Carbon brush for electric machine

A technology of electrical equipment and carbon brushes, applied in electrical components, circuits, current collectors, etc., can solve the problems of insufficiency, and achieve the effects of prolonging life, excellent lubricity, and low friction loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

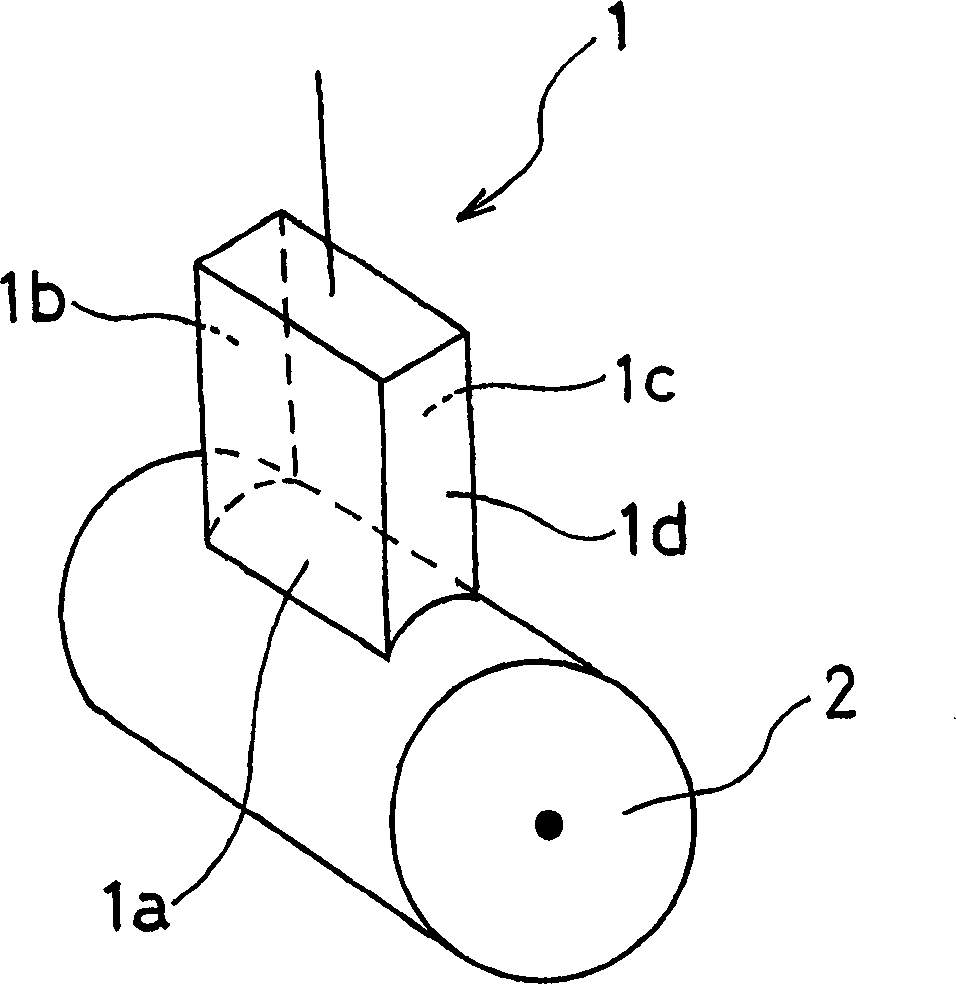

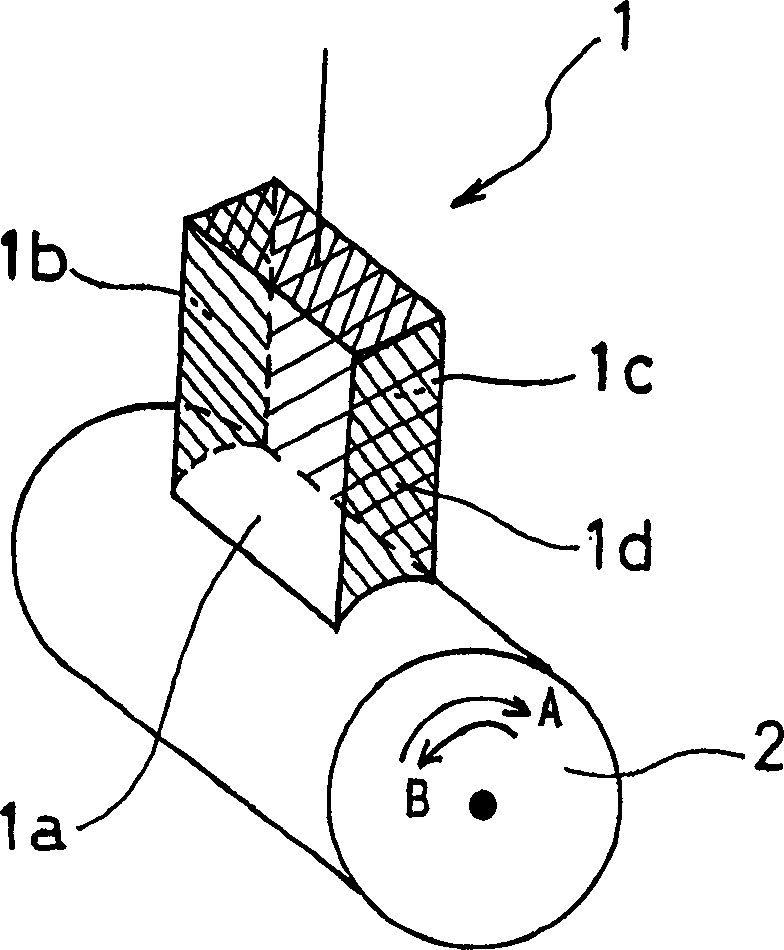

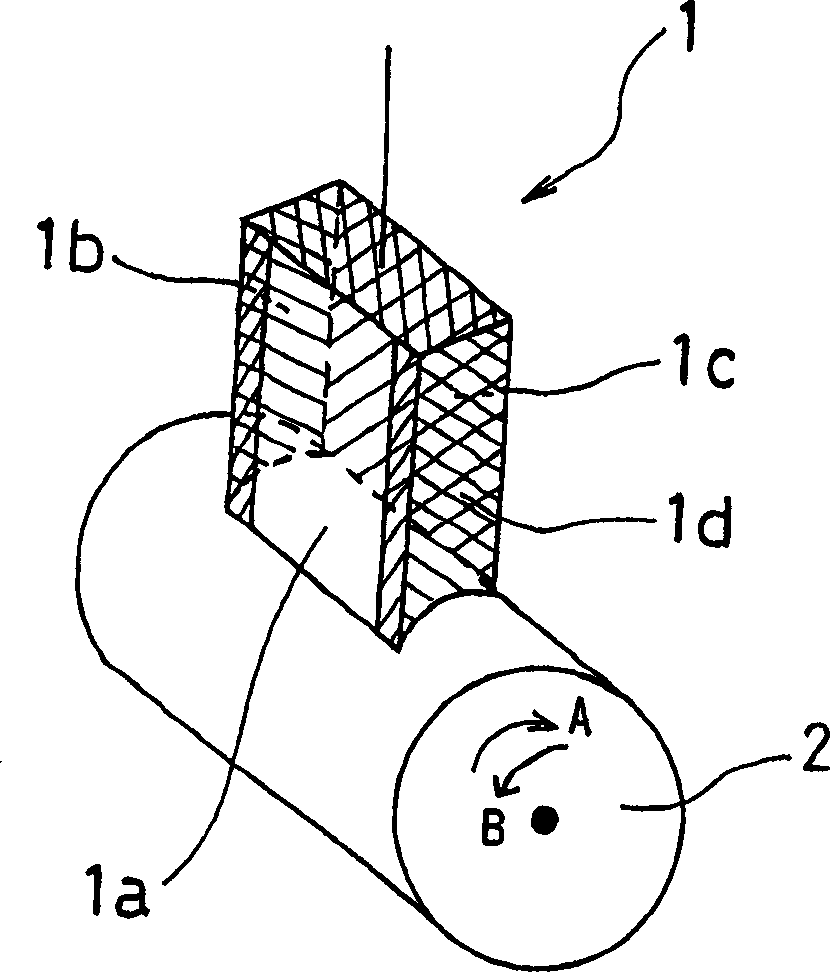

Image

Examples

Embodiment 1

[0039] Mix 70 parts by weight of artificial graphite powder with an average particle size of 40 μm and an ash content of 0.2% or less, 4.7 parts by weight of tungsten disulfide powder, and 0.3 parts by weight of silicon carbide with an average particle size of 50 μm; 25 parts by weight of the phenol resin and methanol were mixed and kneaded at room temperature for 2 hours. Next, methanol is evaporated, dried, crushed to a particle size below 40 mesh, and molded into a size of 7×11×30 mm with a pressure of 200 MPa. Next, this molded body was fired at 600°C for 5 hours in a nitrogen atmosphere to obtain a brush base having a resistivity of 500 µΩ·m. This brush base was immersed in a copper sulfate solution oxidized by adding sodium hydroxide and potassium tartrate, and after adding an aqueous formaldehyde solution as a reducing agent, a 10 µm copper protective film was formed on the surface of the base. Furthermore, when the rotation direction of the commutator is clockwise (di...

Embodiment 2

[0041] Except that the artificial graphite powder with an average particle size of 15 μm, an ash content of 0.5% or less, high orientation and excellent formability was used as the graphite powder, a brush base with a resistivity of 100 μΩ·m was produced in the same manner as in Example 1, Next, samples were produced in the same manner as in Example 1.

Embodiment 3

[0043] 70 parts by weight of artificial graphite powder with an average particle diameter of 40 μm, 4.7 parts by weight of molybdenum disulfide as a self-lubricating agent, 0.3 parts by weight of silicon carbide powder as a grinding agent, bisphenol-based epoxy resin and acid anhydride-based hardened 25 parts by weight of additives are added together, mixed and kneaded at 130°C for 1 hour, shaped in the same way as in Example 1, and cured at 220°C to make a brush base with a resistivity of 2,000μΩ·m Thereafter, samples were produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com