the substrate, and then blow dry with high-purity nitrogen for later use;

[0027] (2) Spin coating WO 3 Anhydrous ethanol dispersion

[0028] 10mg of WO 3 (>99.9%) powder into 20ml of absolute ethanol, and use a stirrer to make it evenly dispersed, and then use a pipette to draw 5μl of WO 3 Anhydrous ethanol dispersion was evenly spin-coated on the cleaned SiO 2 / Si substrate;

[0029] (3) Substrate drying treatment

[0030] will spin-coat the WO 3 SiO in absolute ethanol dispersion 2 / Si substrate is placed on a heating stage, and absolute ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com