Method for preparing mono-disperse tungsten disulfide nano slices

A tungsten disulfide, nanosheet technology, applied in nanostructure fabrication, chemical instruments and methods, nanotechnology, etc., can solve the problems of inability to laterally divide and refine the basal plane, limit catalytic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

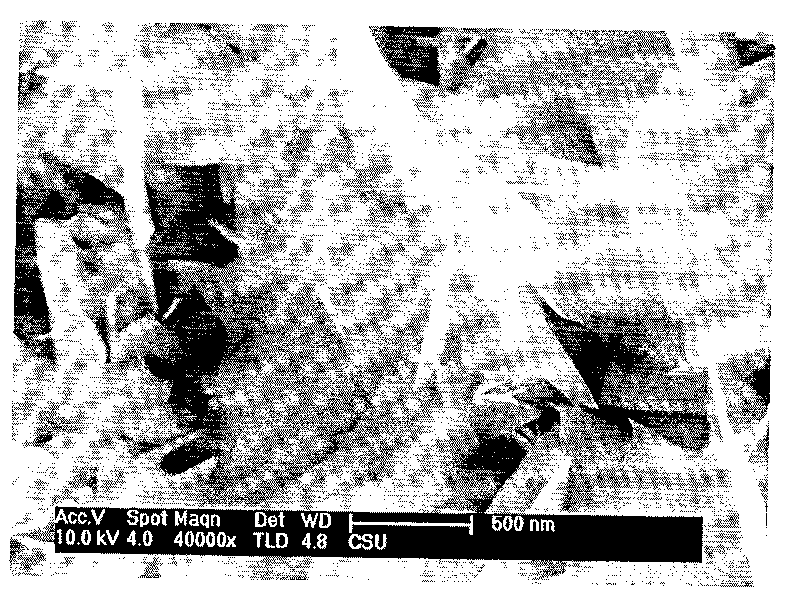

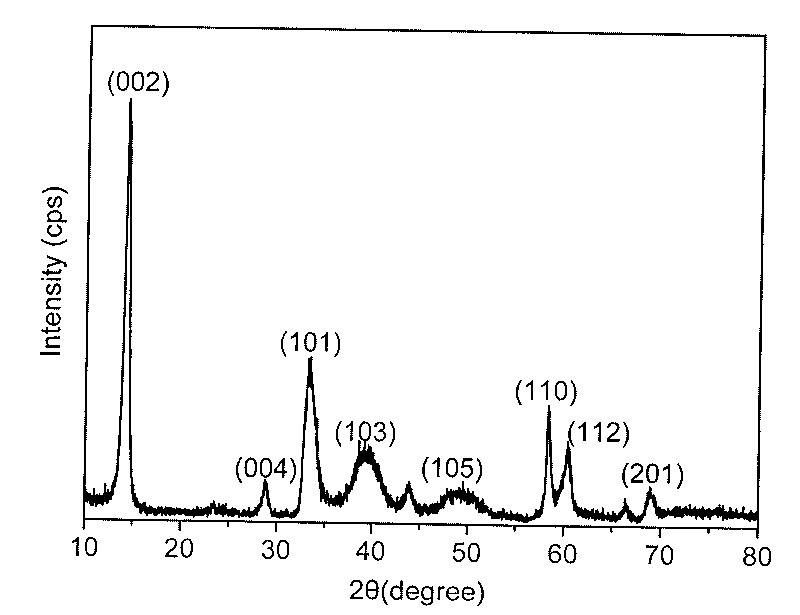

[0013] Mix 5g of tungsten oxide and 10g of sulfur into a stainless steel ball milling jar, pass in argon as a protective gas, use stainless steel balls as a ball milling medium with a ball-to-material ratio of 60:1, and mill at 400rpm for 24h. Take 1g of the activated product from ball milling and put it into a porcelain boat, and take another porcelain boat and fill it with 2g of sulfur; the tube furnace is pre-filled with argon to exhaust the air, and heated to 600°C, then place the above two boats in the heating zone , where the porcelain boat filled with sulfur is placed at the upstream of the gas as a supplementary sulfur source; after being kept at a constant temperature for 0.5h in an argon atmosphere, it is cooled to 250°C with the furnace in a hydrogen atmosphere, the porcelain boat is taken out, and the black powder is collected to obtain Monodisperse tungsten disulfide nanosheets with a thickness of about 4nm. figure 1 It is a field emission scanning electron micros...

