Tungsten disulfide/graphene nanobelt composite material and preparation method thereof

A graphene nanoribbon, tungsten disulfide technology, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of poor conductivity, the excellent performance of pure tungsten disulfide cannot be fully utilized, etc. The effect of ingenious operation, experimental design, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

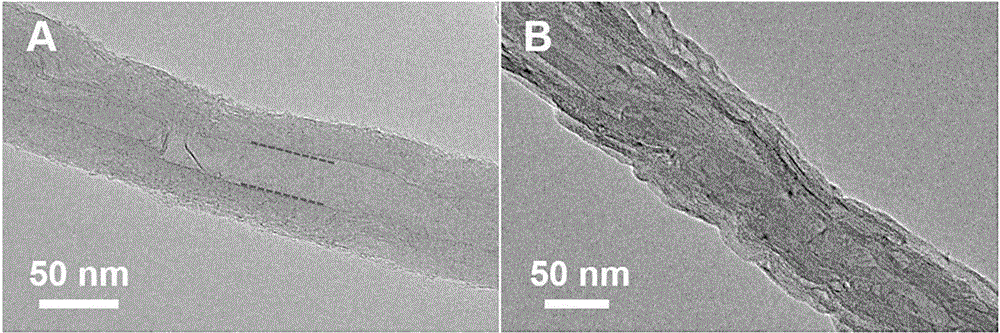

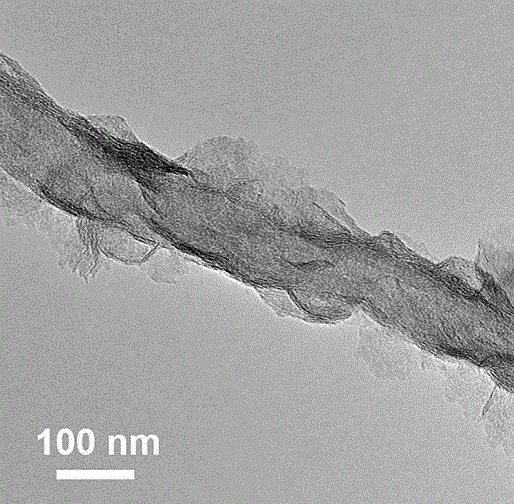

[0043] Embodiment 1, This embodiment includes the following steps:

[0044](1) Disperse 150 mg of multi-walled carbon nanotubes in 98% concentrated sulfuric acid, and then add 85% phosphoric acid after the dispersion is uniform, and keep stirring during this process to obtain a uniform dispersion;

[0045] (2) Add 750mg potassium permanganate to the above dispersion, add in batches, and keep stirring;

[0046] (3) Slowly raise the temperature of the reaction system to 70°C. After the temperature is stable, keep it warm for a period of time and keep stirring;

[0047] (4) Cool the resulting mixed dispersion to room temperature naturally, then pour it into ice water containing 7mL of 50% hydrogen peroxide, and let it settle overnight;

[0048] (5) Wash the obtained precipitate several times with 10% hydrochloric acid aqueous solution, and then wash it several times with a mixed solution of ethanol / ether;

[0049] (6) Centrifugal drying to obtain solid graphene oxide nanobelt...

Embodiment 2

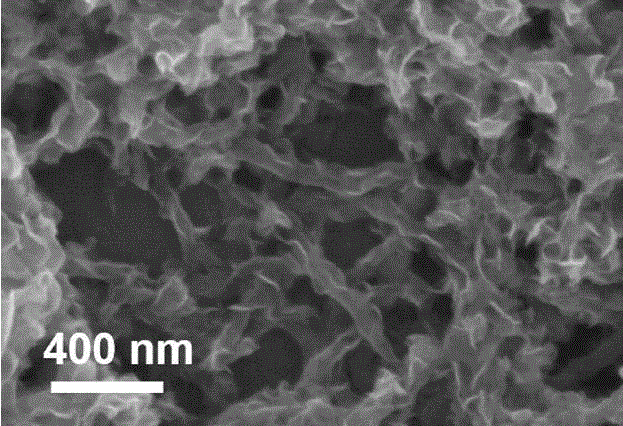

[0054] Embodiment 2, Change the quality of ammonium thiotungstate in Example 1 to 22mg, and the rest are the same as in Example 1. The composite material finally obtained is denoted as GNRWS 2 -2.

Embodiment 3

[0055] Embodiment 3, Change the quality of ammonium thiotungstate in Example 1 to 44 mg, and the rest are the same as in Example 1. The composite material finally obtained is denoted as GNRWS 2 -3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com