Arc extinction brush and method for eliminating electric arc of power generator with this arc-extinction brush

A generator and arc suppression technology, applied to circuits, current collectors, electrical components, etc., can solve problems such as poor oxide film, unfavorable brush operation, and inability to help form oxide film, etc., to achieve the effect of convenient use and no impact on production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

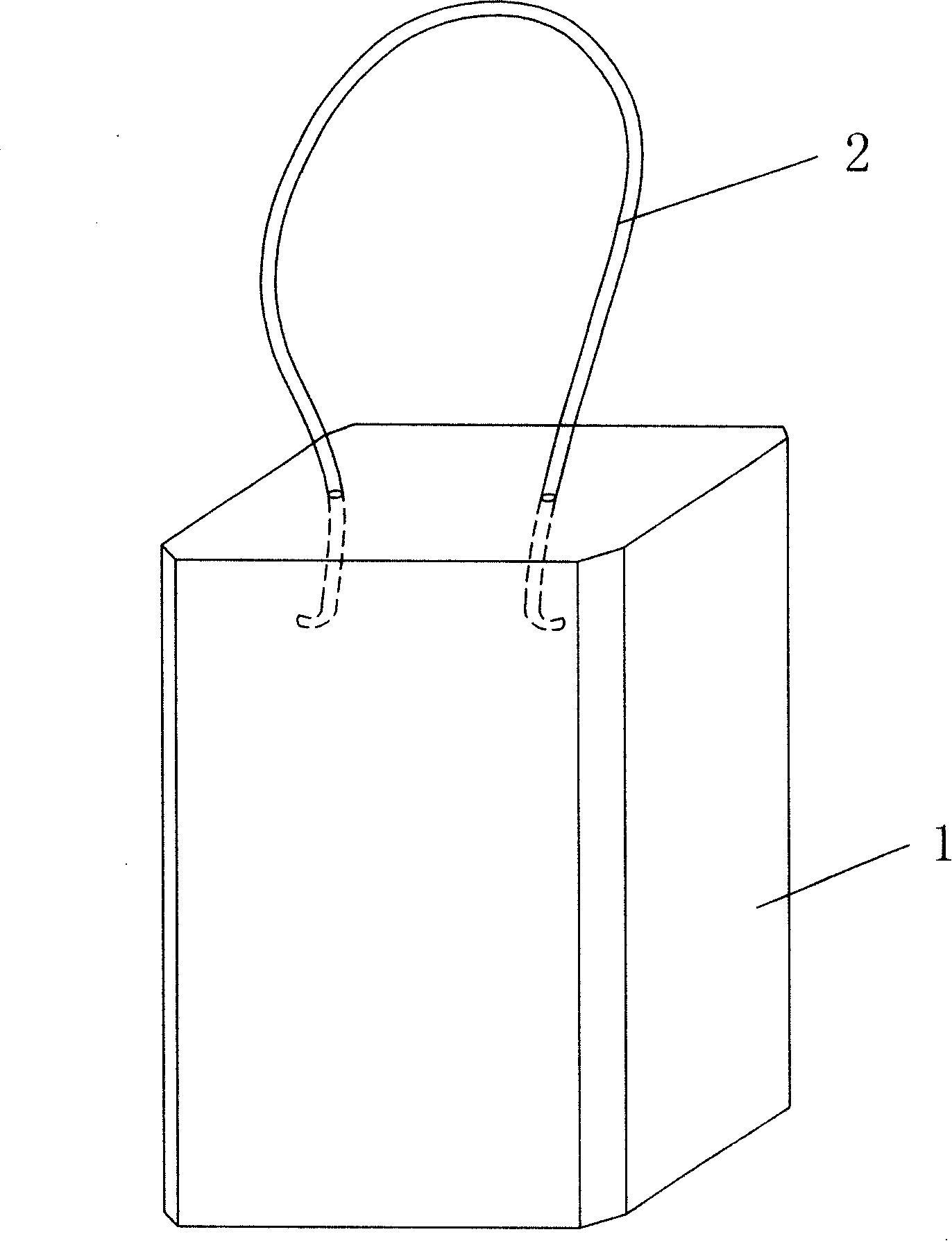

Image

Examples

no. 1 example

[0047] (1) The first embodiment: splashing sparks occur during the operation of a large generator slip ring brush (4 rows of single poles, 10 pieces in each row, and the sliding apparent area of a single brush is 2.5×3.2=8 square centimeters) (production site It is called "flaming"), and the human eyes observed that the intermittent transfer of the flames was irregular, but the fault did not seriously deteriorate. After 35 days of the flames, the on-site staff did not get better.

[0048] The composition (weight) ratio of the arc suppression brush used in this example is 1% tin, 20% wax, and 79% molybdenum disulfide. Use this arc suppression brush to help and promote the rapid formation of oxide film, increase the sliding contact resistance, and establish the contact voltage drop required for normal operation. In this embodiment, the first predetermined time is 1 to 3 seconds, and the second predetermined time It took 1 to 3 hours. After three times of operation, the fire wa...

no. 2 example

[0049] (2) The second embodiment: in a large unit (but not the same unit as above), the current of the slip ring brush is seriously uneven during operation, which causes the brush braid to overheat, discolor and burn out: several (not more than 10) brushes are burned every day The brush braid, and which brush is blown is irregular in time and space, regardless of the size of the new brush and the old brush, and the contact surface size, and is even insensitive to the pressure of the compression spring. After more than 10 days of treatment, there is no improvement.

[0050] The composition (weight) ratio of the arc suppression brush used in this example is 1% tin, 29% wax, and 70% molybdenum disulfide. With this arc-suppressing brush, the 6 faults were completely eliminated in the same way as the above example, and it has been running normally since then.

[0051] (3) The third embodiment (self-vibration of brush sliding friction): a large-scale generator slip ring has four ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com