Embodiment 2

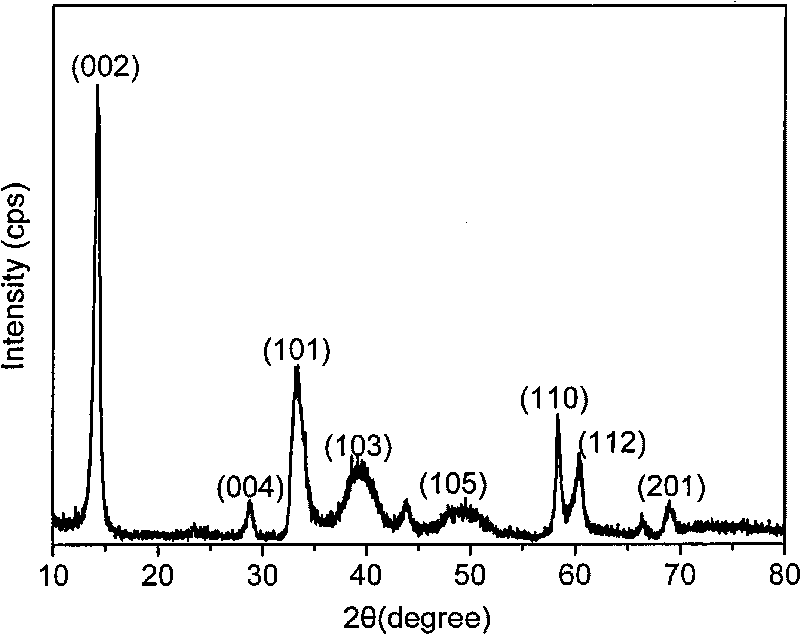

[0015] Mix 5g of tungsten oxide and 10g of sulfur into a stainless steel ball milling tank, pass in argon as a protective gas, use stainless steel balls as a ball milling medium with a ball-to-material ratio of 60:1, and mill at 400rmp for 24h. Take 1g of the activated product from ball milling and put it into a porcelain boat. The tube furnace is filled with argon gas to exhaust the air, and heated to 600°C. Then place the porcelain boat in the heating zone without supplementary sulfur source; under argon atmosphere After constant temperature for 2 hours, cool down to 200°C with the furnace in a hydrogen atmosphere, take out the porcelain boat, collect black powder, and use XRD for detection. The results show that the product contains tungsten disulfide and partial tungsten oxide, indicating that the vulcanization is not complete, so it must be pre- Supplementary sulfur source.

Embodiment 3

[0017] Mix 5g of tungsten oxide and 10g of sulfur into a stainless steel ball milling tank, pass in argon as a protective gas, use stainless steel balls as a ball milling medium with a ball-to-material ratio of 60:1, and mill at 400rmp for 24h. Take 1g of the activated product from the ball mill and put it into a porcelain boat, and take another porcelain boat and fill it with 2g of sulfur; the tube furnace is pre-filled with argon to exhaust the air, and heated to 500°C, and then put the above two boats in the heating zone , where the porcelain boat filled with sulfur was placed in the upstream of the gas as a supplementary sulfur source; after being kept at a constant temperature for 2 hours in an argon atmosphere, it was cooled to 200°C with the furnace, the porcelain boat was taken out, and the black powder was collected. The experimental results showed that the product was not fully vulcanized. , only a small amount of flaky tungsten disulfide is generated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com