Conveying belt for paper conveyer and manufacturing method thereof

A kind of paper transportation and conveyor belt technology, which is used in the field of conveyor belts and its manufacturing fields, which can solve problems such as uneven friction, insufficient paper conveying, and high surface hardness of the conveyor belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

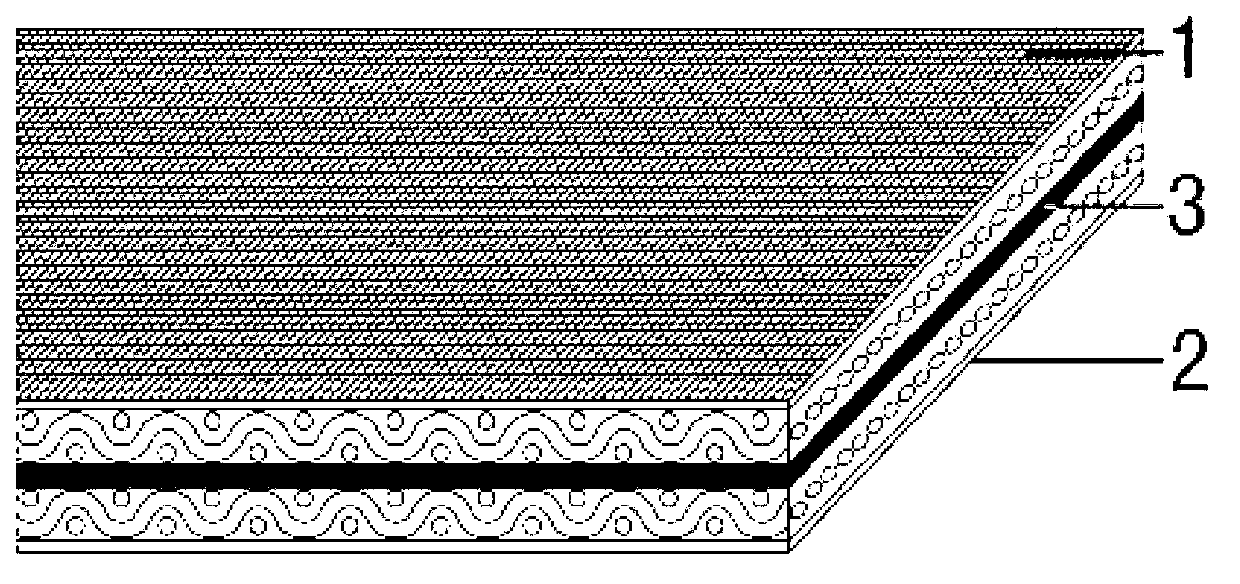

[0028] Conveyor belt drive belt for paper conveyor of the present invention, such as figure 1 As shown, the conveyor belt includes a middle layer and an upper and lower surface, and the upper and lower surfaces are bonded together with the middle layer through an adhesive. % accelerator, 0.05~0.08% colorant and 40~45% methanol.

[0029] The middle layer is made of polyester material, and the 1% constant elongation strength is 4.5N / mm, which can effectively improve the phenomenon that the belt will lose rotation due to elongation and reduce the transmission efficiency.

[0030] The adhesive used is isocyanate adhesive, which has high bonding strength, and will not cause delamination during operation due to insufficient peeling force, which will affect the service life of the belt.

[0031] Its manufacturing method is as follows:

[0032] Step 1. Polyether-type TPU (thermoplastic polyurethane) and MC6 nylon particles are dried in a drying box (800Kg drying box). After drying, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com