Aluminum-magnesium carbon sliding plate brick for converter slag stopping and production method thereof

A technology of aluminum-magnesium-carbon sliding bricks and converter slag blocking, which is applied in the field of refractory materials, can solve the problems that magnesia-carbon bricks cannot meet the high-strength friction requirements of mechanism sliding plates, and achieve the elimination of high-energy consumption firing process and excellent slag erosion resistance , The effect of large absolute thermal expansion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

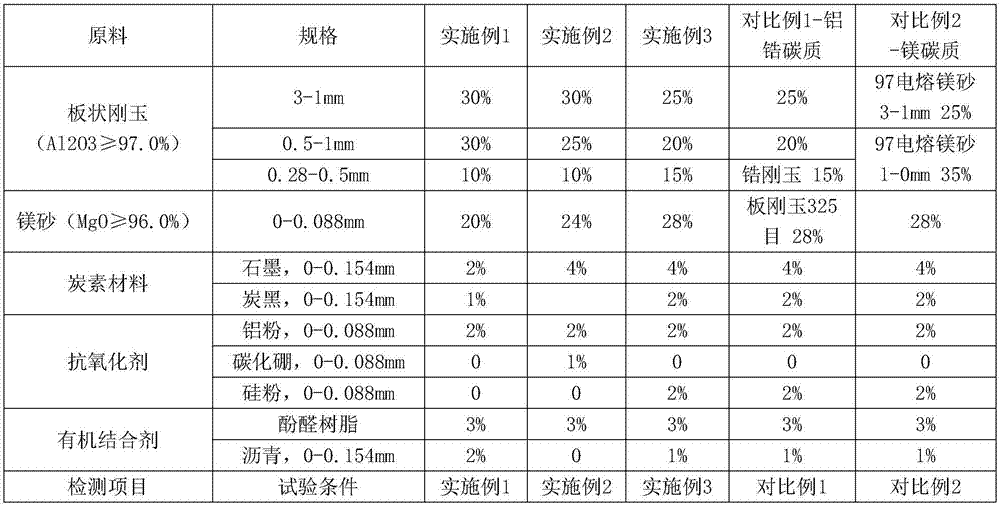

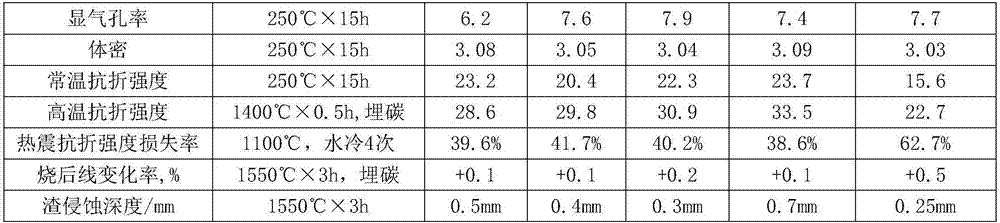

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment.

[0027] A method for preparing an aluminum-magnesium-carbon sliding brick for slag blocking in a converter is characterized in that it is carried out in accordance with the following steps:

[0028] Step 1 Premixing: Feeding and mixing: first premix magnesia powder, antioxidants, asphalt powder, and carbon materials for 5-10 minutes;

[0029] Step 2 Feeding and mixing: first pour the corundum particles into the mixer and dry mix for 1-3 minutes, then add phenolic resin and continue mixing for 3-8 minutes, finally add pre-mixed powder, and continue mixing for 15-30 minutes to form a slurry;

[0030] Step 3 Press molding: Add the mixed mud into the mold and use a 1000-ton friction brick press to press it into adobe;

[0031] Step 4 Baking and curing: put the adobe in a drying kiln to bake and cure, the baking temperature is 250-300°C, and the holding time is 10-20h;

[0032] Step 5: G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com